Preparation method of polycarboxylic acid water reducer

A technology of water reducer and polycarboxylate, which is applied in the field of preparation of polycarboxylate water reducer, can solve problems affecting product use and unstable performance, and achieve the goal of ensuring stable performance, promoting performance stability, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

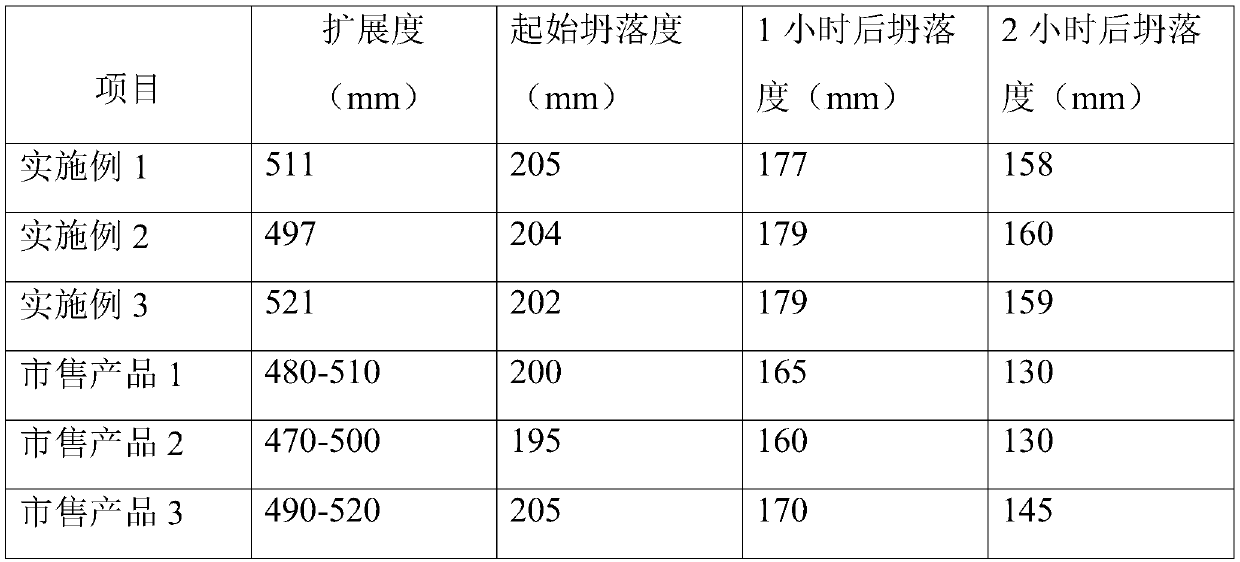

Examples

Embodiment 1

[0012] Embodiment 1, a kind of preparation method of polycarboxylate water reducer, its steps are:

[0013] Step 1: Pour 32% by weight of polyethylene glycol methacrylate monomer into the reactor, and add 63.35% by weight of water into the reactor for stirring to make it evenly mixed;

[0014] Step 2: Add 0.5% by weight of triethylenetetramine, 4% by weight of acrylic acid, and 0.15% by weight of vitamin C into the mixing tank, the concentration of acrylic acid is above 95%, and the purity of vitamin C is above 99%. , stir the three in the mixing tank evenly;

[0015] Step 3: Within two hours, keep the stirring shaft in the mixing tank and the reactor in working condition, and gradually and evenly add the mixture in the mixing tank into the reactor, and keep stirring in the reactor until the reaction is completed and the temperature of the material drops to room temperature .

Embodiment 2

[0016] Embodiment 2, a kind of preparation method of polycarboxylate water reducer, its steps are:

[0017] Step 1, pour 38% by weight of polyethylene glycol methacrylate monomer into the reactor, and add 58% by weight of water in the reactor for stirring to make it evenly mixed;

[0018] Step 2, adding 0.2% by weight of triethylenetetramine, 3.5% by weight of acrylic acid, and 0.3% by weight of vitamin C into the mixing tank, the concentration of acrylic acid is above 95%, and the purity of vitamin C is above 99% , stir the three in the mixing tank evenly;

[0019] Step 3: Within two hours, keep the stirring shaft in the mixing tank and the reactor in working condition, and gradually and evenly add the mixture in the mixing tank into the reactor, and keep stirring in the reactor until the reaction is completed and the temperature of the material drops to room temperature .

Embodiment 3

[0020] Embodiment 3, a kind of preparation method of polycarboxylate superplasticizer, its steps are:

[0021] Step 1: Pour 35% by weight of polyethylene glycol methacrylate monomer into the reactor, and add 60% by weight of water into the reactor for stirring to make it evenly mixed;

[0022] Step 2, adding 0.5% by weight of triethylenetetramine, 4.7% by weight of acrylic acid, and 0.2% by weight of vitamin C into the mixing tank, the concentration of acrylic acid is above 95%, and the purity of vitamin C is above 99% , stir the three in the mixing tank evenly;

[0023] Step 3: Within two hours, keep the stirring shaft in the mixing tank and the reactor in working condition, and gradually and evenly add the mixture in the mixing tank into the reactor, and keep stirring in the reactor until the reaction is completed and the temperature of the material drops to room temperature .

[0024] When the room temperature is lower than 0 degrees Celsius, turn on the heating rod in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com