Patents

Literature

48results about How to "Increase specific energy absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

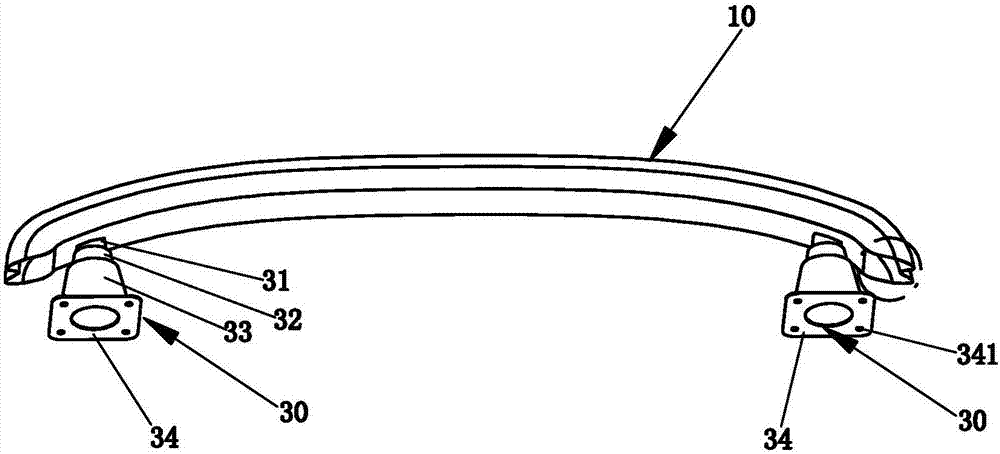

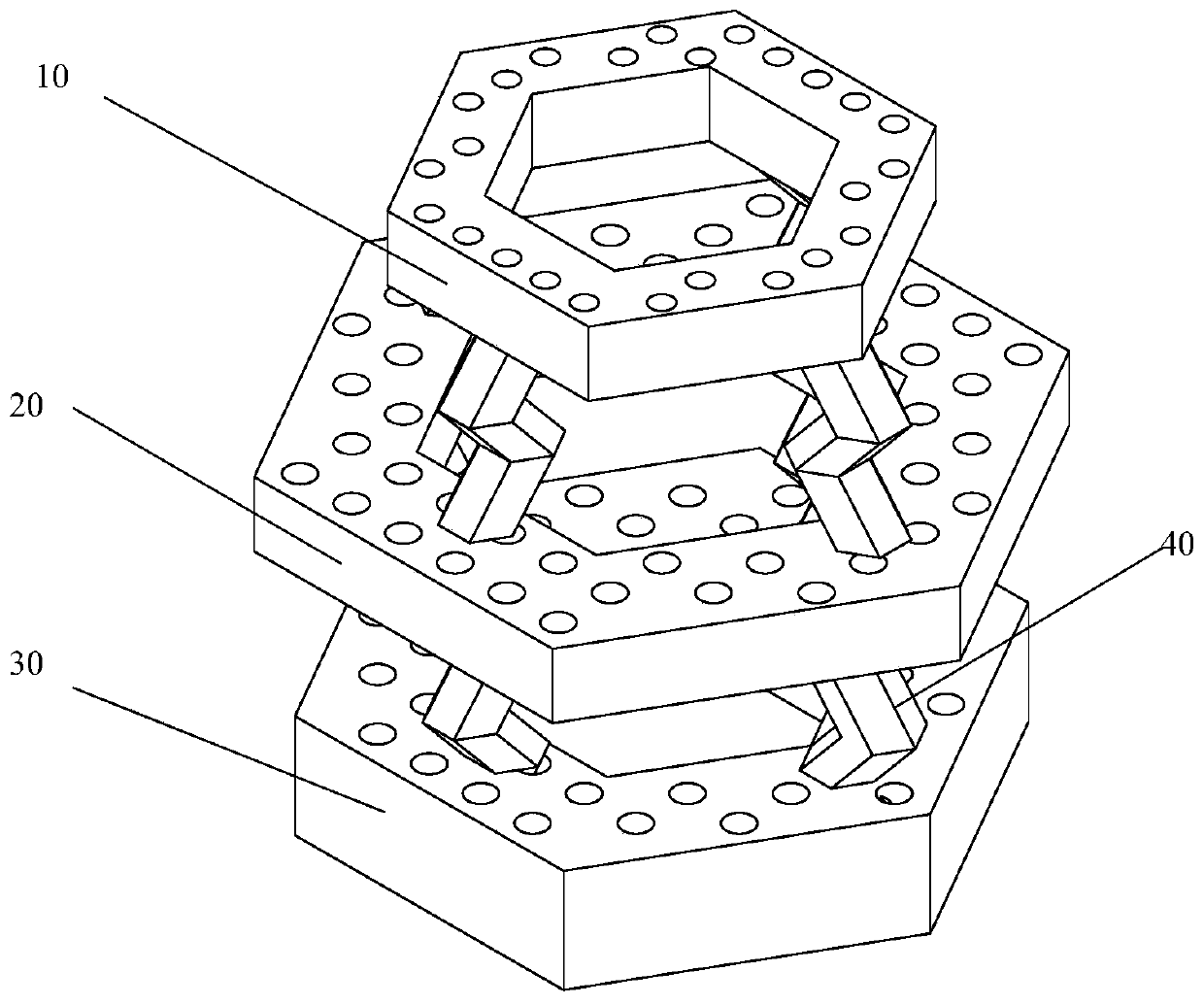

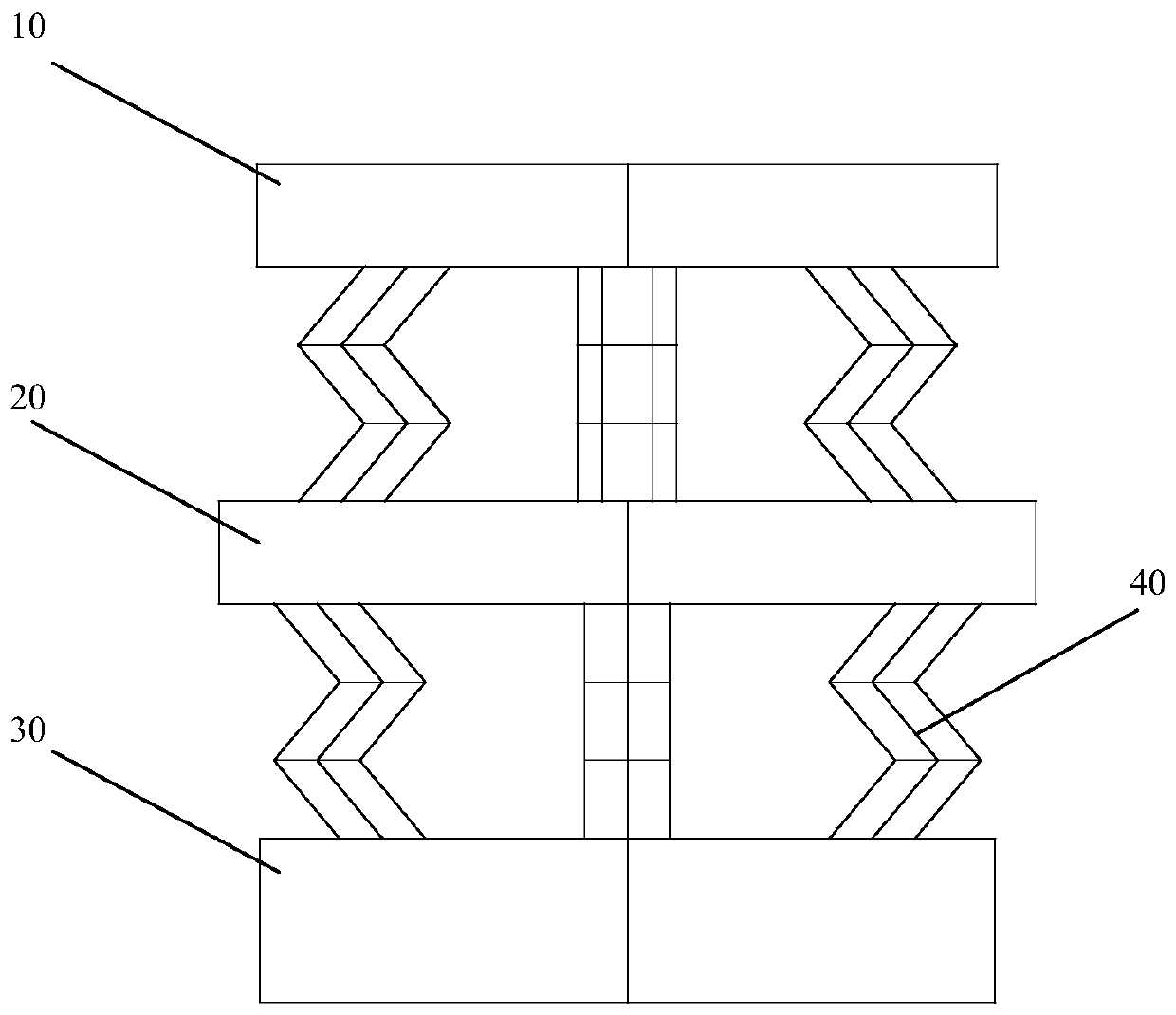

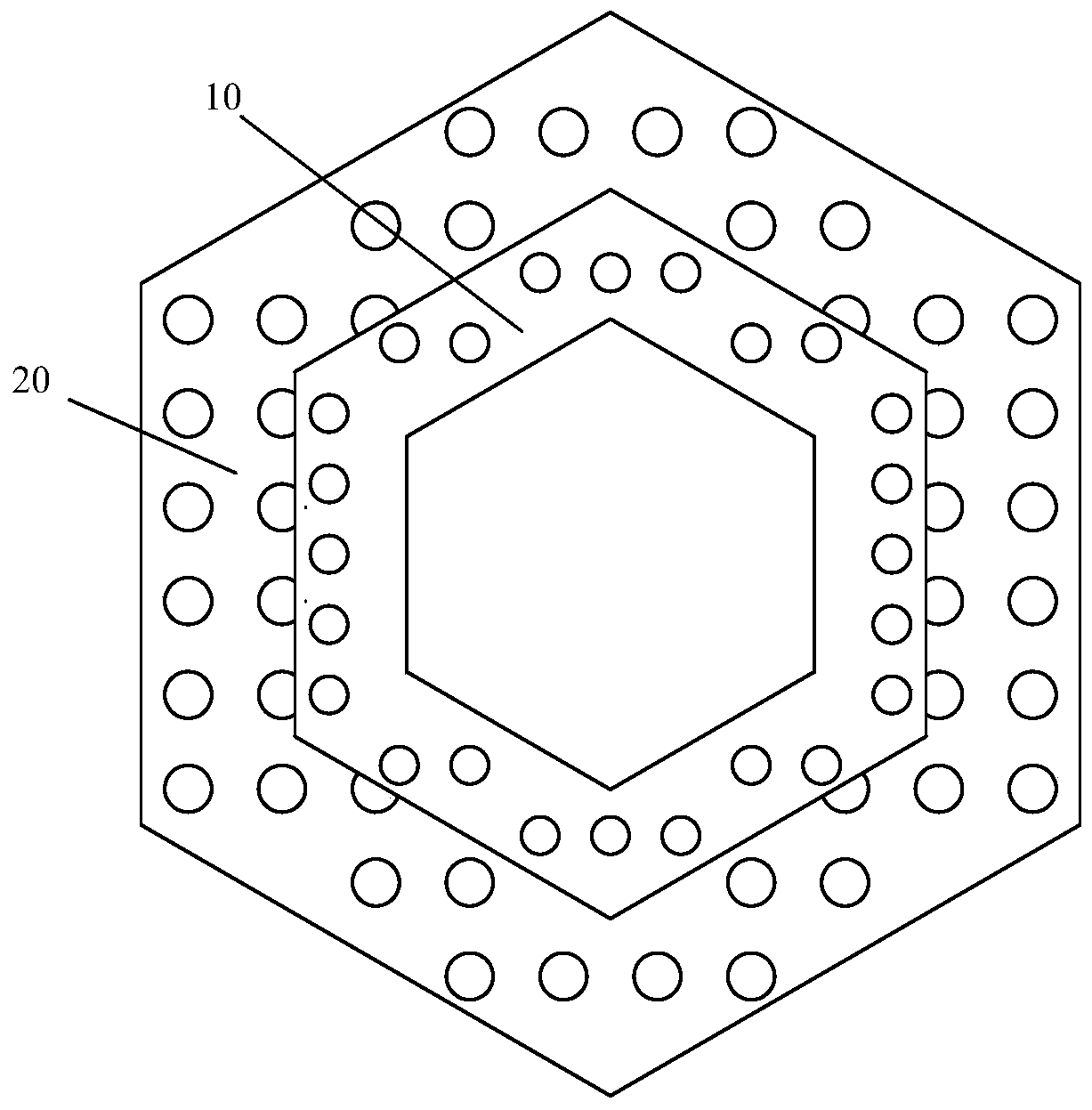

Automobile front anti-collision beam structure and application thereof to automobiles

ActiveCN107985237AObvious graded featuresImprove buffering effectInternal combustion piston enginesBumpersSingle stageThree stage

Disclosed are an automobile front anti-collision beam structure and application thereof to automobiles. The automobile front anti-collision beam structure is composed of a main beam, an inner plate and an energy absorbing device, wherein the inner plate is fixedly connected to the main beam; the energy absorbing device is fixedly connected to the inner plate and at least composed of a bottom plate, a first conical tube, a second conical tube and a third conical tube; the bottom ends of the first conical tube, the second conical tube and the third conical tube are fixedly mounted onto the bottom plate, and the first conical tube, the second conical tube and the third conical tube are gradually nested from inside to outside; the heights of the three conical tubes are gradually reduced from inside to outside, the diameters of the bottom ends of the three conical tubes are gradually increased from inside to outside, the thicknesses of the three conical tubes are gradually increased from inside to outside, and the tapers of the three conical tubes are gradually increased from inside to outside. According to the automobile front anti-collision beam, when collision deformation occurs, crumple of a single stage gradually develops into simultaneous crumple of two stages and then into simultaneous crumple of three stages, plastic deformation can be gradually increased, a regular and stable deformation mode and significant buffer effects can be achieved, and energy absorption can be gradually increased. Therefore, the automobile front anti-collision beam can enhance structural stability and crashworthiness and meanwhile improve the collision angle adaptability.

Owner:HUAQIAO UNIVERSITY

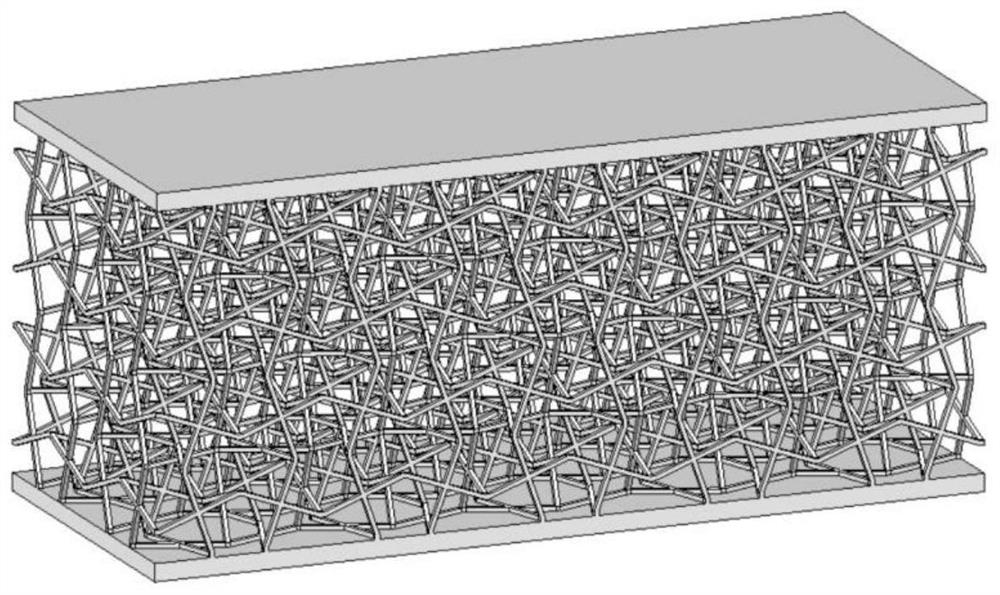

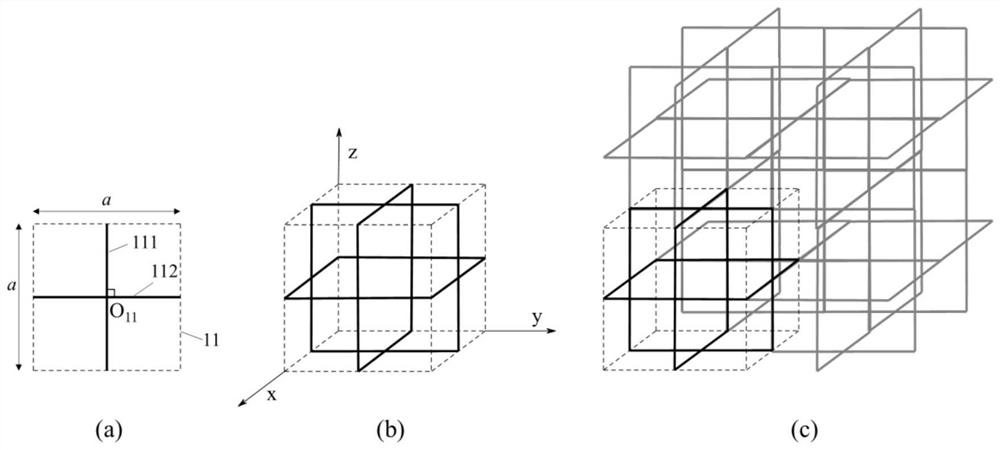

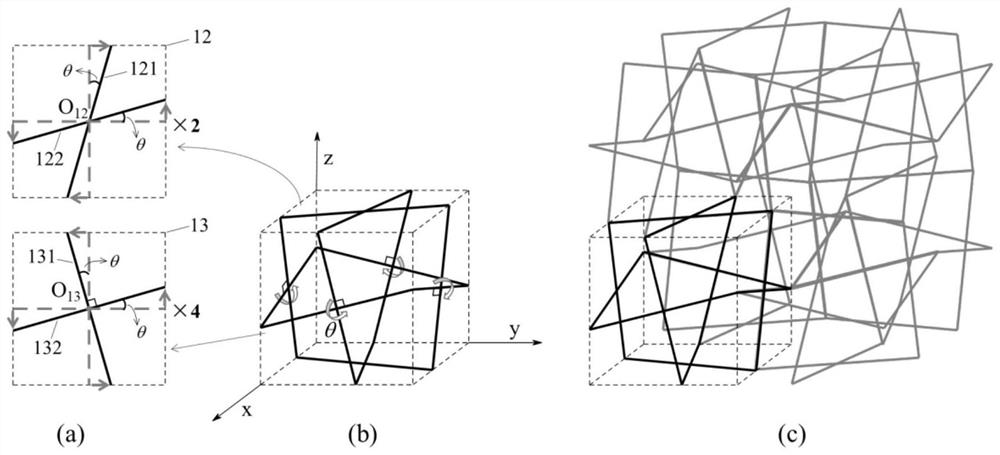

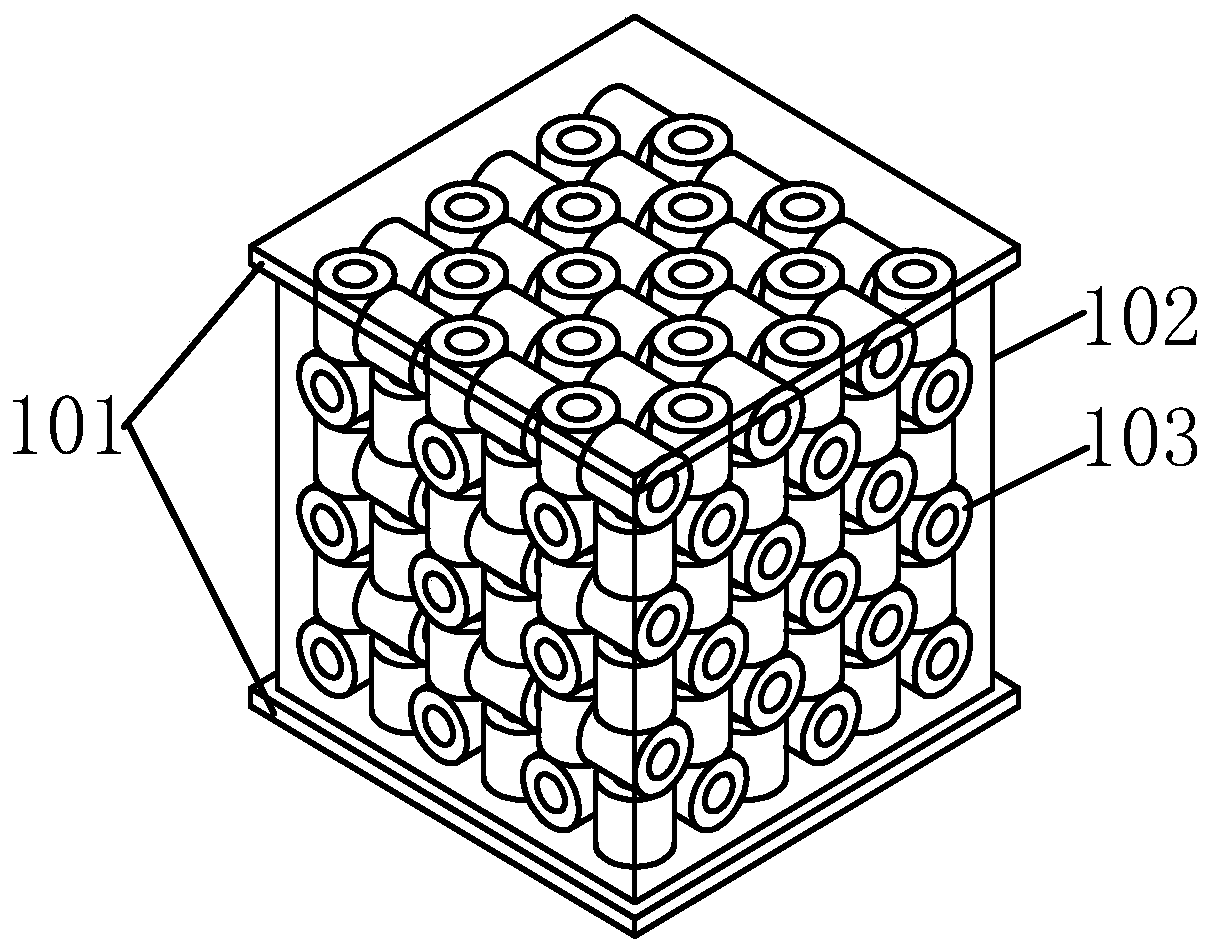

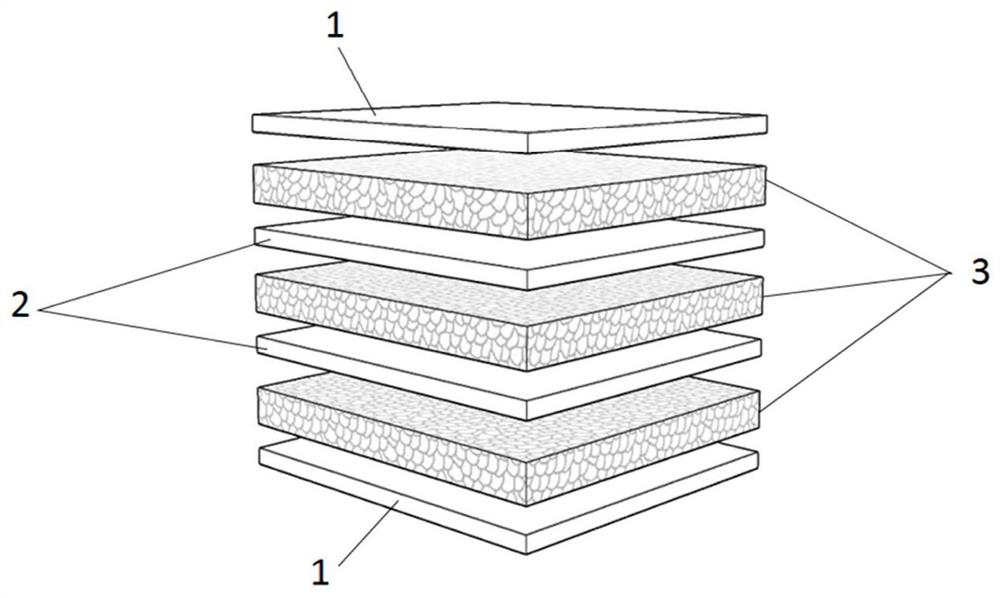

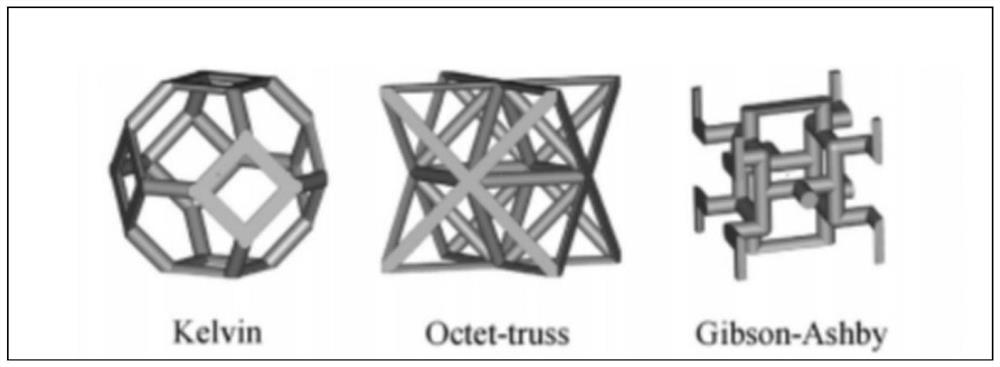

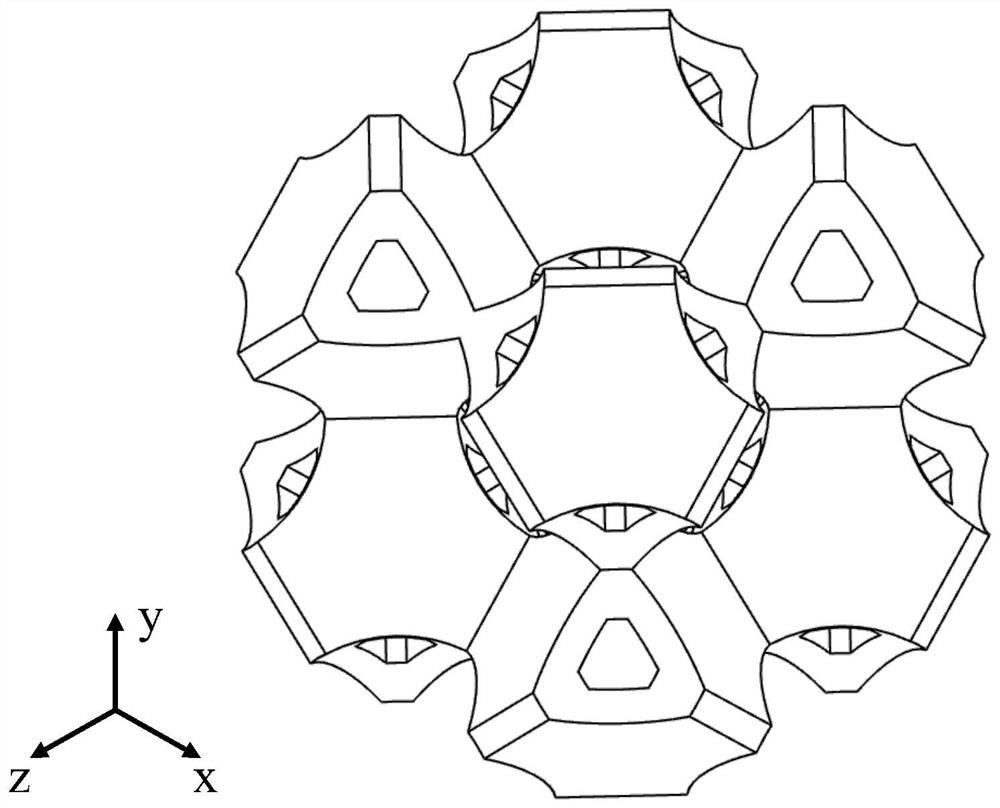

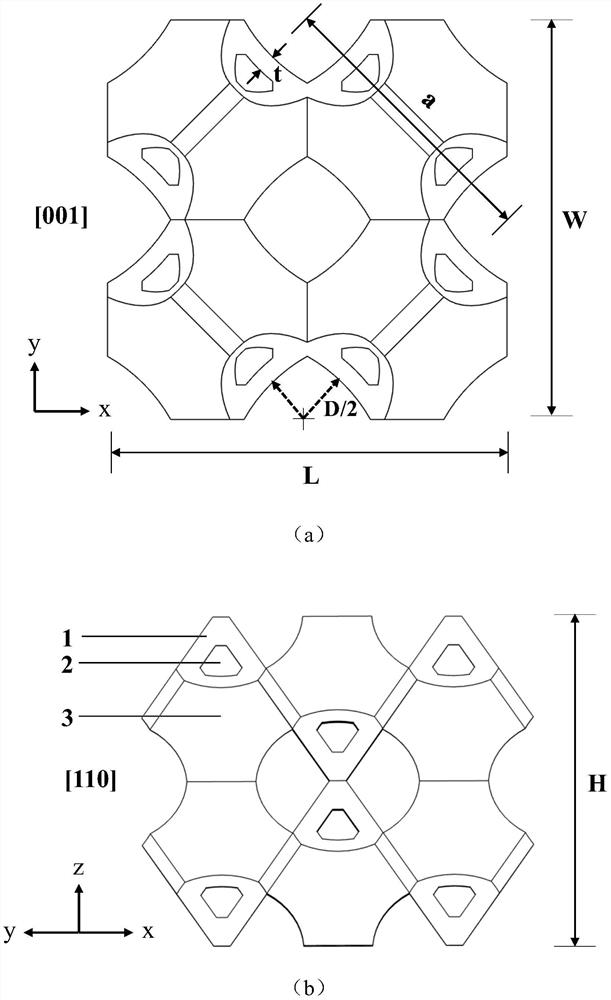

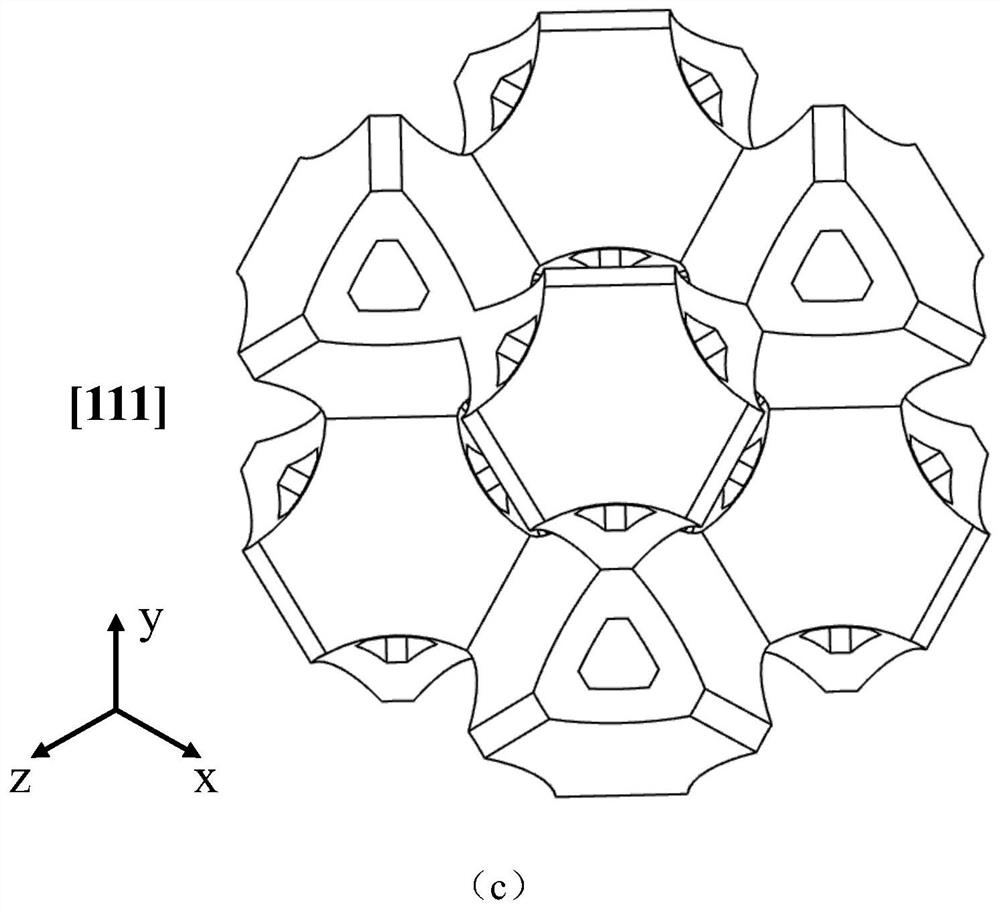

Impact-resistant and high-energy-absorption lattice sandwich structure with negative poisson ratio characteristic

PendingCN112140647AResistance to compressive loadsLight structureLayered productsHigh energySpecific modulus

The invention discloses an impact-resistant and high-energy-absorption lattice sandwich structure with a negative poisson ratio characteristic. The lattice sandwich structure is formed on the basis ofa high-performance negative poisson ratio lattice core material. The negative poisson ratio lattice core material is obtained by changing an included angle between a supporting column and a coordinate axis through a three-dimensional cubic structure. When the included angle between the supporting column and the coordinate axis is not equal to zero, the negative poisson ratio lattice core materialis obtained. The negative poisson ratio lattice material and two thin plates form a novel negative poisson ratio lattice sandwich structure, and the structure has the characteristics of a traditionalauxetic lattice structure and a traditional lattice sandwich structure at the same time, that is, the structure has the characteristics of the negative poisson ratio and the same-direction curvature;meanwhile, has excellent mechanical properties such as ultra-light weight, high specific modulus, high specific strength, impact resistance and high energy absorption. In addition, the sandwich structure has high adjustability, and the mechanical property of the lattice sandwich structure can be adjusted and controlled within a large range by adjusting the deflection angle of the supporting column and the relative density of the lattice material. The lattice sandwich structure has a great application prospect in the field of aerospace.

Owner:BEIHANG UNIV

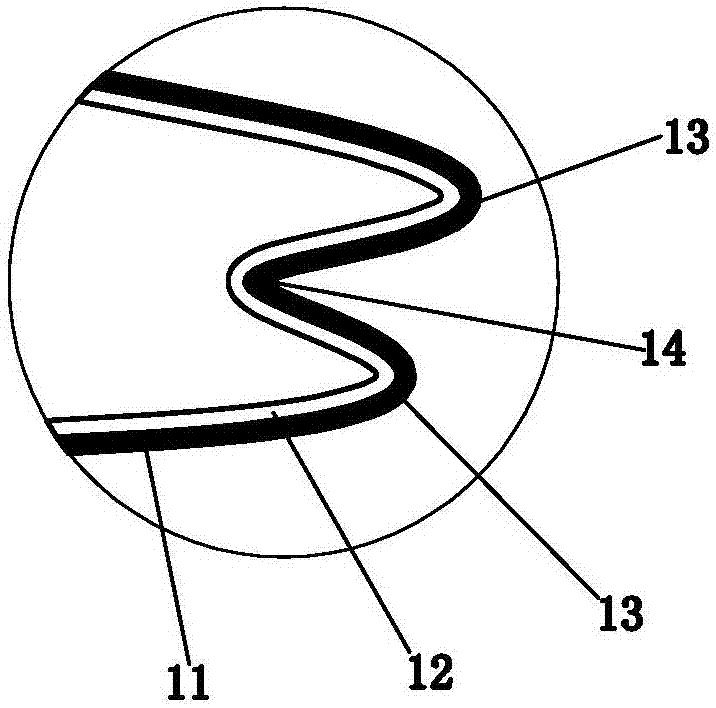

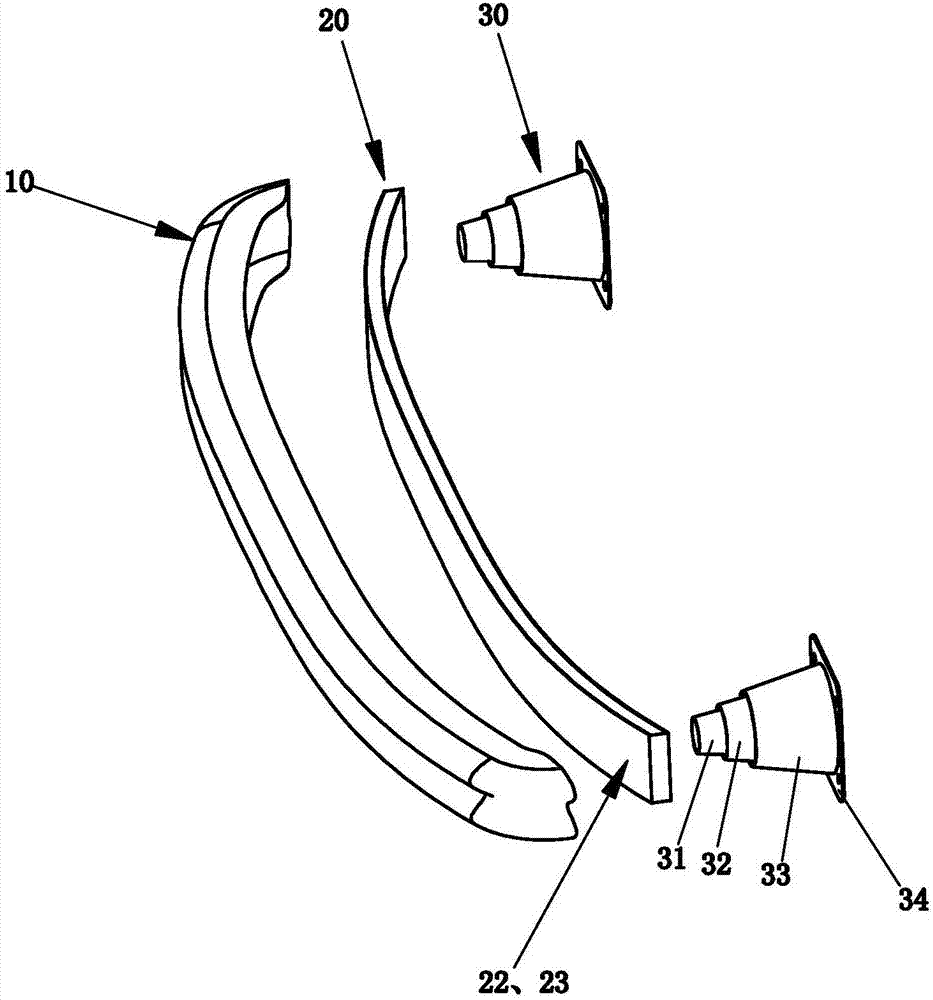

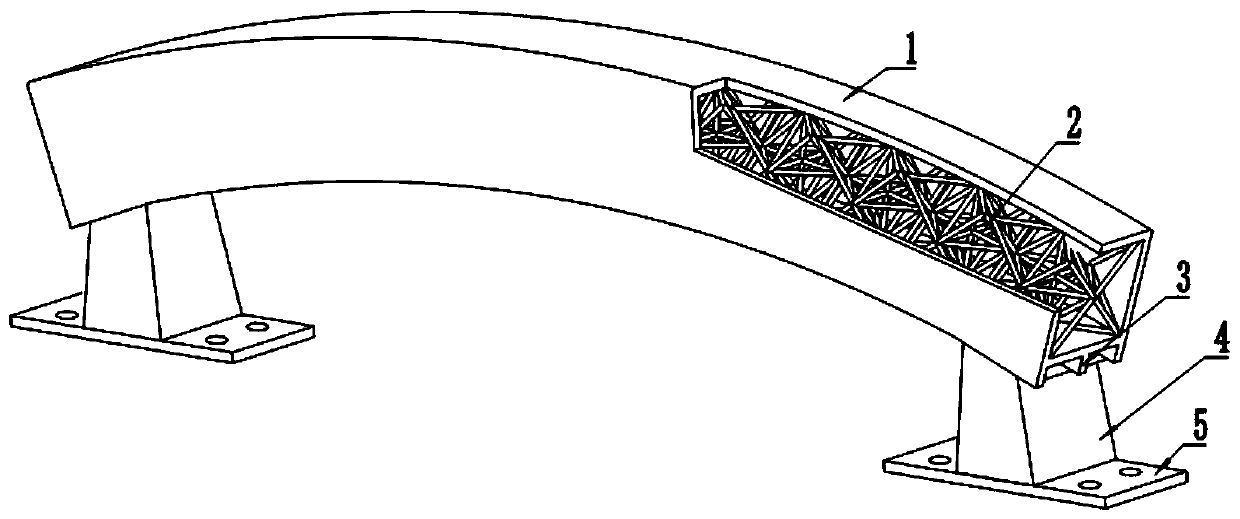

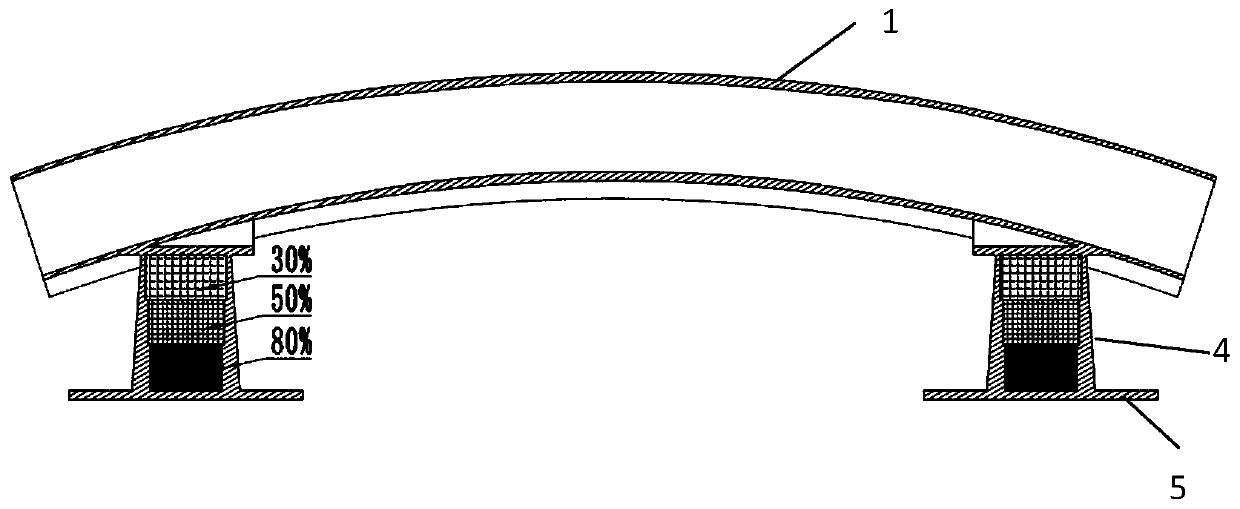

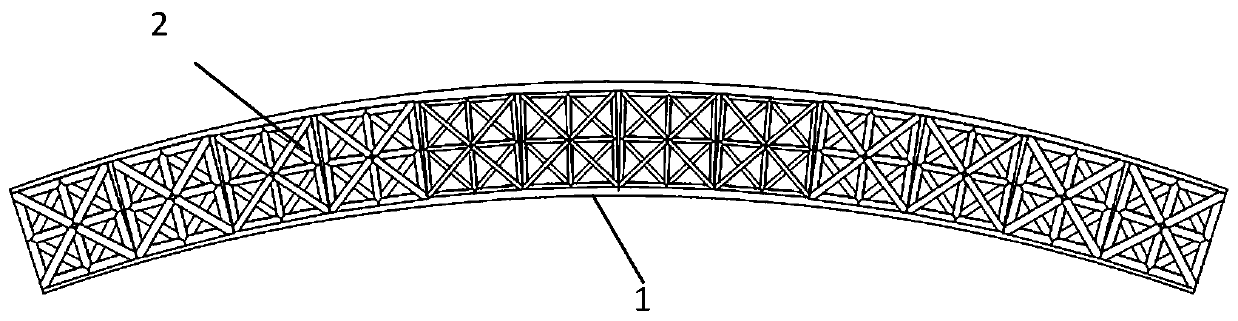

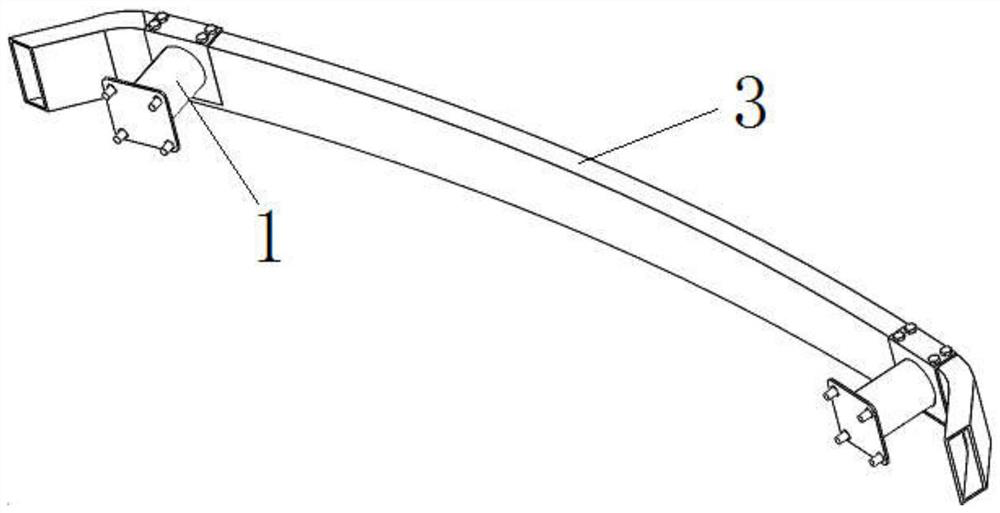

Passenger car anti-collision beam assembly

PendingCN110949295AEffective cushioning against impactLight in massBumpersEnergy absorptionCar passenger

The invention discloses a passenger car anti-collision beam assembly which comprises an anti-collision beam outer shell, the anti-collision beam outer shell comprises an arc-shaped shell body formed by continuously extending a rectangular frame along an arc line path, the continuous wall thickness of the arc-shaped shell body is in gradient change from the middle to the two sides of the arc line path, and the anti-collision beam outer shell is filled with a truss structure. Energy absorption boxes are fixedly arranged at the two ends of the side, facing the circle center of the arc line, of the anti-collision beam shell correspondingly, and the energy absorption boxes are filled with foamed aluminum materials. The passenger car anti-collision beam assembly has the advantages of being lightin weight, strong in energy absorption, high in specific energy absorption, large in bending strength, good in buffering performance, capable of effectively buffering forward and inclined impacts borne by a passenger car, capable of reducing maximum impacts borne by passengers to the maximum extent and capable of playing a good role in protecting cars and passengers.

Owner:HUAQIAO UNIVERSITY

Hierarchical origami-shaped automobile collision energy-absorbing structure

PendingCN110641403AIncrease dynamicsImprove dynamic performanceBumpersMetal layered productsTitanium metalMetallic materials

The invention discloses a hierarchical origami-shaped automobile collision energy-absorbing structure. The hierarchical origami-shaped automobile collision energy-absorbing structure comprises a plurality of energy-absorbing layers and an origami-shaped induction tube, wherein the origami-shaped induction tube is a Z-shaped folded metal tube formed by folding a metal sheet through a Miura foldingmethod; adjacent energy-absorbing layers are connected with each other through the folded paper-shaped induction tubes; the plurality of energy-absorbing layers comprise a honeycomb energy-absorbing layer and a porous material energy-absorbing layer coaxially distributed from top to bottom; the honeycomb energy-absorbing layer comprises two first metal plates and a metal material with a special-shaped honeycomb structure filled between the two first metal plates; and the porous material energy-absorbing layer comprises two second metal plates and a porous metal material filled between the twosecond metal plates. The hierarchical origami-shaped automobile collision energy-absorbing structure has good dynamic performance and safety; and sufficient strength and energy-absorbing are ensured by using aluminum alloy, titanium metal and porous metal while having very light weight

Owner:HUAQIAO UNIVERSITY

Composite material negative Poisson's ratio structure energy absorption box and design method thereof

PendingCN113642211AIncrease total energy absorption and specific energy absorptionReduce peak impact forceDesign optimisation/simulationMulti-objective optimisationGenetics algorithmsElement analysis

The invention discloses a composite material negative Poisson's ratio structure energy absorption box and a design method thereof. The method includes compounding and filling a metal negative Poisson's ratio structure and a non-metal matrix material in an energy absorption box body; establishing a self-adaptive parameterized model of the composite material negative Poisson's ratio structure energy absorption box; changing the porosity of the matrix material and the thickness of the negative Poisson's ratio structure to carry out finite element analysis on the whole energy absorption box and the inner core thereof; carrying out design variable sampling by utilizing an optimal Latin hypercube sampling technology; establishing an approximate model between a design variable and an optimization target by using a double-response method; and performing multi-objective optimization design by applying a second-generation non-dominated genetic sorting genetic algorithm to obtain the high-robustness energy absorption box. The specific energy absorption of the energy absorption box is improved, the peak collision impact force of the energy absorption box is reduced, and the front collision passive safety performance of an automobile is greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

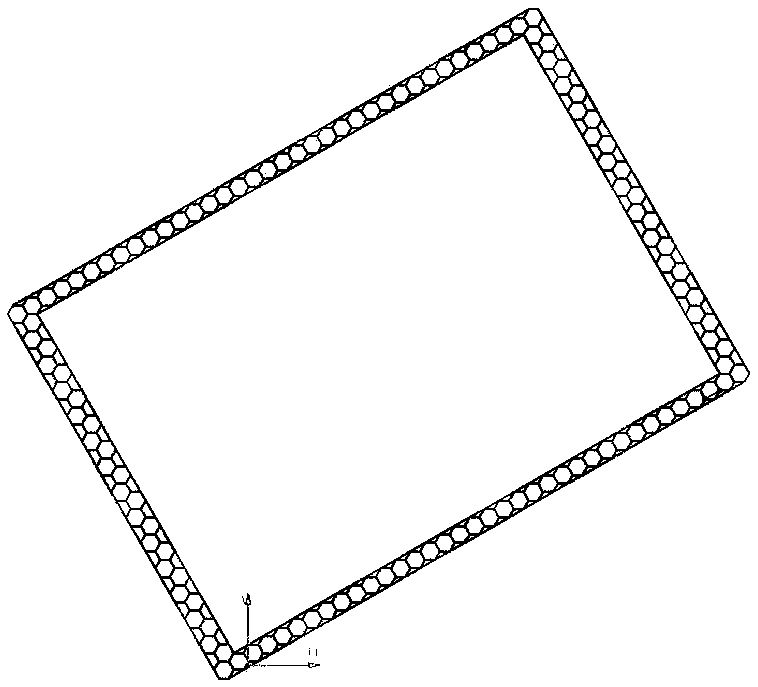

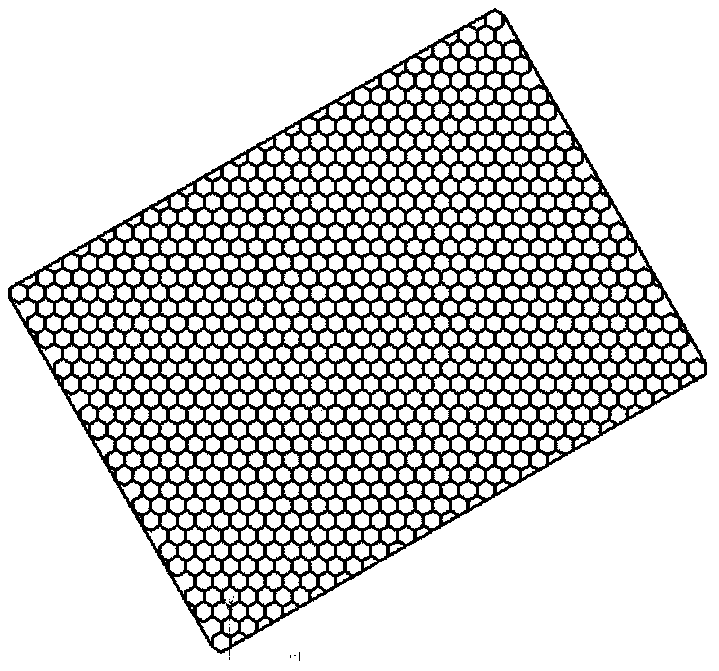

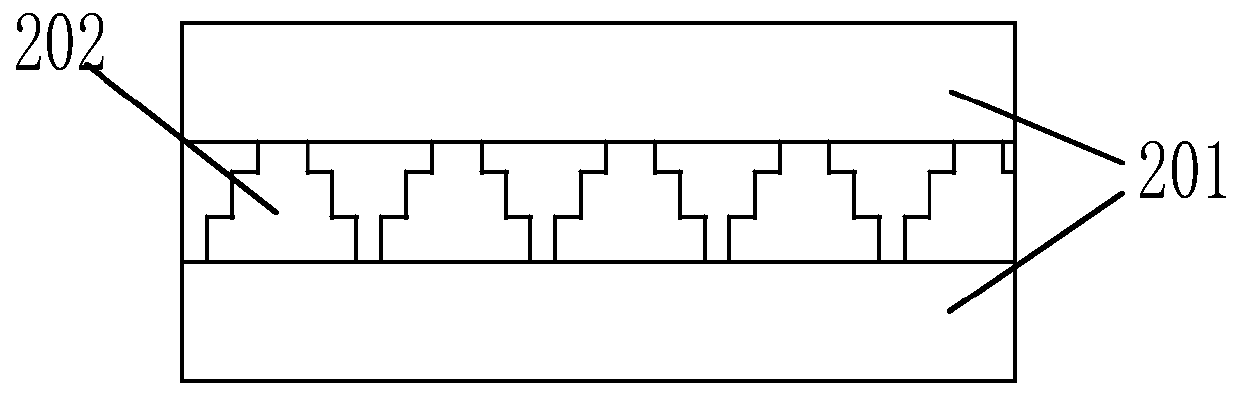

Variable-thickness honeycomb automobile battery pack shell structure

PendingCN108832054AHigh specific stiffnessIncrease the impact energy absorption characteristicsCell component detailsBatteriesThin walledHoneycomb

The invention discloses a variable-thickness honeycomb automobile battery pack shell structure. The battery pack shell structure is composed of a shell sidewall, a rear end cover and a front end cover. The sidewall and the rear end cover are honeycomb-filled sandwich structures, and the front end cover is a thin plate structure. The thickness of the honeycomb wall of the rear end cover increases from the back to the front (from the tail of a vehicle to the head end of the vehicle) in the axial direction of the honeycomb, and the thickness of the remaining thin-walled plates remains unchanged.By designing the sidewall and the rear end cover of the shell into the honeycomb-filled sandwich structure, collision energy is greatly absorbed when rear-end collision of electric buses occurs; by introducing the variable-thickness design of the honeycomb wall thickness, rear weakness and front strength of the rear end cover are achieved, structural deformation can proceed successively, energy absorption is stable, the collision peak acceleration is reduced, the damage to the battery pack is reduced, and the quality of the shell can be significantly reduced compared with the equal thickness design.

Owner:丹阳科美汽车部件有限公司

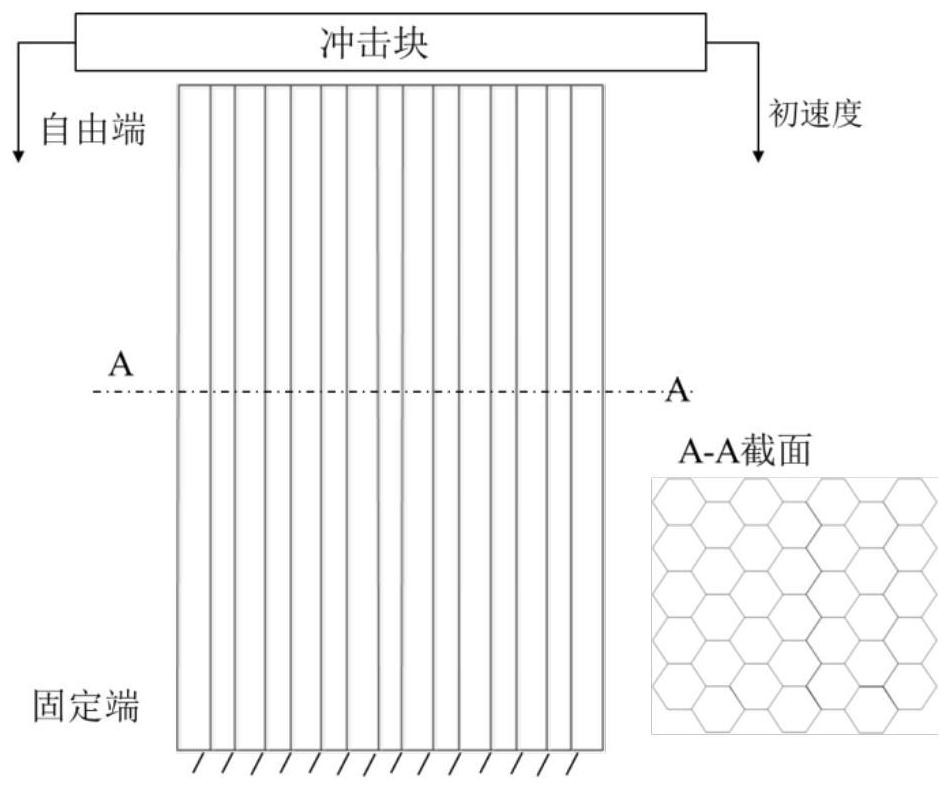

Carbon fiber honeycomb tube structure

InactiveCN108730390ALow densityHigh strengthSpringsSprings/dampers design characteristicsHigh stiffnessCarbon fibers

The invention discloses a carbon fiber honeycomb tube structure, and relates to the field of protective structures. A traditional protective structure is high in weight and simplex in material and structure form. A carbon fiber honeycomb tube is prepared from pultrusion tubes with orthogonal carbon fibers being laid, and the large tubes and the small tubes are connected into a whole through resin.The carbon fiber tube structure obtained through a pultrusion process has the advantages of large strength, high stiffness, fast forming and the like, and is lower in weight, larger in stiffness andhigher in specific energy absorption compared with the traditional protective structure; and the needed forms can be prepared according to the demands, and the application range is wide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

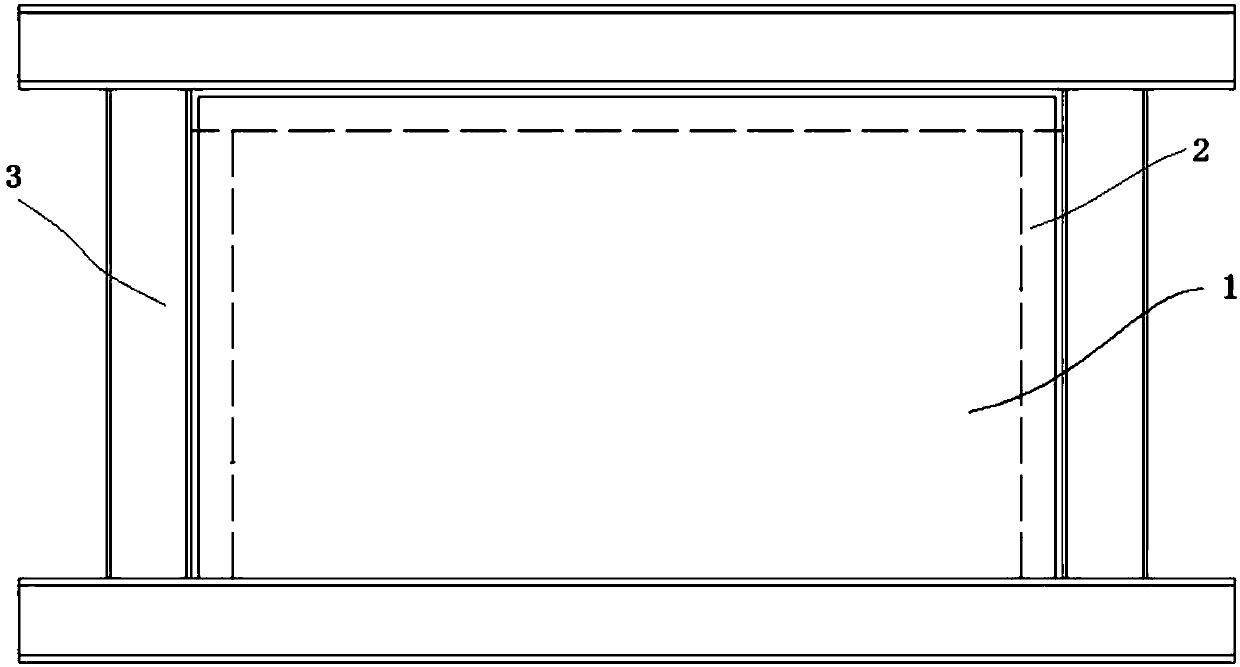

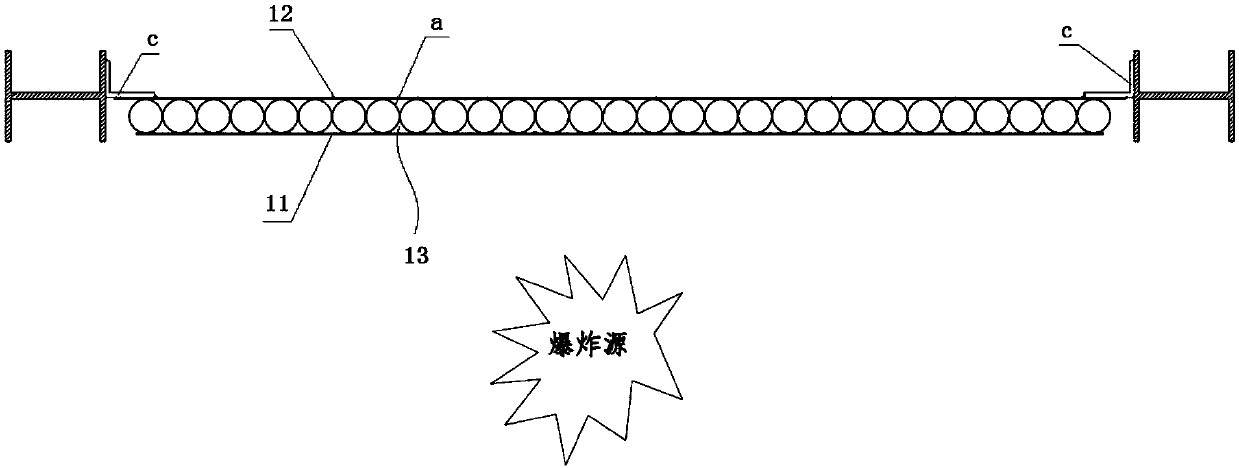

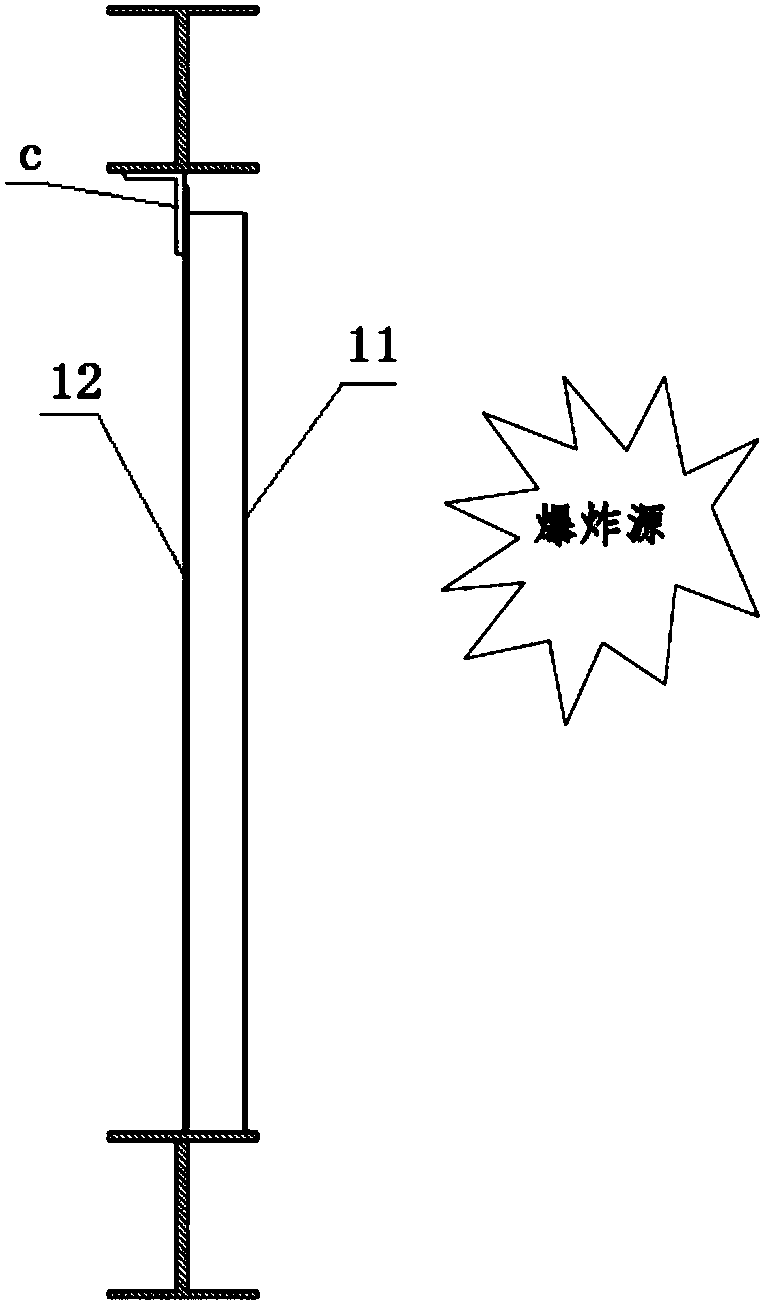

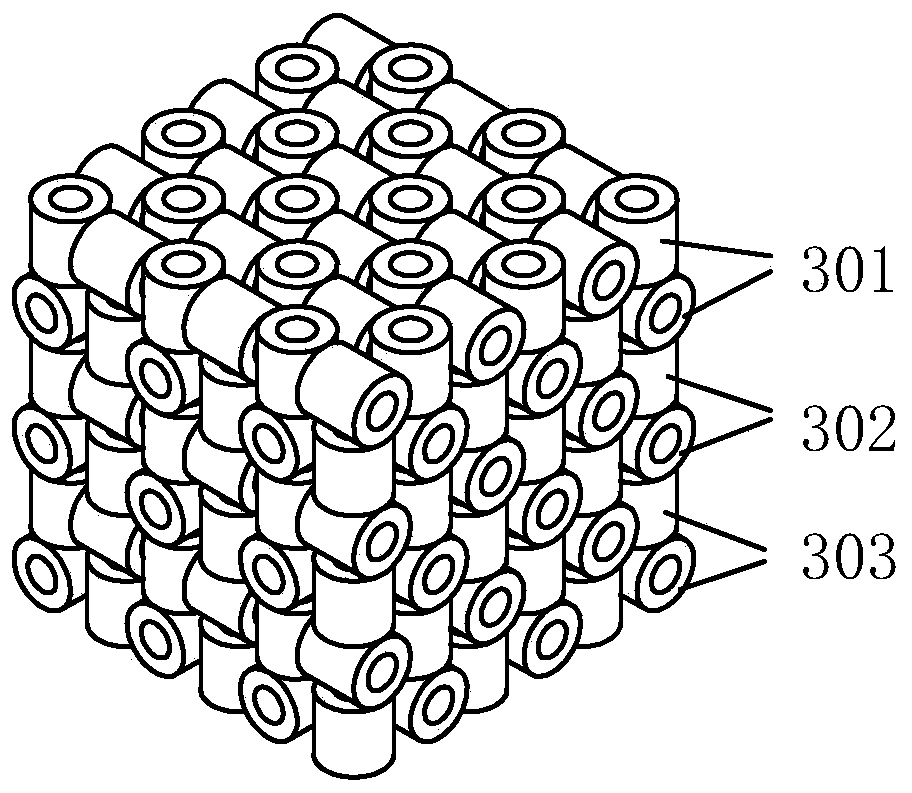

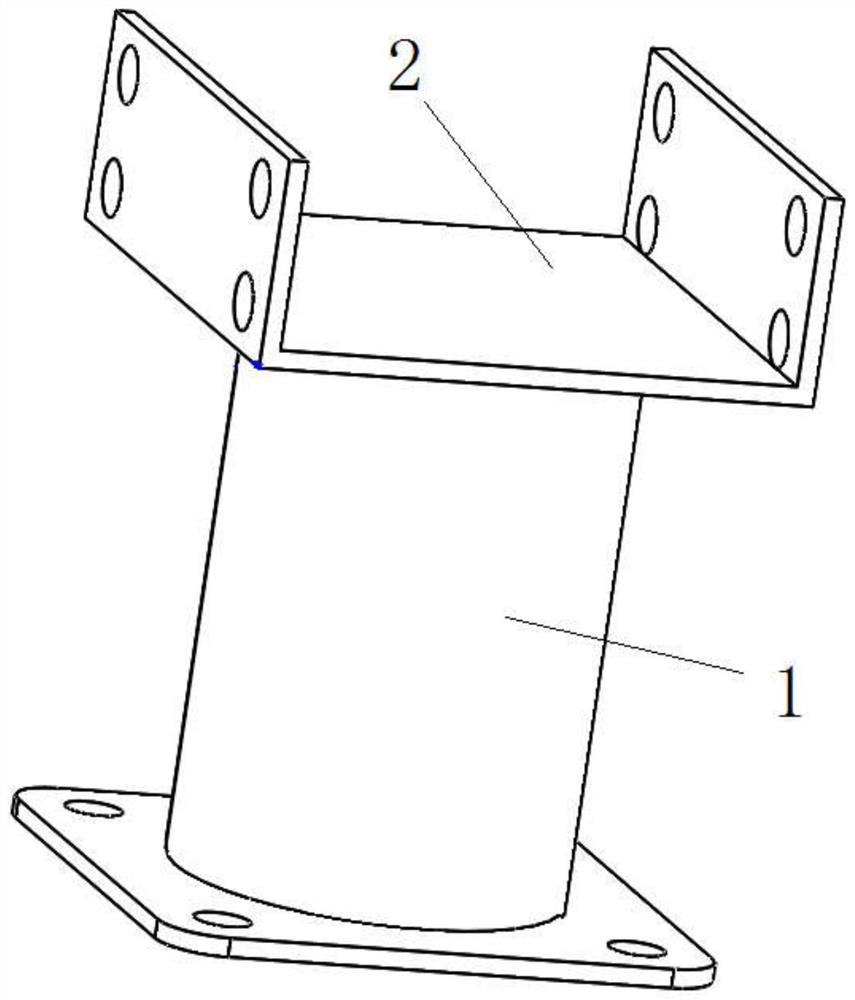

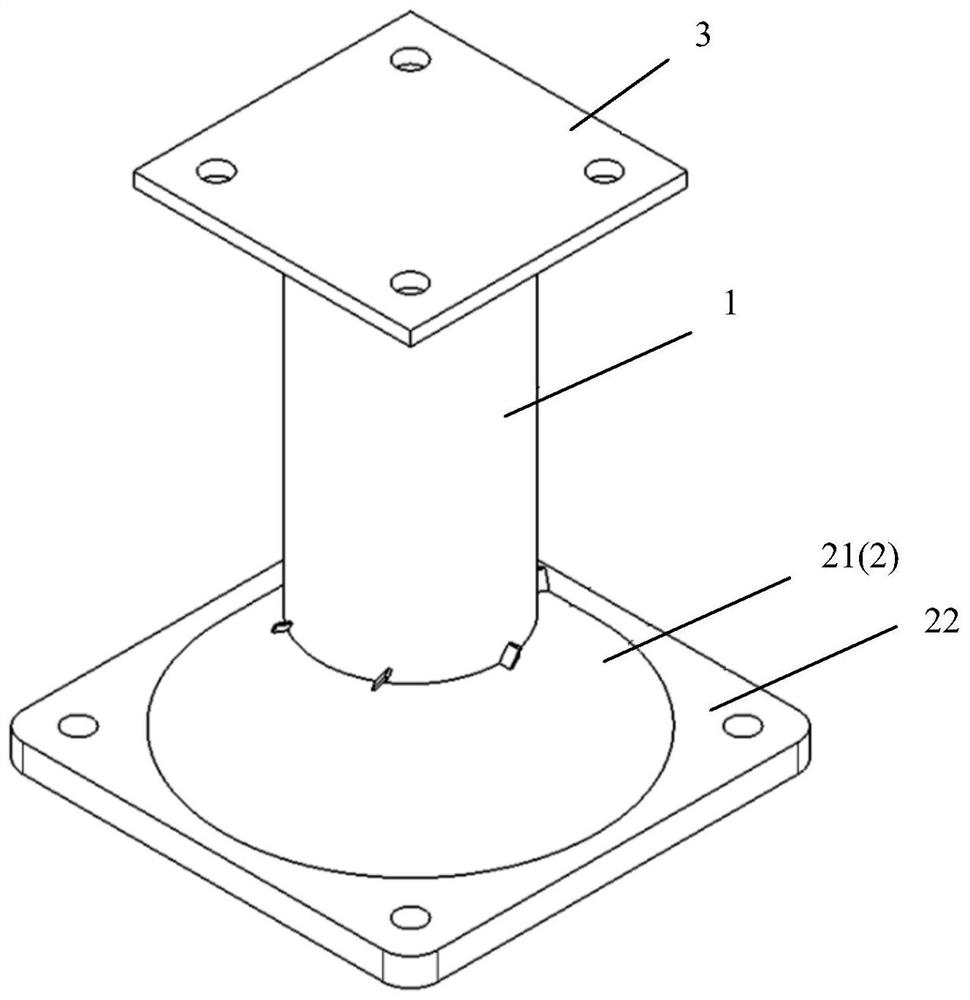

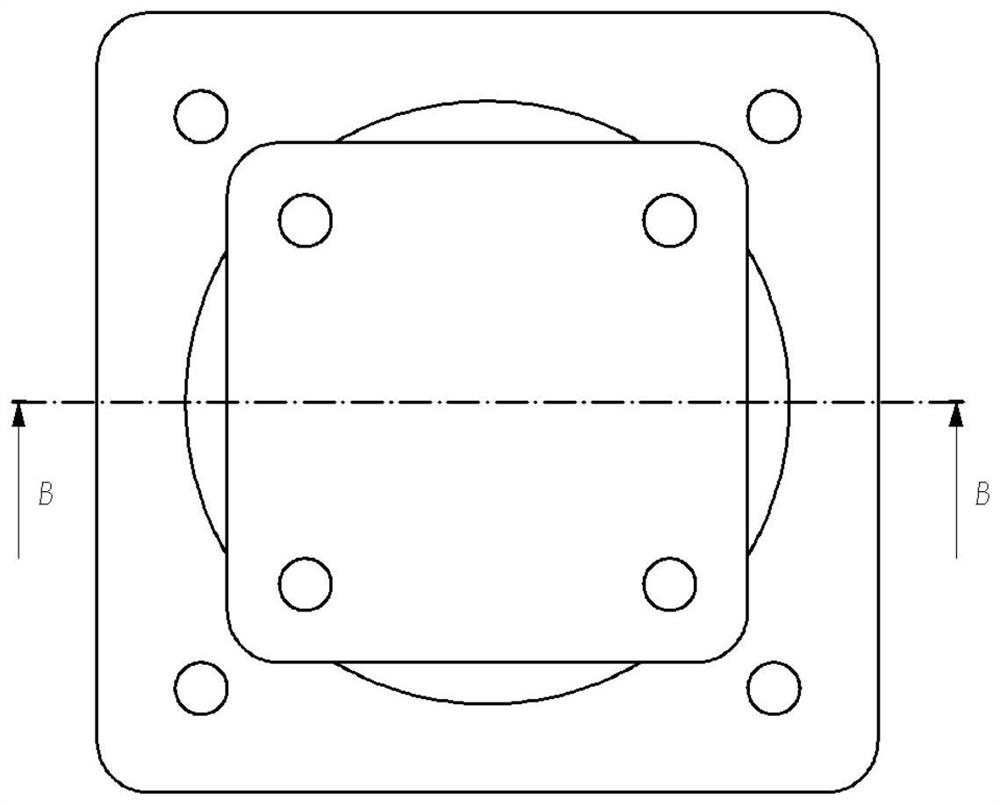

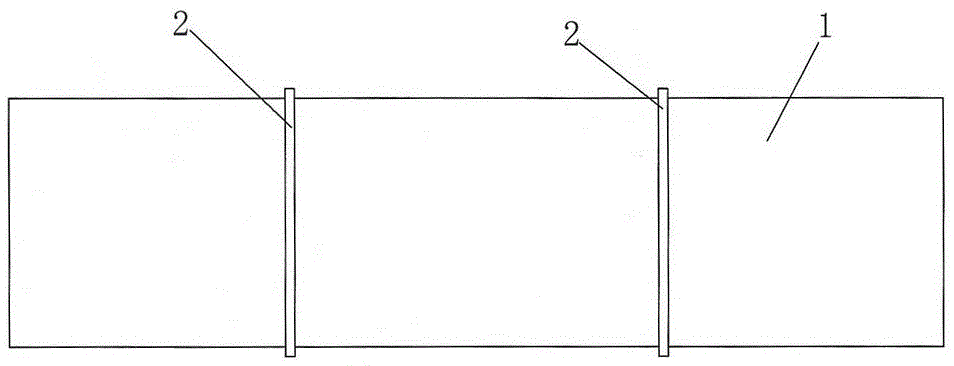

Circular tube type laser welded sandwich plate explosion-proof wall

InactiveCN107558785AHigh energy absorption efficiencyHigh in-plane bending stiffnessProtective buildings/sheltersFloating buildingsIn planeTubes types

The invention discloses a circular tube type laser welded sandwich plate explosion-proof wall. The circular tube type laser welded sandwich plate explosion-proof wall comprises a sandwich plate explosion-proof wall body and a supporting structure body, and the sandwich plate explosion-proof wall body is mounted on a module truss of the upper of a target platform through the supporting structure body; the sandwich plate explosion-proof wall body comprises a first panel, a second panel and a sandwich layer, and the sandwich layer is formed by a plurality of circular tube which are arranged vertically and paralelly; the first panel and the second panel are correspondingly arranged on the two sides of the sandwich layer, the first panel serves as an explosion facing face, and the second panelserves as an explosion backing face; and the first panel and the second panel are correspondingly connected with each circular tube in the sandwich layer in a laser welded mode. The sandwich layer ofthe explosion-proof wall body has the characteristics of being high in specific energy absorption, low in first peak crumpled load and long in crumpled stroke so that the explosion-proof wall body canabsorb impact energy well; and meanwhile, the first panel and the second panel are arranged on the two sides of the sandwich layer, so that the explosion-proof wall body has the characteristics of being large in in-plane bending rigidity and high in specific strength, and the explosion-proof capability of the explosion-proof wall body can be further improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

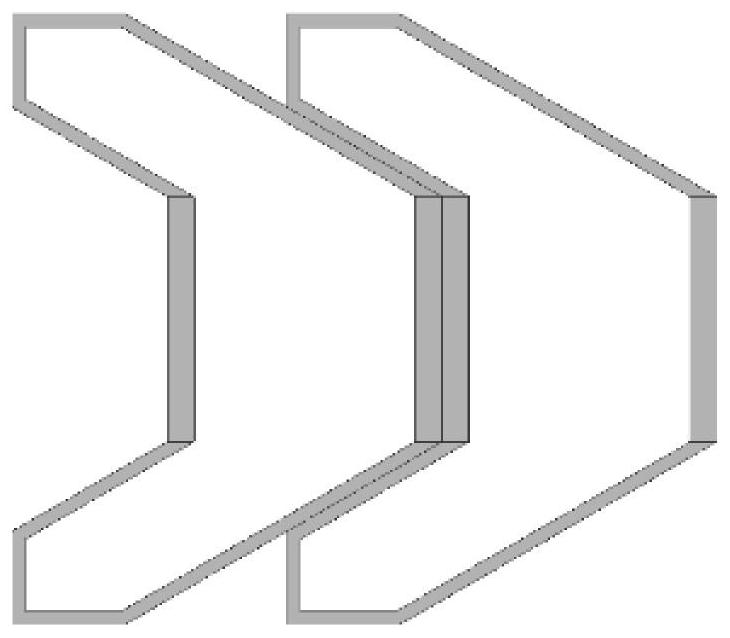

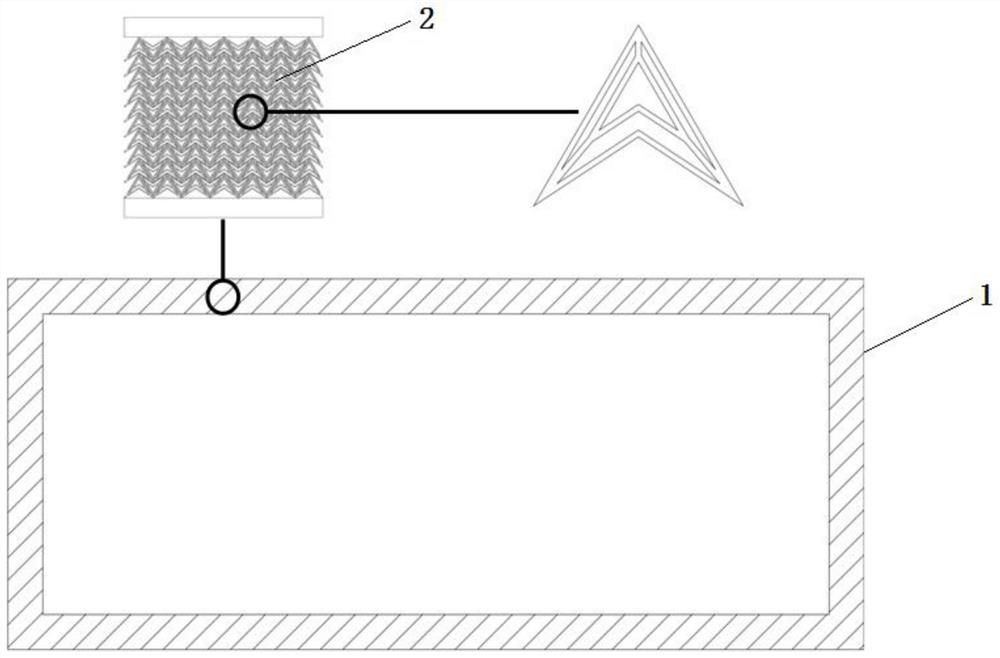

Automotive collision energy-absorption sandwich structure

ActiveCN110843710AImprove applicabilityEffective response to collisionsBumpersInternal combustion piston enginesTitanium metalStructural engineering

The invention provides an automotive collision energy-absorption sandwich structure. The automotive collision energy-absorption sandwich structure is characterized in that an end energy-absorption layer, an energy-absorption inner core and an energy-absorption inner core wrapping layer are included; the end energy-absorption layer is formed by compositing titanium metal layers and aluminum alloy level corrugated pipes, and the aluminum alloy level corrugated pipes are arranged between the two titanium metal layers; the energy-absorption inner core comprises aluminum alloy circular pipes and metal foam materials, and the metal foam materials are arranged in an aluminum alloy circular pipe interlayer; an energy-absorption inner core structure is formed by inner core unit cell structures on an X axis, a Y axis and a Z axis in an array mode according to an upright-inversion-upright sequence, and all the inner core unit cell structures are connected in a braze welding mode; and the inner core unit cell structures comprise the aluminum alloy circular pipes and the metal foam materials, and the metal foam materials are arranged in the aluminum alloy circular pipe interlayer. The problemsof high peak stress, low efficiency, high weight, narrow application face and the like of a traditional collision energy-absorption box are solved.

Owner:HUAQIAO UNIVERSITY

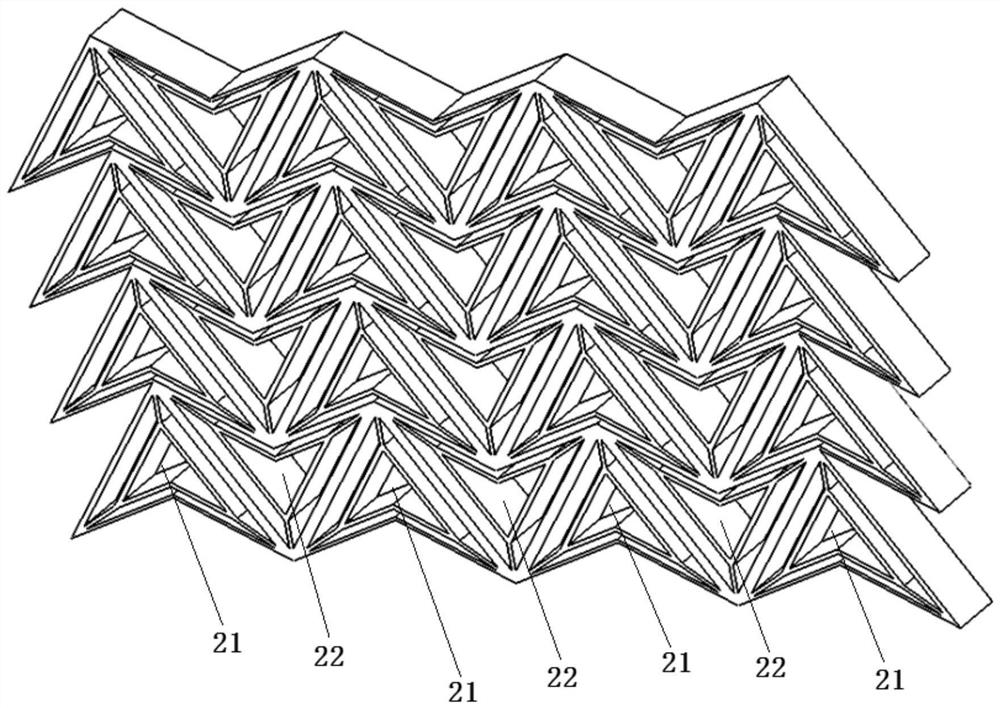

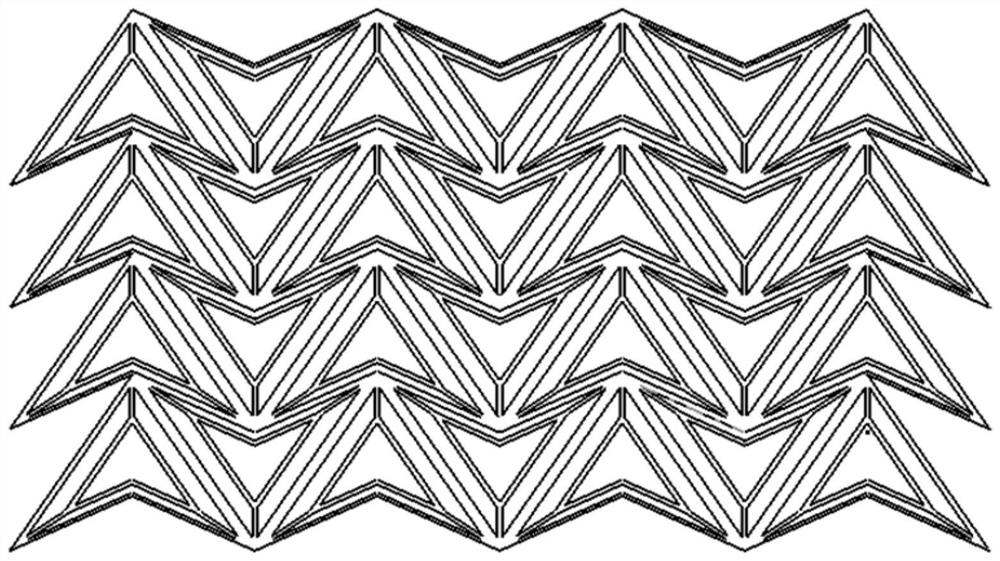

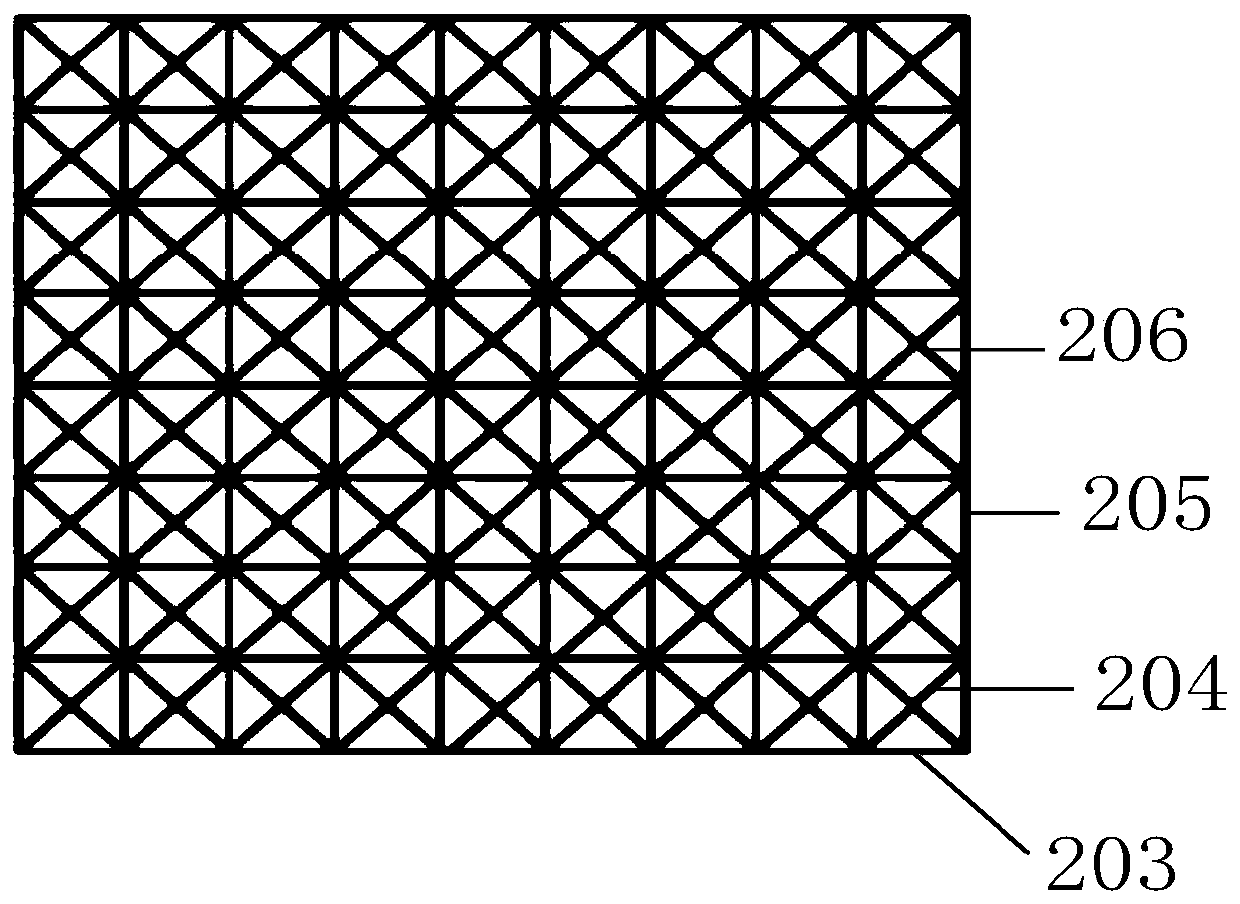

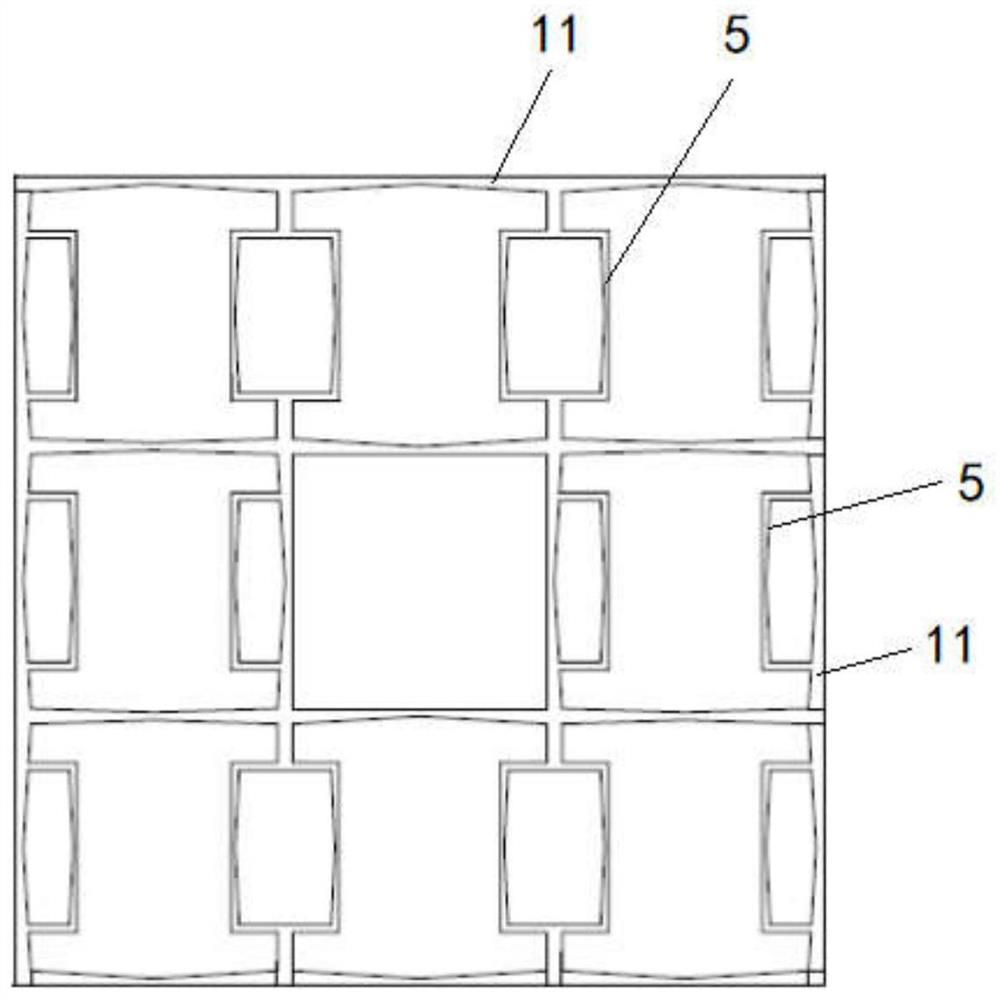

Battery pack sandwich shell with negative Poisson's ratio layered quadrilateral energy absorption structure

ActiveCN113991221ATaking into account the energy absorption effectTaking impact resistance into considerationCell component detailsEnergy absorptionEngineering

The invention discloses a battery pack sandwich shell with a negative poisson ratio layered quadrilateral energy absorption structure. The battery pack sandwich shell comprises a shell and an energy absorption structure; the energy absorption structure comprises energy absorption units and inverted energy absorption units, and the inverted energy absorption units are arranged between every two adjacent energy absorption units; each energy absorption unit comprises a first energy absorption cell body and a second energy absorption cell body arranged in the first energy absorption cell body; the first energy-absorbing cell body is an isosceles triangle with a concave bottom edge, the concave angle theta1 of the bottom edge is an obtuse angle, and the vertex of the concave angle is located on the angular bisector of the vertex angle of the first energy-absorbing cell body; the second energy-absorbing cell body is an isosceles triangle with a concave bottom edge, the concave angle theta2 of the bottom edge is an obtuse angle, the two bevel edges of the second energy-absorbing cell body are parallel to the two bevel edges of the first energy-absorbing cell body respectively, and a gap is reserved between the concave bottom edge of the second energy-absorbing cell body and the concave bottom edge of the first energy-absorbing cell body; and the three vertexes of the second energy absorption cell body are connected with the three vertexes of the first energy absorption cell body through linear connecting walls correspondingly. The shell is simple in structure and has both the energy absorption effect and the impact resistance.

Owner:JILIN UNIV

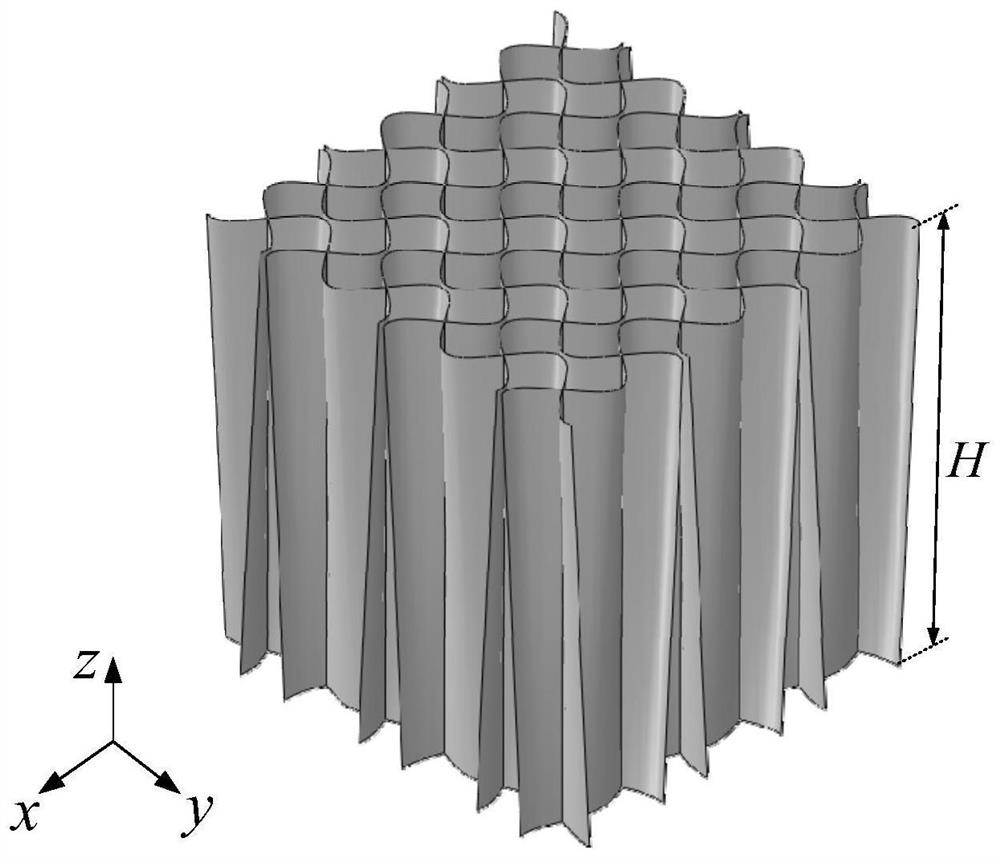

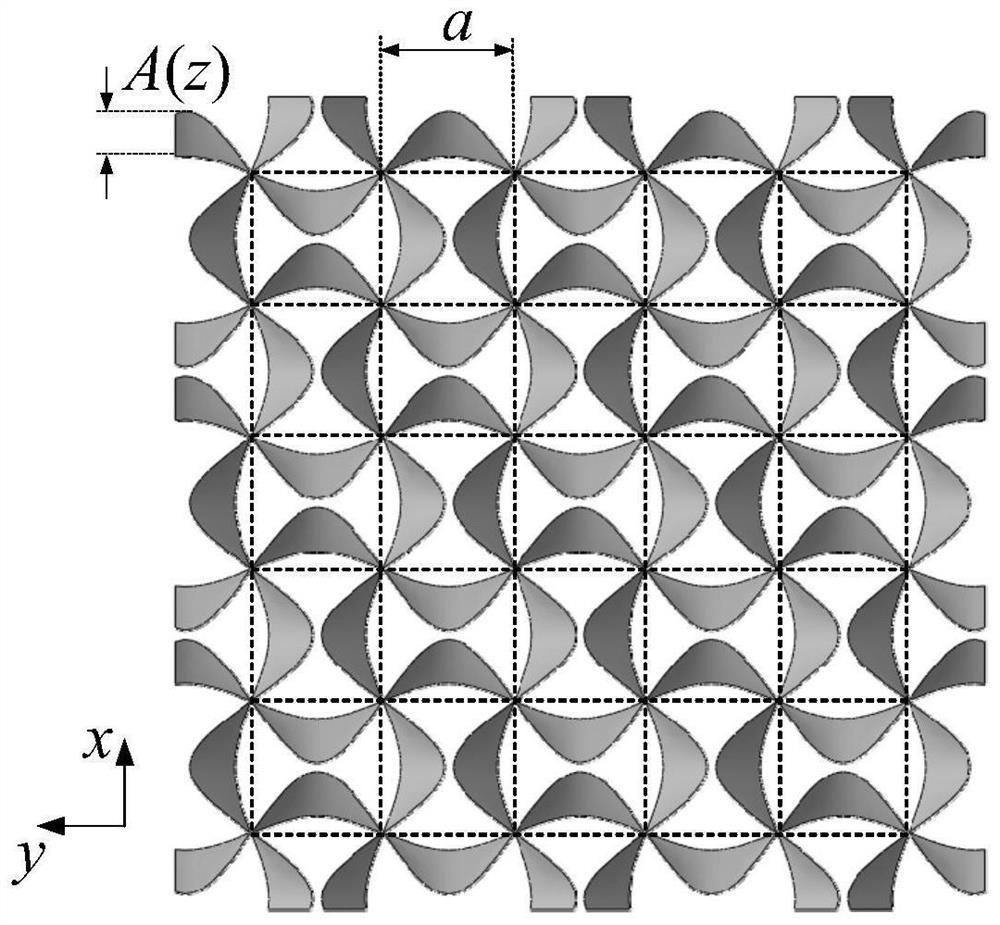

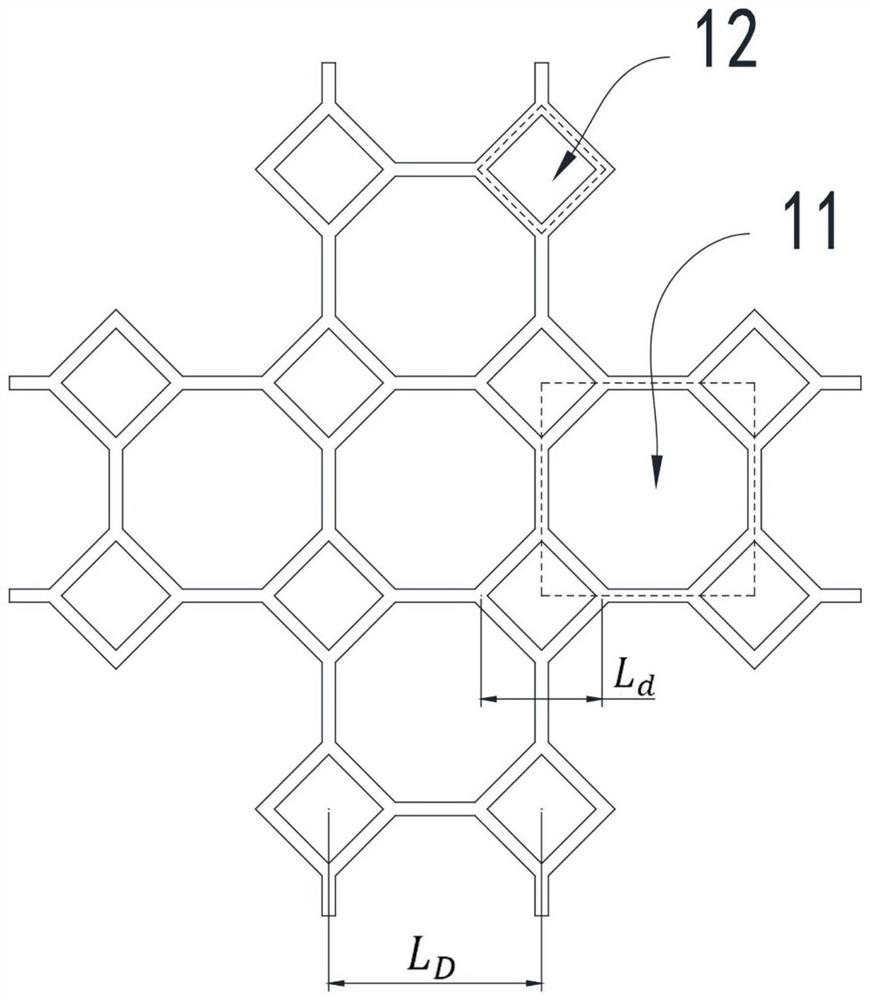

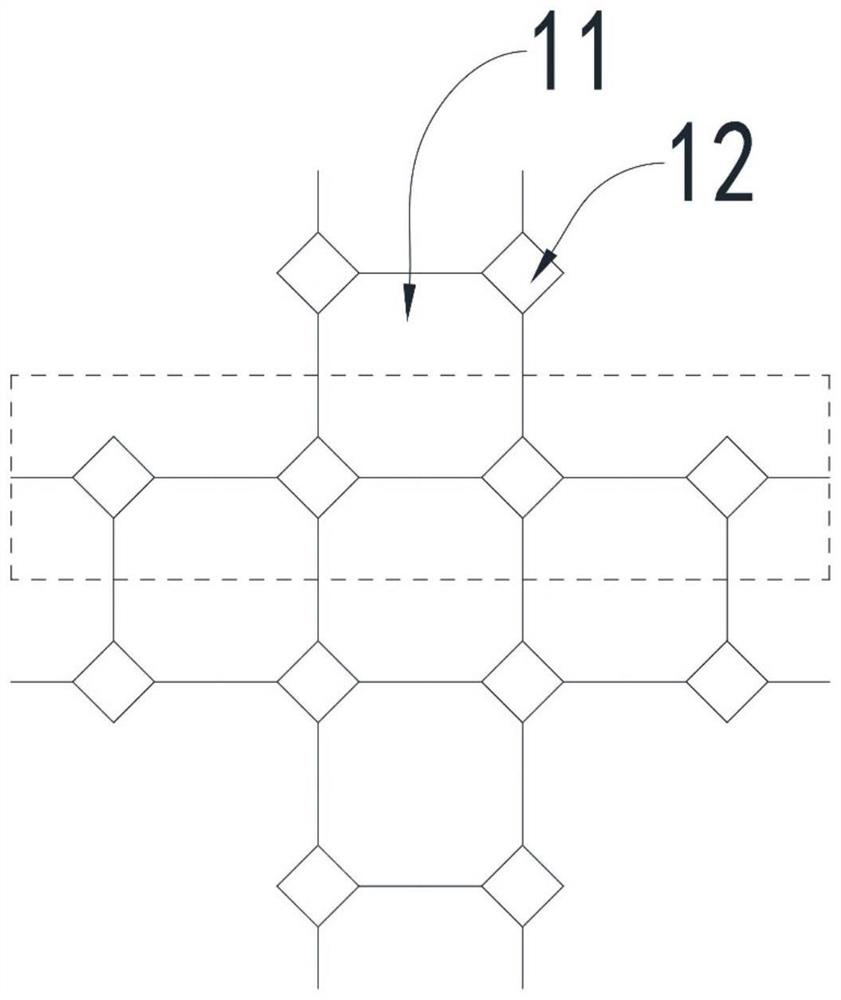

Three-dimensional curved wall mixed phase regular quadrilateral chiral honeycomb

PendingCN114060445AStructural force-displacement curve is smoothImprove energy absorptionSpringsElastic dampersEnergy absorptionHoneycomb structure

The invention discloses a three-dimensional curved wall mixed phase regular quadrilateral chiral honeycomb, and belongs to the technical field of safety protection. The chiral honeycomb is composed of a straight-wall honeycomb framework and curved surfaces, wherein the straight-wall honeycomb framework is composed of honeycomb cell elements, and the curved surfaces abut against the adjacent curved surfaces when being impacted; and the curved surfaces are spliced on the honeycomb cell elements to form the three-dimensional curved wall mixed phase chiral honeycomb. Compared with the prior art, the three-dimensional curved wall mixed phase chiral honeycomb has the beneficial effects that the adjacent curved surfaces of the three-dimensional curved-wall mixed-phase chiral honeycomb abut against each other to dissipate energy, a novel energy absorption mechanism is formed, an advantage that a force-displacement curve of a traditional straight wall honeycomb structure is stable is kept, and the total energy absorption amount and specific energy absorption are greatly improved on the premise of not wasting extra space. In addition, axial rigidity of the curved surfaces with wide upper parts and narrow lower parts is also greatly improved, and an average value of force-displacement curves can be greatly improved.

Owner:SUN YAT SEN UNIV

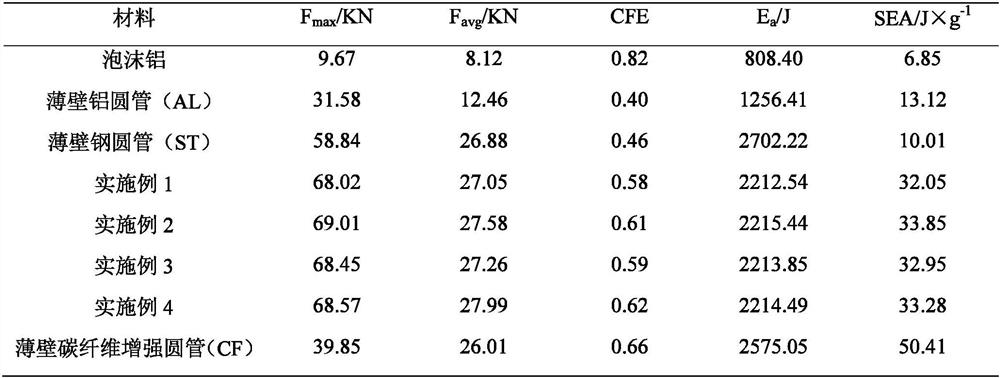

Automobile collision energy-absorbing composite material and preparation method thereof

PendingCN112208164AHigh specific strengthHigh strengthMetal layered productsEnergy absorptionUltimate tensile strength

The invention belongs to the technical field of automobile safety protection, and particularly discloses an automobile collision energy absorption composite material and a preparation method thereof.The composite material comprises M layers of particle reinforced foamed aluminum core materials and M+1 layers of dual-phase steel plates, the foamed aluminum core materials and the dual-phase steel plates are sequentially and alternately stacked, and the dual-phase steel plates are composed of austenite phases and martensite phases. According to the automobile collision energy-absorbing material,martensite is induced to form through dual-phase steel deformation at the moment of collision, so that a large amount of energy is absorbed at the moment of collision, the structure is kept stable, then residual energy is absorbed through porous fluffy foamed aluminum, and the defects that a traditional collision energy-absorbing structure is prone to losing efficacy at the moment of collision, and the energy absorption effect cannot be completely reflected are overcome. Besides, the dual-phase steel has higher strength and work hardening rate than aluminum alloy and other light metals, so that higher specific energy absorption can be realized under the condition of not sacrificing the strength and light weight, the same safety goal is achieved, and meanwhile, more cost is saved.

Owner:CISDI ENG CO LTD +1

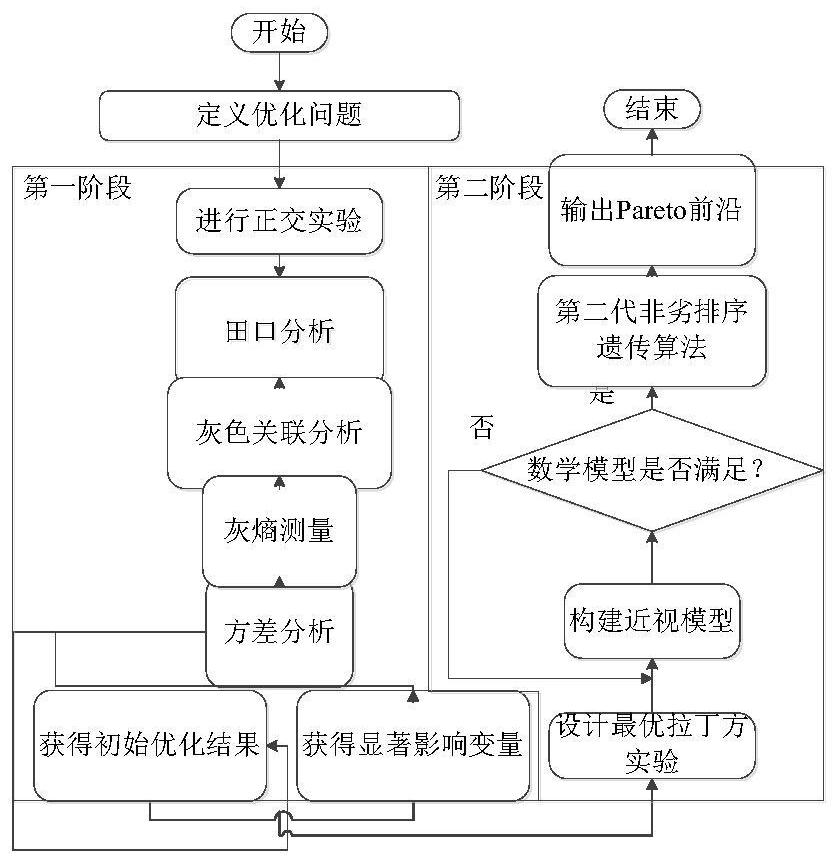

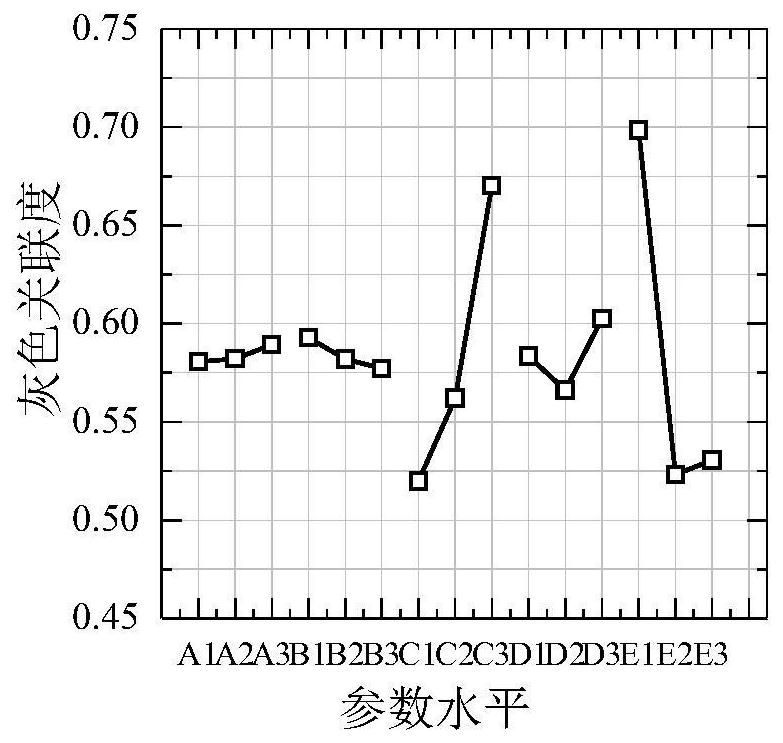

Multi-cell energy absorption structure combination optimization design method

InactiveCN113190917AMiniaturizationImprove securityGeometric CADDesign optimisation/simulationGrey correlation analysisElement model

The invention discloses a multi-cell energy absorption structure combination optimization design method, which comprises the following steps: establishing a multi-cell energy absorption structure finite element model according to a material to be optimized, and determining a design variable, a constraint condition and an optimization target; carrying out an orthogonal experiment according to the established three-level design variable table of the variables and an optimization target; establishing a target response data matrix, and performing Taguchi analysis on the target response data matrix; performing grey correlation analysis based on the normalized signal-to-noise ratio sequence of each response to obtain a grey correlation coefficient sequence corresponding to each response; determining a preliminarily optimized variable combination to realize rapid positioning of a preliminarily optimized result in a large space; selecting a significant influence variable and carrying out secondary optimization by using a preliminary optimization variable; and carrying out multi-objective continuous optimization design to obtain a Pareto leading edge of an optimization problem, and determining an optimal compromise design point. According to the method, the specific energy absorption of the structure can be improved, the peak acceleration can be reduced, and the lightweight and safety performance of the structure can be improved to a great extent.

Owner:WUHAN UNIV OF TECH

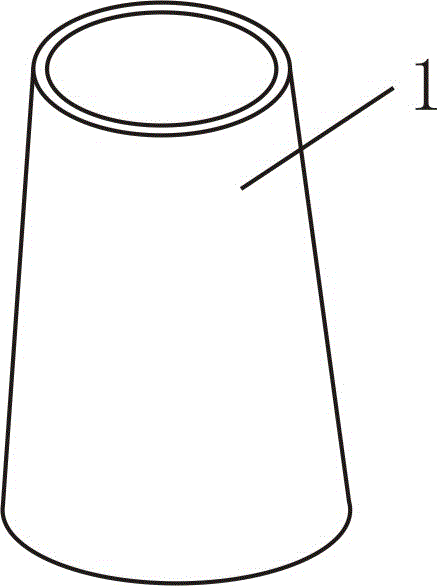

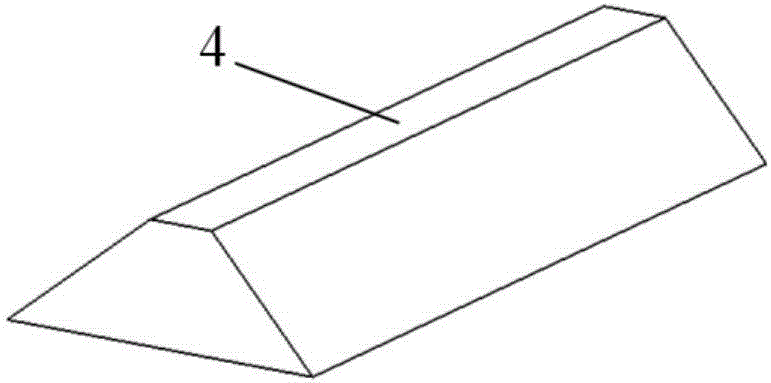

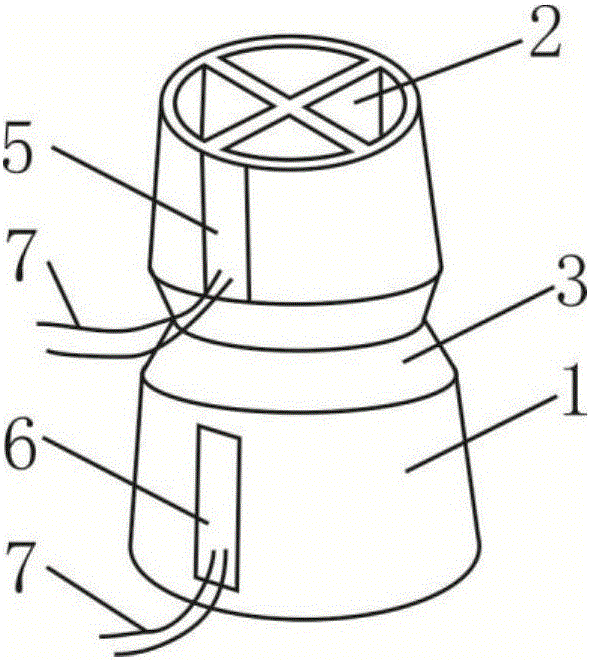

Single crystal cell metal tube for absorbing energy during vehicle collision

InactiveCN105459931AIncrease specific energy absorptionSmall initial peak loadBumpersConical tubeEngineering

The invention provides a single crystal cell metal tube for absorbing energy during vehicle collision. A main body is a conical thin wall pipe, the taper of the main body is 0.3, and the ratio of the wall thickness to height of the main body is (1:15)-(1:30). In an oblique collision process of a conical tube with the taper of 0.3, with the decrease of an oblique collision deflection angle, the component force in a loading velocity direction increases, so that the initial peak load is increased and the specific energy absorption is increased. Therefore, optimization is realized when the taper is 0.3.

Owner:CHENGDU KAISHENG SCI & TECH

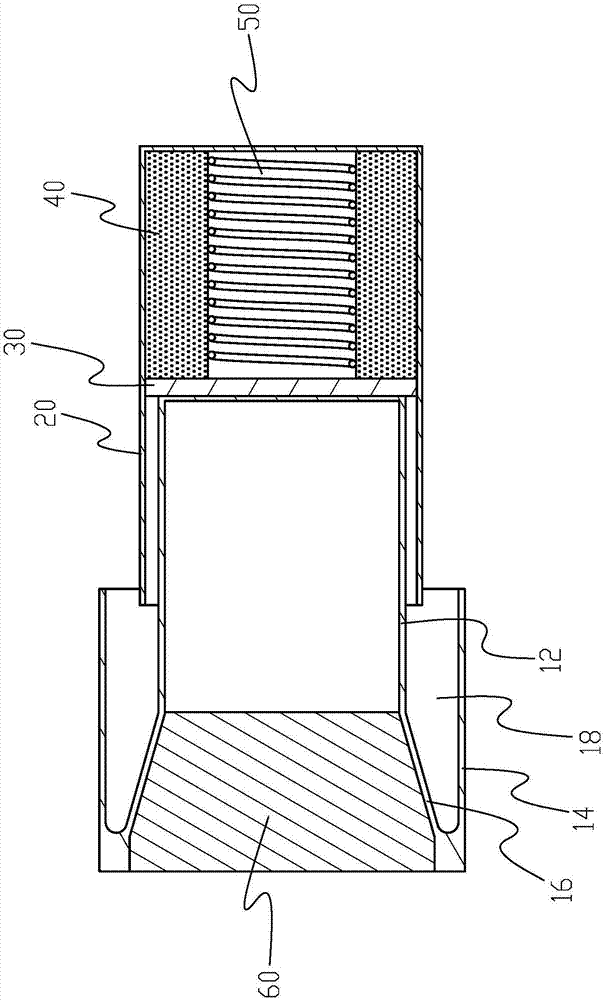

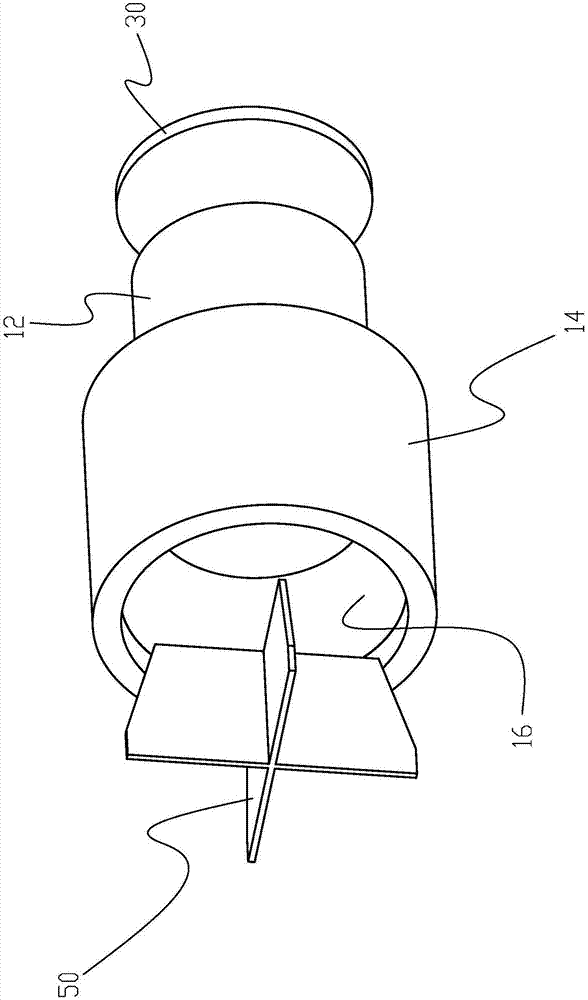

Efficient energy absorption device capable of achieving graded collapse

The invention discloses an efficient energy absorption device capable of achieving graded collapse. The efficient energy absorption device comprises a front shell, a rear shell, a gasket, a filler andan elastic piece. The front shell comprises an inner wall, an outer wall and a connecting wall, the connecting wall is formed through forward expansion and extension, being of a horn structure, of the front end of the inner wall, the outer wall covers the connecting wall and the front end of the inner wall, the front end of the outer wall is connected with the front end of the connecting wall, and an annular groove is defined by the outer wall, the connecting wall and the inner wall; the gasket is arranged in the rear shell, so that the internal space of the rear shell is divided into a frontpart and a rear part by the gasket, the filler is arranged in the space of the rear part of the rear shell, the filler is of a hollow structure, and the elastic piece is located in the middle of thefiller; and the inner wall is inserted into the space of the front part of the rear shell, the gasket is pressed by the inner wall and the elastic piece from the two sides correspondingly, and the diameter of the rear shell is between the maximum diameter and the minimum diameter of the connecting wall. The efficient energy absorption device has the advantages that the energy absorption efficiencyis high, the impact acceleration can be decreased, and the structure is simple.

Owner:HUAQIAO UNIVERSITY

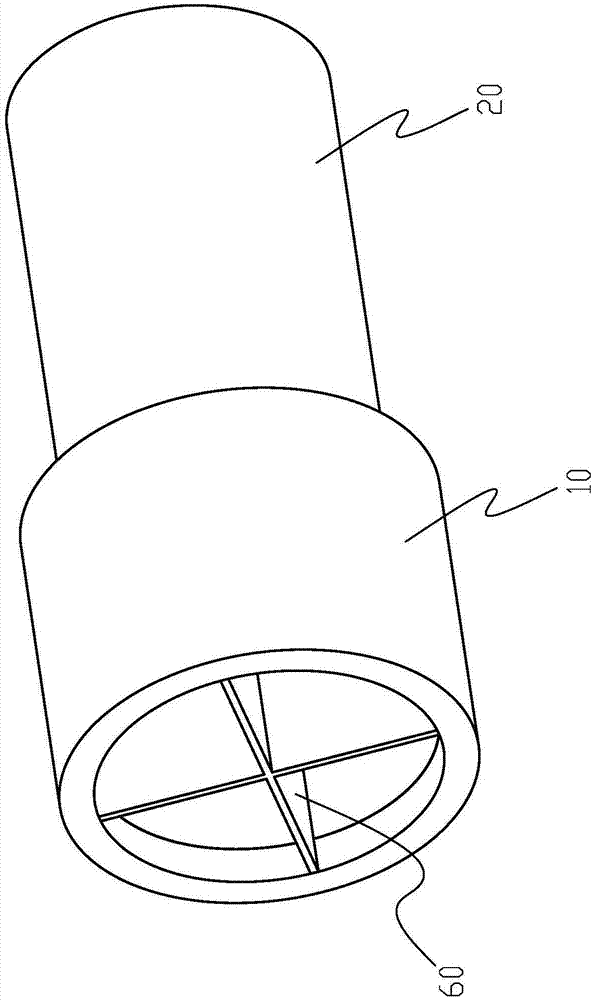

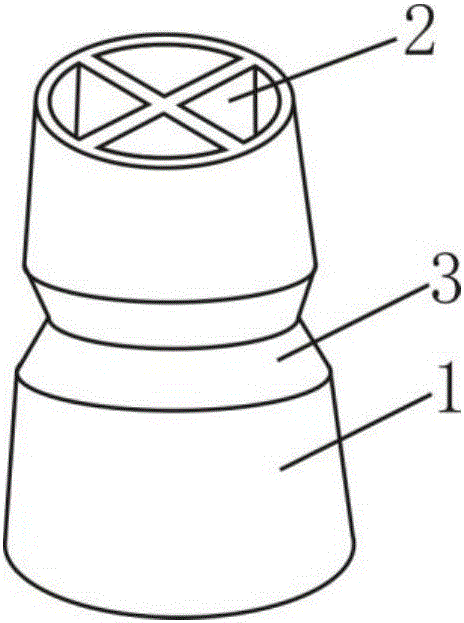

Four-unit-cell metal tube for absorbing energy during automobile collisions

InactiveCN106740604AIncrease specific energy absorptionImprove energy absorptionBumpersEnergy absorptionConical tube

The invention discloses a four-unit-cell metal tube for absorbing energy during automobile collisions. A body is a conical thin walled tube. A cross-shaped tube wall is arranged inside the body. The tube wall extends from the top end of the body to the bottom end of the body. An inward-concave preformed deformation groove is formed in the middle of the body. The taper of the body is 0.3. During contact between a conical tube and a rigid wall, due to the fact that the outer diameter of the conical tube is smaller than that of a circular tube, the strength of the conical tube is lowered, the conical tube is more easily compressed compared with a circular tube with the larger outer diameter, and a small initial peak load is generated correspondingly. Accordingly, in the collision energy absorption process of the thin walled tube, compared with the circular tube, the specific absorbed energy of the thin-walled tube can be increased due to the conical tube; due to the taper of the conical tube is 0.3, in the inclined collision process, the component force in the speed loading direction is increased along with decrease of the inclined collision angle, so that the initial peak load is increased, and the specific absorbed energy is increased; accordingly, the taper is 0.3 preferentially. After the preformed deformation groove is added, deformation happens at the preformed deformation groove, the deformation direction and the deformation process become controllable, and the heat absorption performance of the four-unit-cell conical tube is further improved.

Owner:成都贝恩云广告传媒有限公司

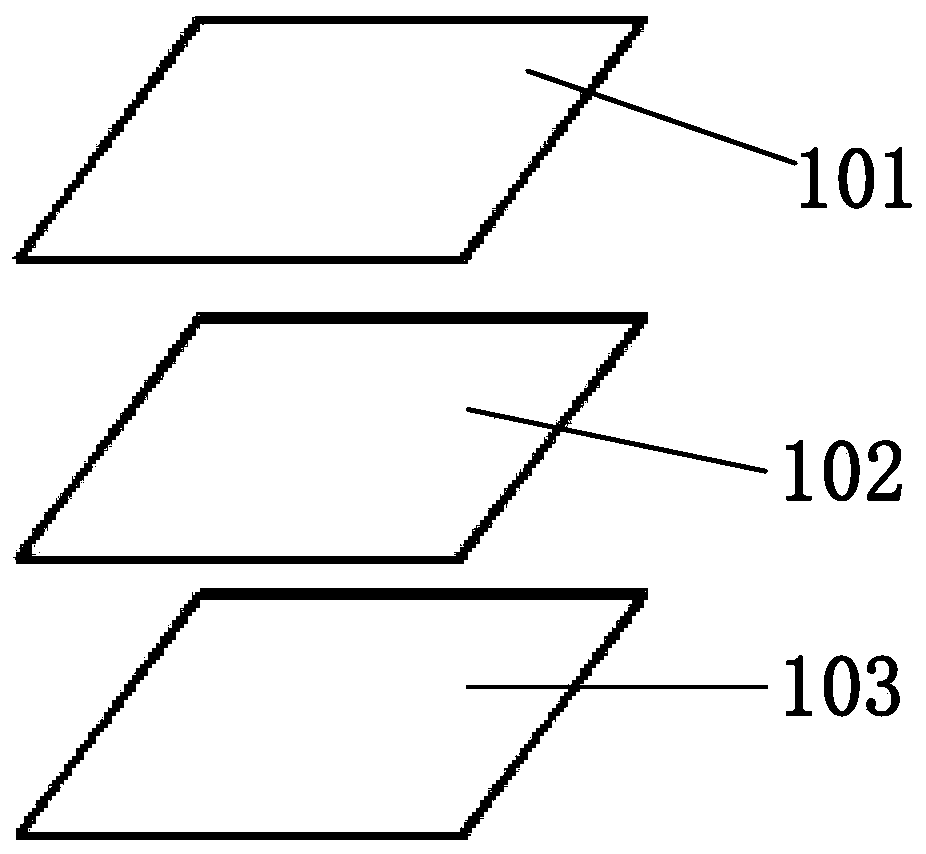

Sandwich structure applied to automobile crash energy-absorption box

ActiveCN110576654AHigh strengthEfficient deliveryInternal combustion piston enginesVehicle componentsFiberEnergy absorption

The invention provides a sandwich structure applied to an automobile crash energy-absorption box. The sandwich structure comprises an upper-layer composite board, a composite interlayer and a bottom-layer composite board which are arranged in a stacked mode, wherein the upper-layer composite plate comprises composite material fiber cloth and a titanium metal plate which are arranged in a stacked manner; the composite interlayer comprises a calabash pipe thin-wall structure and a garland type honeycomb structure; the bottom-layer composite plate comprises a titanium metal plate and a porous metal material which are arranged in a stacked mode. According to the sandwich structure, the problems of high peak stress, low efficiency, heavy weight and the like of a traditional collision energy absorption structure are solved, an efficient and light automobile collision energy absorption structure with low peak stress can be designed, and the safe, light and environment-friendly automobile development target is achieved.

Owner:HUAQIAO UNIVERSITY

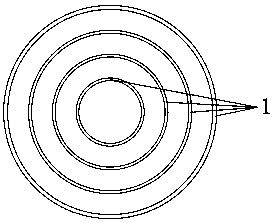

Thin-wall energy absorption device imitating white lotus vein distribution

PendingCN112172721AStable energy absorbing impact forceHigh specific energy absorption and load efficiencyBumpersEnergy absorptionSpecific energy absorption

The invention discloses a thin-wall energy absorption device imitating white lotus vein distribution. The device comprises an energy absorption core, the energy absorption core comprises an outer thin-wall round pipe, an inner thin-wall round pipe, main vein rib plates and branch vein rib plates, the outer thin-wall round pipe and the inner thin-wall round pipe are coaxial, one ends of the main vein rib plates intersect at the axis of the inner thin-wall round pipe, the other ends are respectively arranged at intervals along the circumferential direction of the inner thin-wall round pipe, thebranch vein rib plates are arranged in a cavity inside the outer thin-wall round pipe and outside the inner thin-wall round pipe, and the branch vein rib plates are uniformly distributed on the two sides of the main vein rib plate. The branch vein rib plates and the adjacent branch vein rib plates are intersected on the inner surface of the outer thin-wall circular pipe or the outer surface of theouter thin-wall circular pipe. The number of the main vein rib plates is 4-7. According to the invention, the total energy absorption can be enhanced, the specific energy absorption and load efficiency is higher, the passive safety of an automobile is greatly improved, and casualties are reduced; and the whole body is made of aluminum or an aluminum alloy material, so that the weight can be greatly reduced, and the light weight of the automobile can be better met.

Owner:JIANGSU UNIV OF SCI & TECH

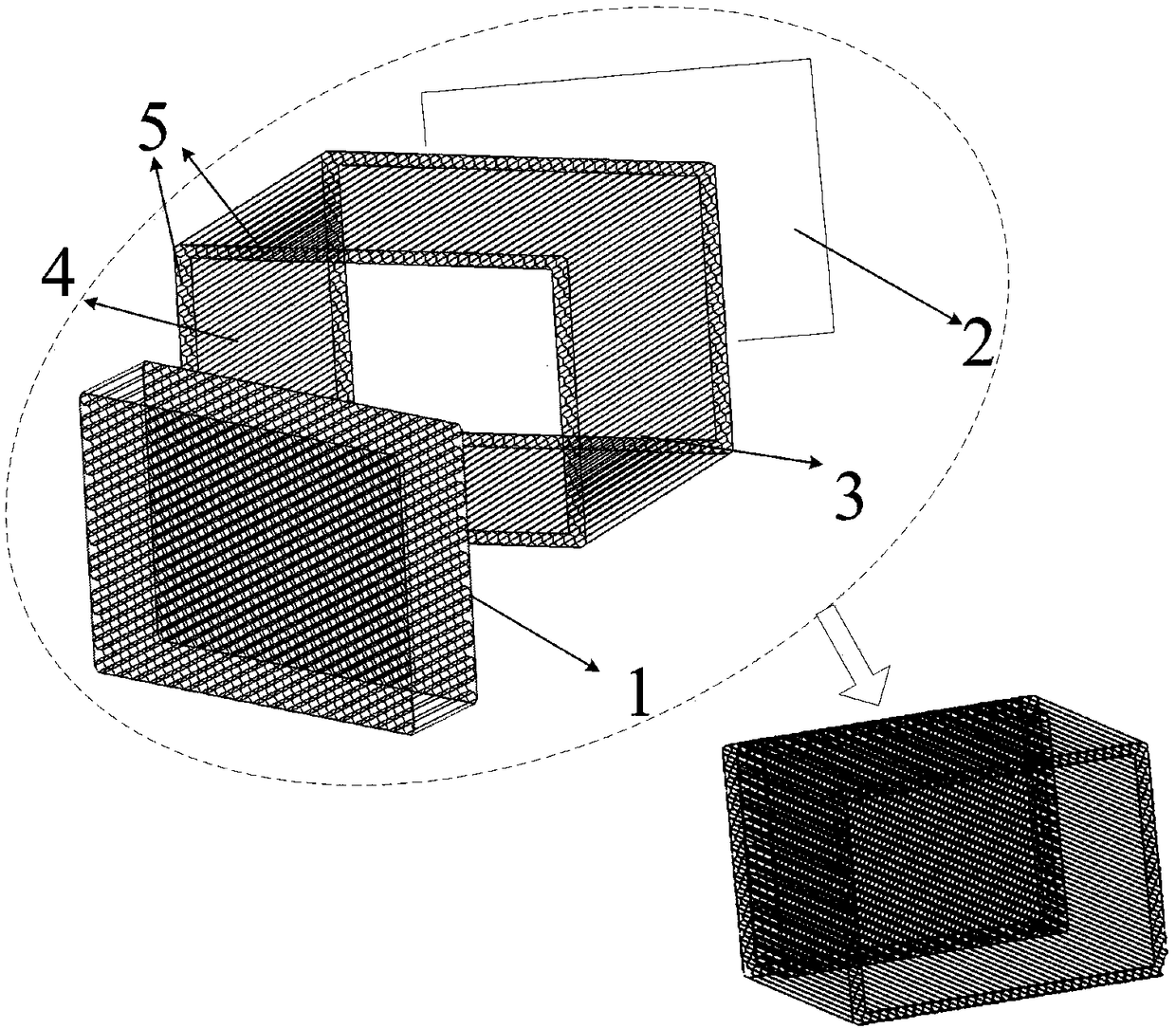

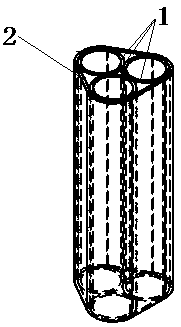

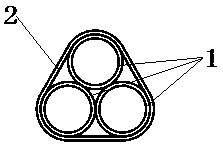

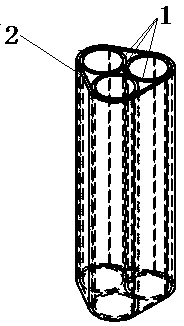

Novel automobile energy absorption box and preparation method thereof

The invention discloses a novel automobile energy absorption box which comprises core bodies and a wrapping layer, wherein each core body is obtained by rolling composite unidirectional carbon fiber prepreg cloth into a cylinder; the composite unidirectional carbon fiber prepreg cloth is formed by stacking and curing 6-12 layers of unidirectional carbon fiber prepreg cloth; the wrapping layer is formed by stacking and curing 6-12 layers of unidirectional carbon fiber prepreg cloth; the wrapping layer wraps and fixes at least two or more core bodies; and the adjacent core bodies are tightly attached to each other. The novel automobile energy absorption box is prepared by carrying out vitrification heat treatment through a three-stage heating method. The novel automobile energy absorption box is prepared through the process routes of cutting, laying, vacuumizing, hot pressing, vitrifying, polishing, slotting and the like, an existing automobile energy absorption box can be partially or completely replaced, and the problems that an automobile energy absorption box is low in specific energy absorption, large in weight, poor in energy absorption capacity, too high in cost and the like are solved.

Owner:GUANGXI UNIV FOR NATITIES

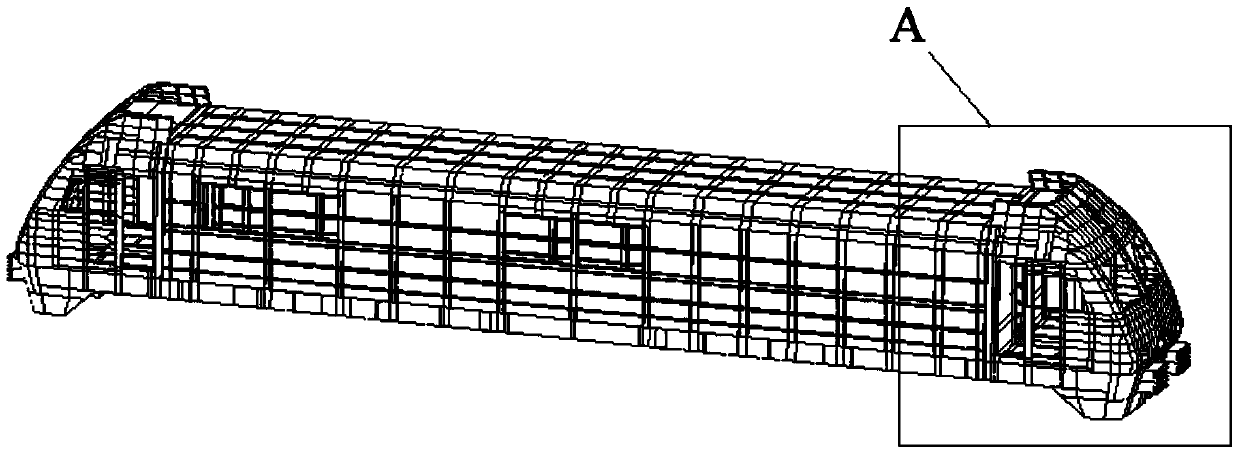

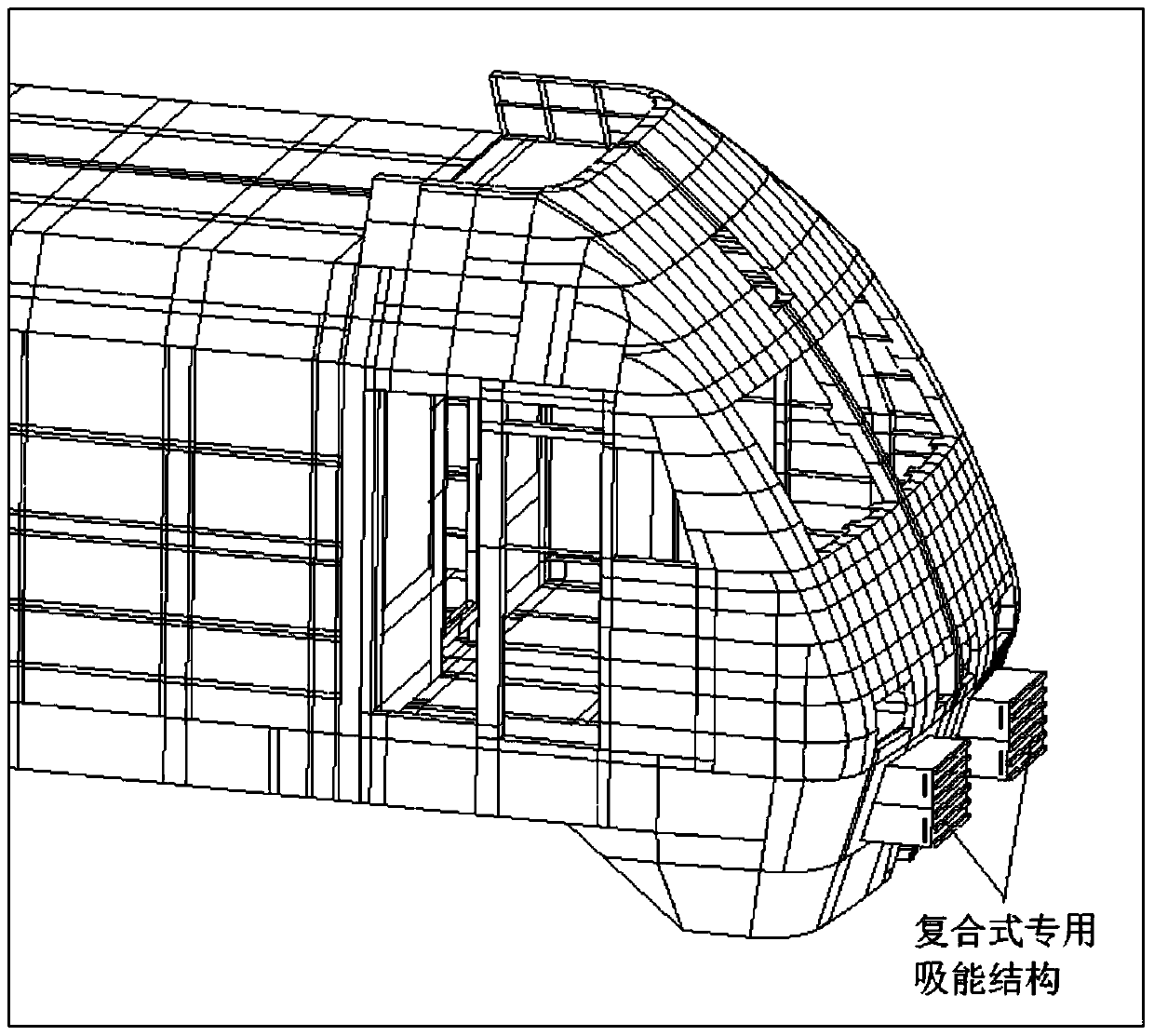

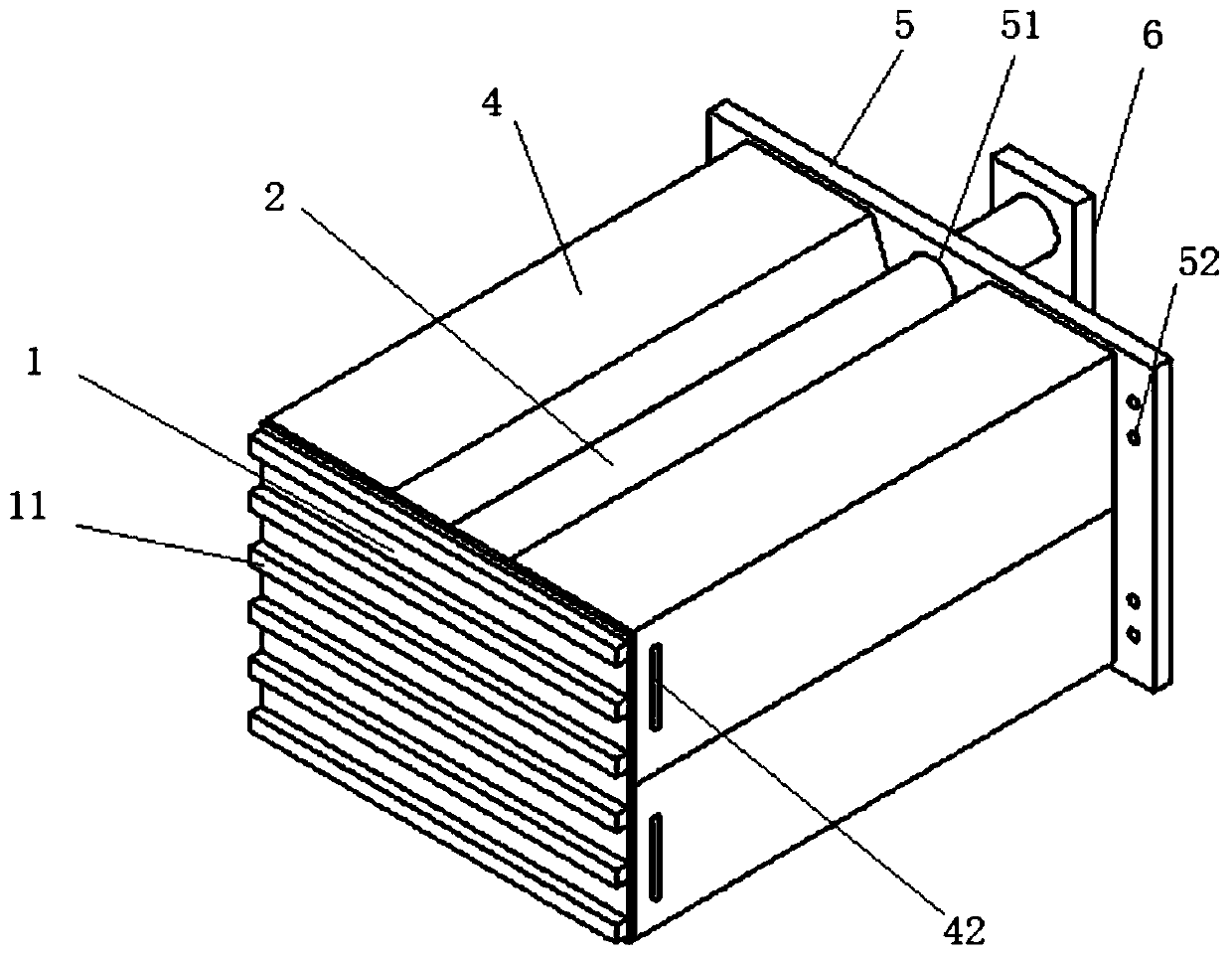

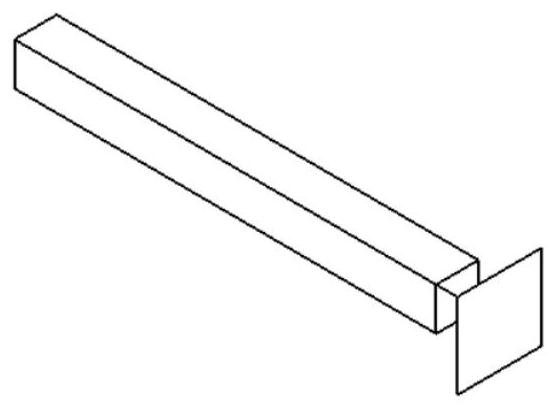

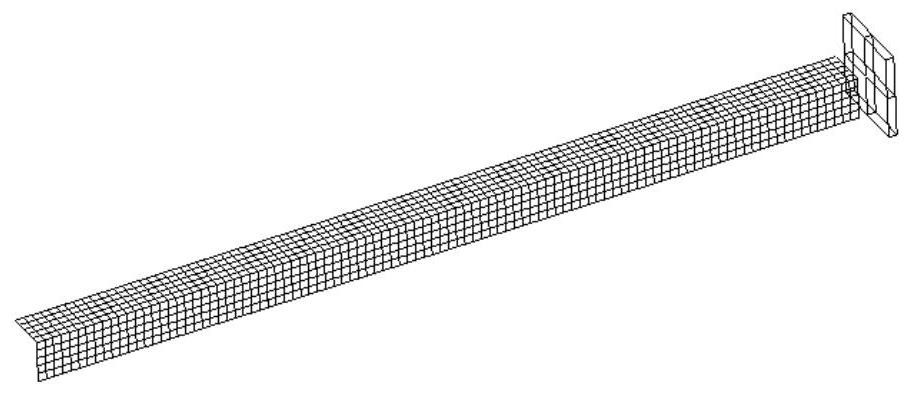

Guidance composite special energy-absorbing structure and its application on trains

ActiveCN105620505BRealize passive safety protectionStable and controllable deformationRailway wheel guards/bumpersEnergy absorptionEngineering

Owner:CENT SOUTH UNIV

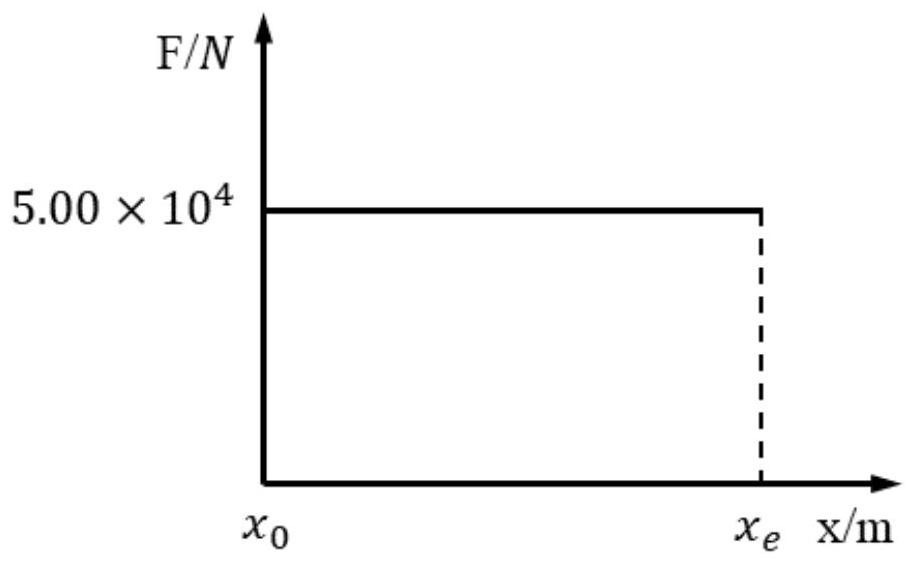

Energy absorption structure optimization method taking expected force response process as target

ActiveCN112199876AStrong energy absorptionInitial peak force heightGeometric CADDesign optimisation/simulationElement modelEnergy absorption

The invention discloses an energy absorption structure optimization method taking an expected force response process as a target, and the method comprises the steps: setting a proper expected force response curve, continuously updating the value of a target function in an optimization process in an iteration mode so as to obtain a new finite element model, and enabling an actual force response curve of a structure to be gradually close to the expected force response curve. And the energy absorption capacity of the structure is improved. According to the method, the deformation mode of the thin-walled tube can be changed, low-energy-absorption Euler deformation is changed into high-energy-absorption progressive buckling deformation, and multiple energy absorption evaluation indexes can be improved at the same time. The optimized actual force response curve of the thin-walled tube is closer to the expected force response curve. The energy absorption component obtained through the methodcan generate an ideal deformation mode, more impact kinetic energy is dissipated, and great guiding significance is achieved for design of energy absorption devices of various vehicles.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

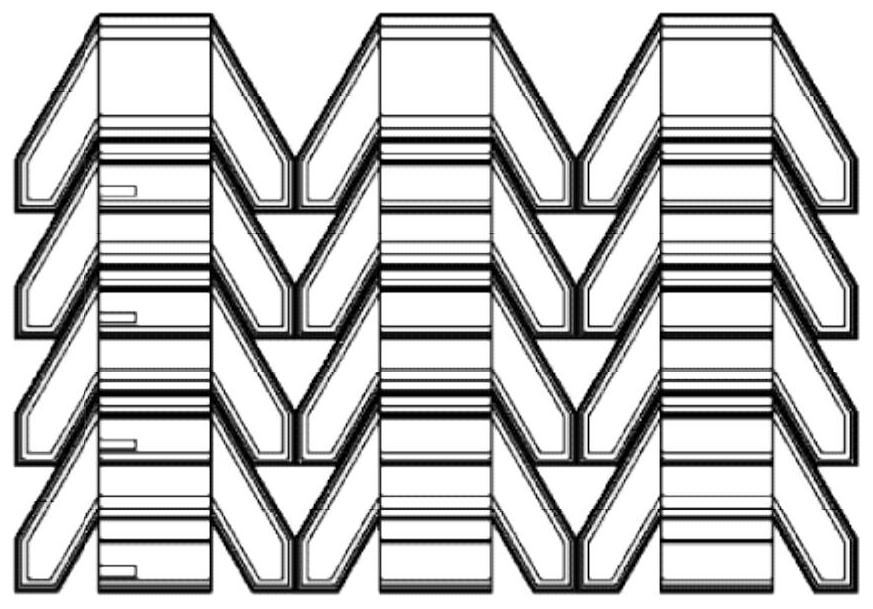

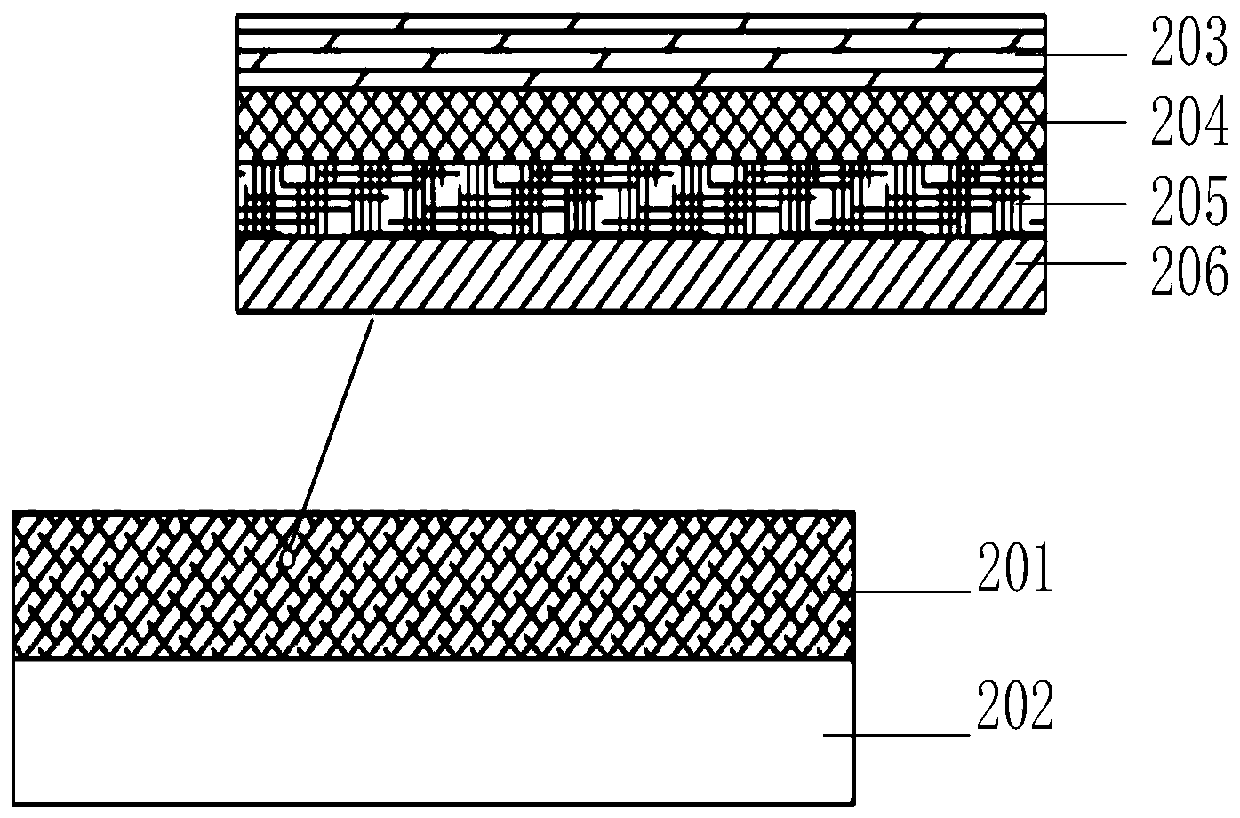

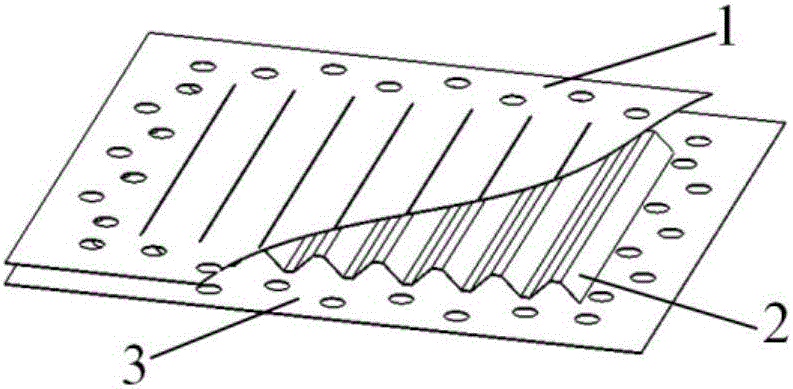

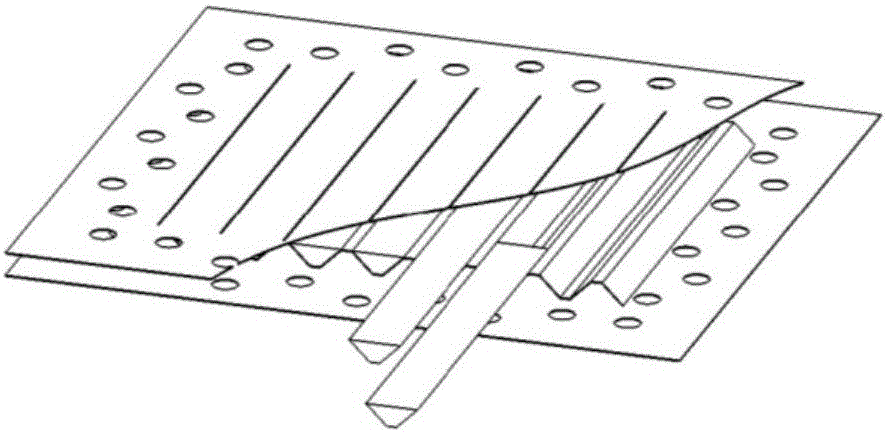

Semi-filled corrugated hybrid sandwich plate of foam material and preparation method of semi-filled corrugated hybrid sandwich plate of foam material

InactiveCN106739273AIncrease the dynamic instability critical loadImproved local buckling performanceLamination ancillary operationsLaminationInstabilitySurface plate

The invention discloses a semi-filled corrugated hybrid sandwich plate of a foam material and a preparation method of the semi-filled corrugated hybrid sandwich plate of the foam material. Only one half of hole in a corrugated core layer is filled with the foam material, so that caused weight increment is not obvious and the filling gain and the specific energy absorption of the sandwich structure are improved. Meanwhile, the semi-filled corrugated hybrid sandwich plate is simple in structure form, easy to prepare and low in preparation material consumption. According to the foam-filled material, on one hand, impact energy can be absorbed through crushing deformation; and on the other hand, contribution of the support stiffness can be provided, the lateral support on a corrugated core layer wall plate is beneficial to improvement of the crushing strength of the core layer wall plate and the dynamic instability critical load, the local buckling performance of a panel and the corrugated core layer is improved, the plastic deformation of the panel can be effectively reduced, and the shock resistance of the sandwich structure is improved through coupling of two materials.

Owner:HUAZHONG UNIV OF SCI & TECH

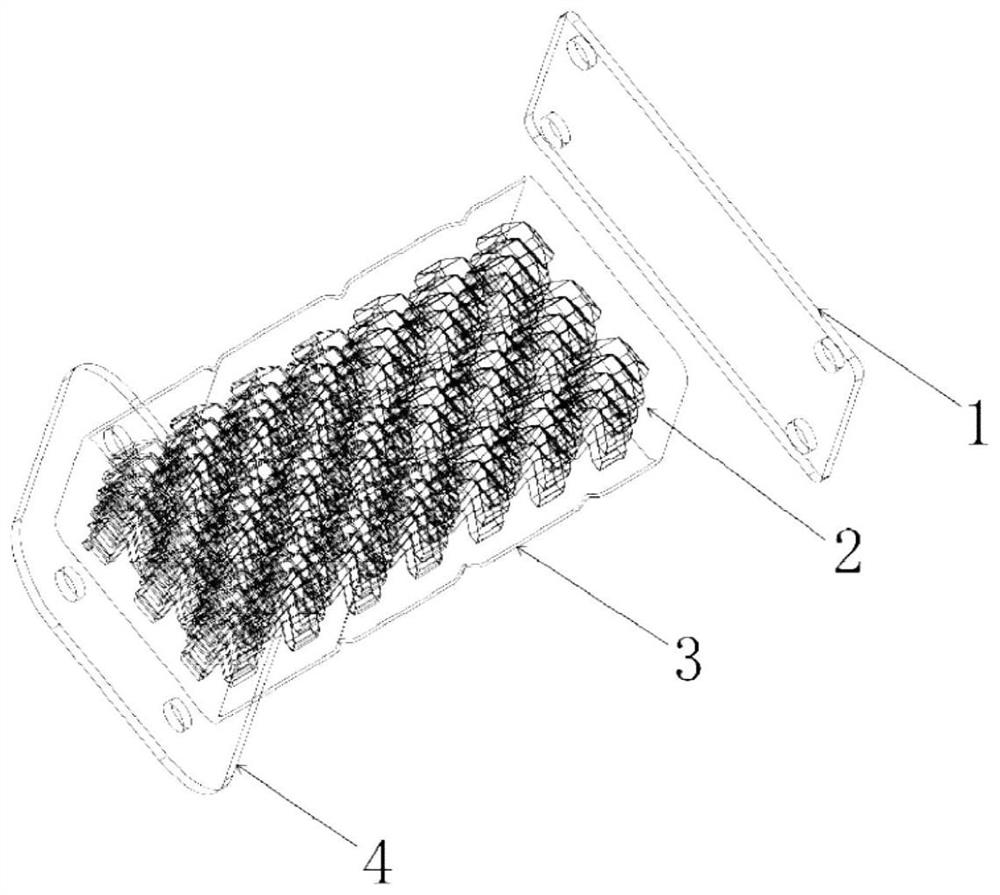

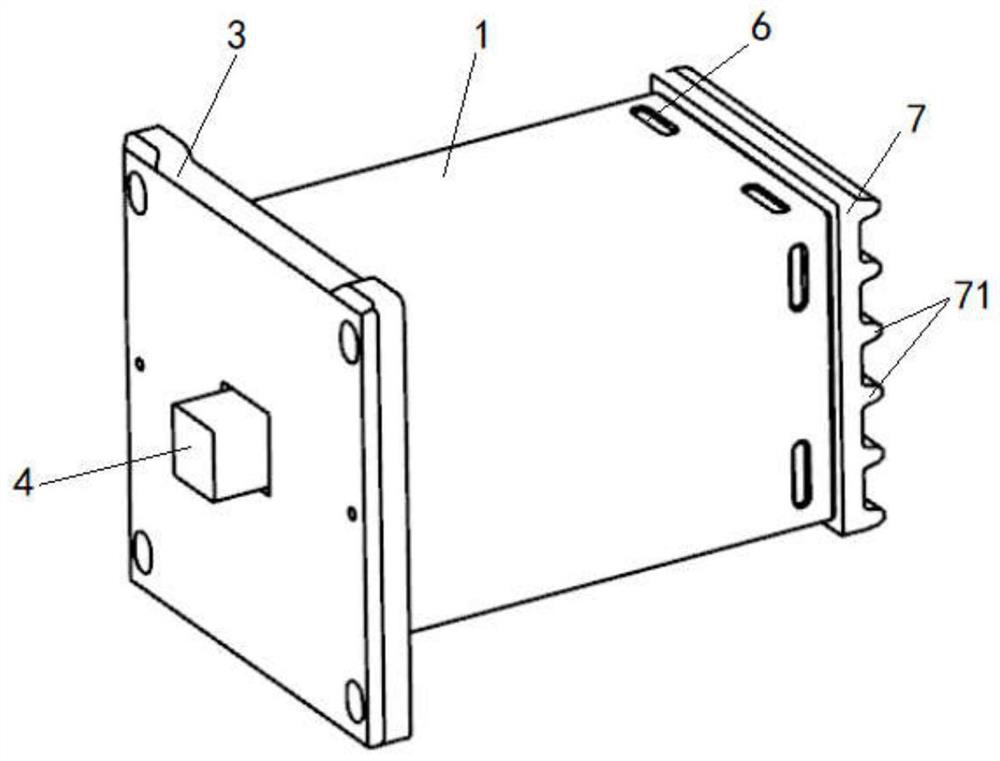

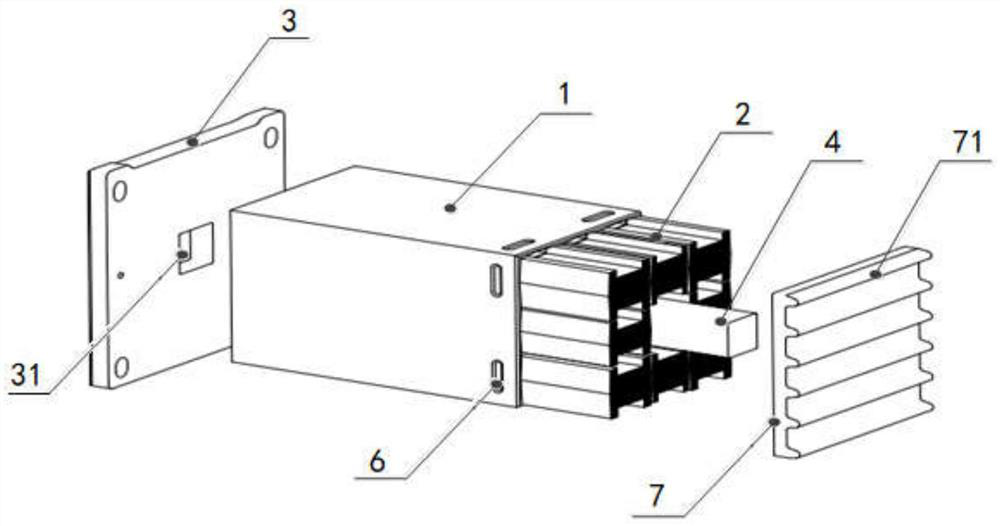

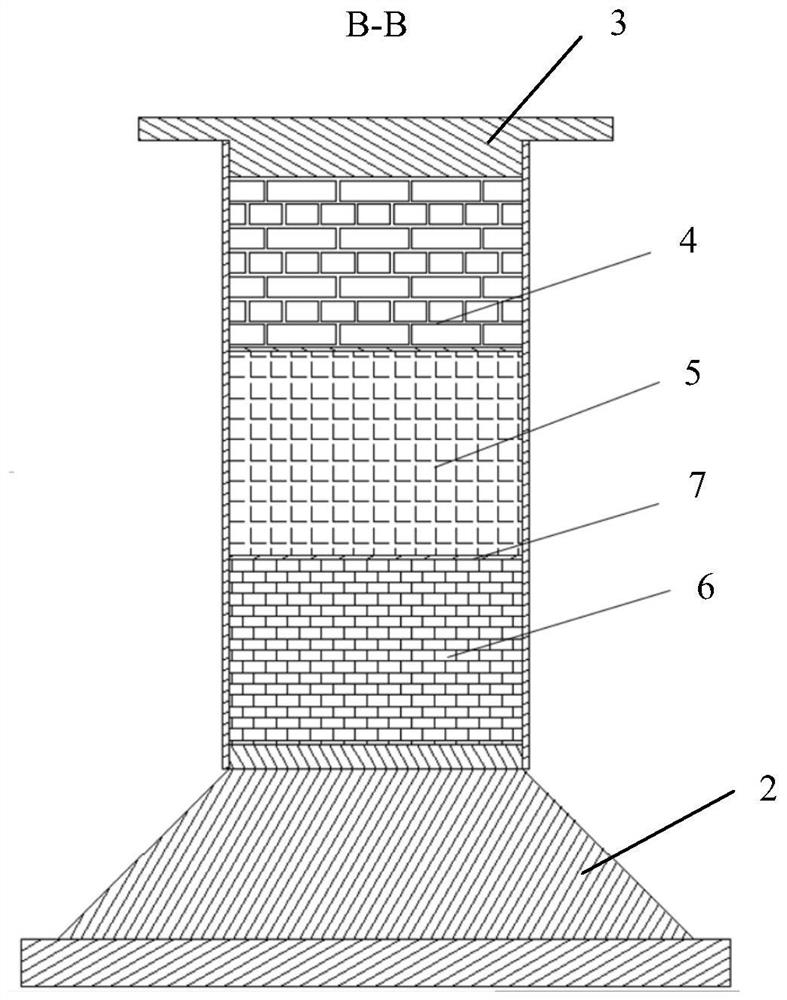

Railway vehicle energy absorption structure

ActiveCN114312896AIncrease specific energy absorptionHigh energy absorption efficiencyRailway wheel guards/bumpersRailway transportEnergy absorptionMechanical engineering

The invention discloses a railway vehicle energy absorption structure which is structurally characterized in that the railway vehicle energy absorption structure comprises a gradient multi-cell energy absorption pipe, a filling piece, a mounting plate and a guide rod, and one end of the gradient multi-cell energy absorption pipe is fixedly connected with the mounting plate; the gradient multi-cell energy absorption pipe comprises a plurality of cells, each cell is surrounded by a plurality of side walls to be tubular, and the thickness of the side wall of each cell is gradually increased at a preset gradient from the middle of the side wall to the edges of the two ends of the side wall. The guide rod is arranged in the cell in the center in a penetrating mode, at least one side wall in each cell on the periphery is provided with a bevel rib plate structure, and the extending direction of the bevel rib plate structures is parallel to the extending direction of the side walls of the cells. And cavities of the cells at the periphery are filled with the filling pieces.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Composite energy absorption device

PendingCN113103981AIncrease specific energy absorptionMake up for the disadvantages of single energy absorption form and low energy absorption efficiencyBumpersEnergy absorptionHoneycomb

The invention discloses a composite energy absorption device, which comprises a sleeve, a base and an upper cover, the upper cover is connected to an energy absorption front end of the sleeve, the base is connected to an energy absorption rear end of an energy-absorbing sleeve, and the sleeve is filled with a honeycomb body; a plurality of spiral guide grooves which spirally extend in parallel around the central axis are formed in the wall of the sleeve, and notches which are connected with the spiral guide grooves in a one-to-one correspondence mode and have the same spiral angle are formed in the positions, corresponding to a pipe opening of the sleeve energy absorption rear end, to which the spiral guide grooves extend. The base is provided with a cone-frustum-shaped part, a plurality of blunt cutting edges are arranged on the circumference of the small-diameter end of the cone-frustum-shaped part at intervals, and when the sleeve is connected with the base, the blunt cutting edges are inserted into the notches in the one-to-one correspondence mode. The invention has the following advantages: the energy absorption process is stable, the specific energy absorption is high, and the collision peak force is small.

Owner:HUAQIAO UNIVERSITY

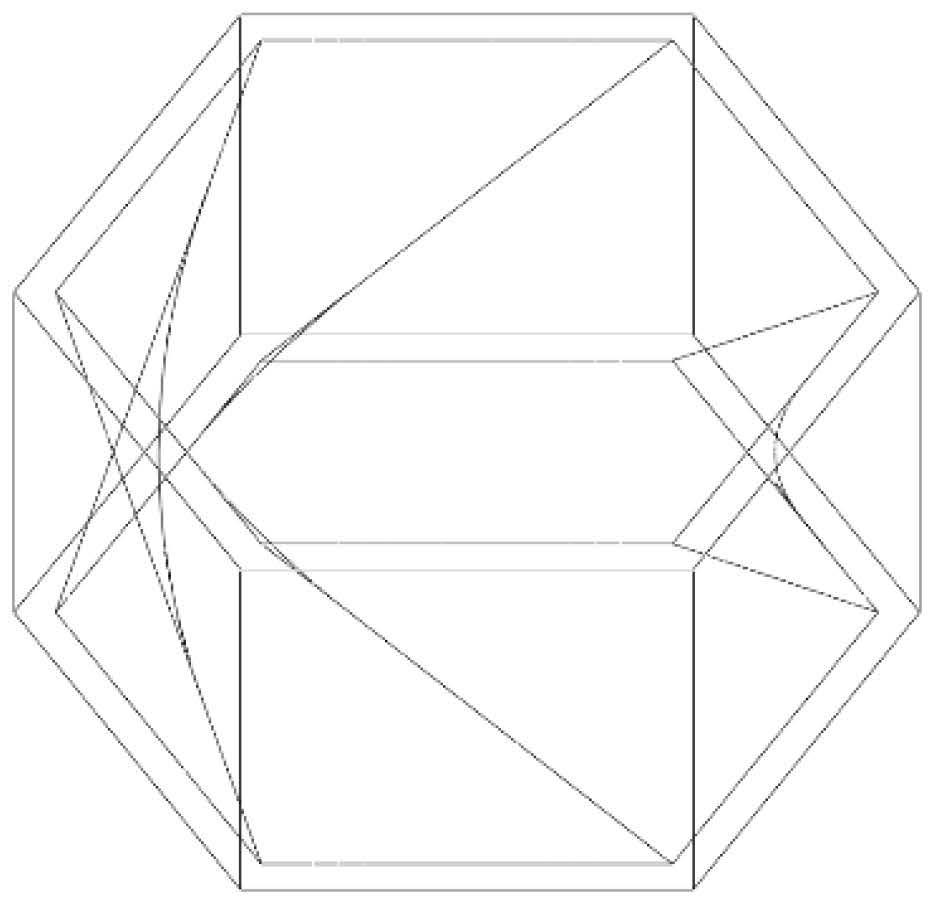

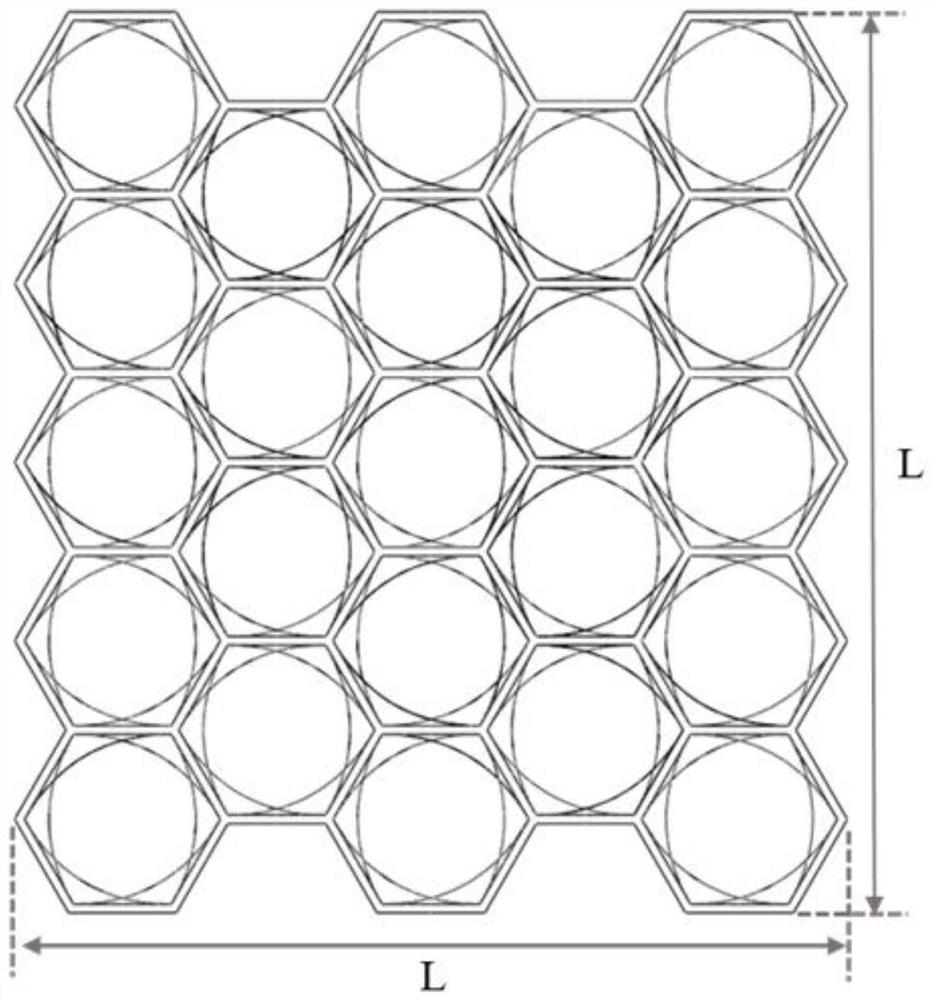

Internal torsion honeycomb structure material and preparation method thereof

ActiveCN114542635AIncrease stiffnessImprove featuresAdditive manufacturing apparatusSpringsPolymer scienceEnergy absorption

The invention relates to an internal torsion honeycomb structure material and a preparation method thereof, and belongs to the technical field of honeycomb materials. The internal torsion honeycomb structure material is composed of a plurality of internal torsion hexagonal honeycomb structure cell units which are arranged in a topological array mode, and the cross section of the outer layer cell wall of each internal torsion hexagonal honeycomb structure cell unit is in a regular hexagon shape. The inner-layer cell wall of each internally-twisted hexagonal honeycomb structure cell unit consists of twisted curved surfaces which are connected in sequence, and the adjacent internally-twisted hexagonal honeycomb structure cell units share the outer-layer cell wall. According to the invention, the inner-layer cell wall of the hexagonal honeycomb is twisted, and the energy absorption characteristic and the specific stiffness performance of the honeycomb structure are regulated and controlled by adjusting the process parameters such as the twisting angle, the cell thickness, the side length, the height and the like; compared with a traditional hexagonal honeycomb structure material, the internal torsion honeycomb structure material has higher specific energy absorption and specific stiffness.

Owner:CHENGDU UNIV

Four-cell metal tube for scientific research

InactiveCN106769078AIncrease specific energy absorptionImprove energy absorptionVehicle shock testingEngineeringMetal

The invention relates to a four-cell metal tube for scientific research. The our-cell metal tube for scientific research comprises a body, where the body is a conic thin-wall tube, the body is internally provided with a crossed tube wall, the tube wall extends from the top end of the body to the bottom end, the middle portion of the body is provided with an inner-concave preformed deformation groove, an upper portion of the preformed deformation groove is provided with an upper acceleration sensor, a lower portion of the preformed deformation groove is provided with a lower acceleration sensor, and the upper acceleration sensor and the lower acceleration sensor are respectively provided with leads for transmitting signals out. According to the four-cell metal tube, after the acceleration sensors are arranged at different positions, speed change of different portions in a deformation process can be tested respectively, an actual deformation process is detected, and better bases are provided for scientific research.

Owner:成都贝恩云广告传媒有限公司

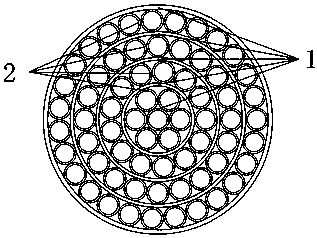

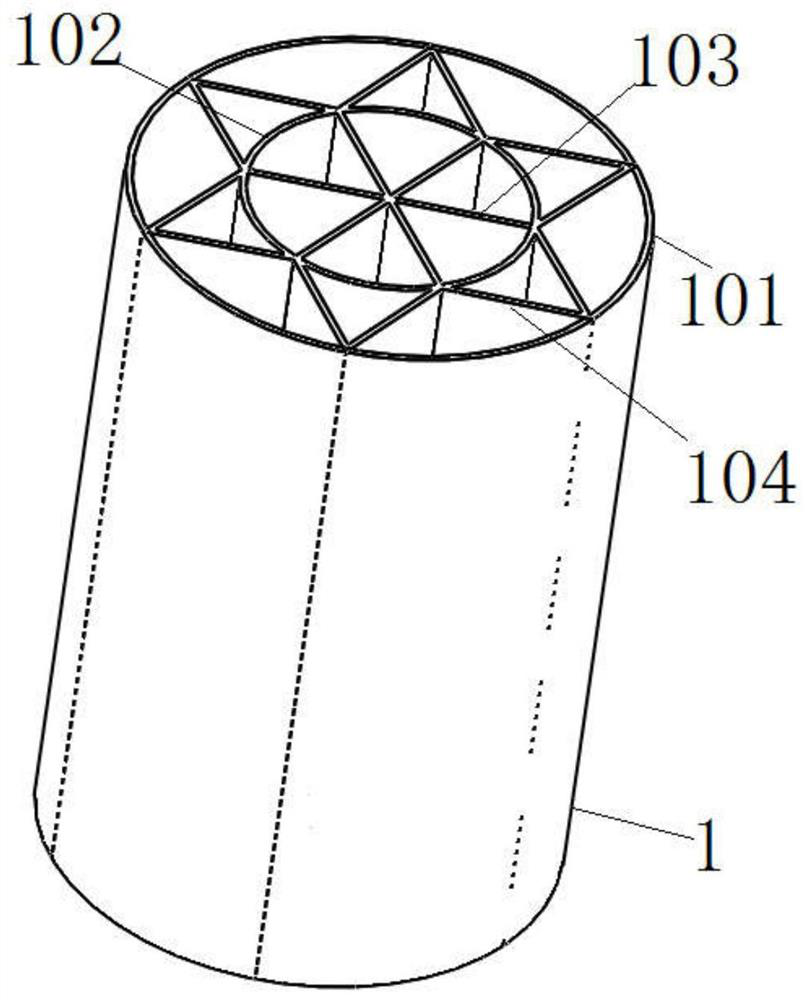

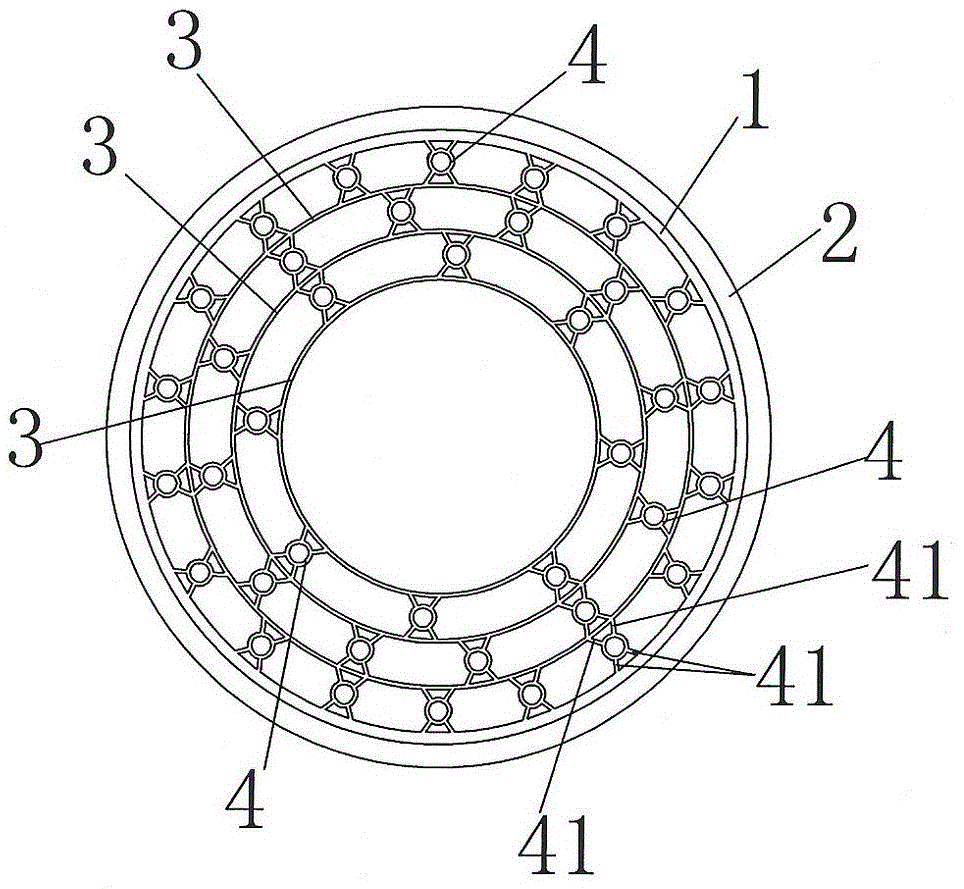

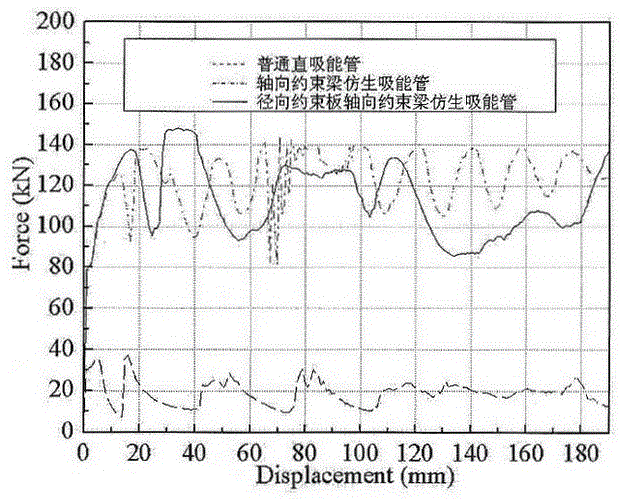

A bionic energy-absorbing tube with imitation bamboo structure

InactiveCN102826060BImproved ability to absorb energy axiallyIncrease specific energy absorptionBumpersEnergy absorptionEngineering

The invention discloses a bionic energy absorption pipe of a bamboo-like structure, comprising a cylindrical outer pipe, a plurality of restraining rings, a plurality of restraining walls and a plurality of restraining beams, wherein the plurality of restraining rings are equidistantly arranged on the cylindrical outer pipe, each restraining wall is cylindrical, the plurality of restraining walls are sleeved in the cylindrical outer pipe, the plurality of restraining beams are arranged between the cylindrical outer pipe and the restraining walls and between the adjacent restraining walls, each restraining beam is connected with the adjacent two restraining walls through two supporting plates, and the restraining beams are in shapes of circular tubes; and the distribution density rho of the restraining beams is equal to n / 2paiR, the rho represents the density of the restraining beams, the n represents the number of each layer of the restraining beams, and the R represents the radius of a circle in which the centers of the restraining beam are located. The bionic energy absorption pipe disclosed by the invention improves the capability of axially absorbing energy, namely improving the SEA (specific energy absorption), and also improving the transverse bearing capability.

Owner:JILIN UNIV

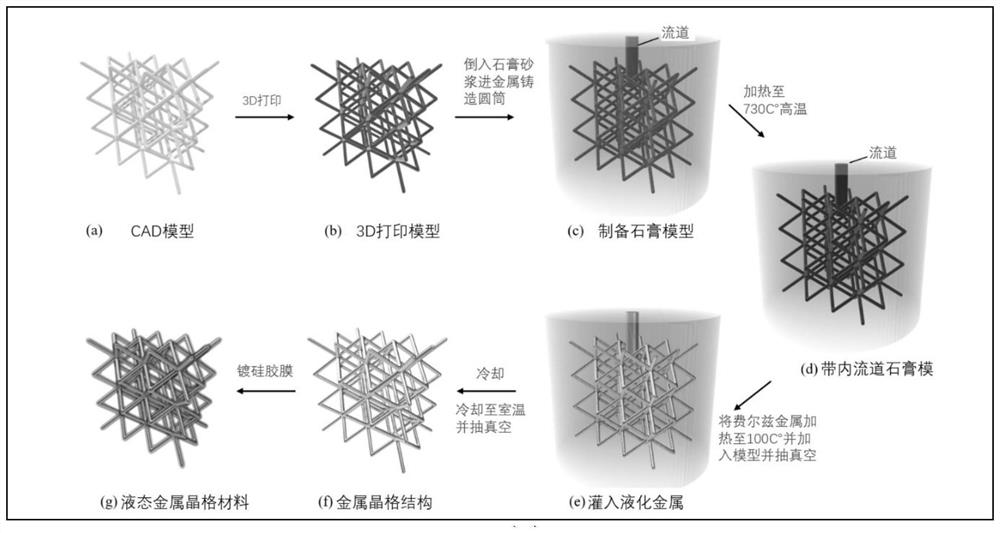

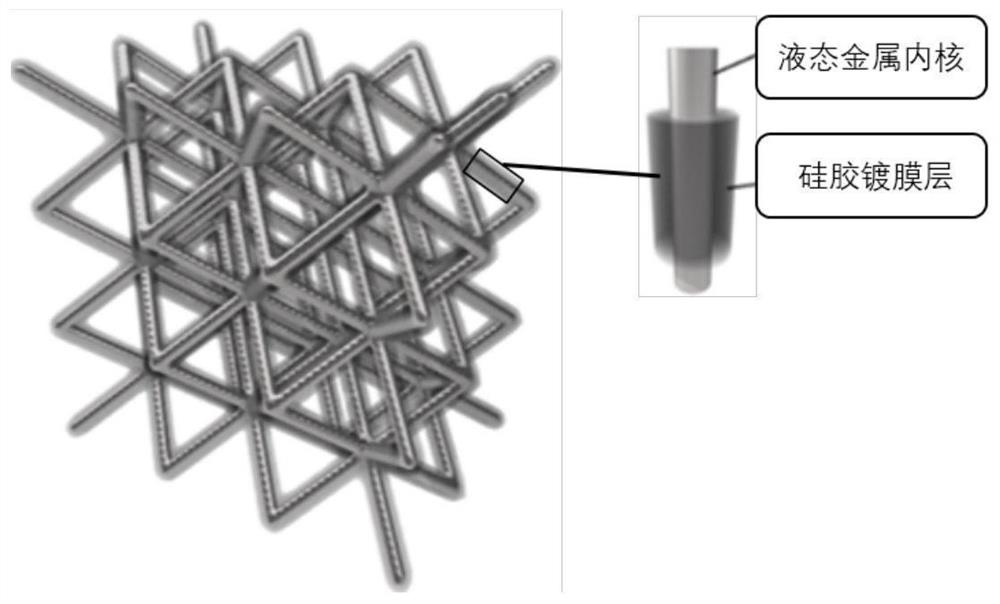

Preparation method of lattice structure metamaterial based on liquid metal

PendingCN114260424AIncrease specific energy absorptionReduce viscosityAdditive manufacturing apparatusFoundry mouldsLiquid metalMetal lattice

The invention discloses a preparation method of a lattice structure metamaterial based on liquid metal. The preparation method comprises the following steps: carrying out light curing molding on lattice units by adopting waxy photosensitive resin, and carrying out 3D printing by combining with a DLP additive manufacturing process to obtain a waxy lattice unit model; the wax lattice unit model is covered with gypsum mortar and a cylindrical high-temperature-resistant shell and placed at the normal temperature till gypsum is hardened; heating the product in a high-temperature heating furnace until the wax lattice unit model is completely vaporized and an internal porous runner is formed; liquid metal is poured into the wax lattice unit model until the porous runner is fully filled, and a metal lattice structure core is obtained; a super-elastic silica gel shell is formed in an immersion coating mode; carrying out curing treatment on the Falz metal lattice structure subjected to film coating; the prepared lattice structure metamaterial based on the liquid metal can achieve the shape memory function of external force and temperature regulation and control, and due to the external elastic layer, the function of recovery after repeated strain bearing can be achieved.

Owner:重庆交通大学绿色航空技术研究院

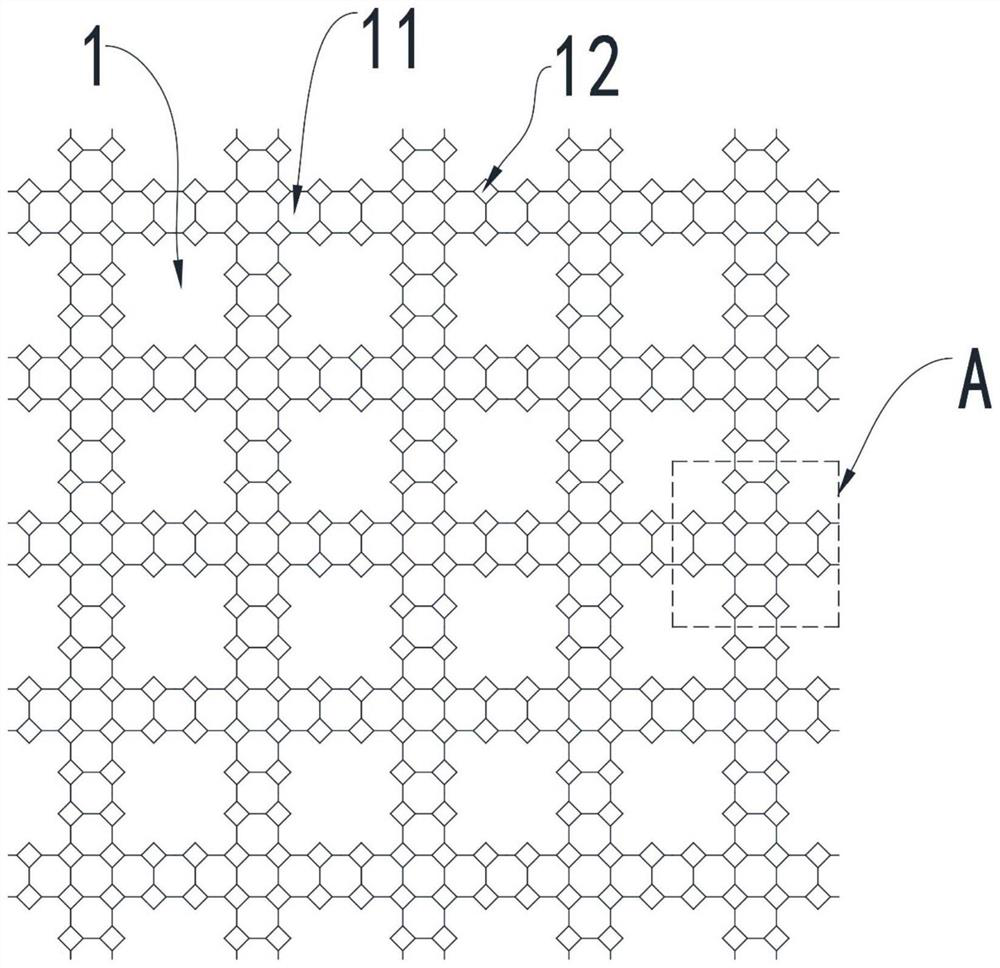

A semi -open pore grid super material and its additive manufacturing method

ActiveCN114178549BHigh specific stiffnessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyPowder bed

Owner:HUAZHONG UNIV OF SCI & TECH +1

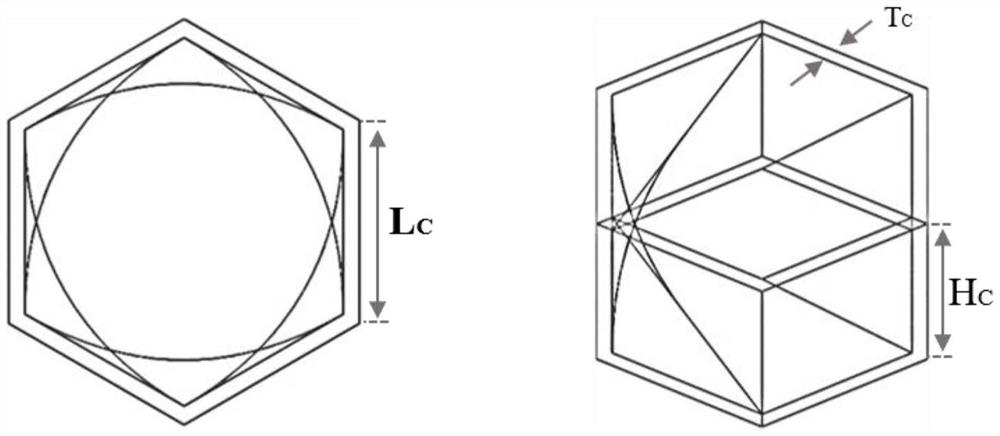

Multi-stage honeycomb structure and design method

PendingCN113819175AImprove energy absorptionEasy to adjustShock absorbersEnergy absorptionEngineering

The invention relates to the technical field of honeycomb structures and particularly relates to a multi-stage honeycomb structure and a design method. The cell wall of the multi-stage honeycomb structure comprises cell walls of a plurality of first-stage honeycomb cell elements which are connected to replace honeycomb cell elements; first-stage real nodes are replaced by second-stage honeycomb cell elements; the whole structure meets the limitation of parameters of the multi-stage structure; compared with the traditional honeycomb structure, the energy absorption performance is higher when working conditions, masses and volumes are same; according to the design method, the cell walls of the honeycomb cells are replaced by the plurality of first-stage honeycomb cells which are connected, the first-stage real nodes are replaced by the second-stage honeycomb cells; various multi-stage structure parameters are introduced, so that the geometric configuration of the multi-stage honeycomb structure can be conveniently adjusted; the large-range regulation and control of the energy absorption performance of the honeycomb structure can be realized; and engineering requirements can be met. Compared with the traditional honeycomb structure, the designed multi-stage honeycomb structure has higher specific energy absorption when the working conditions, the masses and the volumes are same.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com