Method for online calibration of fixed type pyrometers of continuous type annealing furnace

A calibration method and an annealing furnace technology, applied to thermometers, thermometer testing/calibration, furnaces, etc., can solve the problems that pyrometers cannot be calibrated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

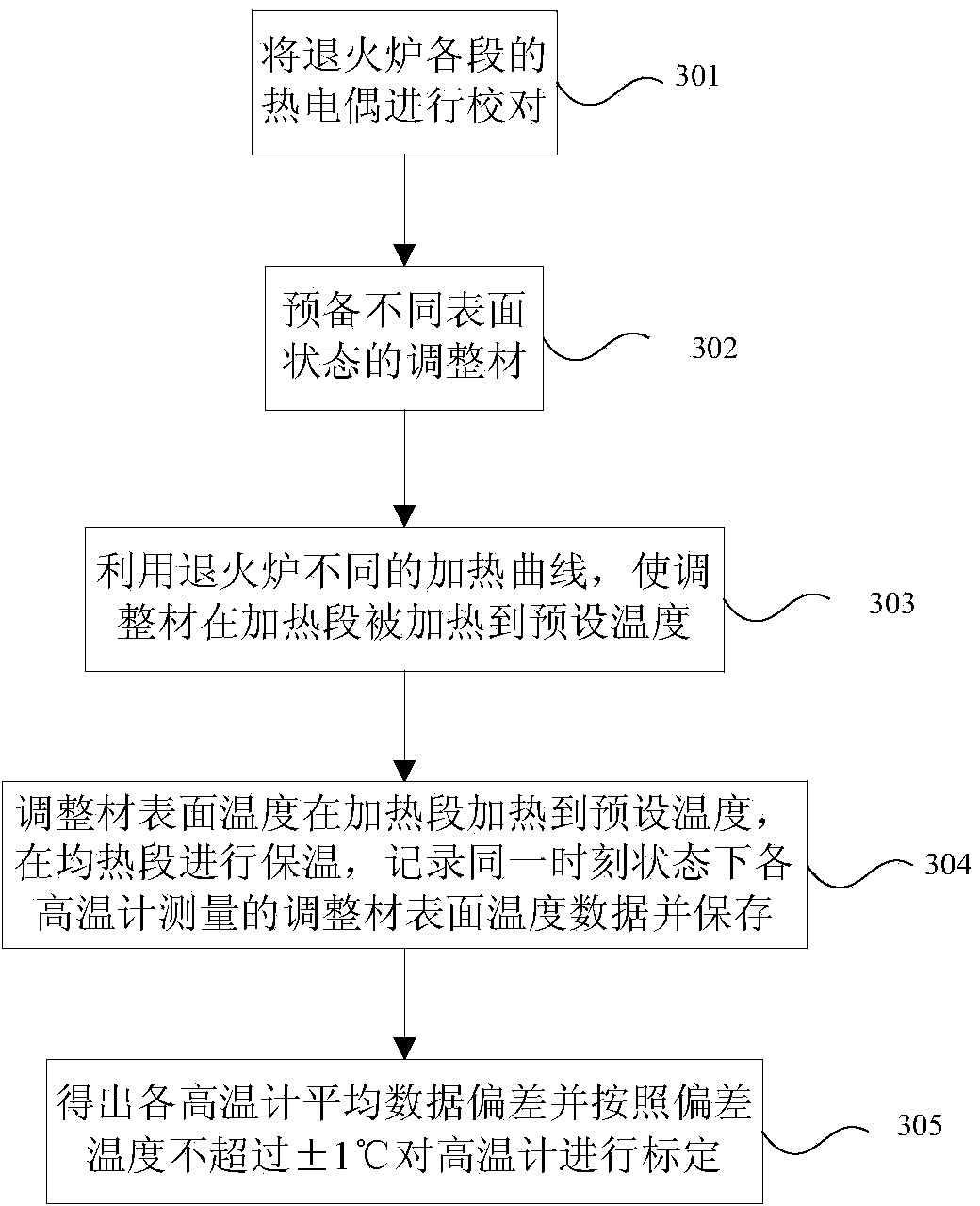

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] The embodiment of the present invention provides a method for online calibration of a fixed pyrometer in a continuous annealing furnace, which solves the problem of calibrating this type of pyrometer without stopping the machine, reduces the inventory of spare parts, and reduces the cost of pyrometers. The frequency of commissioned calibration reduces the cost of pyrometer calibration and reduces the waste of resources.

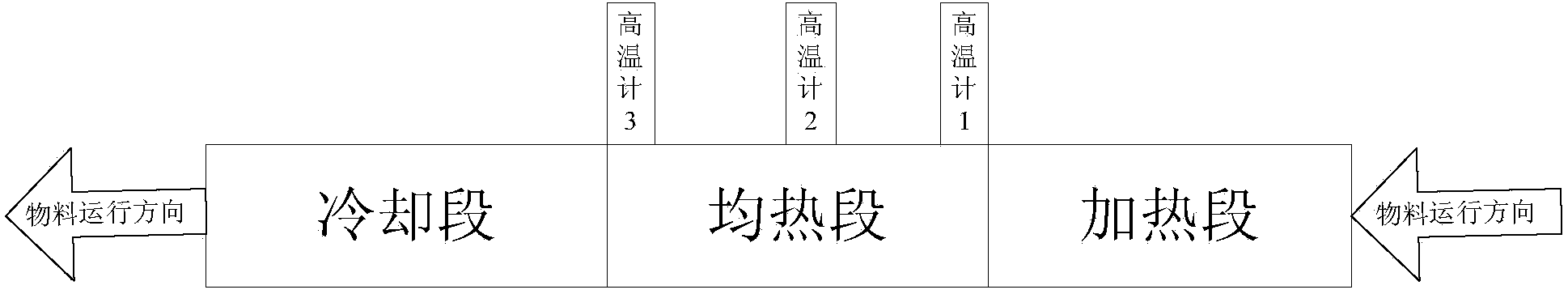

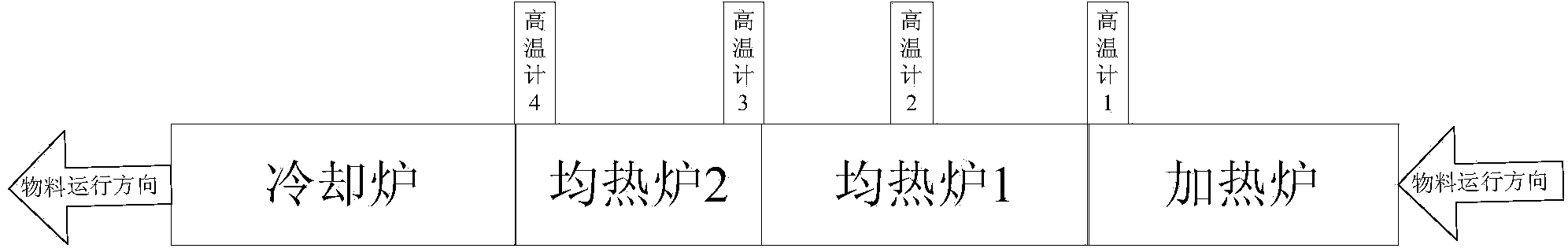

[0016] The calibration method provided in this embodiment is: set the specified temperature mechanism (the heating section is based on the actual furnace conditions, and the temperature of the soaking section is uniform), to ensure that the material reaches the specified temperature at the end of the heating section at the specified operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com