Vertical double-furnace-body chemical vapor deposition equipment

A chemical vapor deposition, dual-furnace technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of hidden dangers of equipment, residues, organic products not being effectively removed, etc., to improve production. Quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

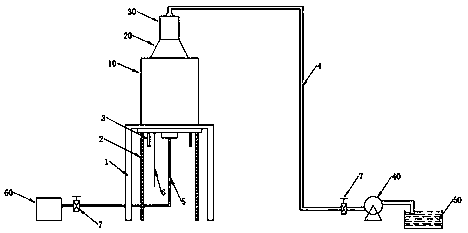

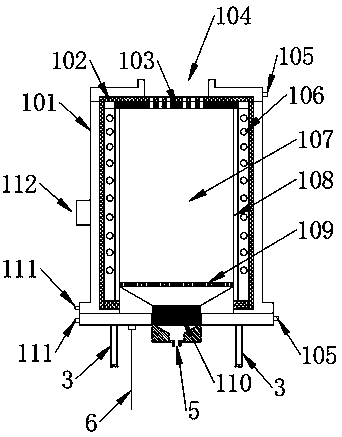

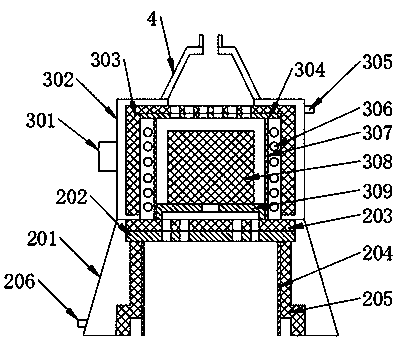

[0027] Vertical double furnace chemical vapor deposition equipment, such as figure 1 As shown, it includes support base 1, lifting system 2, lower furnace body support feet 3, exhaust pipe 4, inlet pipe 5, power cord 6, vacuum valve 7, lower furnace body 10, buffer furnace body 20, upper furnace body 30 , vacuum pump 40, filter tank 50, source gas system 60; the lower furnace body 10 is installed on the support base 1, the lower end of the lower furnace body 10 is connected to the lifting system 2, and the lower furnace body 10 is connected to the source gas system 60 through the intake pipe 5; buffer The body of furnace 20 is installed on the upper end of the lower body of furnace 10, and the upper body of furnace 30 is installed on the buffer body of furnace 20; the upper body of furnace 30 is connected with the vacuum pump 40 through the exhaust pipe 4, and the vacuum pump 40 is connected with the filter tank 50 through the exhaust pipe 4; The buffer furnace body 20 is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com