A preparation process of metal fiber porous material with three-dimensional negative Poisson's ratio

A metal fiber, negative Poisson's ratio technology, applied in the field of porous materials, to achieve the effect of increasing node density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

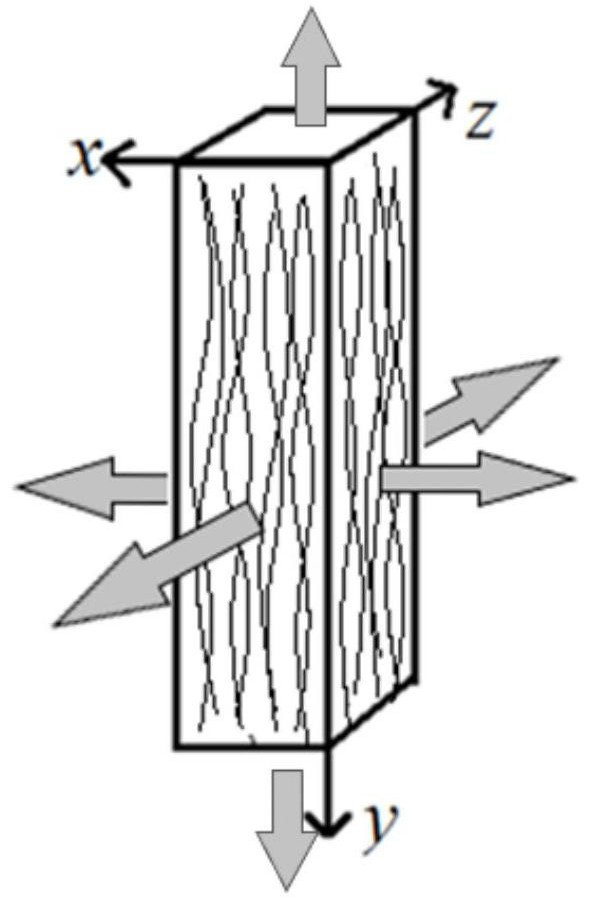

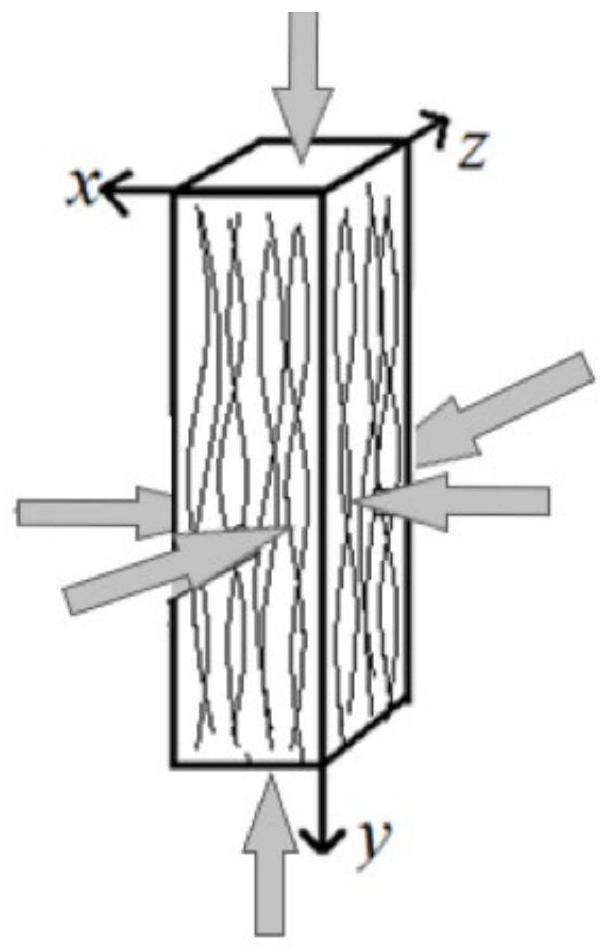

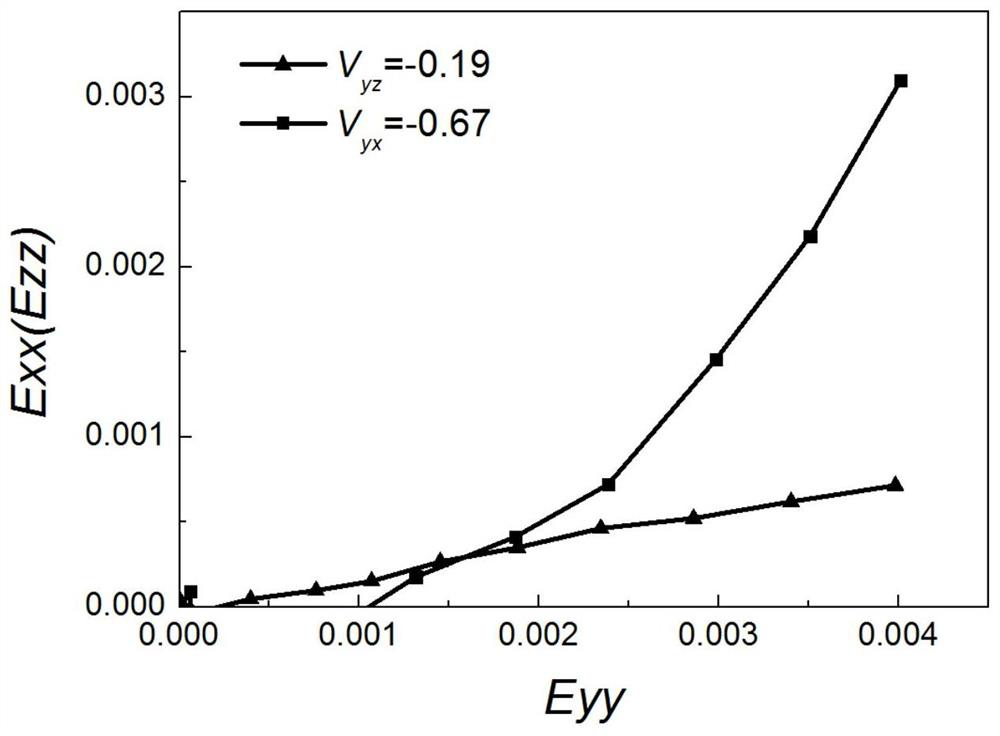

[0030] Step 1: Arrange 150 wavy metal fiber filaments in parallel to form a metal fiber bundle, and then compress the metal fiber bundle to obtain a compressed metal fiber bundle; the compression process is: from a direction perpendicular to the length of the metal fiber filaments. The metal fiber bundle is compressed in two mutually perpendicular directions; the porosity of the compressed metal fiber bundle is 90%, the wire diameter of the metal fiber wire is 200 μm, and the curvature of the wave in the wavy metal fiber wire The radius is 2cm-5cm, the metal fiber wire is 316L stainless steel fiber wire, the compression is carried out under the condition of 30°C, and the compressive strain in each direction in the compression is equal and 50%;

[0031] Step 2, sintering the compressed metal fiber bundle obtained in step 1 at high temperature to obtain a metal fiber porous material with three-dimensional negative Poisson's ...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step 1: Arrange 200 wavy metal fiber filaments in parallel to form a metal fiber bundle, and then compress the metal fiber bundle to obtain a compressed metal fiber bundle; the compression process is: from a direction perpendicular to the length of the metal fiber filaments. The metal fiber bundle is compressed in two mutually perpendicular directions; the porosity of the compressed metal fiber bundle is 88%, the wire diameter of the metal fiber wire is 50 μm, and the curvature of the wave in the wavy metal fiber wire The radius is 2cm-5cm, the metal fiber filament is H65 copper alloy fiber filament, the compression is performed under the condition of 20°C, and the compressive strains in the two mutually perpendicular directions during the compression are 90% and 80% respectively;

[0051] In step 2, the compressed metal fiber bundle obtained in step 1 is sintered at high temperature to obtain a metal fiber porous m...

Embodiment 3

[0056] This embodiment includes the following steps:

[0057] Step 1: Arrange 130 wavy metal fiber filaments in parallel to form a metal fiber bundle, and then compress the metal fiber bundle to obtain a compressed metal fiber bundle; the compression process is: from a direction perpendicular to the length of the metal fiber filaments. The metal fiber bundle is compressed in two mutually perpendicular directions; the porosity of the compressed metal fiber bundle is 85%, the wire diameter of the metal fiber wire is 100 μm, and the curvature of the wave in the wavy metal fiber wire The radius is 2cm-5cm, the metal fiber filaments are 6063 aluminum alloy fiber filaments, the compression is performed under the condition of 25°C, and the compressive strains in the two mutually perpendicular directions during the compression are 50% and 60% respectively;

[0058] In step 2, the compressed metal fiber bundle obtained in step 1 is sintered at high temperature to obtain a metal fiber p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com