Method for balancing rotation torque of helicopter body

A technology for helicopters and balancing torque, applied in the aviation field, can solve the problems of large wake noise, large structure volume, flight speed limitation, etc., and achieve the effect of reducing structure volume, small structure volume, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

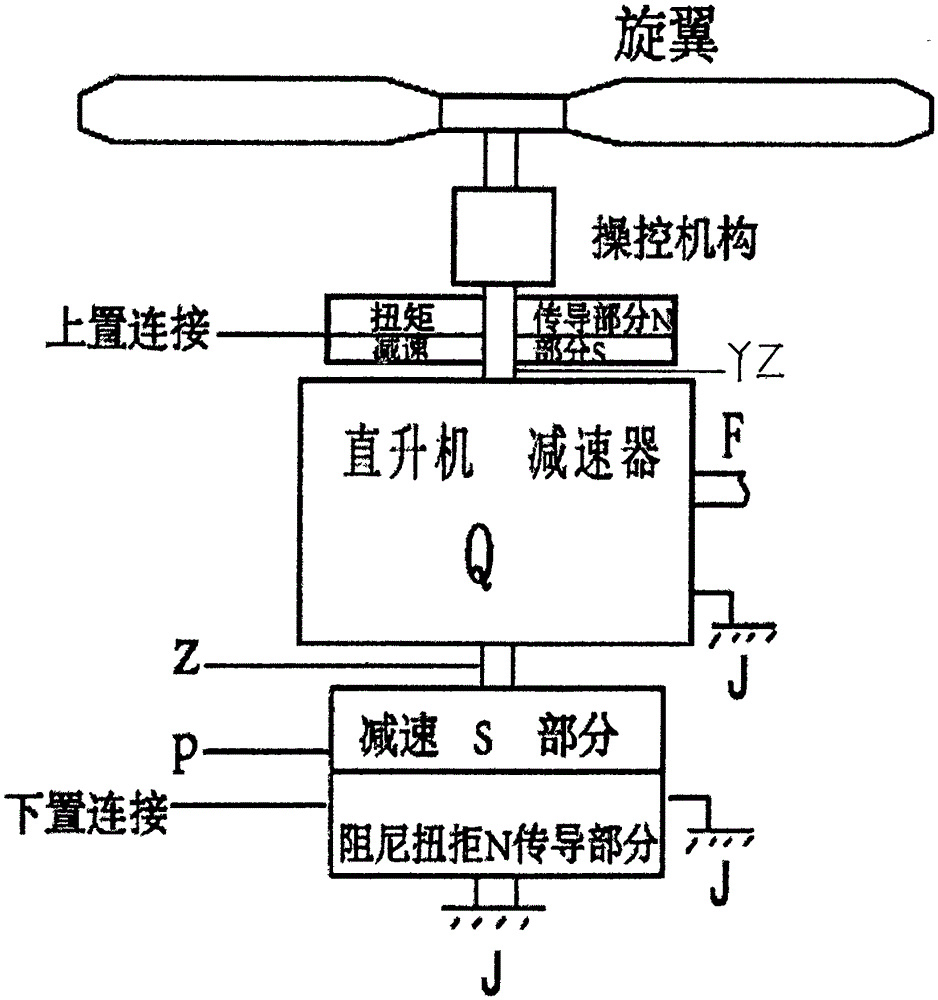

[0028] A method for balancing the rotational torque of a helicopter body, comprising: a helicopter body J, an engine F, and a rotor Y. The combination of structure and composition replaces the traditional helicopter tail rotor structure, tail flow balance body rotation torque structure, and a group of rotor Y structures in the double rotor Y structure.

Embodiment 2

[0030] A structural combination for a method of balancing the rotating torque of a helicopter body, comprising a torque balancer P, the torque balancer P is composed of a deceleration part S and a torque transmission part N: the deceleration part S is connected to the torque transmission part N, and The torque transmission part N transmits balance torque power, and the torque transmission part N outputs damping torque power.

[0031] Example 2:

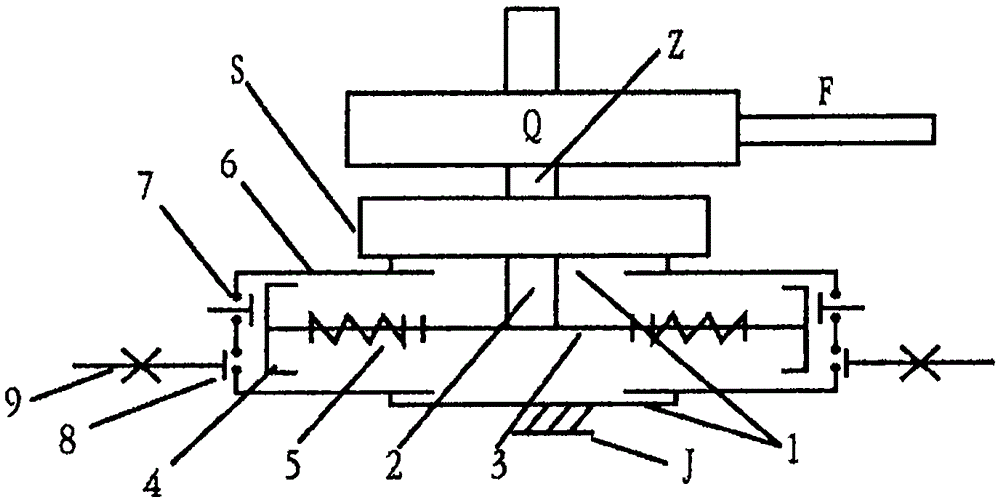

[0032] A kind of structural combination that realizes the method for balancing the rotating torque of the helicopter body described in embodiment 2, the described deceleration part S is based on the actual situation of the power of the helicopter engine and the power transmission structure, in each of the mechanical deceleration In a structure: selection, matching, suitable, specific, structural form, to apply.

Embodiment 3

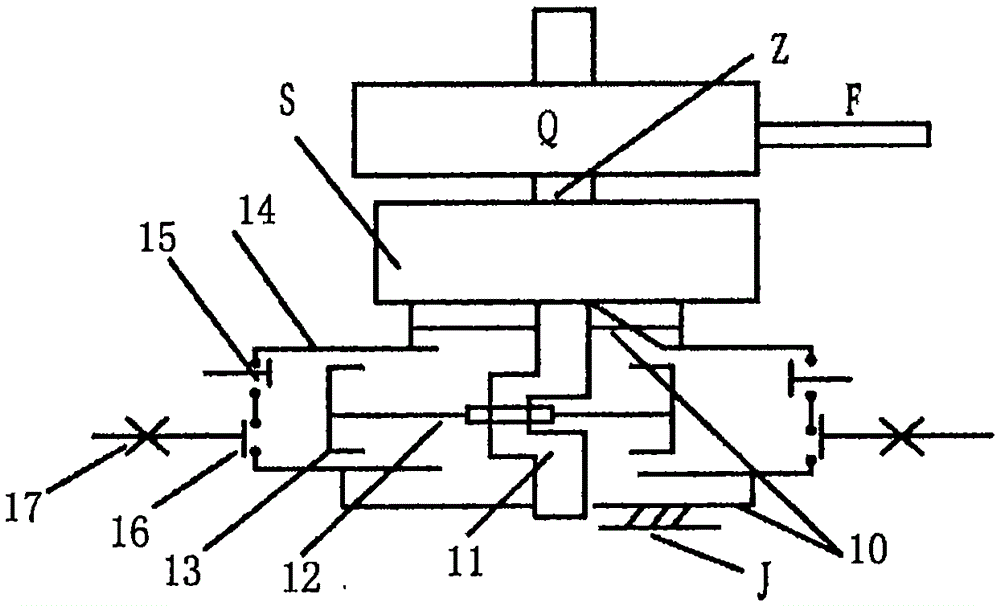

[0034] A structural combination of a method for balancing the rotational torque of the helicopter body described in Embodiment 2 or 3, the torque transmission part N is based on the specific conditions of the torque balancer P and the torque of the deceleration part S, in: hydraulic pressure Technology, power transmission technology, braking technology, and can realize and form, the balance torque is relative to the rotation torque of the body: among various structures of hydraulic pressure damping, frictional damping, magnetic force and magnetic damping functions, choose, match, and suit specific, specific, structural form, to apply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com