Automobile collision energy-absorbing composite material and preparation method thereof

A technology of composite materials and collision energy absorption, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems that the energy absorption effect cannot be fully reflected, and the collision energy absorption material fails, etc., to achieve high specific absorption energy, high work hardening rate, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

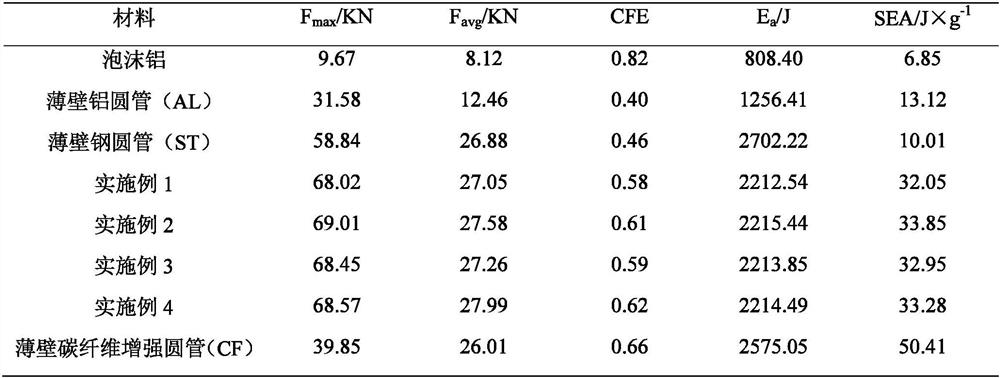

Examples

preparation example Construction

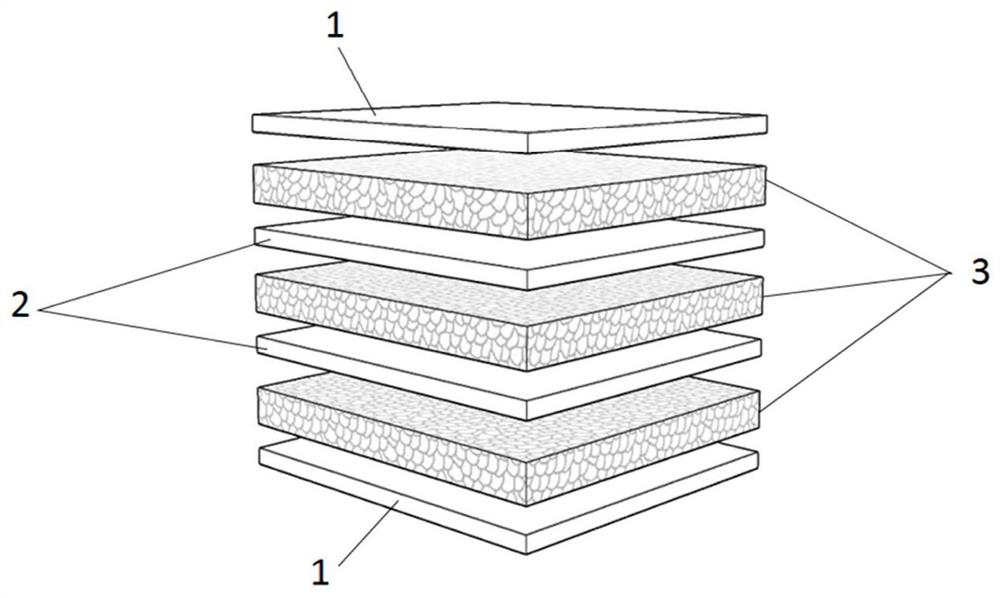

[0035] Specifically, the thickness of the dual-phase steel plate is 0.1-100mm, and the thickness of the particle-reinforced aluminum foam core material is 0.1-500mm. The thickness of dual-phase steel plate and aluminum foam core material can be selected according to actual needs. The preparation method of the automobile collision energy-absorbing composite material of the present invention comprises the following steps:

[0036] (1) Pretreatment of dual-phase steel plate:

[0037] Pre-rolling the dual-phase steel plate located on the outermost layer, the reduction amount is 0.01%-95%. Specifically, the pre-rolling process is selected from any one or more of rolling, cold treatment and heat treatment.

Embodiment 1

[0048] The preparation method of automobile collision energy-absorbing composite material in this embodiment comprises the following steps:

[0049] (1) Pretreatment of dual-phase steel plate

[0050] The thickness of the outermost dual-phase steel plate 1 is 12 mm, the thickness of the inner dual-phase steel plate 2 is 6 mm, and the thickness of the particle-reinforced foamed aluminum core material 3 is 20 mm.

[0051] Cold-rolling the outermost dual-phase steel plate 1 with a drawdown of 10%, after cooling, flame cutting with the inner dual-phase steel plate 2 to adjust the size to be consistent;

[0052] The inner dual-phase steel plate 2 is subjected to solution treatment in a heating furnace with a solution temperature of 1150° C. and a holding time of 20 minutes. After holding the heat, it is taken out and quenched.

[0053] (2) Surface treatment of duplex steel plate

[0054] Washing and drying the pretreated outermost dual-phase steel plate 1 and inner dual-phase ste...

Embodiment 2

[0061] The preparation method of the automobile collision energy-absorbing composite material in this embodiment The preparation method comprises the following steps:

[0062] (1) Pretreatment of dual-phase steel plate

[0063] The thickness of the outermost dual-phase steel plate 1 is 10 mm, the thickness of the inner dual-phase steel plate 2 is 8 mm, and the thickness of the particle-reinforced foamed aluminum core material 3 is 20 mm.

[0064] Cold rolling is performed on the outermost dual-phase steel plate 1, with a downforce of 50%, and after cooling, it is flame-cut together with the inner dual-phase steel plate 2 to adjust the size to be consistent;

[0065] The inner dual-phase steel plate 2 is subjected to solution treatment in a heating furnace, the solution temperature is 1050° C., and the holding time is 30 minutes. After holding the heat, it is taken out and quenched.

[0066] (2) Surface treatment of duplex steel plate

[0067] Washing and drying the pretreate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com