High-rigidity light launching box

A launching box and high-stiffness technology, applied in the field of launching boxes, can solve the problems of unfavorable bomb box weight ratio and motor transport performance, insufficient optimization of hoop stiffness and longitudinal stiffness, unfavorable missile launch, transportation and storage, etc., to improve environmental protection The effect of axial stiffness and load-bearing efficiency, high bending section coefficient, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

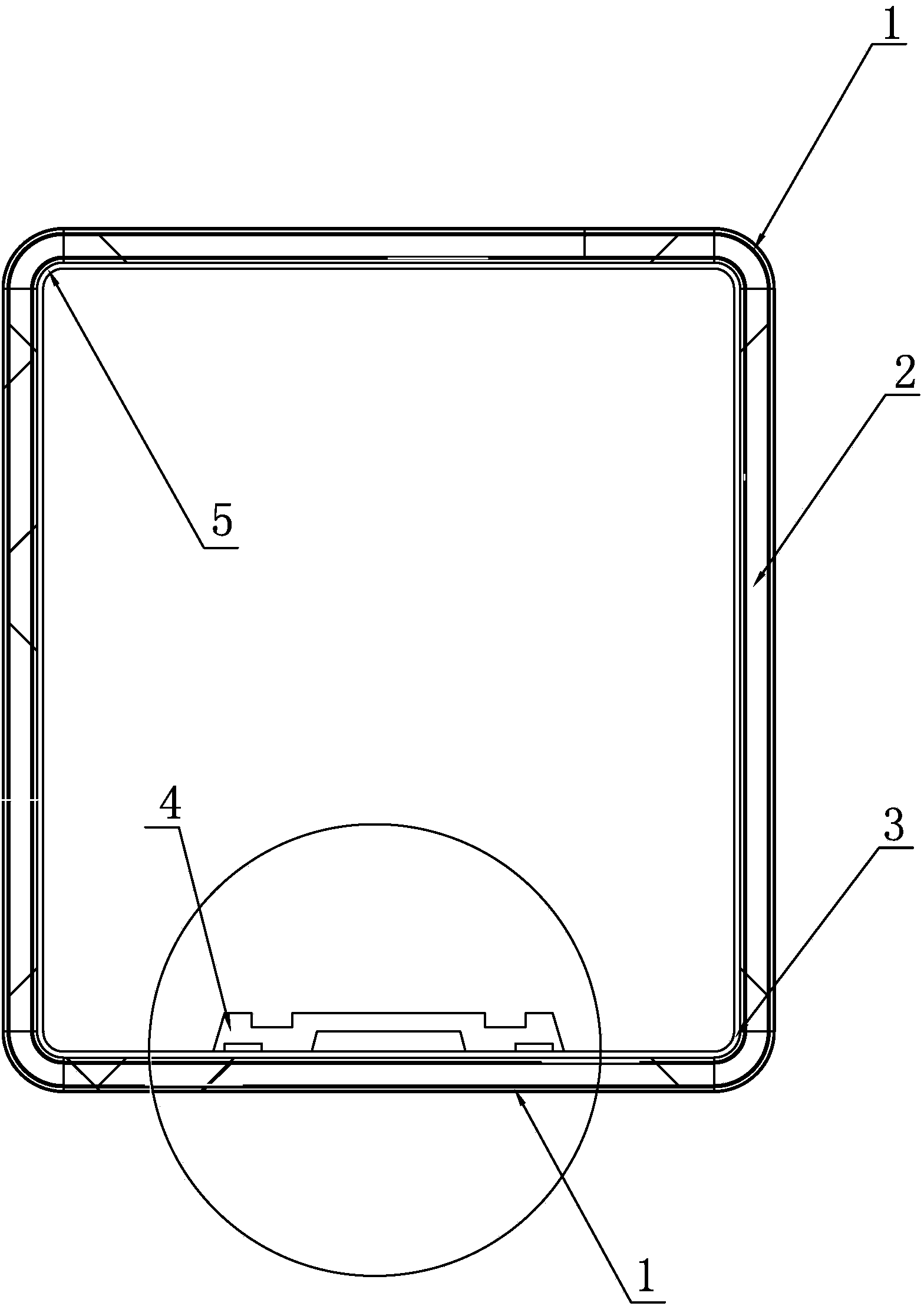

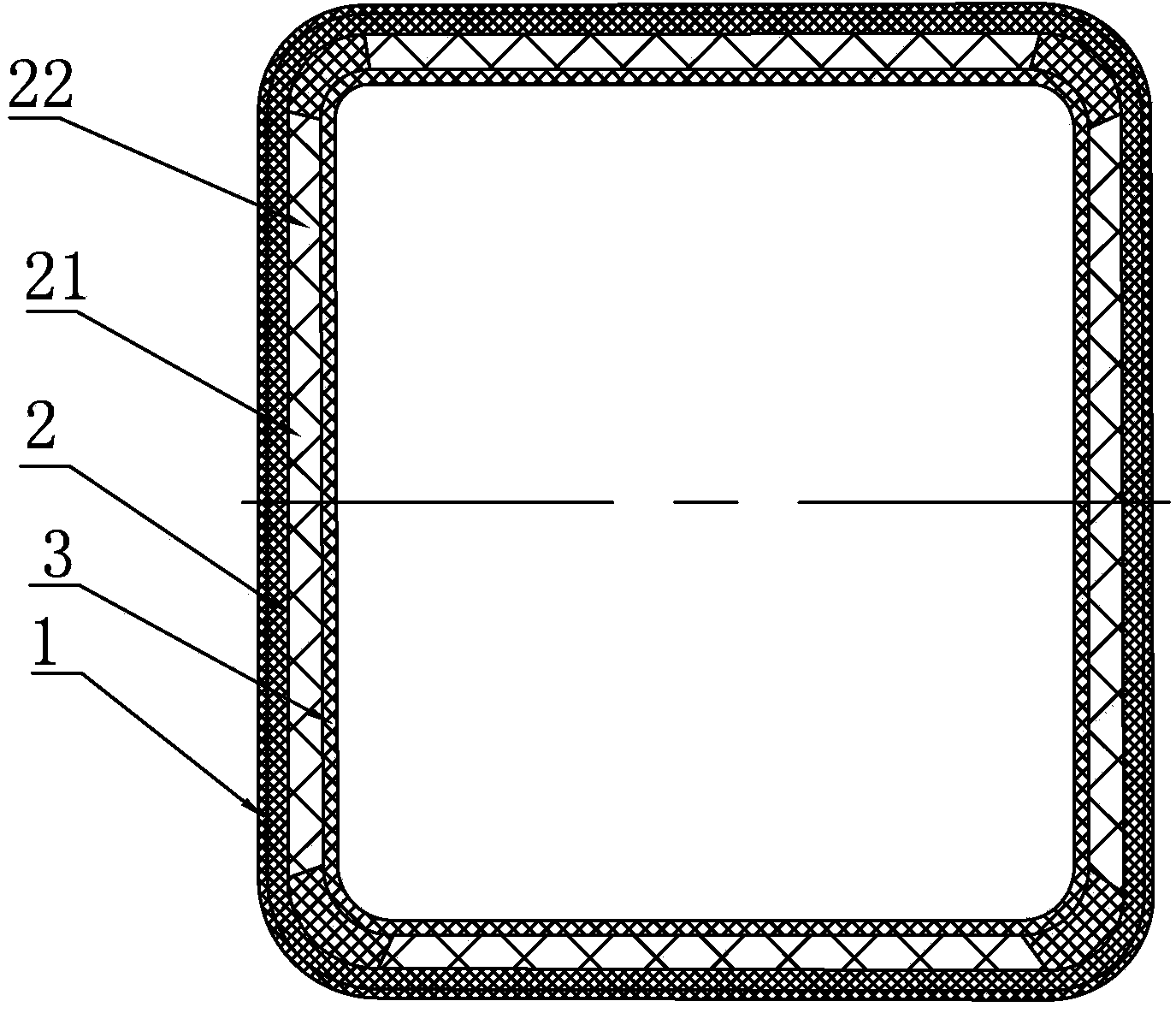

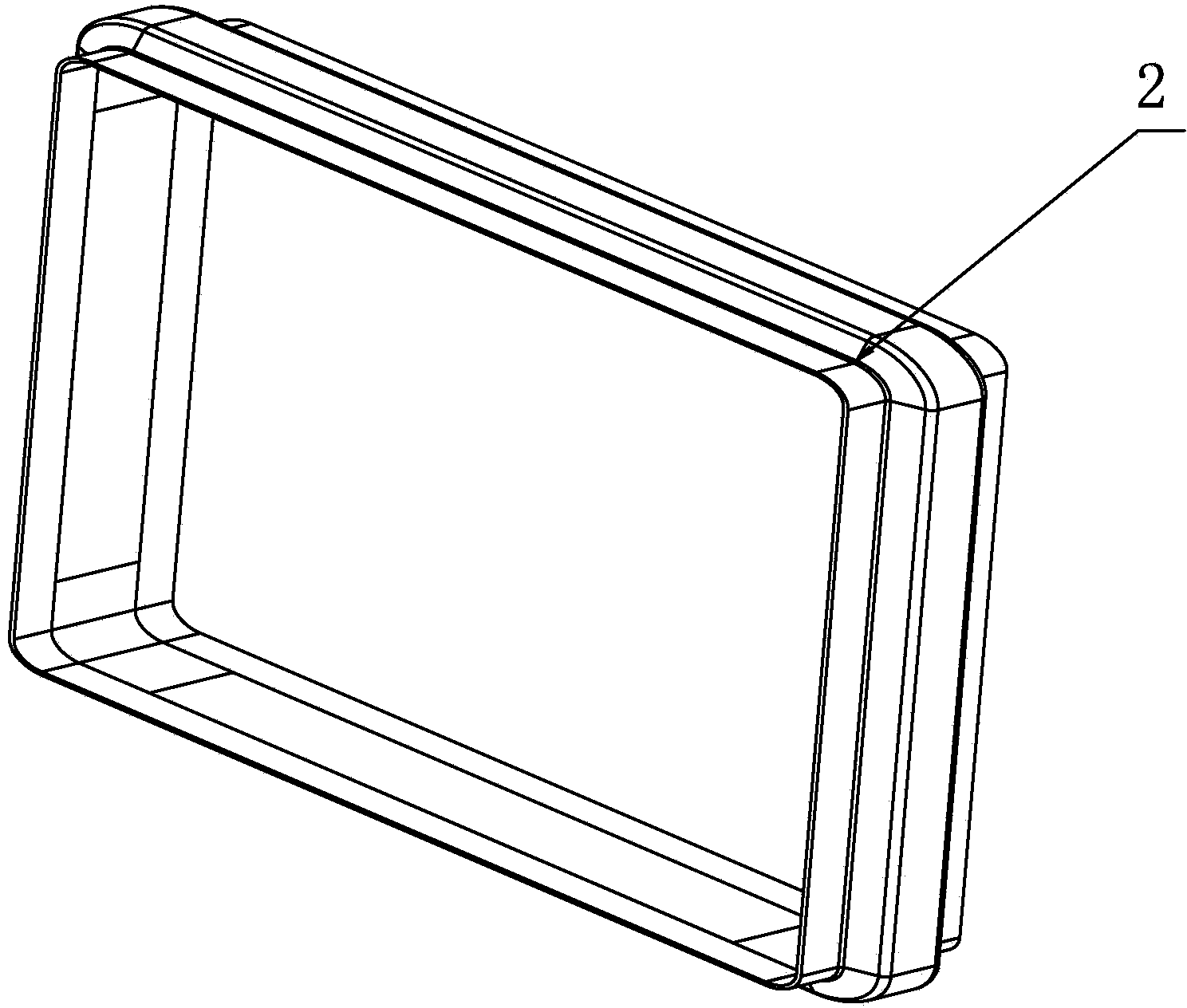

[0024] Such as figure 1 , figure 2 As shown, a high-rigidity and lightweight launching box of the present invention includes an inner skin 3 located at the innermost part of the launching box, an outer skin 1 located at the outermost part of the launching box, longitudinal ribs 4, and evenly distributed inner and outer skins. There are several ring ribs between the skins. The thickness of the inner skin 3 is less than the thickness of the outer skin 1. The cross-sectional shape of the inner and outer skins is rectangular. The inner skin 3 and the outer skin 1 of the launching box are the main parts of the launching box. The base of the load-bearing structure and the connecting structure, the ring ribs are used as the skeleton of the entire launch box body, and are connected to the inner skin 3 and the outer skin 1 by adhesives. In order to increase the connection strength, the ring ribs and the inner The joints of the skin 3 and the outer skin 1 are provided with evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com