Automobile front anti-collision beam structure and application thereof to automobiles

A front anti-collision beam, automobile technology, applied in vehicle components, vehicle safety arrangements, bumpers, etc., can solve problems such as increased maintenance costs, body frame damage, occupant safety threats, etc., to enhance structural stability and crashworthiness. , the effect of reducing the initial collision peak force and reducing the instantaneous acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

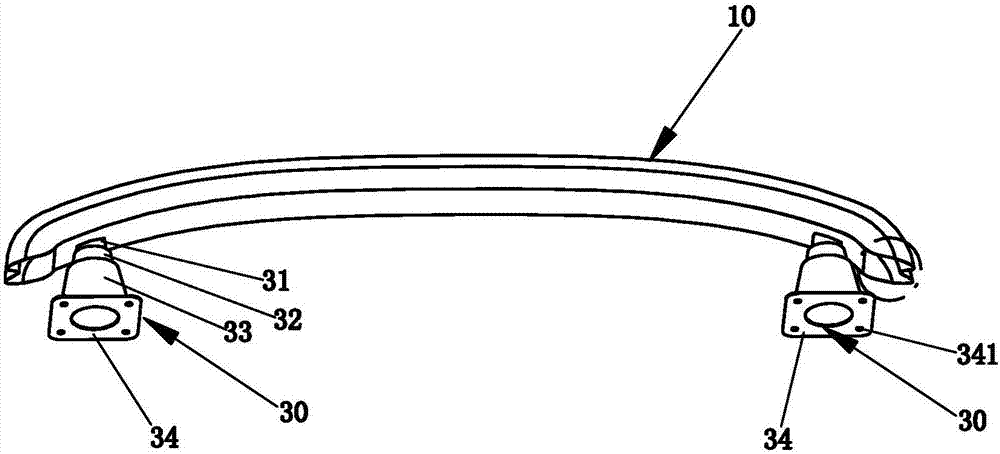

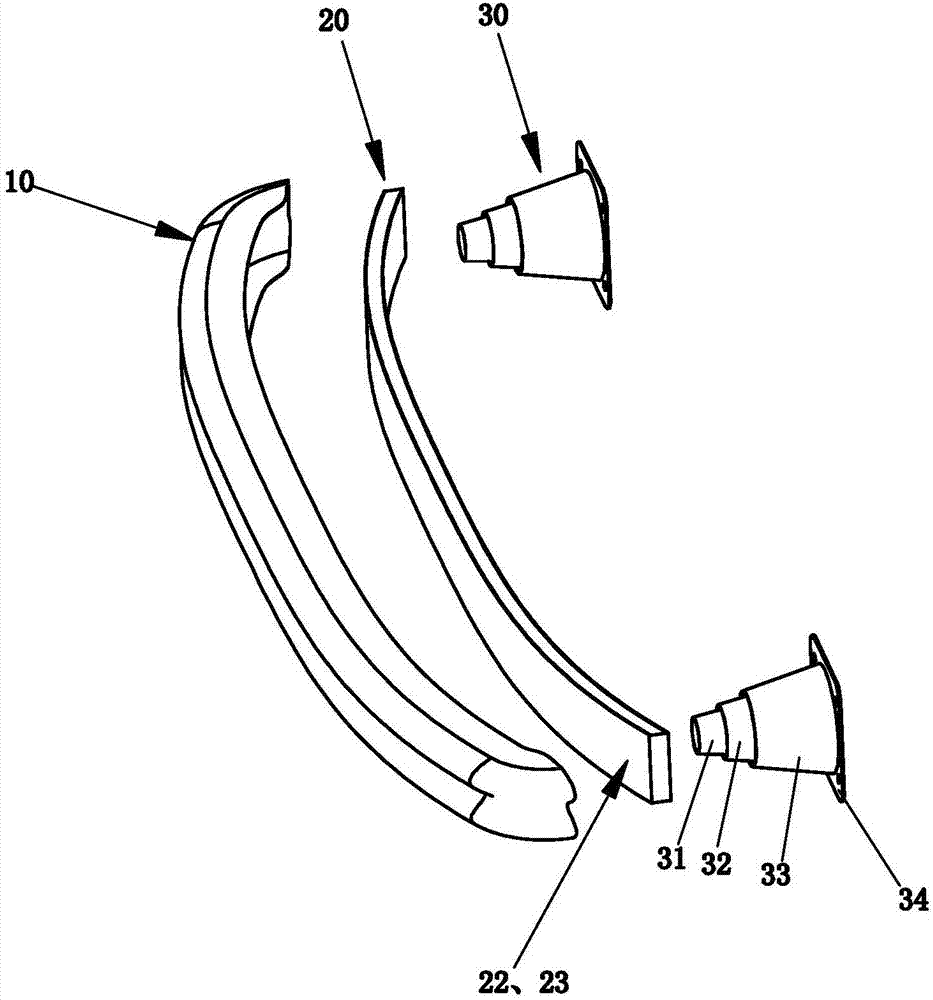

[0032] refer to Figure 1 to Figure 7 , the automobile front anti-collision beam structure, which includes a main beam 10, an inner panel 20 and an energy absorbing device 30.

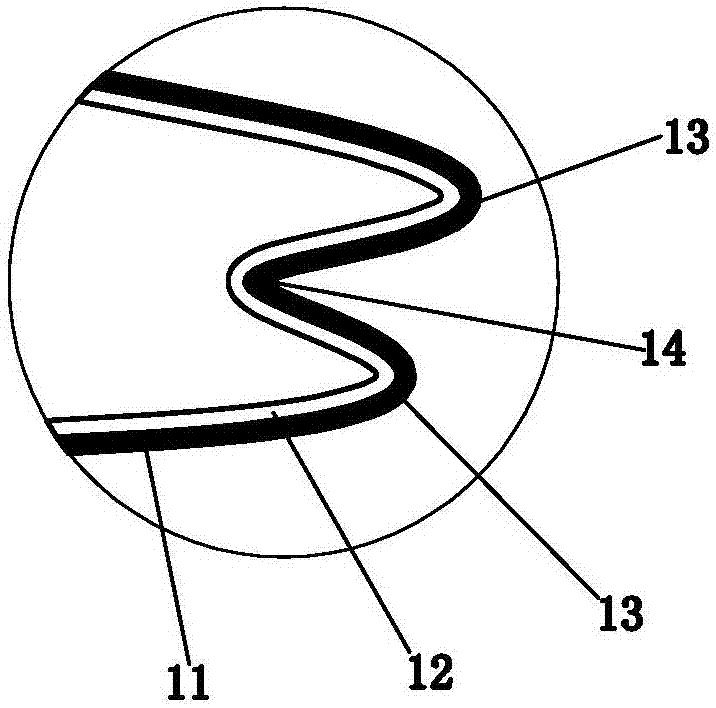

[0033] The main beam 10 includes a carbon fiber outer shell 11 and an aluminum inner shell 12, and the two are glued together, and the thickness of the carbon fiber outer shell 11 is 1-2 mm, and the thickness of the aluminum inner shell 12 is 1-2 mm. Not only can the crashworthiness of the main beam be improved, but also the aluminum inner shell and the carbon fiber outer shell are materials with light weight and good energy absorption effect, which is conducive to the realization of the purpose of lightweight, and can absorb part energy. In this embodiment, the thickness of the carbon fiber shell 11 is set to 2 millimeters, the thickness of the aluminum inner shell 12 is set to 2 millimeters, the total lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com