Flexible supporting structure and method for rock burst roadway

A technology for impact ground pressure and support structure, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of slow support construction, frequent occurrences, and high costs, reducing roadway damage, ensuring safety, and improving The effect of gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

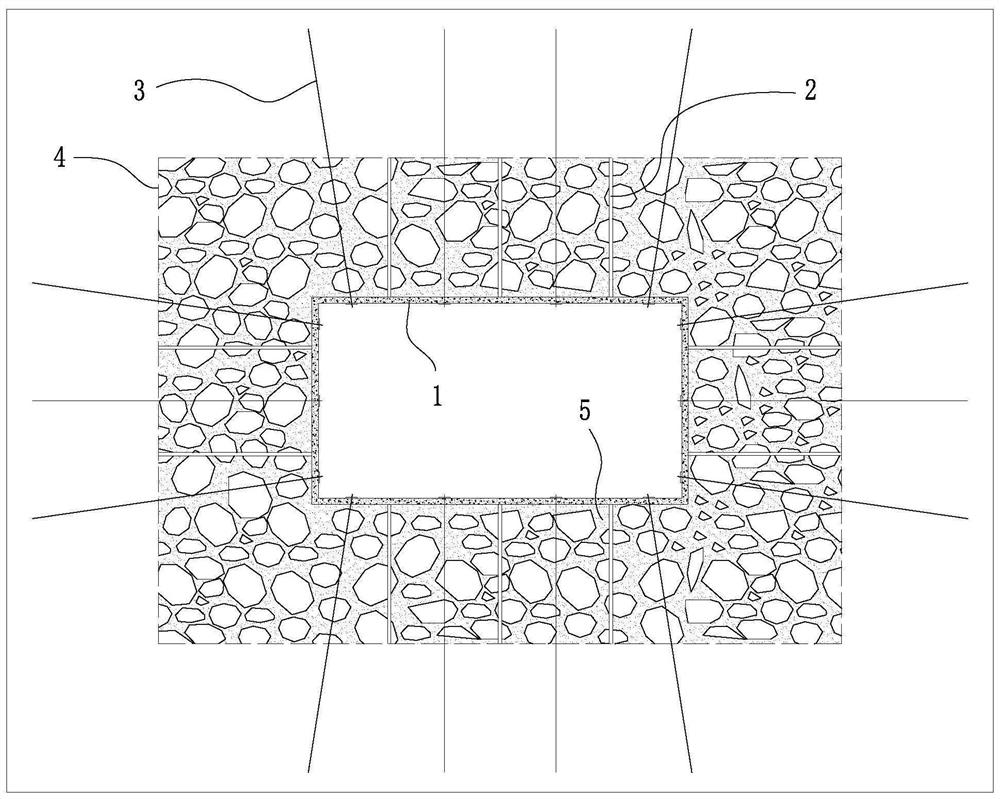

[0022] Such as figure 1 As shown, a flexible support structure for rock burst roadway, including thin sprayed lining 1, roadway surrounding rock grouting hole 2 and anchor cable 3; said thin sprayed lining 1 is arranged on the surface of roadway surrounding rock, thin sprayed The lining layer 1 is made of reactive resin thin sprayed layer material; the number of grouting holes 2 in the surrounding rock of the roadway is several, and a number of grouting holes 2 in the surrounding rock of the roadway are set Inject epoxy resin grouting material; the number of anchor cables 3 is several, and several anchor cables 3 are arranged on the surrounding rock around the roadway; The combination of grouting materials and anchor cables laid on the surrounding rocks of the roadway forms a large space for "reactive resin thin spray layer support o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com