Semi-filled corrugated hybrid sandwich plate of foam material and preparation method of semi-filled corrugated hybrid sandwich plate of foam material

A foam material and foam filling technology, used in chemical instruments and methods, lamination, manufacturing tools, etc., can solve the problems of low lateral support strength and crush strength, improve local buckling performance, reduce plastic deformation, The effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

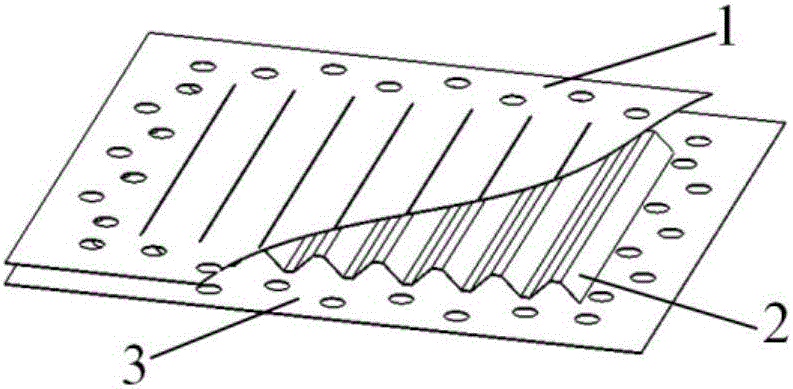

Embodiment example 1

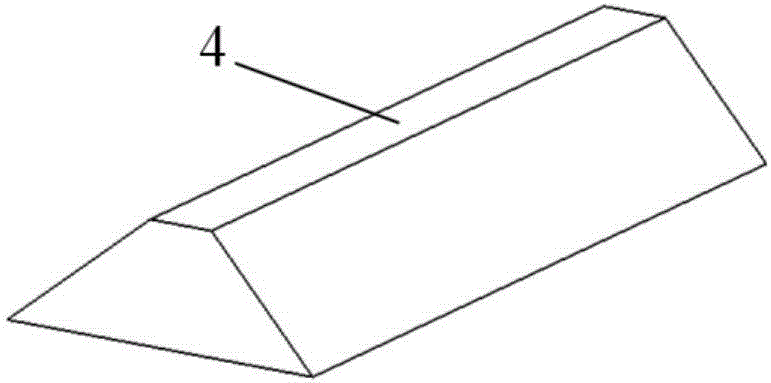

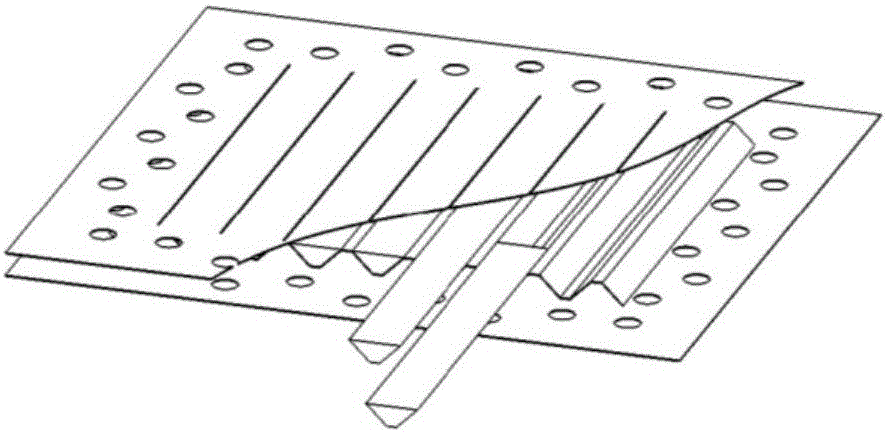

[0026] Implementation case 1: 1) Firstly, the 304 stainless steel plate is made into a corrugated core layer by molding and folding technology, and then cut into the design size by wire electric discharge cutting (EDM). The board is made of upper and lower panels by laser cutting technology. The in-plane size is 452mm long and 440mm wide. The corrugated core layer and the panel are cleaned to remove the residual oil in the process, and connected by laser welding technology. Filled corrugated sandwich panels; 2) Then, according to the size of the pores of the corrugated core layer, the foam sheet is cut into trapezoidal prisms that match the size of the pores; 3) Finally, the trapezoidal prism-shaped foam is filled to all In the pores of the corrugated core layer near the upper panel, a half-filled corrugated hybrid sandwich panel is obtained.

Embodiment example 2

[0027] Implementation case 2: 1) First, the 304 stainless steel plate is made into a corrugated core layer by molding and folding technology, and then cut into the design size by wire electric discharge cutting (EDM). The board is made of upper and lower panels by laser cutting technology. The in-plane size is 452mm long and 440mm wide. The corrugated core layer and the panel are cleaned to remove the residual oil in the process, and connected by laser welding technology. Filled corrugated sandwich panels; 2) Then, according to the size of the pores of the corrugated core layer, the foam sheet is cut into trapezoidal prisms that match the size of the pores; 3) Finally, the trapezoidal prism-shaped foam is filled to all In the pores of the corrugated core layer close to the side of the lower panel, a half-filled corrugated hybrid sandwich panel is obtained.

[0028] Adopt following experiment verification effect of the present invention:

[0029] Specimen Nos. TP-1 and TP-2 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com