Carbon fiber honeycomb tube structure

A honeycomb tube and carbon fiber technology, applied in the design features of springs/shock absorbers, shock absorbers, springs, etc., can solve the problems of difficulty in achieving energy absorption, low specific energy absorption and specific strength, and cumbersome production steps, etc. Achieve the effect of light structure, low density and flexible preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment and accompanying drawing, technical scheme of the present invention is described further:

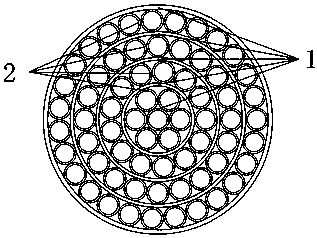

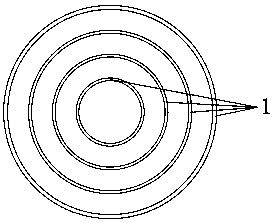

[0019] Such as figure 1 As shown, a carbon fiber honeycomb tube structure, including a large tube 1 and a small tube 2; the large tubes 1 are arranged in sequence from the inside to the outside, and there are N layers; each layer of large tubes 1 is arranged in parallel to form a concentric circle; the Nth layer of large tubes (1) Arranged on the outermost side of the honeycomb structure, the small tubes 2 are not filled in the large tubes 1 of the first layer, and the small tubes 2 are evenly filled between the large tubes 1 . 7N-8 identical small tubes 2 are evenly filled between the large tube 1 of the N-th layer and the large tube 1 of the N-1 layer; the outer diameter of the small tube 2 is equal to the inner diameter of the large tube 1 of the N-th layer minus the large tube of the N-1 layer 1 difference in outer diameter. Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com