A kind of dot matrix core structure and its cutting interlocking preparation method

A lattice and core technology, which is applied in the field of lattice core structure and its cutting and interlocking preparation, can solve the problems of poor buckling resistance, improve the ability to resist local buckling of the panel, improve energy absorption, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: a kind of method adopting cutting interlocking to prepare lattice core structure, described method comprises the steps:

[0057] Step 1: Cutting the interlocking strips: Use the wire electric discharge machine to cut multiple superimposed plates into multiple identical interlocking strips. The thickness of the superimposed plates is preferably about 20mm. 3.5 mm / min. During EDM cutting, the cutting accuracy can be ensured by properly adjusting the tightness of the cutting wire; Set, and connect the end to end in order to form an integral body;

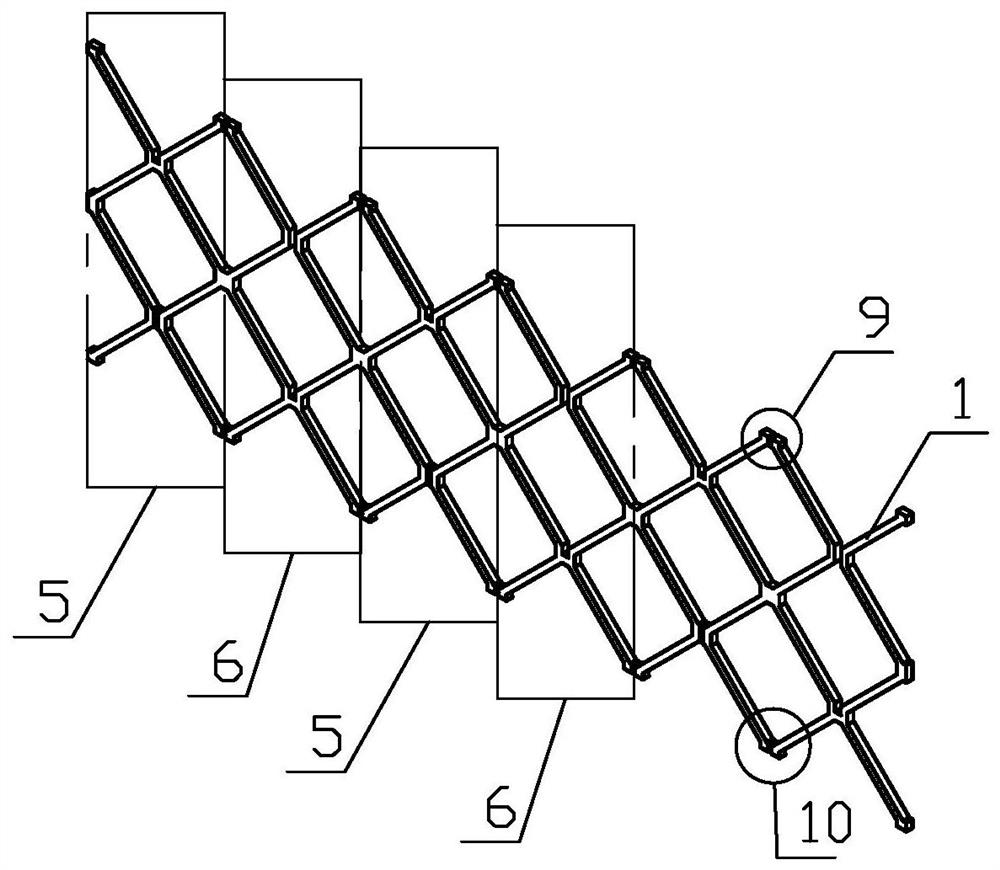

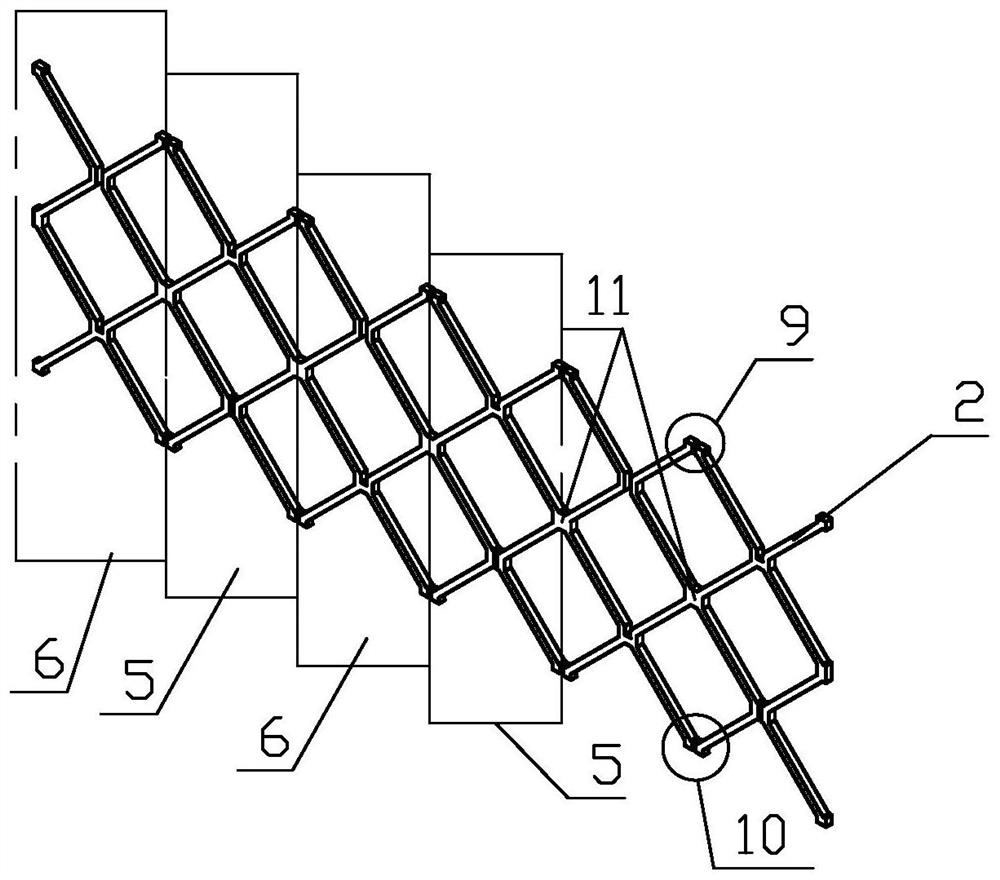

[0058] Step 2: Divide the interlocking strip: use an electric spark cutting machine to divide the interlocking strip into multiple first horizontal interlocking strips 1, multiple second horizontal interlocking strips 2, multiple first longitudinal interlocking strips 13 and multiple A second longitudinal interlocking strip 14;

[0059] Step 3: Assembling the dot matrix core: the first horizontal interlocking str...

Embodiment 2

[0061] Embodiment 2: a kind of method that adopts cutting interlocking method to prepare lattice core structure, described method comprises the following steps:

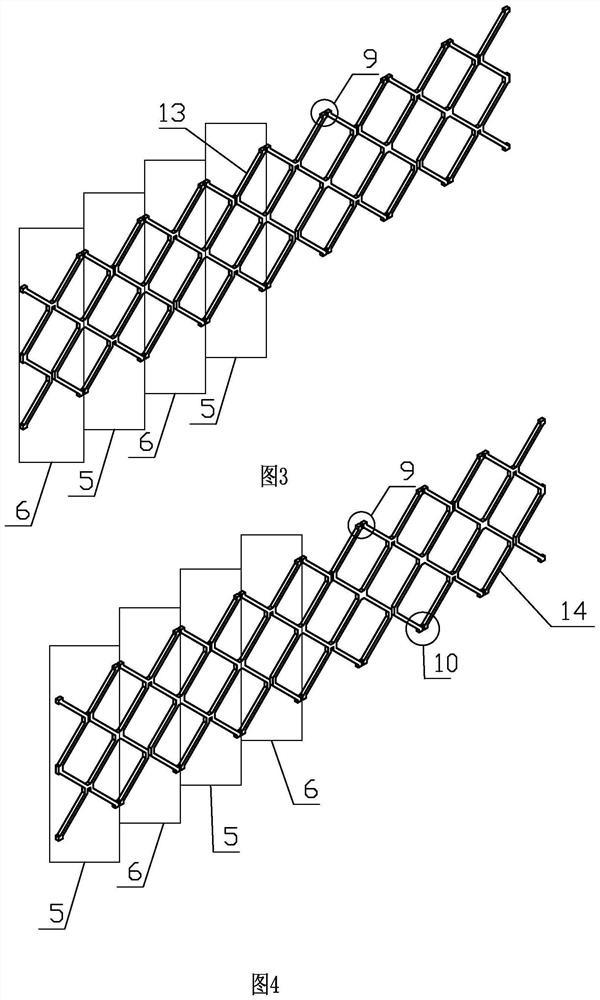

[0062] Step 1: Cutting the interlocking strips: using a laser cutting machine to cut the plate into interlocking strips, the interlocking strips are alternately arranged side by side by the first dot matrix unit 5 and the second dot matrix unit 6, and connected end to end in sequence integrally formed;

[0063] Step 2: Divide the interlocking strip: use a laser cutting machine to divide the interlocking strip into a plurality of first horizontal interlocking strips 1, a plurality of second horizontal interlocking strips 2, a plurality of first longitudinal interlocking strips 13 and a plurality of The second longitudinal interlocking strip 14;

[0064]Step 3: Assembling the dot matrix core: the first horizontal interlocking strip 1 and the second horizontal interlocking strip 2 are alternately arranged in parallel a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com