Fully assembled light abutment and construction method thereof

A fully-assembled and light-weight technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of large construction area, reduce component size, environmental pollution, etc., achieve the improvement of anti-knock performance and strengthen the bridge abutment Strength and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

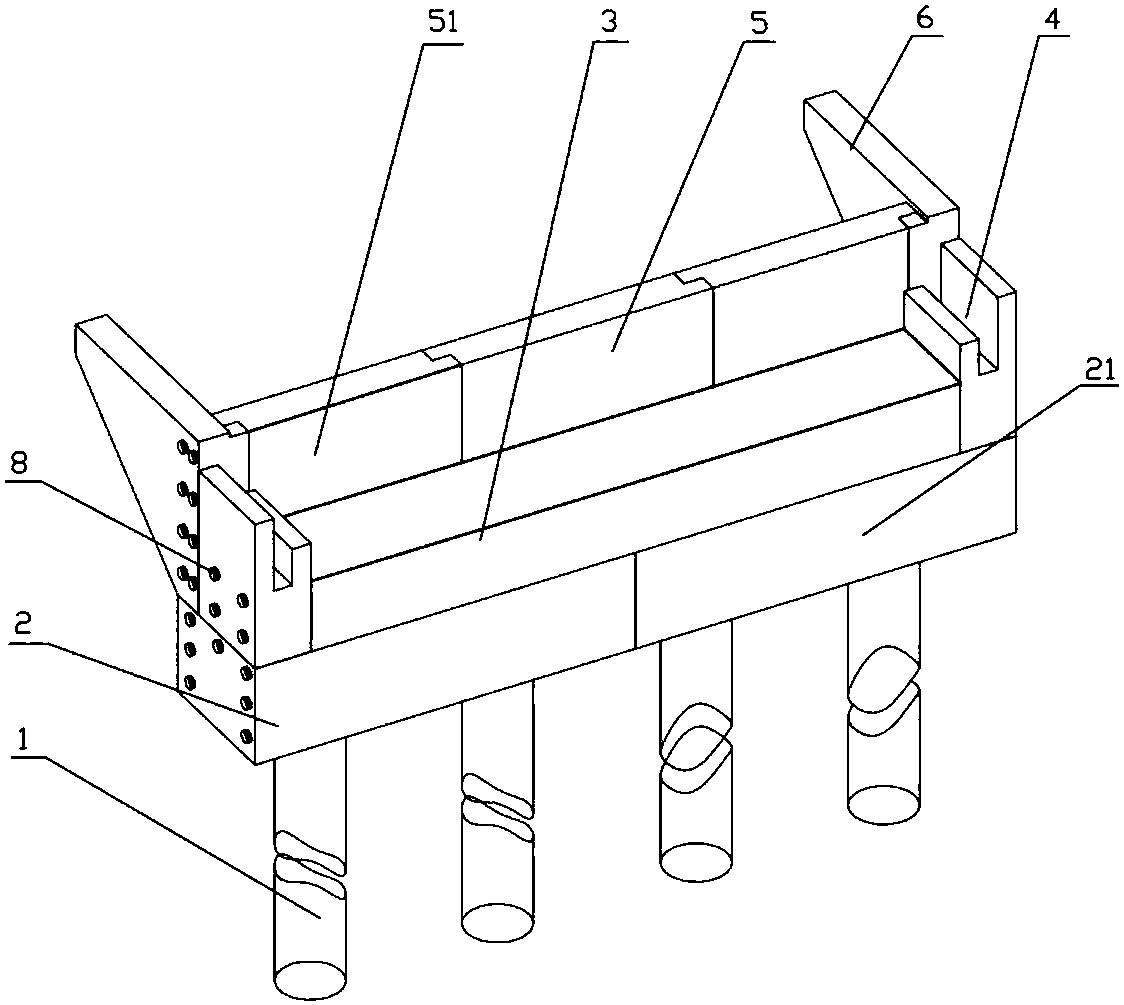

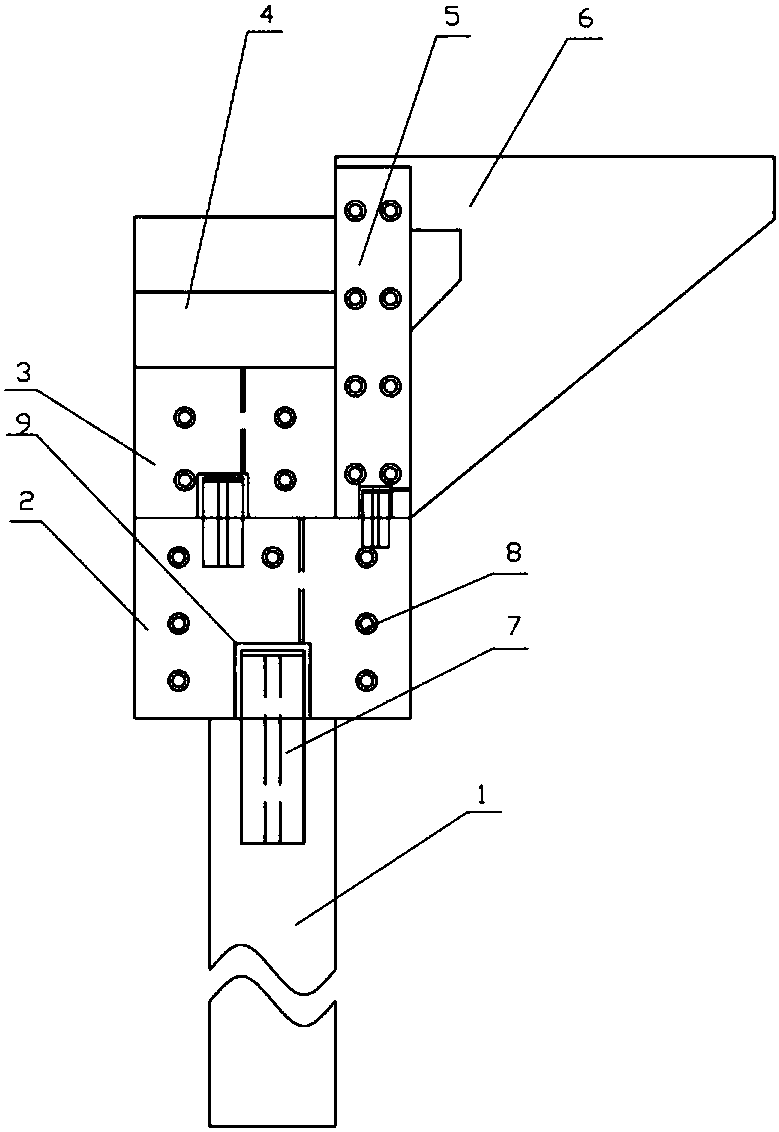

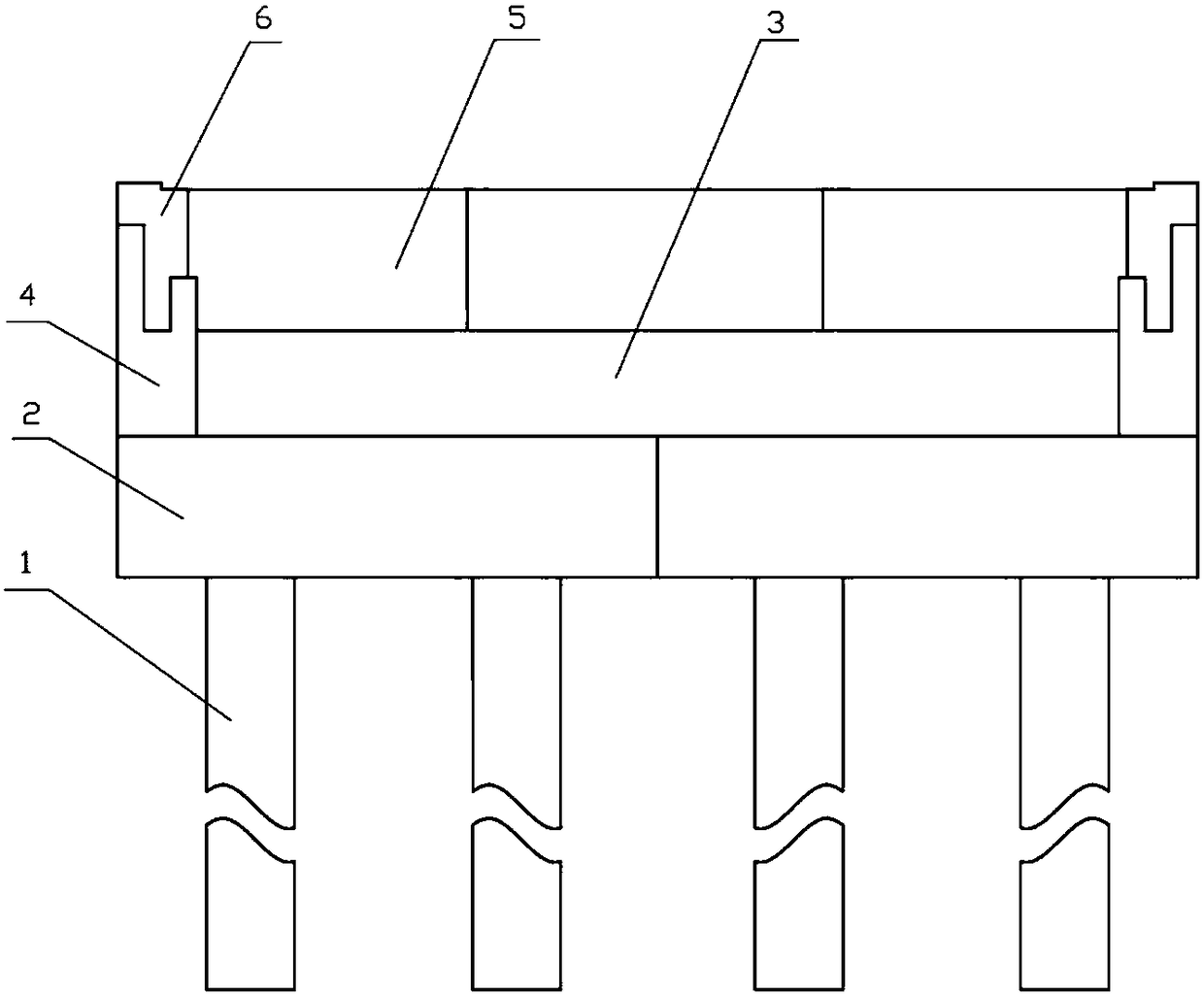

[0043] Such as Figure 1 to Figure 9 As shown, a fully assembled light-duty abutment includes a pile foundation 1, a cap 2 installed above the pile foundation 1, an abutment cap 3 installed above the cap 2, and an abutment cap 3 installed at the left and right ends of the abutment cap 3 and located at The double block 4 above the cap 2, the back wall corbel 5 and the ear wall 6 located on one side of the platform cap 3 and installed above the cap 2, the double stop 4 is connected with the back wall corbel 5, and the cap 2 , platform cap 3, double block 4, back wall corbel 5 and ear wall 6 are UHPC prefabricated components with internal reinforcement cages, pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com