Energy absorption structure optimization method taking expected force response process as target

An energy-absorbing structure and optimization method technology, applied in the field of traffic safety, can solve problems such as reducing the amount of calculation, affecting the optimization results, and poor accuracy of the dynamic analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

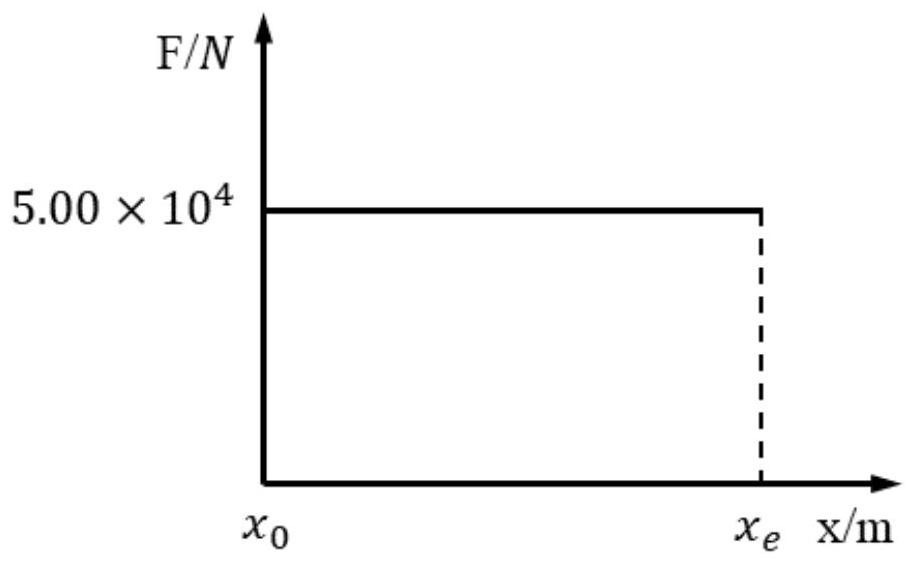

[0085] This embodiment is an energy-absorbing structure optimization method targeting the expected force response history, and the specific process is:

[0086] Step 1, establish the original finite element model of the thin-walled pipe under impact:

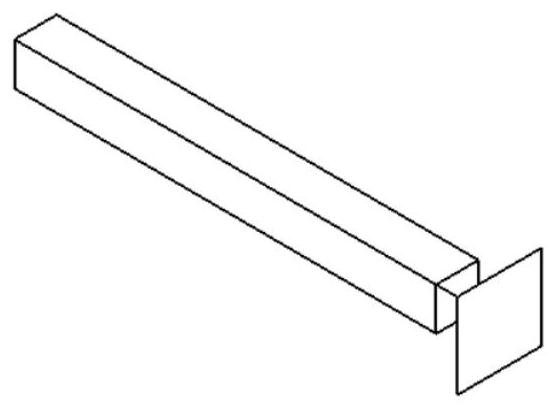

[0087] According to the structural characteristics of the impacted thin-walled tube and the rigid impact plate, the original finite element model of the thin-walled tube under impact is established. Such as figure 1 As shown, the structural characteristics of the impacted thin-walled tube and the rigid impact plate are divided into two parts, one part is a thin-walled tube with a square cross section, the side length of the thin-walled tube is 100 mm, the length is 1000 mm, and the wall thickness is 3.0 mm; the other part is a square rigid impact plate with a side length of 200mm. The rigid impingement plate is located at one end face of the thin-walled tube, and the center line in the length direction of the thin-walled tube ...

Embodiment 2

[0139] This embodiment is an energy-absorbing structure optimization method targeting the expected force response history, and the specific process is:

[0140] Step 1, establish the original finite element model of the thin-walled pipe under impact:

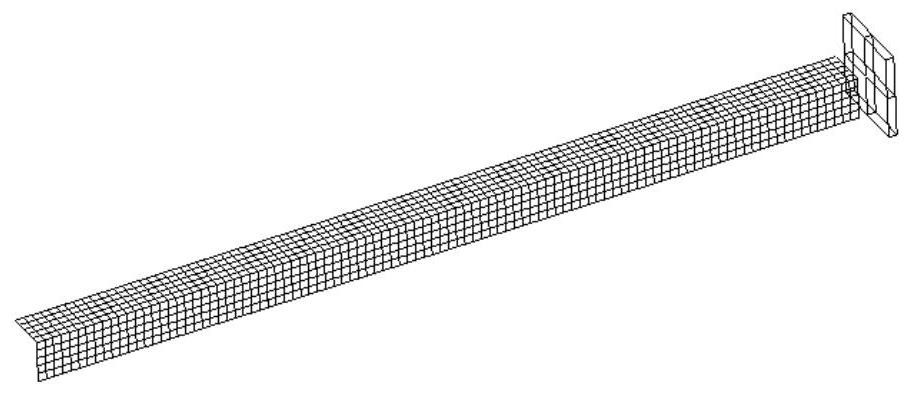

[0141] According to the structural characteristics of the impacted thin-walled tube and the rigid impact plate, the original finite element model of the thin-walled tube under impact is established. Such as Figure 8 and Figure 9 As shown, the structural characteristics of the impacted thin-walled tube and the rigid impact plate are divided into two parts, one part is a thin-walled tube with a square cross section, the side length of the thin-walled tube is 100 mm, the length is 1000 mm, and the wall thickness is 3.0 mm; the other part is a rectangular rigid impact plate located at one end of the thin-walled tube, the impact plate is 880mm long and 400mm wide.

[0142] The thin-walled tube is located at one end of the rigid ...

Embodiment 3

[0190] This embodiment is an energy-absorbing structure optimization method targeting the expected force response history, and the specific process is:

[0191] Step 1, establish the original finite element model of the thin-walled pipe under impact:

[0192] According to the structural characteristics of the impacted thin-walled tube and the rigid impact plate, the original finite element model of the thin-walled tube under impact is established. like Figure 8 and Figure 9 As shown, the structural characteristics of the impacted thin-walled tube and the rigid impact plate are divided into two parts, one part is a thin-walled tube with a square cross section, the side length of the thin-walled tube is 100 mm, the length is 1000 mm, and the wall thickness is 3.0 mm; the other part is a rectangular rigid impact plate located at one end of the thin-walled tube, the impact plate is 880mm long and 400mm wide.

[0193] The thin-walled tube is located at one end of the rigid imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com