Memory-alloy driving front ducted ejector of variable-cycle engine adjustable mechanism

A variable cycle engine, memory alloy technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of structural weight, complex control system complexity of the mechanism, etc., to reduce the transmission distance of the mechanism, reduce the weight and volume, and reduce the overall The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

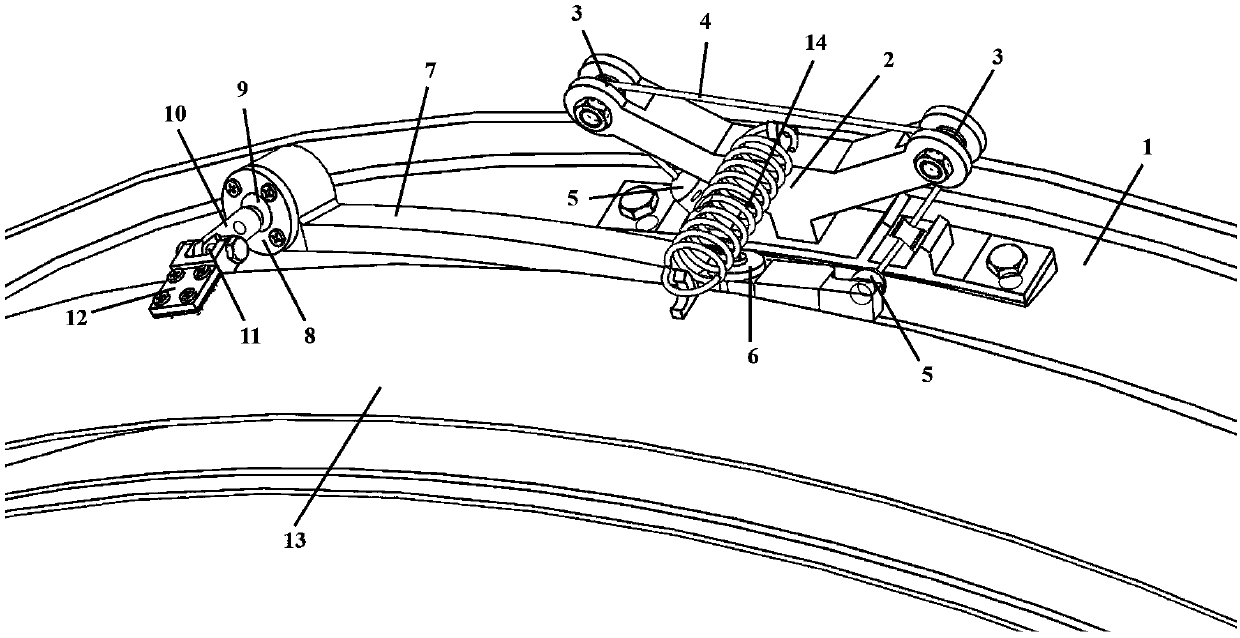

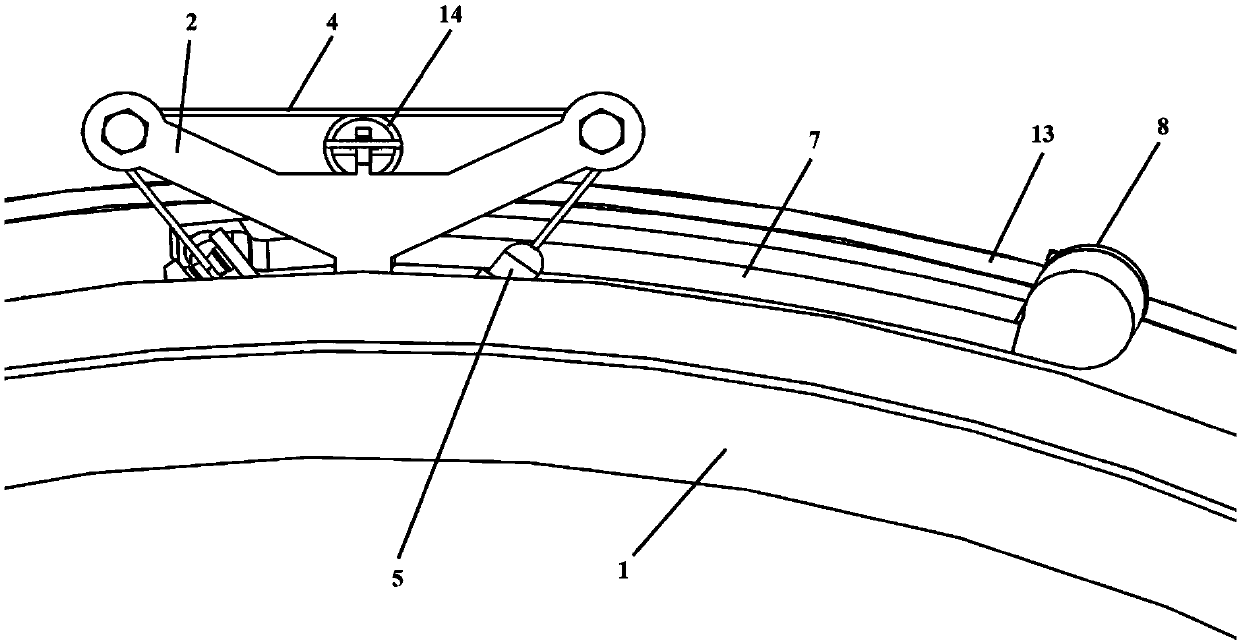

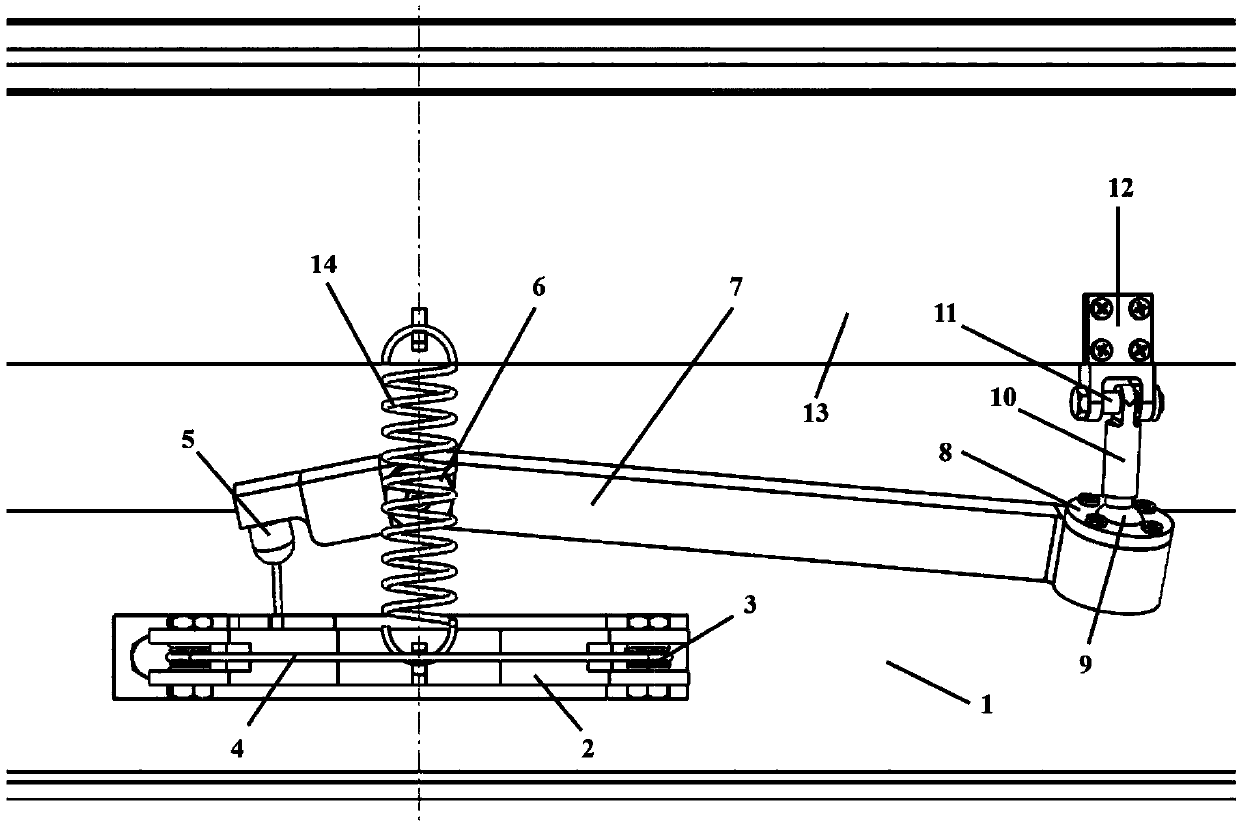

[0039] The specific implementation of duct ejector before memory alloy drives in the present invention is as follows:

[0040] Four main structures of the present invention are evenly distributed in the circumferential direction outside the core drive fan casing, and the specific working process of each mechanism is as follows. When the temperature is lower than the phase transition temperature of the memory alloy, that is, after cooling through the air flow through the flow channel, the bias spring 14 directly pulls the valve body 13 to make it in an open state, and the connecting rod 10 connected with it through the cylindrical pair moves accordingly, passing through the spherical surface. The pair makes the crank 7 rotate, pull the memory alloy wire 4 to elongate and load, when the memory alloy wire 4 is heated by the resistance wire, austenite phase transformation occurs to restore the shape before loading, pull the crank 7 to rotate, and then pull the valve body through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com