Internal torsion honeycomb structure material and preparation method thereof

A technology of honeycomb structure and internal torsion, which is applied in the direction of additive processing, weight reduction, springs, etc., can solve problems such as shear damage, and achieve the effect of high stiffness and energy absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

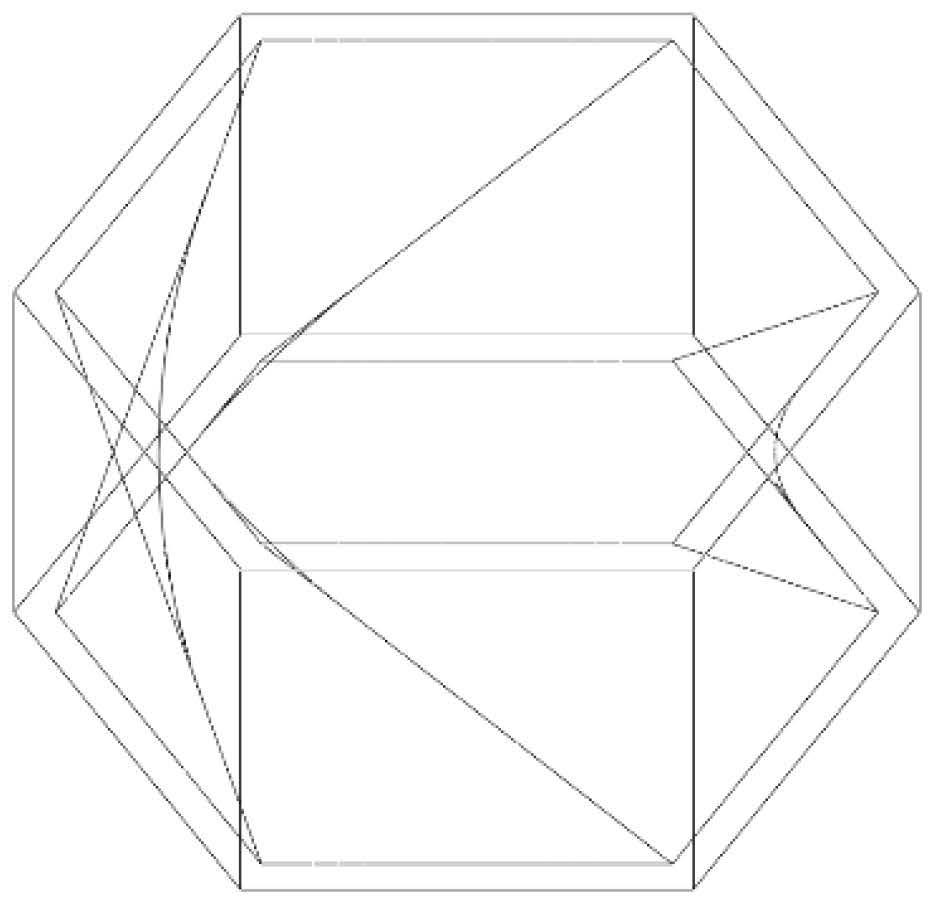

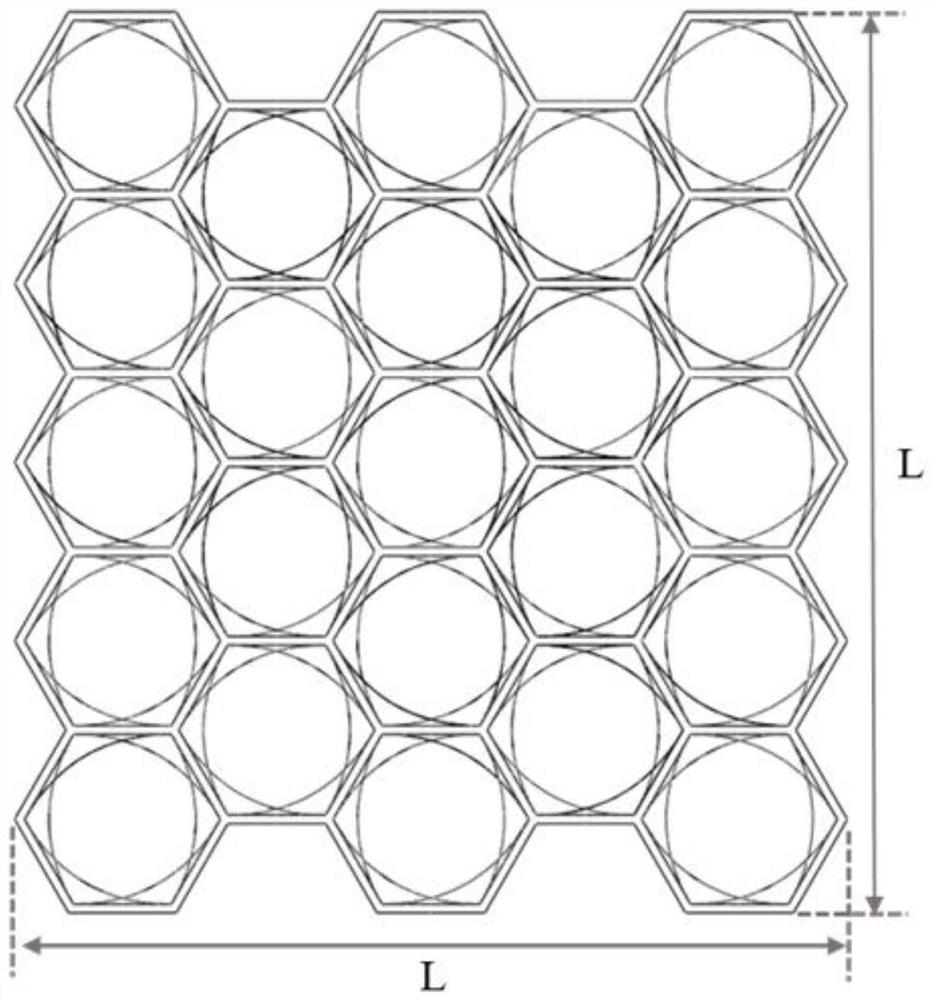

[0026] Example 1: An internal torsional honeycomb structure material (see Figures 1 to 3 ), composed of several internal torsional hexagonal honeycomb cell cell cells arranged in a topological array, the cross-section of the outer cell wall of each inner torsional hexagonal honeycomb structure cell cell unit is a regular hexagon, and the inner cell wall of each inner torsional hexagonal honeycomb structure cell cell unit is composed of torsional surfaces that are successively connected; adjacent internal torsional hexagonal honeycomb structure cell units share the outer cell wall;

[0027] The adjacent outer cell wall of the inner torsional hexagonal honeycomb structure cell unit is vertically connected, the upper torsional surface within the inner torsional hexagonal honeycomb structure cell unit is misaligned and connected with the lower torsional surface, and the vertices of the adjacent torsional surface are connected;

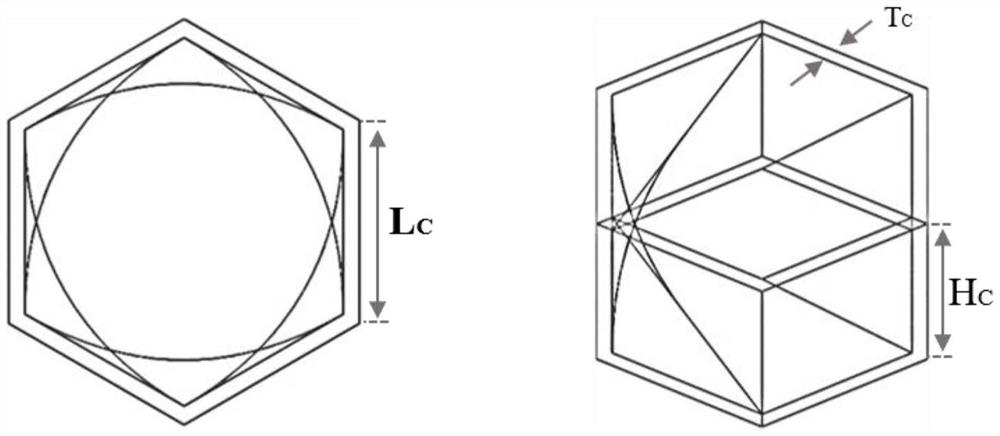

[0028] The edge length of the cell cell unit of the inte...

Embodiment 2

[0031] Example 2: The preparation method of the internal torsional honeycomb structure material described in Example 1, the specific steps are as follows:

[0032] (1) Design the inner torsional hexagonal honeycomb structure cell cell unit: the cross-section of the outer cell wall of the inner torsional hexagonal honeycomb structure cell unit is regular hexagonal, and the adjacent outer cell wall is vertically connected; the inner layer cell wall is a torsional surface that is successively connected, the upper torsional surface is misaligned with the lower torsional surface, and the vertices of the adjacent torsional surface are connected, and the torsion angle θ is 30 ° ~ 75 °; the cell wall thickness of the inner torsional hexagonal honeycomb structure cell unit is adjusted to adjust the relative density of the internal torsional honeycomb structure material to the preset value , where the preset value is between 0.1 and 0.5;

[0033] (2) The internal torsional hexagonal honeyco...

Embodiment 3

[0035] Example 3: Preparation method of internal torsional honeycomb structure material, the specific steps are as follows:

[0036] (1) Design of inner torsional hexagonal honeycomb structure cell cells: the cross-section of the outer cell wall of the inner torsional hexagonal honeycomb structure cell cell is a regular hexagon, and the adjacent outer cell wall is vertically connected; the inner layer cell wall is a torsional surface that is successively connected, the upper torsional surface is misaligned with the lower torsional surface, the vertices of the adjacent torsional surface are connected, and the torsional angle θ is 45° (the edge length of the inner torsional hexagonal honeycomb structure cell cell is equal to Lc and the height is Hc) By adjusting the cell wall thickness of the cell unit of the internal torsion hexagonal honeycomb structure t to adjust the relative density of the internal torsional honeycomb structure material to 0.237;

[0037](2) The internal torsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com