Variable Displacement Compressor

a compressor and variable displacement technology, applied in the direction of positive displacement engines, reciprocating piston engines, liquid positive displacement engines, etc., can solve the disadvantages of sealing parts and the durability of rotational and drive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Hereinafter, concrete embodiments of the present invention will be explained referring to figures.

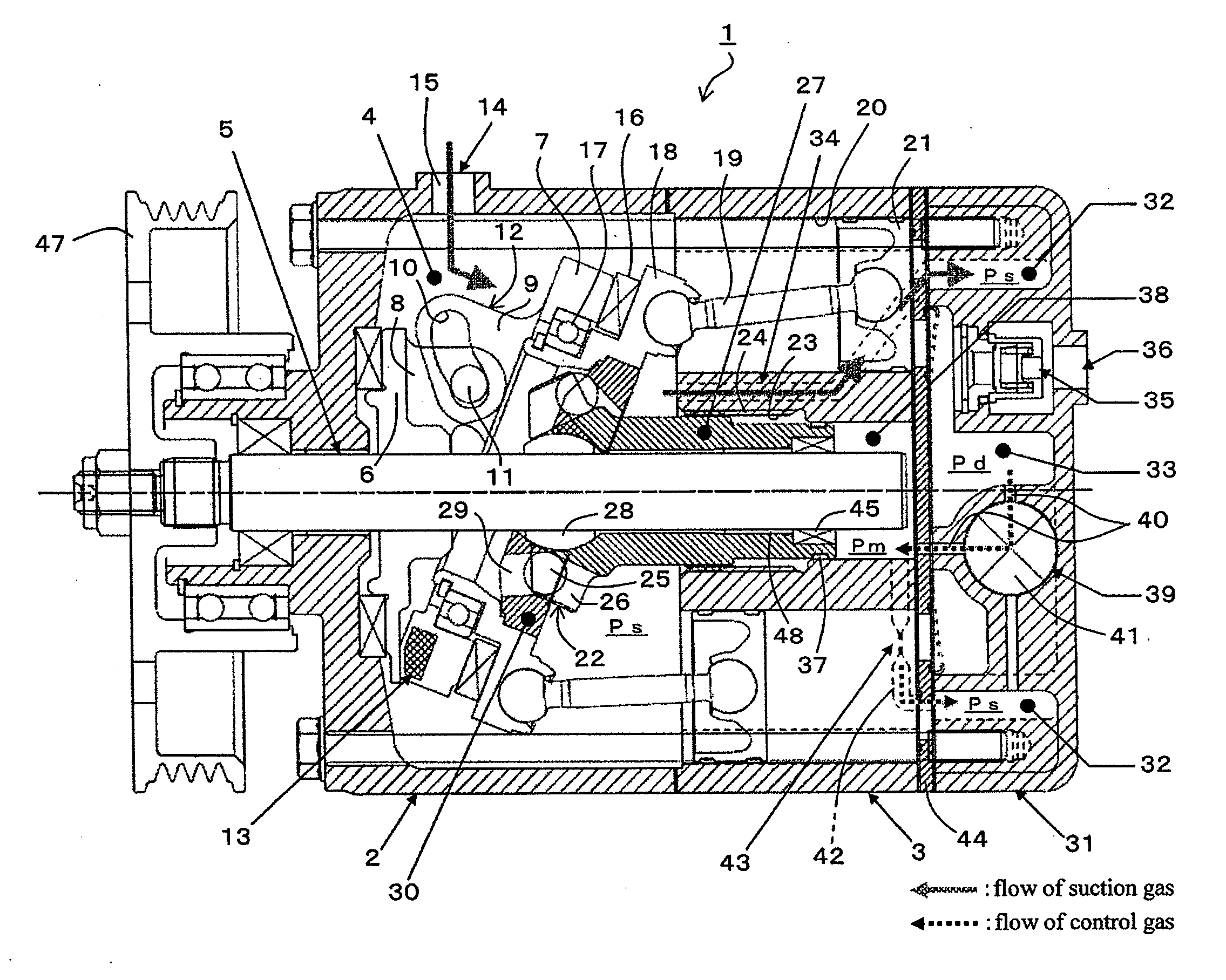

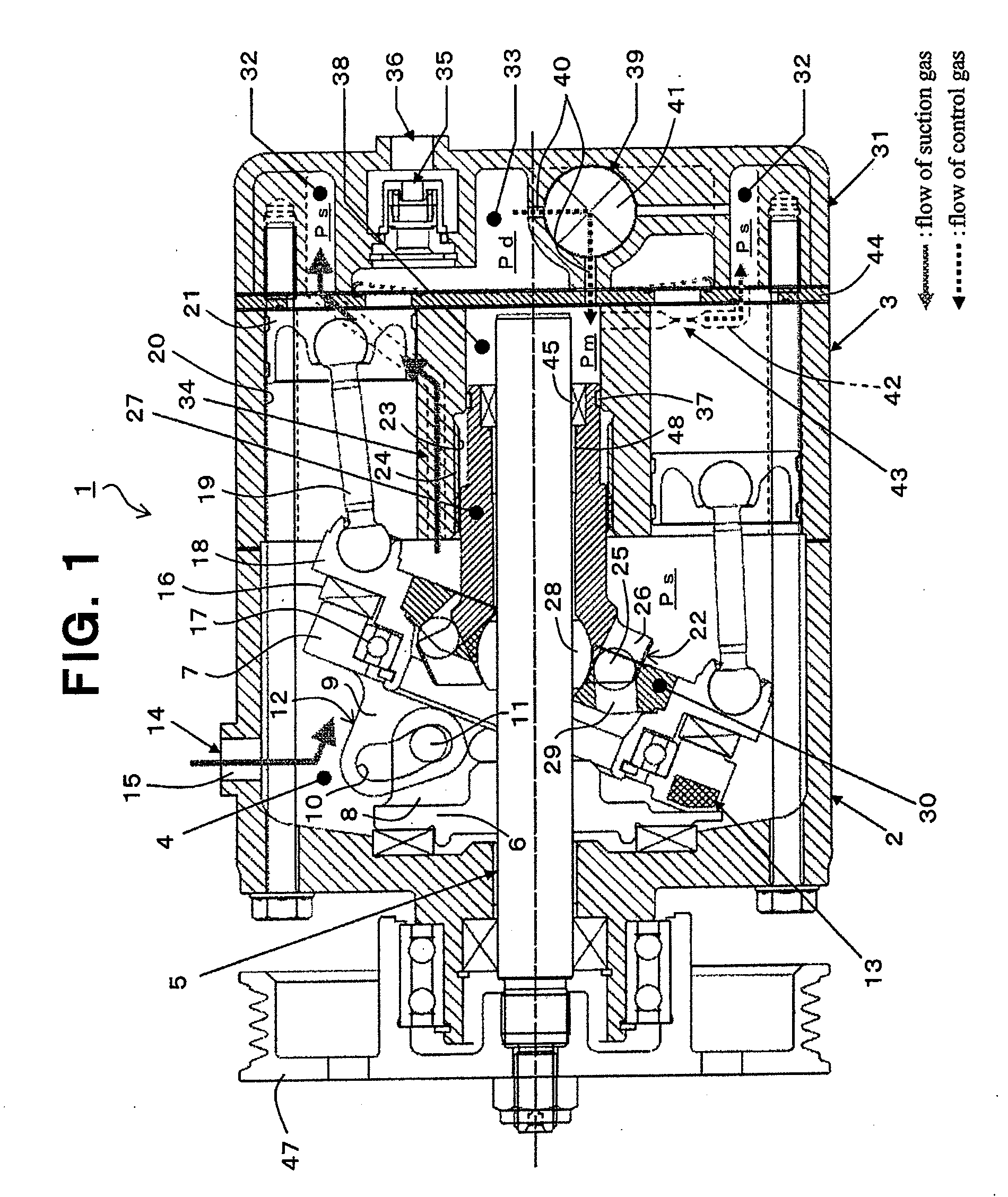

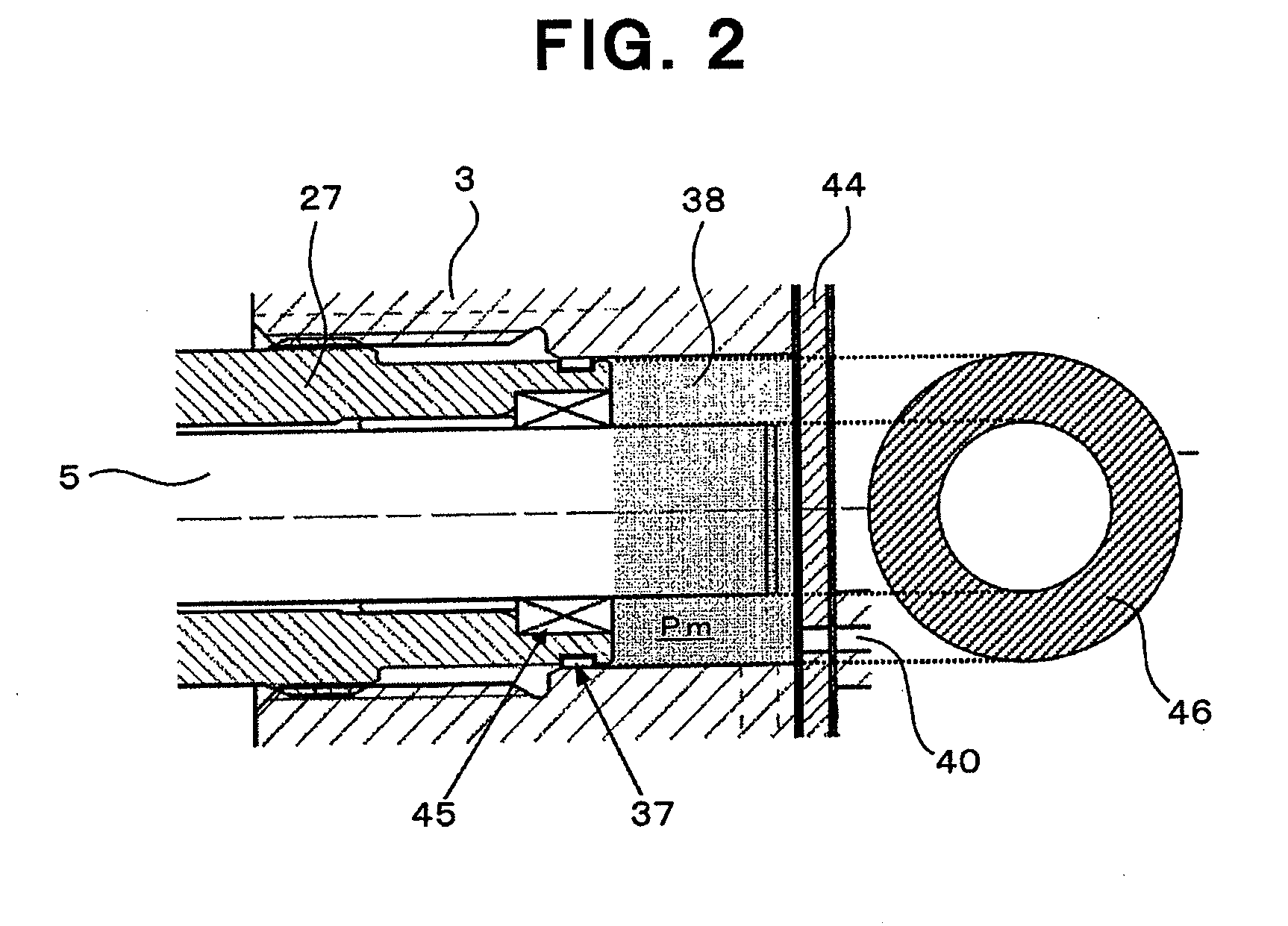

[0044]FIGS. 1 to 6 show a variable displacement compressor according to a first embodiment of the present invention. FIG. 1 shows a state at the time of a maximum displacement (a maximum cam angle [a maximum swash plate angle]) of a variable displacement compressor 1, and FIG. 3 shows a state at the time of a minimum displacement (a minimum cam angle [a minimum swash plate angle]). In FIG. 1, a main shaft 5 is inserted into a crank chamber 4 formed by a front housing 2 and a cylinder block 3, relatively to main shaft 5, provided is a rotor 6 which is fixed to main shaft 5 and rotated integrally with main shaft 5, and disposed is a swash plate 7 which can be changed in its tilt angle relative to main shaft 5 and which can be rotated integrally with main shaft 5. Between rotor 6 and swash plate 7, provided is a hinge mechanism 12 forming a sliding mechanism wherein an arm 8 extendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com