Car structure

a technology for cars and structures, applied in the direction of axle-box lubrication, railway bodies, windows, etc., can solve the problems of high stress on the face plate, concentrated deformation due to vertical load, etc., to avoid the increase in the weight of the structure, the side structure can be light in weight, and the thickness of the second joint part can be increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

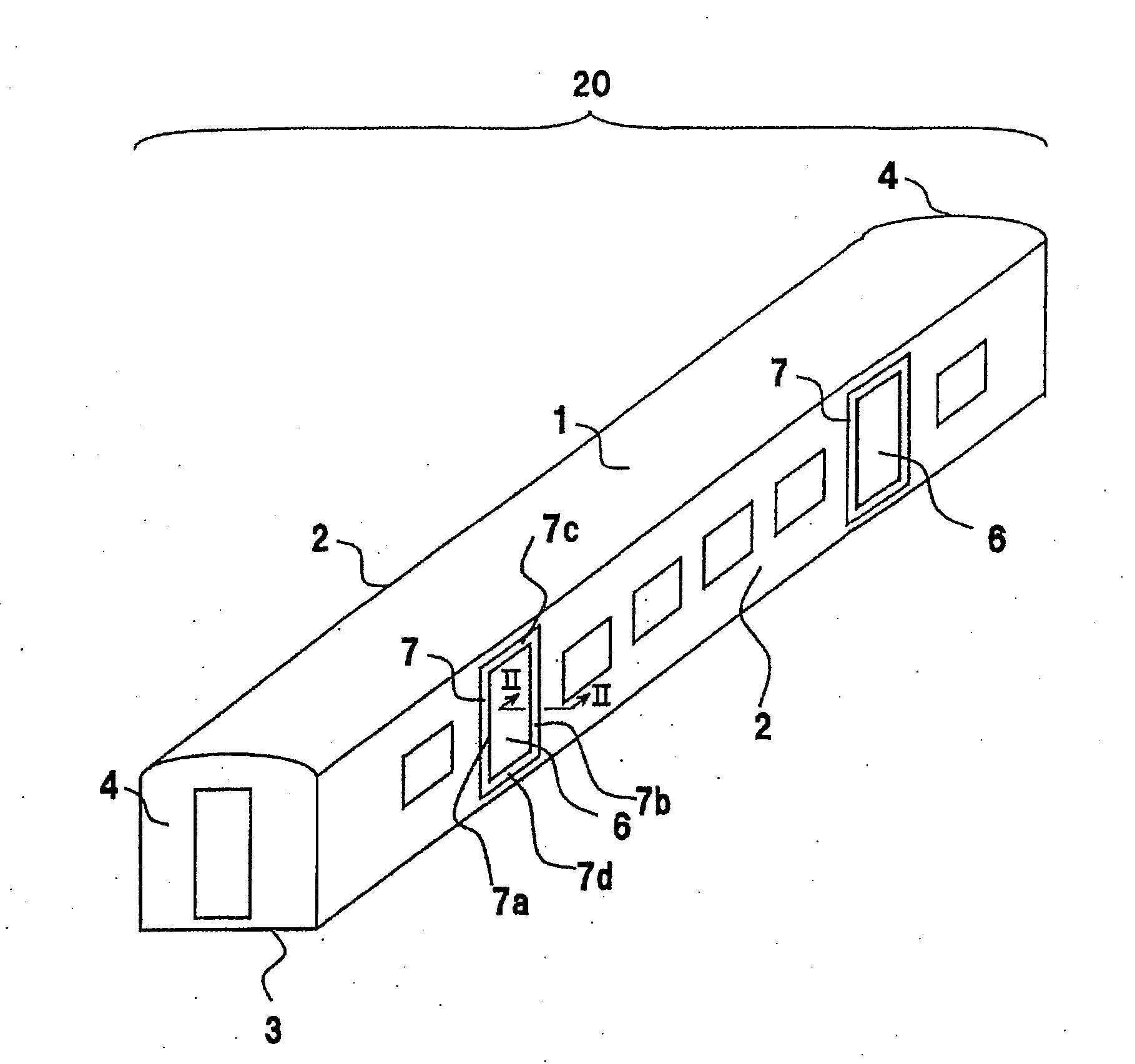

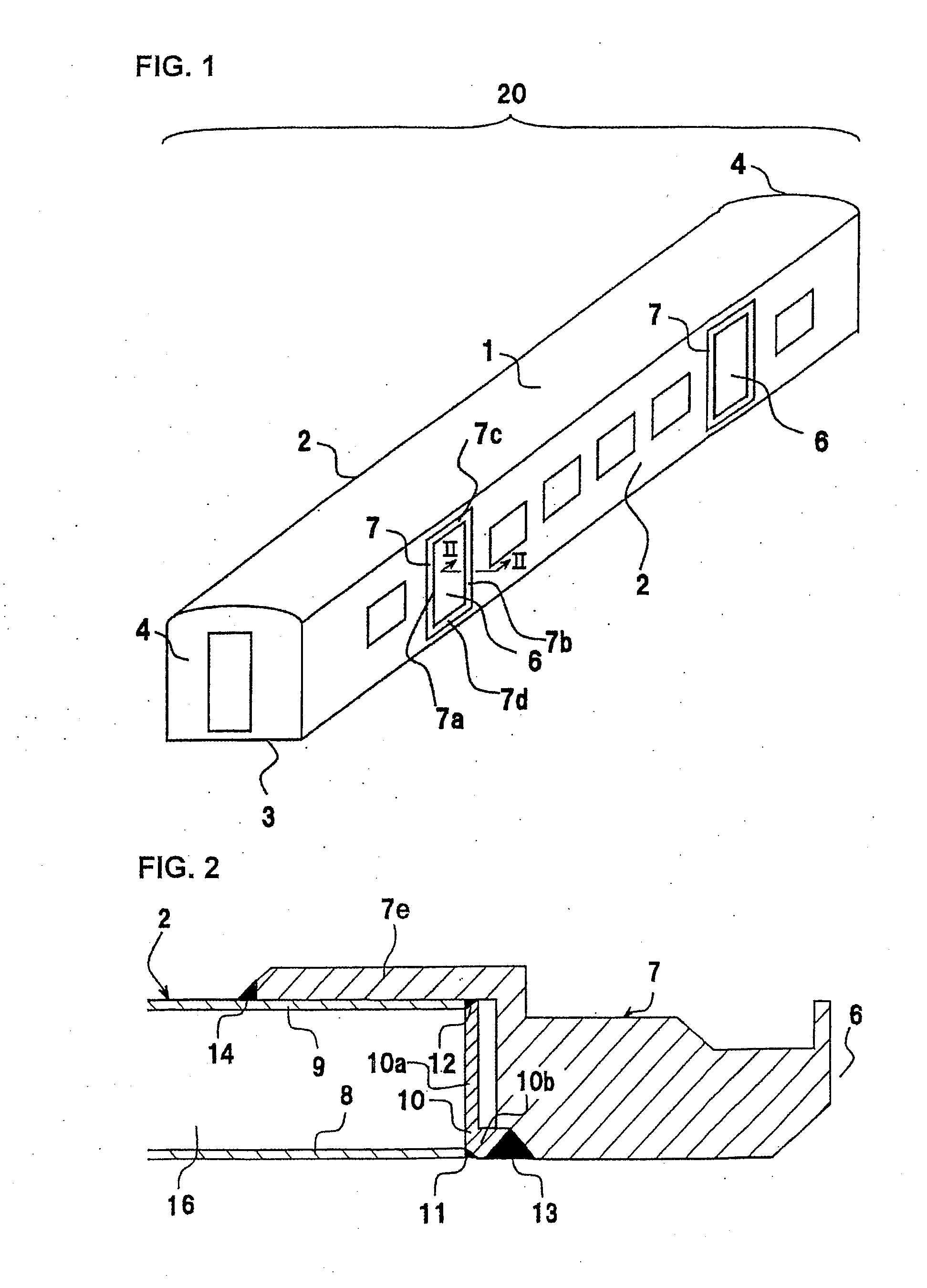

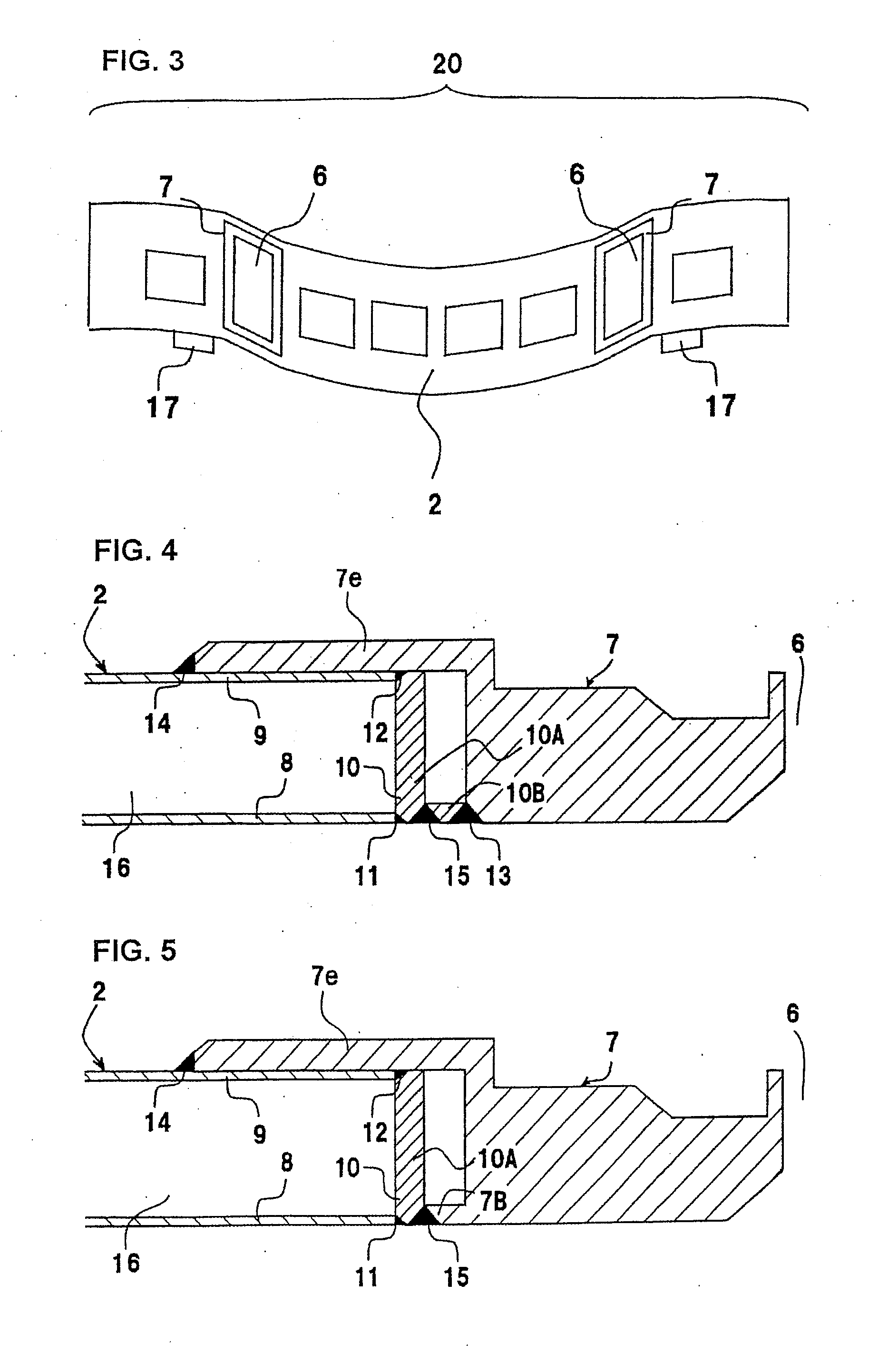

[0021]A first embodiment of the present invention will be described with reference to FIGS. 1 to 3.

[0022]In an embodiment shown in FIG. 1, a rail car structure 20 comprises a roof component 1 forming an upper side, two side structures 2, 2 forming lateral sides, an underframe 3 forming a lower side, and two end components 4, 4 forming end sides.

[0023]Each of the roof component 1, the side structures 2, 2, the underframe 3, and the end components 4, 4 is formed by jointing (welding or friction stir welding) a plurality of extruded members.

[0024]The extruded members forming the roof component 1, the side structures 2, 2, and the underframe 3 are hollow members made of aluminum alloy and the hollow members are extruded in a longitudinal direction of the railroad car structure 20. The extruded members forming the end components 4, 4 are single materials with ribs made of aluminum alloy and the single materials are extruded in a vertical direction of the railroad car structure 20.

[0025]F...

embodiment 2

[0036]A second embodiment of the present invention will be described with reference to FIG. 4.

[0037]In the second embodiment, the L-shaped fitting 10 in the embodiment in FIG. 2 is composed of a first joint part 10A and a second joint part 10B which are two separate members. In the embodiment in FIG. 4, the first joint part 10A and the second joint part 10B are in the form of plates and it is not necessary to form an L-shaped fitting 10 with cut-out members or extruded members as in FIG. 2. Therefore, the material and processing cost can be reduced. The first joint part 10A and the second joint part 10B are butt welded as shown by a welded part 15 so that they are coupled to form an L-shape in a cross section perpendicular to the opening edge as shown in the figure. Although the plate 10B is welded to the plate 10A here, the plate 10B may be welded to the face plate 8.

embodiment 3

[0038]A third embodiment of the present invention will be described with reference to FIG. 5.

[0039]In the third embodiment, the second joint part 10B in the second embodiment is integrally formed with the frame 7. In other words, the second joint part is provided as a projecting part 7B which projects from the frame 7 towards the side structure 2. The first joint part 10A and the second joint part 7B are welded by a welded part 15 and coupled to form an L-shape in a cross section perpendicular to the opening edge. According to the third embodiment, the L-shaped fitting can be easily formed and the processes of jointing the second joint part 7B can be reduced, in comparison to the first embodiment shown in FIG. 2.

[0040]Although jointing of the plate members has been described as welding in the above described embodiments, friction stir welding may be used instead of welding. Here, jointing means welding or friction stir welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com