Single-hole double-signal double-sided backboard and manufacturing method thereof

A manufacturing method and dual-signal technology, which are applied in the directions of making wiring diagrams of printed circuits, manufacturing of printed circuits, and forming electrical connections of printed components, etc., can solve problems such as increasing the difficulty of development, increasing the weight of equipment, and prolonging the development cycle, so as to improve the node density. , to meet the needs of use, the effect of extensive use of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the specific implementation, structure, Features and their effects are described in detail below.

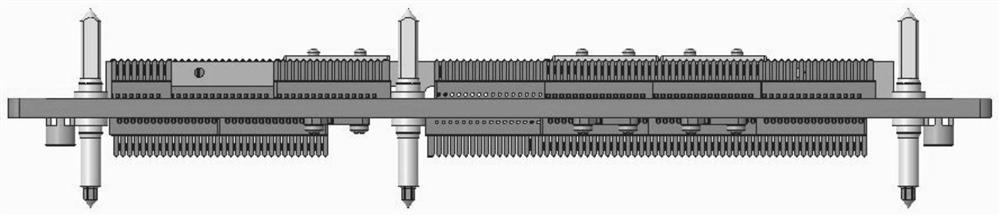

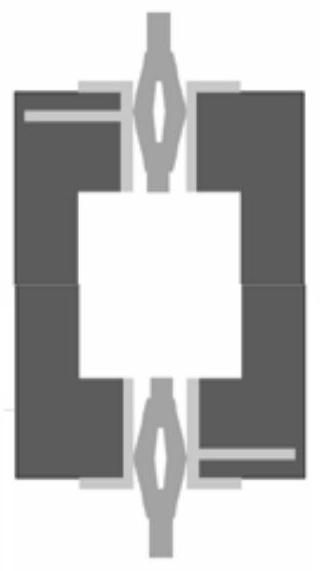

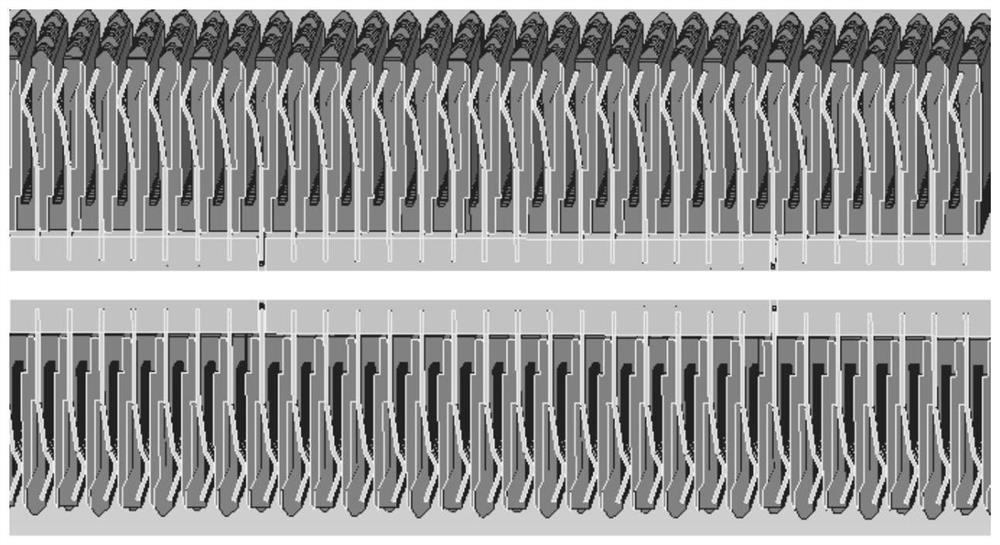

[0036] see Figure 1-4 , which is a schematic diagram of the structure of each part of the single-hole dual-signal double-sided backplane of the present invention, the single-hole dual-signal double-sided backplane includes a printed board 3, and the printed board 3 is provided with jacks 5 extending along the thickness direction. , the front board connector 1 fixed on the front face of the printed board 3 and the rear board connector 2 fixed on the rear face of the printed board 3 correspond to the printed board 3 through the pins protruding therefrom The cooperation of the jack 5 realizes the communication with the printed board 3 .

[0037] Both ends of the same socket 5 on the printed board 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com