Variant gradient lattice structure based on additive manufacturing

A lattice structure and additive manufacturing technology, applied in the field of lattice structures, can solve the problems affecting the bearing characteristics of the overall structure, prominent stress concentration effect of nodes, large size differences, etc., and achieve excellent mechanical properties, strong achievability, The effect of excellent energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment discloses a unidirectional variant gradient lattice structure, which, on the basis of the traditional uniform lattice structure, extends the size of the unit cells to form a series of new unit cells with different topologies and relative densities, and then They are periodically arranged to form different layers, and finally combined to form a gradient structure with density gradient characteristics. Since this kind of gradient structure only changes the size of the unit cell, the rod diameter does not change, which makes the connection between different layers of the structure more stable, solves the problem of weakening of the connection of the traditional gradient structure, and improves the bearing capacity of the structure. The unique high energy absorption capacity of the gradient structure provides a reference for the design of protective devices with excellent impact resistance characteristics.

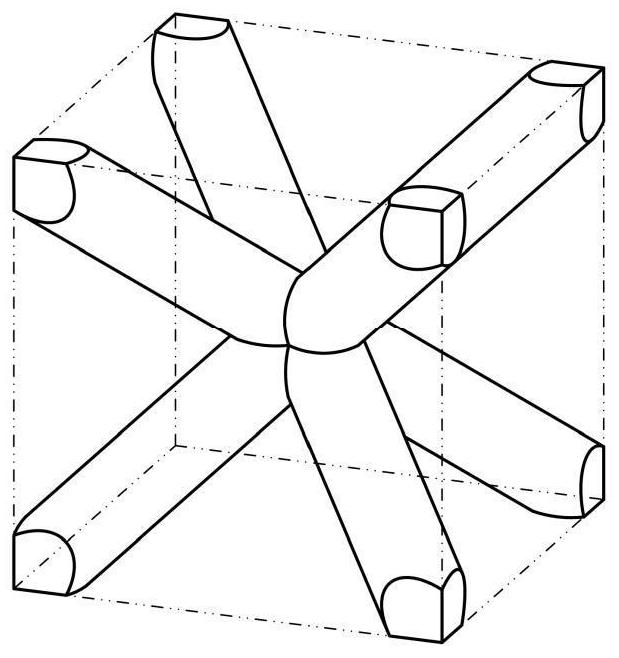

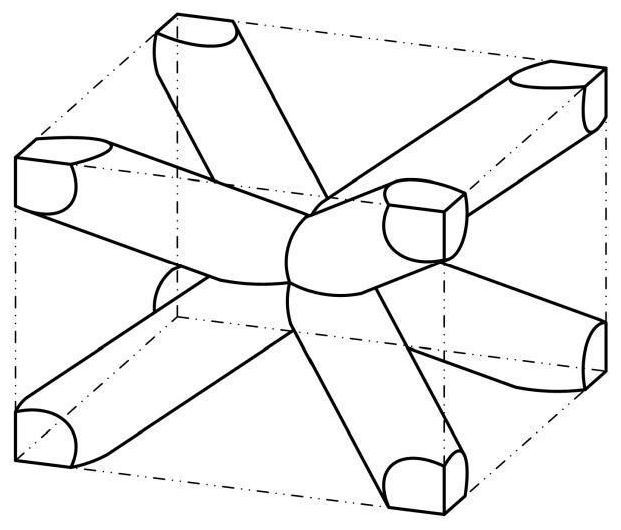

[0027] like figure 1 , the common BCC structure i...

Embodiment 2

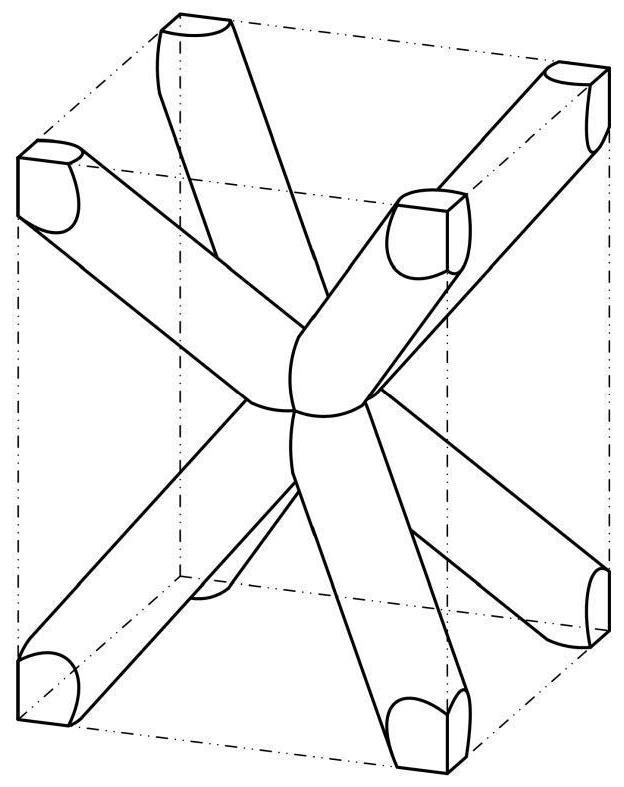

[0032] Further, through the multi-directional variant design of the structure, more and more complex gradient structures can be designed, and the node connection is stable and reliable, and the node connection problem of different layers of the existing gradient structure is solved. In addition, using the high degree of freedom design advantage of additive manufacturing technology, the structure is designed with multi-directional variants, and the obtained multi-directional variant radially gradient structure provides a new reference for the biomimetic design of bone implants. like Figure 7 ,8,9, the variant gradient lattice structure includes four variant gradient lattice layers that are repeatedly stacked and interconnected; each variant gradient lattice layer includes twenty-four variants that are repeatedly arranged and interconnected Gradient unit cell column; each variant gradient unit cell column includes four lattice cells that are repeatedly arranged and interconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com