Energy absorption structure optimization method taking expected force response process as target

An energy-absorbing structure and optimization method technology, applied in the field of traffic safety, can solve problems such as unreasonableness, uncertainty of optimization results, influence of optimization results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

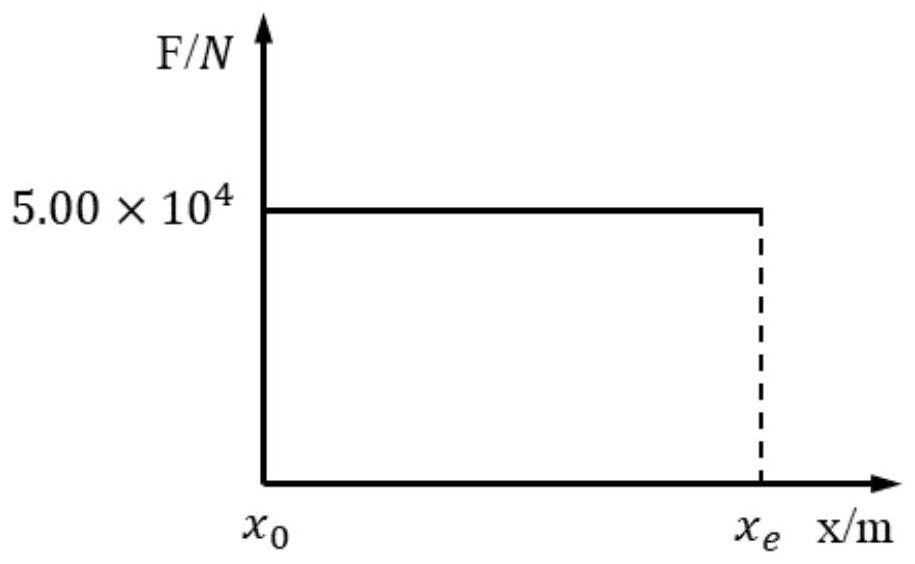

[0085]This embodiment is a method of optimizing the ability to measure the desired force response process, and the specific process is:

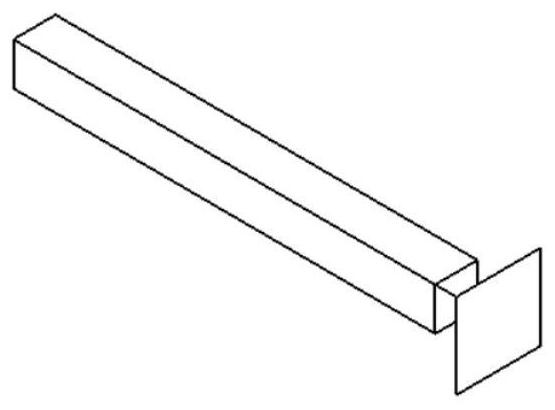

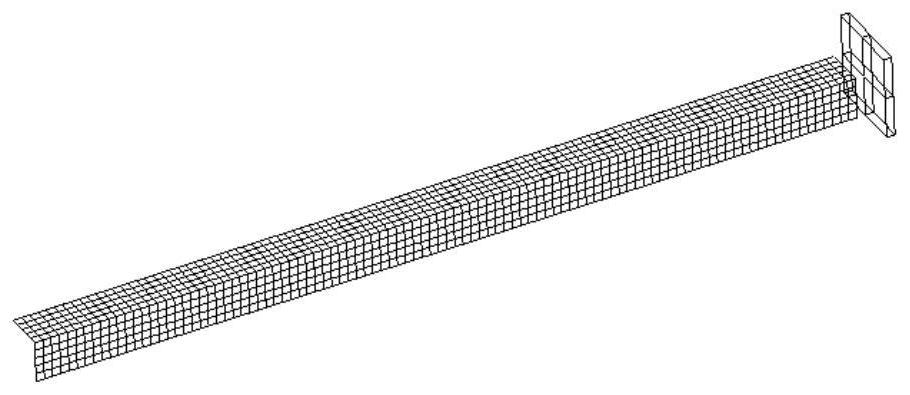

[0086]Step 1, establish the original finite element model of the impact of thin-walled tube:

[0087]The original finite element model of the impact is established based on the structural characteristics of the impact thin-walled tube and the rigid impact plate. Such asfigure 1 As shown, the structural feature of the impact thin-walled tube and the rigid impact plate is divided into two parts, and a portion is a thin-walled tube having a square cross section, the thin wall tube is 100 mm, and the length is 1000 mm, the wall thickness is 3.0. mm; another part is a square rigid impact board with a side length of 200 mm. The rigid impact plate is located at one end of the thin wall tube and causes the center line of the thin-walled tube to coincide with the geometric center of the rigid impingement plate; the end surface of the thin wall tube and the surfa...

Embodiment 2

[0139]This embodiment is a method of optimizing the ability to measure the desired force response process, and the specific process is:

[0140]Step 1, establish the original finite element model of the impact of thin-walled tube:

[0141]The original finite element model of the impact is established based on the structural characteristics of the impact thin-walled tube and the rigid impact plate. Such asFigure 8 withFigure 9 As shown, the structural feature of the impact thin-walled tube and the rigid impact plate is divided into two parts, and a portion is a thin-walled tube having a square cross section, the thin wall tube is 100 mm, and the length is 1000 mm, the wall thickness is 3.0. MM; another part is a rectangular rigid impact plate at one end of the thin wall tube, which is 880 mm long and 400 mm wide.

[0142]The thin-walled tube is located at one end of the rigid impingement plate and intersects the geometric center line of the thin-walled cross section to the center line in the ...

Embodiment 3

[0190]This embodiment is a method of optimizing the ability to measure the desired force response process, and the specific process is:

[0191]Step 1, establish the original finite element model of the impact of thin-walled tube:

[0192]The original finite element model of the impact is established based on the structural characteristics of the impact thin-walled tube and the rigid impact plate. Such asFigure 8 withFigure 9 As shown, the structural feature of the impact thin-walled tube and the rigid impact plate is divided into two parts, and a portion is a thin-walled tube having a square cross section, the thin wall tube is 100 mm, and the length is 1000 mm, the wall thickness is 3.0. MM; another part is a rectangular rigid impact plate at one end of the thin wall tube, which is 880 mm long and 400 mm wide.

[0193]The thin-walled tube is located at one end of the rigid impingement plate and intersects the geometric center line of the thin-walled cross section to the center line in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com