Method for producing sulfur-based composite fertilizer by using monoammonium phosphate instead of phosphoric acid

A technology of sulfur-based compound fertilizer and monoammonium phosphate, which is applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve the problems of difficult utilization of phosphogypsum, increased storage costs, and hidden dangers of environmental governance, and achieves Avoid environmental hazards, improve whiteness, and increase corporate benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

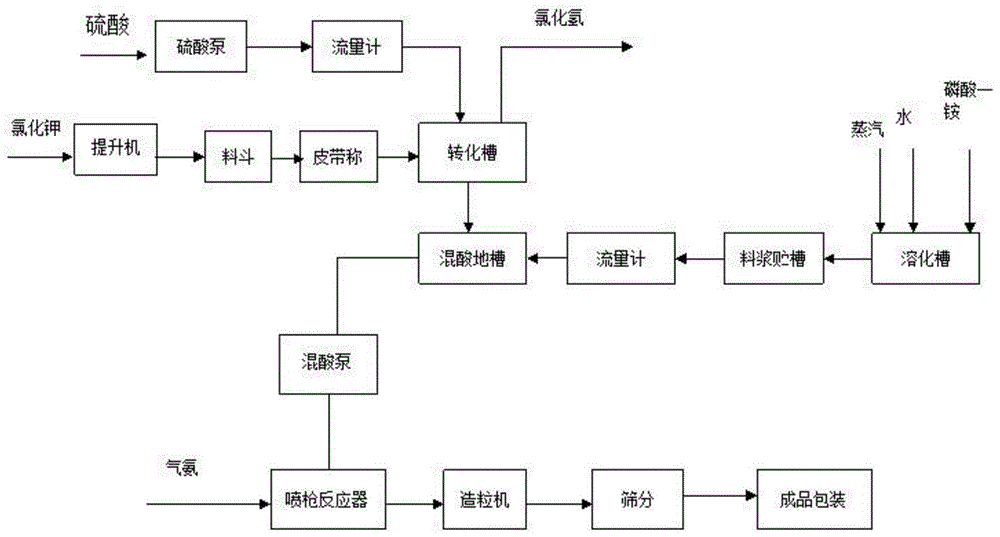

Method used

Image

Examples

Embodiment 1

[0017] (1) Preparation method of monoammonium phosphate slurry: dissolve monoammonium phosphate with water or compound fertilizer tail gas washing liquid, heat with low-pressure steam, control the pressure of low-pressure steam at 0.1MPa, control the temperature of monoammonium phosphate slurry at 50°C, The specific gravity of ammonium slurry is 1.30g / ml.

[0018] (2) The method of preparing mixed acid: from the circulation tank H of the sulfuric acid workshop 2 SO 4 Sulfuric acid with a mass content of 98%, the sulfuric acid enters the conversion tank after being metered by a flow meter. Potassium chloride enters the hopper through the elevator, and then enters the conversion tank after being weighed by the belt and reacts with sulfuric acid in the first zone of the conversion tank. During the reaction, low-pressure steam is added, and the pressure of the low-pressure steam is controlled at 0.1MPa. The internal reaction was controlled at 100°C.

[0019] A solution containi...

Embodiment 2

[0033] The difference between this example and Example 1 is that the low-pressure steam pressure used is controlled at 0.6MPa, the temperature of the monoammonium phosphate slurry is controlled at 80°C, the specific gravity of the monoammonium phosphate slurry is 1.40g / ml, potassium chloride, sulfuric acid , Material ratio of monoammonium phosphate slurry 1t: 1.0m 3 : 2.50m 3 ; Mixed acid specific gravity: 1.60g / ml. After the mixed acid reacts with ammonia gas, the neutralization degree of ammonia and mixed acid is 1.60.

Embodiment 3

[0035] The difference between this example and Example 1 is that the low-pressure steam pressure is controlled at 0.4MPa, the temperature of the monoammonium phosphate slurry is controlled at 70°C, the specific gravity of the monoammonium phosphate slurry is 1.34g / ml, potassium chloride, sulfuric acid, phosphoric acid Material ratio of ammonium slurry 1t: 0.855m 3 : 1.50m 3 ; Specific gravity of mixed acid: 1.50g / ml. After the mixed acid reacts with ammonia gas, the neutralization degree of ammonia and mixed acid is 1.55.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com