Crusher

A crusher and driving machine technology, applied in the field of machinery, can solve the problems of untimely maintenance, low design life of the coupling, high cost, etc., and achieve the effects of convenient installation and replacement, long service life and high degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

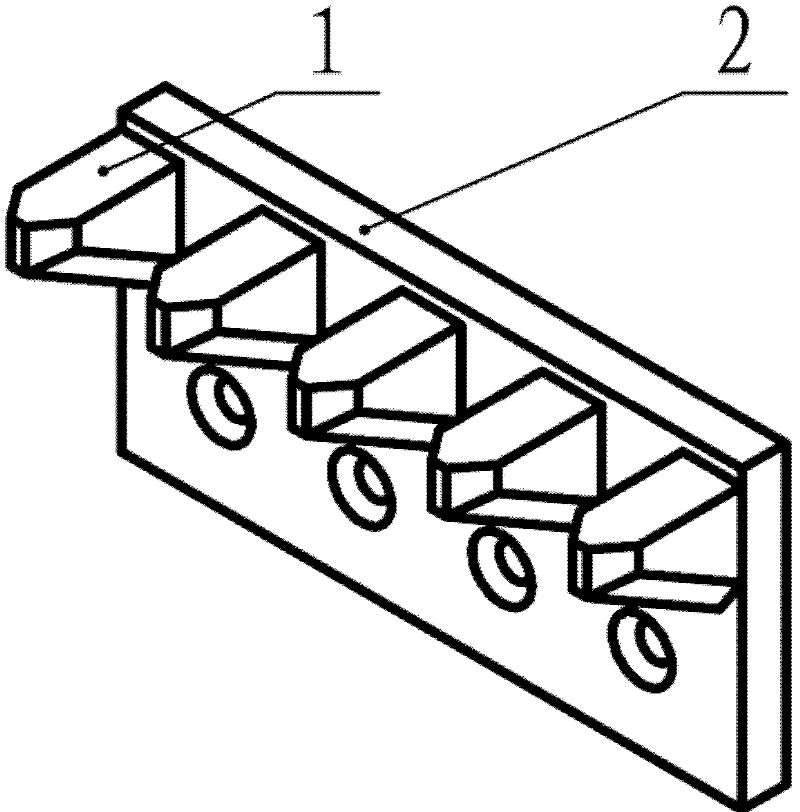

[0036] see figure 1 The side comb structure of the crusher used in the present invention includes a plate 1 and teeth 2 arranged on the plate 1. The teeth 2 are welded or clamped on the plate 1, preferably welded on the plate 1. The number of teeth 2 can be one or more, if more than one, multiple teeth 2 are welded on the same side of the plate 1 in parallel. Both the plate 1 and the teeth 2 are made of wear-resistant steel plates.

[0037] During the specific processing of the side comb structure, the side comb structure of the crusher is formed by welding plate 1 and tooth 2, and the wear-resistant steel plate is cut into plate 1 and tooth 2 by flame cutting, water cutting and other cutting methods. 2 shape, use the edge milling machine to carry out edge treatment and chamfering on the cut plate, if the blanking method adopted can meet the appearance requirements, then no edge treatment is required. After the blanking and edge processing are completed, the welding surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com