Single crystal cell metal tube for absorbing energy during vehicle collision

A metal tube, single cell technology, used in bumpers and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

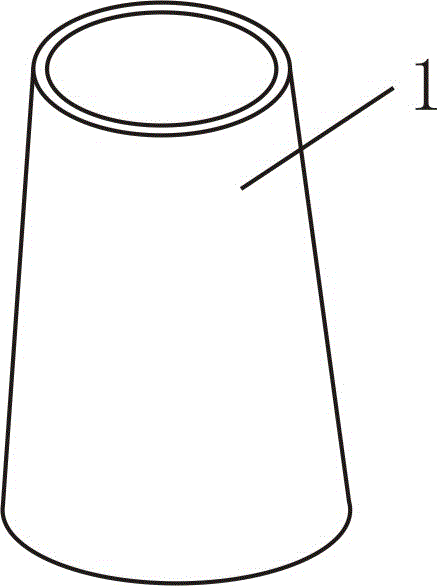

[0010] -Such as figure 1 As shown, the single cell metal tube used for energy absorption when the car is collided is characterized in that the main body 1 is a tapered thin-walled tube. Body 1 has a taper of 0.3. The ratio of the wall thickness to the height of the main body 1 is 1:15-1:30, and the optimal ratio is 1:25.

[0011] We established different simulation models to obtain initial peak load (IPL) and specific energy absorption (SEA), which are data characterizing energy absorption characteristics. These models have straight circular tubes and tapered tubes with three different tapers. The tapers of the tapered tube geometry models are 0.05, 0.1, 0.2 and 0.3, respectively. The three conical canals are the single-crystal cell spinal canal, the two-crystal cell spinal canal and the four-crystal cell spinal canal. Conical tubes with different tapers have the same maximum outer diameter. The geometric model is meshed with Hypermesh, and the pipe wall is made of LD2 alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com