Rectangular steel tube concrete column and construction method thereof

A technology of rectangular steel pipes and concrete columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of limiting the application of high-strength steel, restraining less than circular steel pipes, and wasting steel, and achieves improved local buckling performance, low cost, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

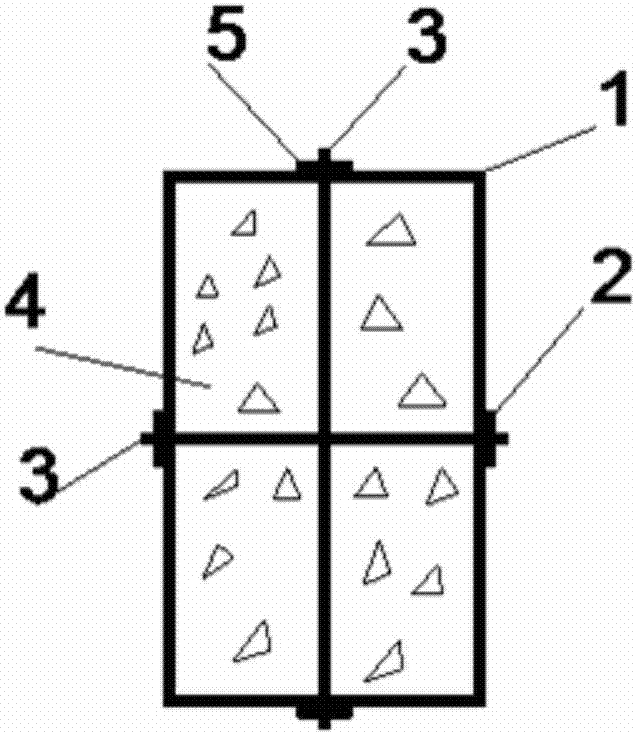

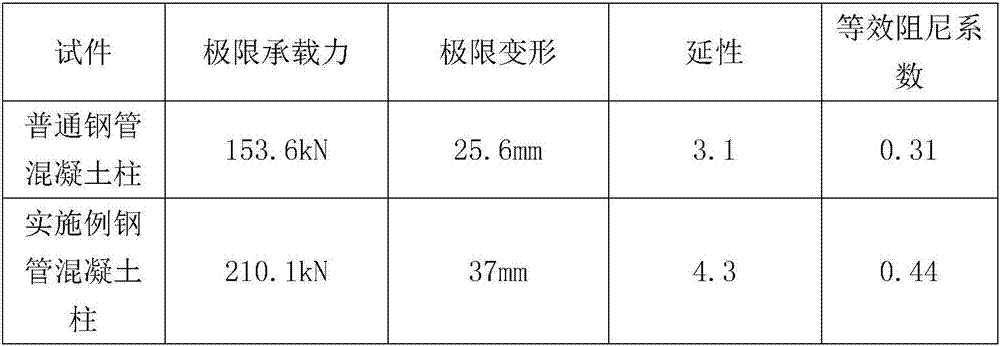

[0010] Embodiment of the present invention: rectangular steel pipe concrete column, including rectangular steel pipe 1, concrete column 4, a cross-shaped prestressed rod 3 is arranged in the middle of the rectangular steel pipe 1, and the end of the prestressed rod 3 is connected with a rectangular gasket. The gasket is attached to the outside of the rectangular steel pipe 1; the rectangular gasket includes a long-side rectangular gasket 2 attached to the long side of the rectangular steel pipe 1 and a short-side rectangular gasket 5 attached to the short side of the rectangular steel pipe 1; Among them, the side lengths of the long sides of the cross section of the concrete column 4 are respectively a, the side lengths of the long sides of the cross section of the concrete column 4 are respectively b, and the wall thickness of the rectangular steel pipe 1 is c; the diameter of the prestressed rod 3 is not less than 2.5c ; The thickness of the rectangular spacer is not less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com