Preparation process of metal fiber porous material with three-dimensional negative Poisson's ratio

A metal fiber, negative Poisson's ratio technology, applied in the field of porous materials, to achieve the effect of increasing node density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

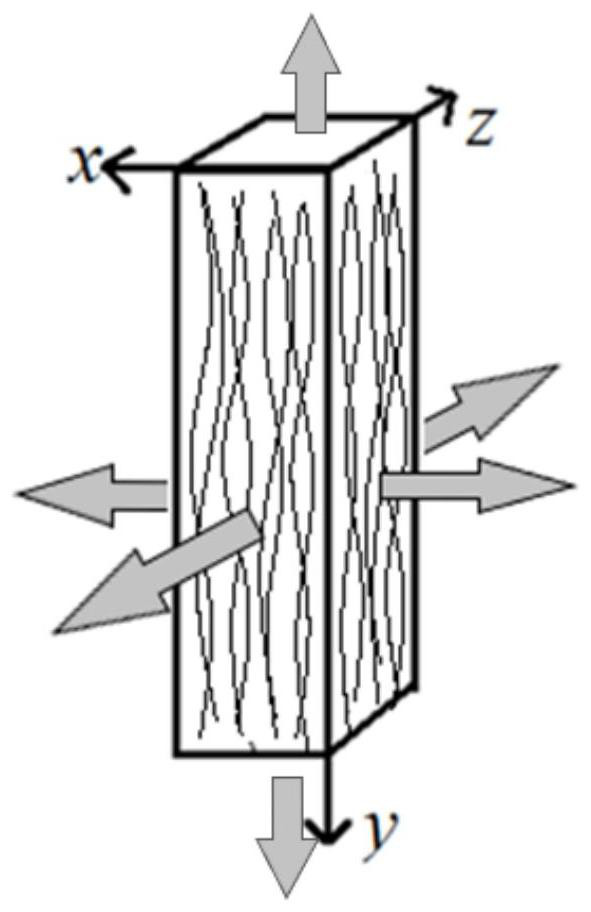

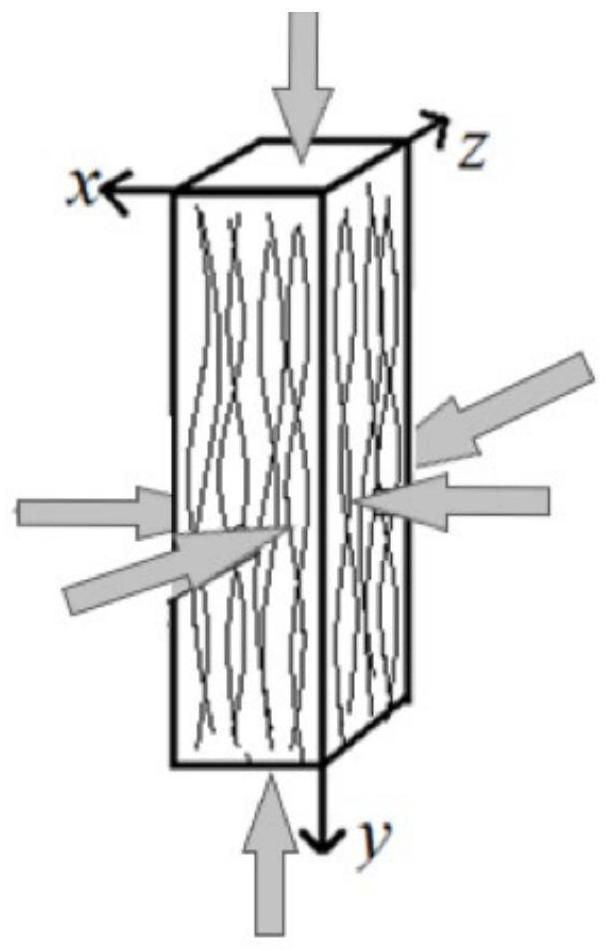

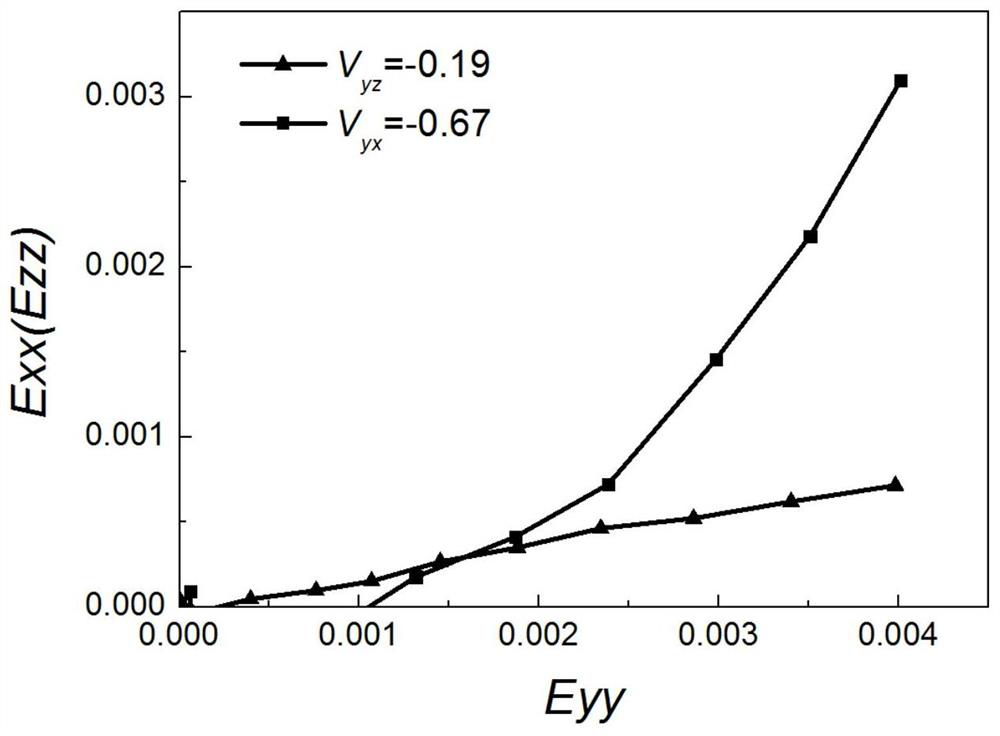

[0030] Step 1. Arrange 150 wavy metal fiber filaments in parallel to form a metal fiber bundle, and then compress the metal fiber bundle to obtain a compressed metal fiber bundle; the compression process is: from the direction perpendicular to the length of the metal fiber filament The metal fiber bundles are respectively compressed in two mutually perpendicular directions; the porosity of the compressed metal fiber bundles is 90%, the wire diameter of the metal fiber wires is 200 μm, and the curvature of the waves in the wavy metal fiber wires is The radius is 2cm-5cm, the metal fiber wire is 316L stainless steel fiber wire, the compression is carried out at 30°C, and the compression strain in each direction during the compression is equal and 50%;

[0031] Step 2: Sintering the compressed metal fiber bundles obtained in Step 1 at high temperature to obtain a metal fiber porous material with a three-dimensional negative P...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step 1. Arrange 200 wavy metal fibers in parallel to form metal fiber bundles, and then compress the metal fiber bundles to obtain compressed metal fiber bundles; the compression process is: from the direction perpendicular to the length of the metal fibers The metal fiber bundles are respectively compressed in two mutually perpendicular directions; the porosity of the compressed metal fiber bundles is 88%, the wire diameter of the metal fiber wires is 50 μm, and the curvature of the waves in the wavy metal fiber wires is The radius is 2cm to 5cm, the metal fiber is H65 copper alloy fiber, the compression is carried out at 20°C, and the compression strains in two mutually perpendicular directions during the compression are 90% and 80% respectively;

[0051] Step 2: Sintering the compressed metal fiber bundles obtained in Step 1 at high temperature to obtain a metal fiber porous material with a three-dimensional nega...

Embodiment 3

[0056] This embodiment includes the following steps:

[0057] Step 1. Arrange 130 wavy metal fibers in parallel to form metal fiber bundles, and then compress the metal fiber bundles to obtain compressed metal fiber bundles; the compression process is: The metal fiber bundles are respectively compressed in two mutually perpendicular directions; the porosity of the compressed metal fiber bundles is 85%, the wire diameter of the metal fiber wires is 100 μm, and the curvature of the waves in the wavy metal fiber wires is The radius is 2cm-5cm, the metal fiber wire is 6063 aluminum alloy fiber wire, the compression is carried out at 25°C, and the compression strains in two mutually perpendicular directions during the compression are 50% and 60% respectively;

[0058] Step 2: Sintering the compressed metal fiber bundles obtained in Step 1 at high temperature to obtain a metal fiber porous material with a three-dimensional negative Poisson's ratio effect; the temperature of the sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Radius of curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com