Preparation method of lattice structure metamaterial based on liquid metal

A technology of lattice structure and liquid metal, applied in metal processing equipment, devices for coating liquid on the surface, manufacturing tools, etc., can solve limited problems, achieve wide application scenarios, rapid response and recovery of heat transfer performance, The effect of high specific energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

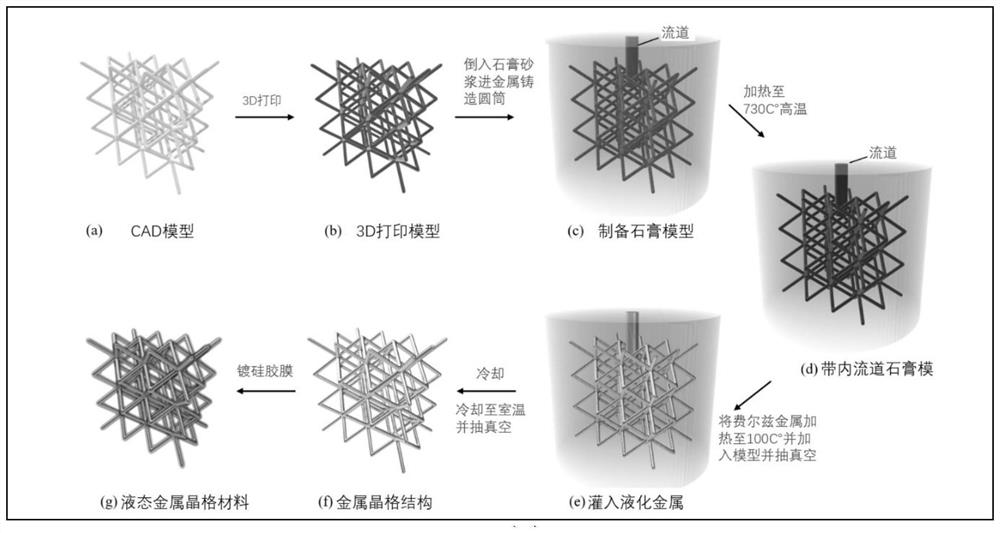

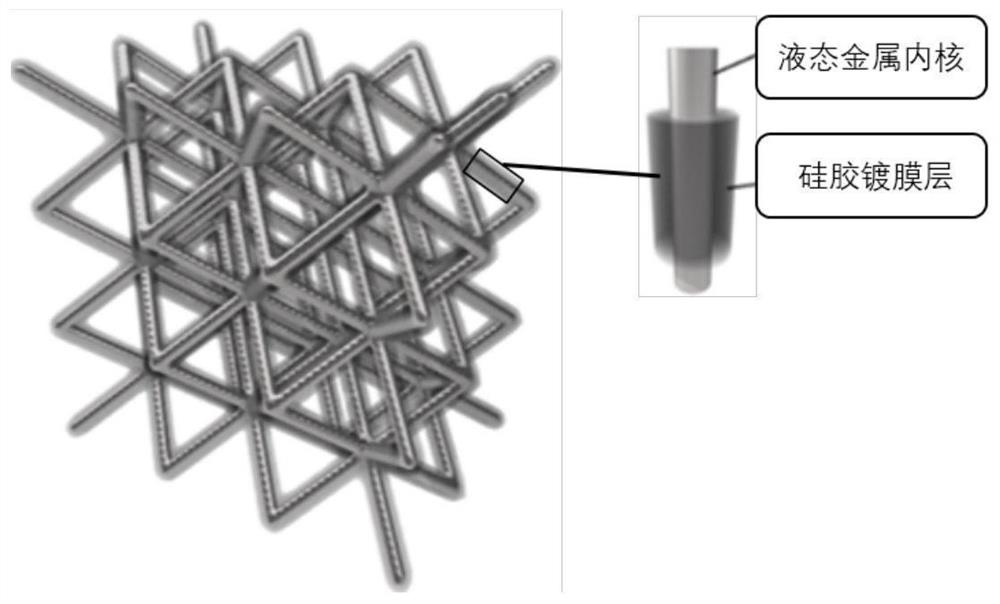

[0032] The preparation method of the liquid metal-based lattice structure metamaterial of this embodiment includes the following steps:

[0033] S1, using waxy photosensitive resin to light-cure the lattice unit and combine it with DLP additive manufacturing process for 3D printing to obtain a waxy lattice unit model:

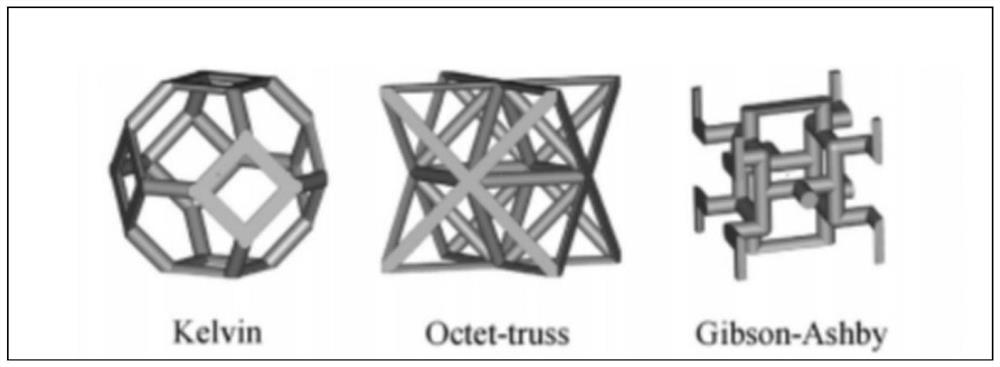

[0034] (1) Select the basic unit form of the lattice structure:

[0035] The lattice structure includes two types of lattices: truss and curved surface. Commonly used truss structures include Octet, BCC, FCC, etc., and curved surface lattice structures include Diamond, Primitive, etc. By evaluating the mechanical failure mode of connection points such as trusses and curved surfaces after loading, it can be judged whether it can be used to prepare liquid metal lattice structure metamaterials. If the main failure mode is tensile or fracture deformation, it is not suitable for the preparation of this preparation method. The present invention illustrates the prep...

Embodiment 2

[0048] The preparation method of the liquid metal-based lattice structure metamaterial of this embodiment includes the following steps:

[0049] S1, using waxy photosensitive resin to light-cure the lattice unit and combine it with DLP additive manufacturing process for 3D printing to obtain a waxy lattice unit model:

[0050] (1) Select the basic unit form of the lattice structure:

[0051] The lattice structure includes two types of lattices: truss and curved surface. Commonly used truss structures include Octet, BCC, FCC, etc., and curved surface lattice structures include Diamond, Primitive, etc. By evaluating the mechanical failure mode of connection points such as trusses and curved surfaces after loading, it can be judged whether it can be used to prepare liquid metal lattice structure metamaterials. If the main failure mode is tensile or fracture deformation, it is not suitable for the preparation of this preparation method. The present invention illustrates the prep...

Embodiment 3

[0064] The preparation method of the liquid metal-based lattice structure metamaterial of this embodiment includes the following steps:

[0065] S1, using waxy photosensitive resin to light-cure the lattice unit and combine it with DLP additive manufacturing process for 3D printing to obtain a waxy lattice unit model:

[0066] (1) Select the basic unit form of the lattice structure:

[0067] The lattice structure includes two types of lattices: truss and curved surface. Commonly used truss structures include Octet, BCC, FCC, etc., and curved surface lattice structures include Diamond, Primitive, etc. By evaluating the mechanical failure mode of connection points such as trusses and curved surfaces after loading, it can be judged whether it can be used to prepare liquid metal lattice structure metamaterials. If the main failure mode is tensile or fracture deformation, it is not suitable for the preparation of this preparation method. The present invention illustrates the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com