Multi-stage honeycomb structure and design method

A design method and level honeycomb technology, applied in mechanical equipment, shock absorbers, springs/shock absorbers, etc., can solve the problem of difficult to meet the needs of use, and achieve the effect of high energy absorption performance and high specific energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

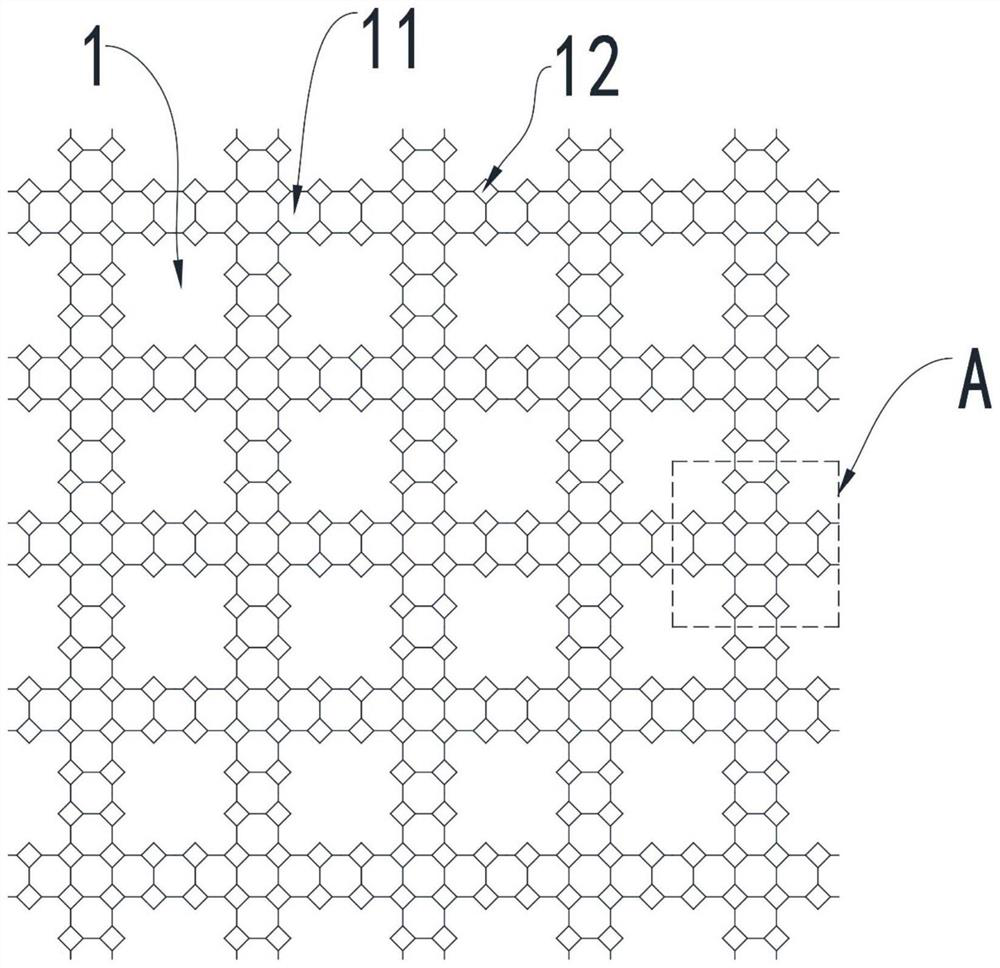

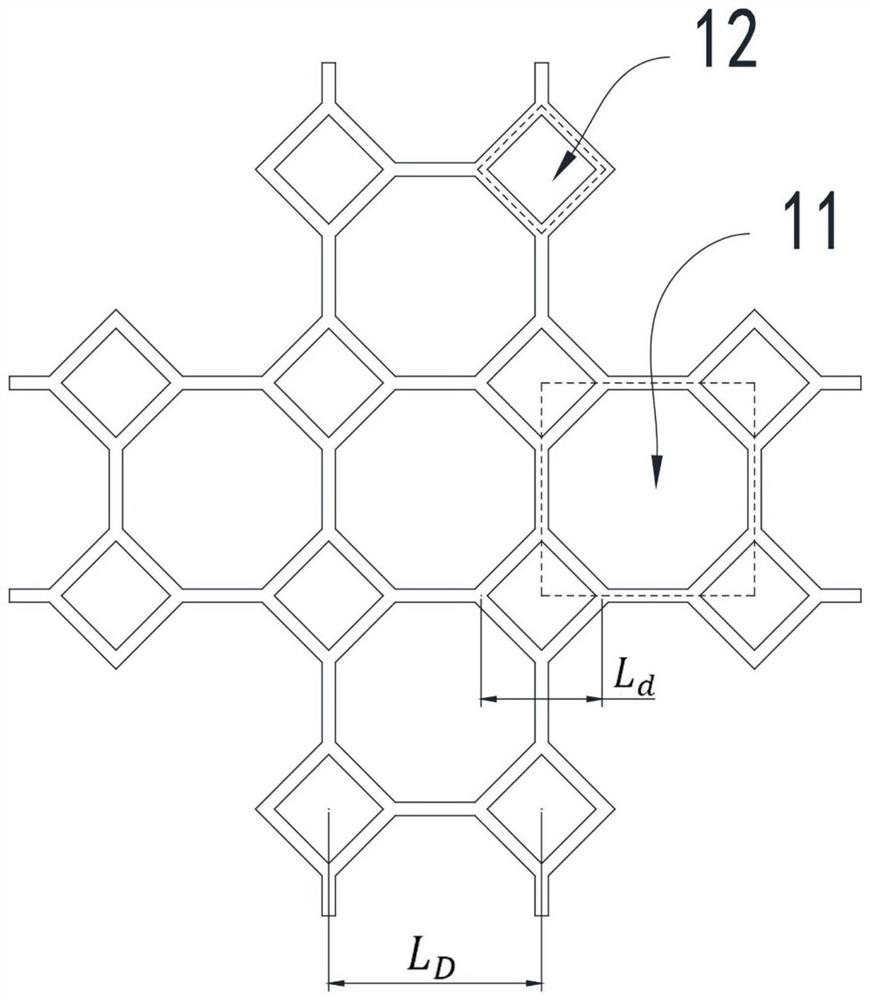

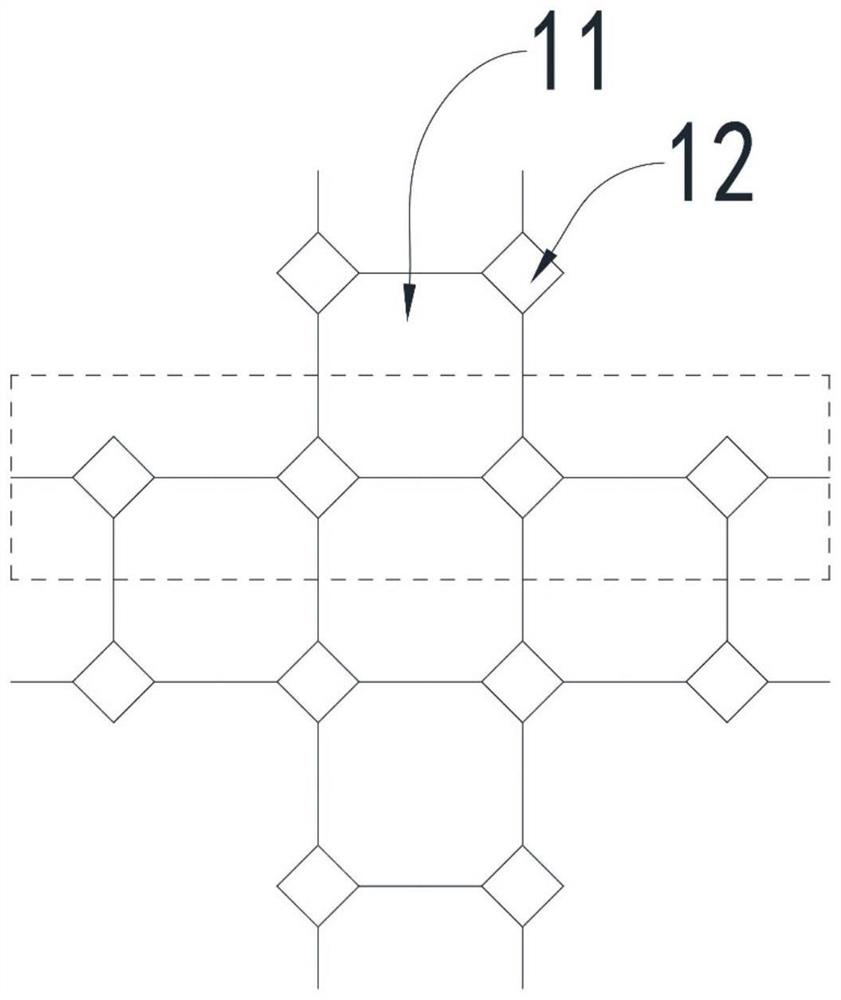

[0056] see figure 1 and figure 2 As shown, a multi-stage honeycomb structure provided by the embodiment of the present invention includes a plurality of honeycomb cells 1, the cross section of the honeycomb cells 1 is a regular quadrilateral, and the cell walls of the honeycomb cells 1 include a plurality of connected primary honeycomb cells. Cell 11, the first-level honeycomb unit 11 is a regular quadrilateral, the intersection of the cell walls of the first-level honeycomb unit 11 is a first-level real node, and each first-level honeycomb unit 11 has 4N first-level real nodes, where N =1, the first-level real node is replaced by the second-level honeycomb cell 12, that is, the position of the first-level real node is replaced by the second-level honeycomb cell structure. After the first-level real node is replaced by the second-level honeycomb cell unit 12, the intersection of the cell walls of the first-level honeycomb unit 11 is a second-level honeycomb unit, which will ...

Embodiment 2

[0073] The confirmation and adjustment of the multi-level structure parameters in the second embodiment and the first embodiment are basically the same, and the similarities will not be repeated. The difference is that the cross section of the honeycomb cell 1 is a regular hexagon, and the cell wall of the honeycomb cell 1 It includes a plurality of connected first-level honeycomb cells 11. The first-level honeycomb cells 11 are regular polygons. A first-level real node, the first-level real node is replaced by a second-level cellular unit 12, and the second-level cellular unit 12 is a regular polygon or a circle. When the second-level cellular unit 12 is a regular polygon, the second-level cellular unit 12 The intersection of the cell walls is a second-level real node, and each second-level honeycomb cell 12 has 3M second-level real nodes, wherein: N and M are both positive integers.

[0074] Including n secondary honeycomb cells 12 in the cell wall length direction of the ho...

Embodiment 3

[0084] The design method of the multistage honeycomb structure that the present embodiment provides, comprises the following steps:

[0085] (1) Obtain the size and performance of the required honeycomb structure;

[0086] (2) Determine the shape and size of the honeycomb cells;

[0087] (3) A plurality of connected first-level honeycomb cells are used as the cell walls of the honeycomb cells, and the intersection of the cell walls of the first-level honeycomb cells is a first-level real node, and the second-level honeycomb cells are used to replace the first-level real nodes, The intersection of the cell walls of the second-level honeycomb cell is a second-level solid node, which determines the honeycomb shape of the first-level honeycomb cell and the second-level honeycomb cell;

[0088] When the cross-section of the cell is a regular hexagon, each primary cell has 3N secondary cells, and each secondary cell has 3M secondary real nodes or the number of secondary cells The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com