Sandwich structure applied to automobile crash energy-absorption box

A collision energy absorption and sandwich technology, which is applied to vehicle components, layered products, chemical instruments and methods, etc., can solve the problems of failing to meet the requirements of safety, light weight and environmental protection, failing to achieve better results, and high peak stress , to achieve the effects of small mass, improved energy absorption efficiency, and reduced peak stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The description will be further elaborated below in conjunction with specific embodiments. It should be noted that: the following examples are only used to illustrate the present invention and do not limit the technical solutions described in the present invention, and all technical solutions and improvements thereof that do not depart from the scope of the present invention should be included in the claims of the present invention.

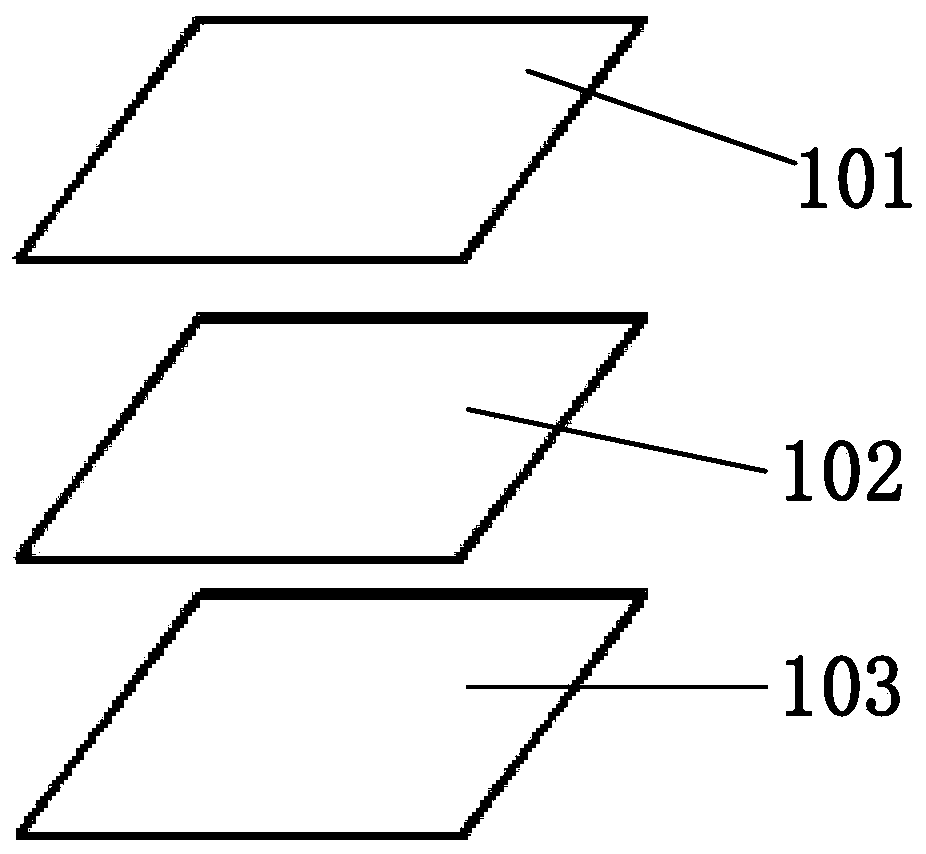

[0023] What the present invention provides is a kind of sandwich structure applied to the crash box of the automobile, such as figure 1 As shown, it includes an upper composite board 101 , a composite interlayer 102 , and a bottom composite board 103 .

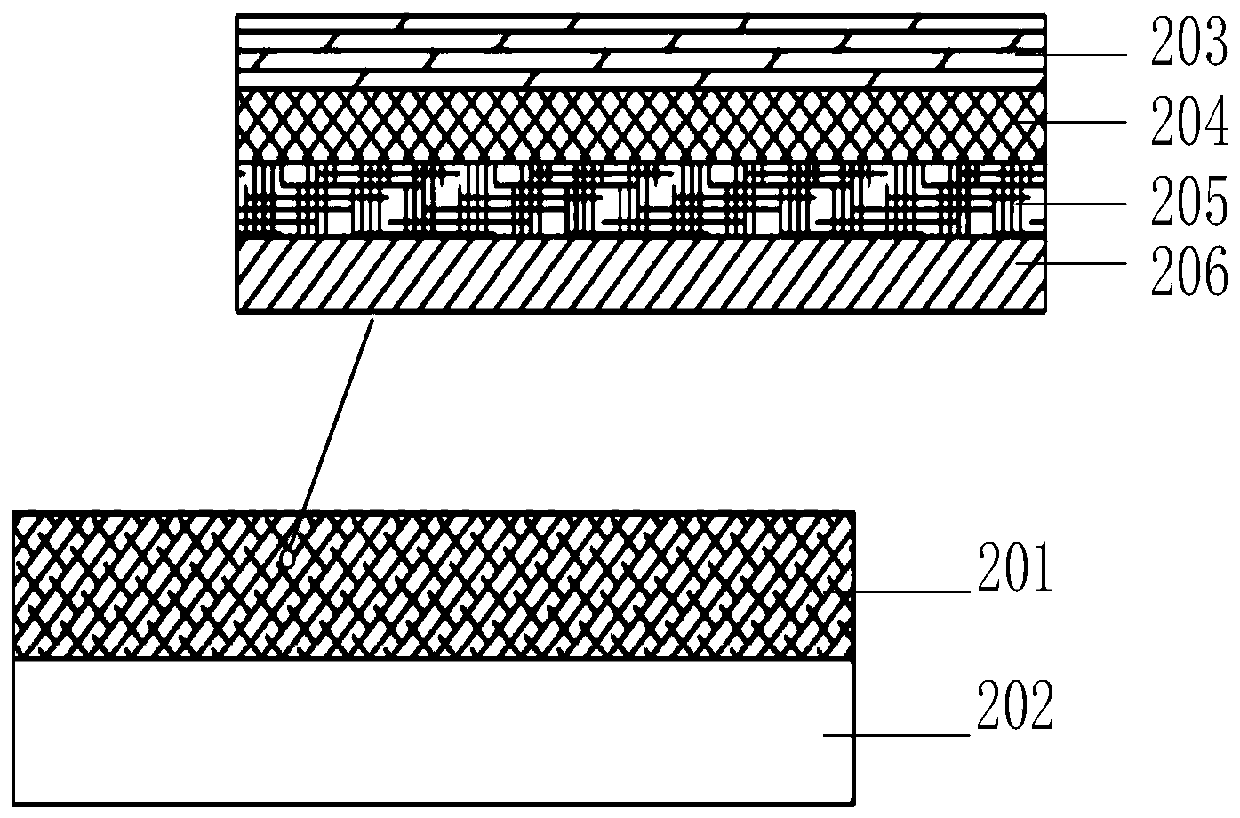

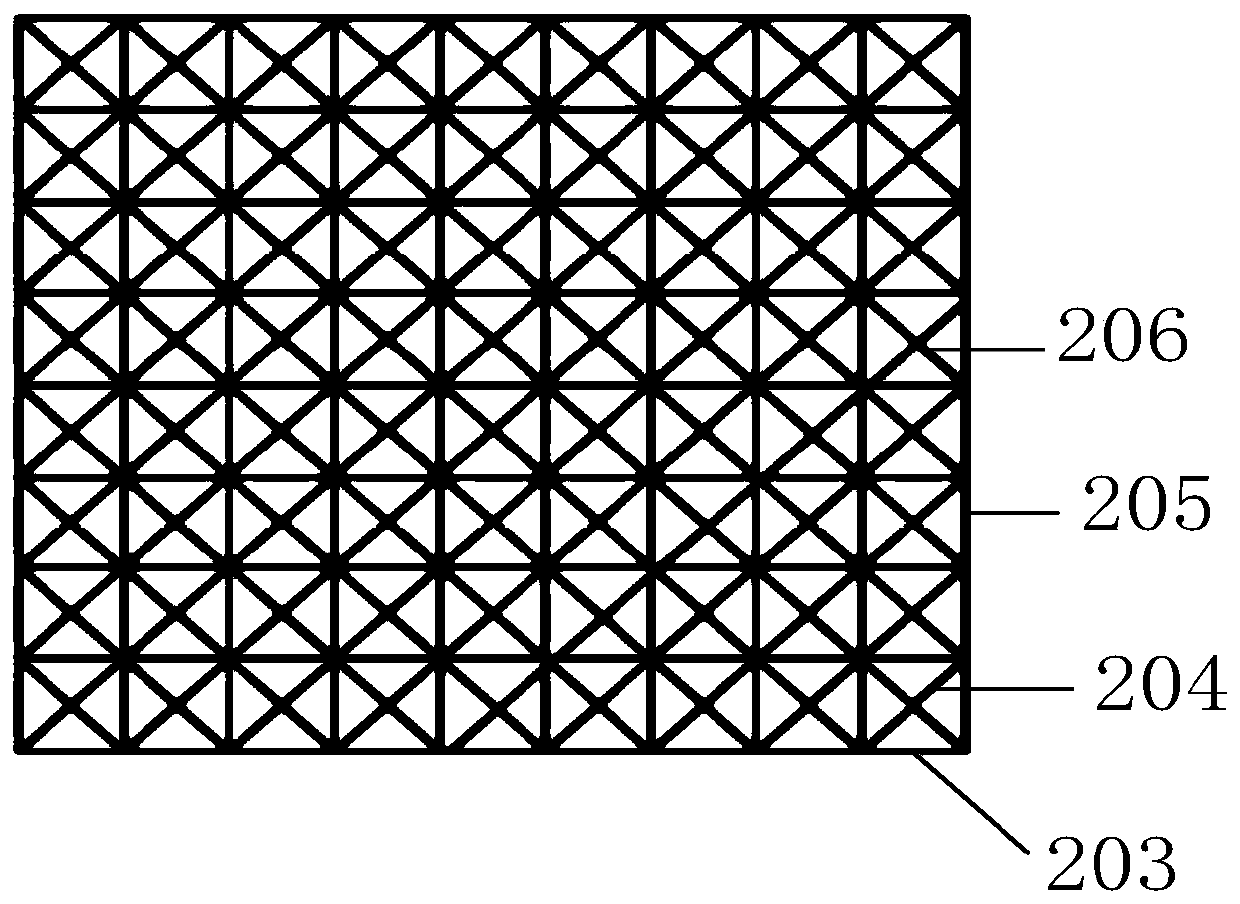

[0024] Among them, 101 upper composite boards such as figure 2 with image 3 As shown, it includes a composite material fiber cloth 201 and a titanium metal plate 202; the composite material fiber cloth 201 is composed of aramid fiber 203, carbon fiber 204, glass fiber 205 and metal fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com