Three-dimensional curved wall mixed phase regular quadrilateral chiral honeycomb

A regular quadrilateral, mixed-phase technology, applied in elastic shock absorbers, shock absorbers, springs, etc., can solve the problems of low safety, low stability of deformation mode, poor energy absorption effect, etc., to eliminate the influence of randomness , The force-displacement curve is smooth and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

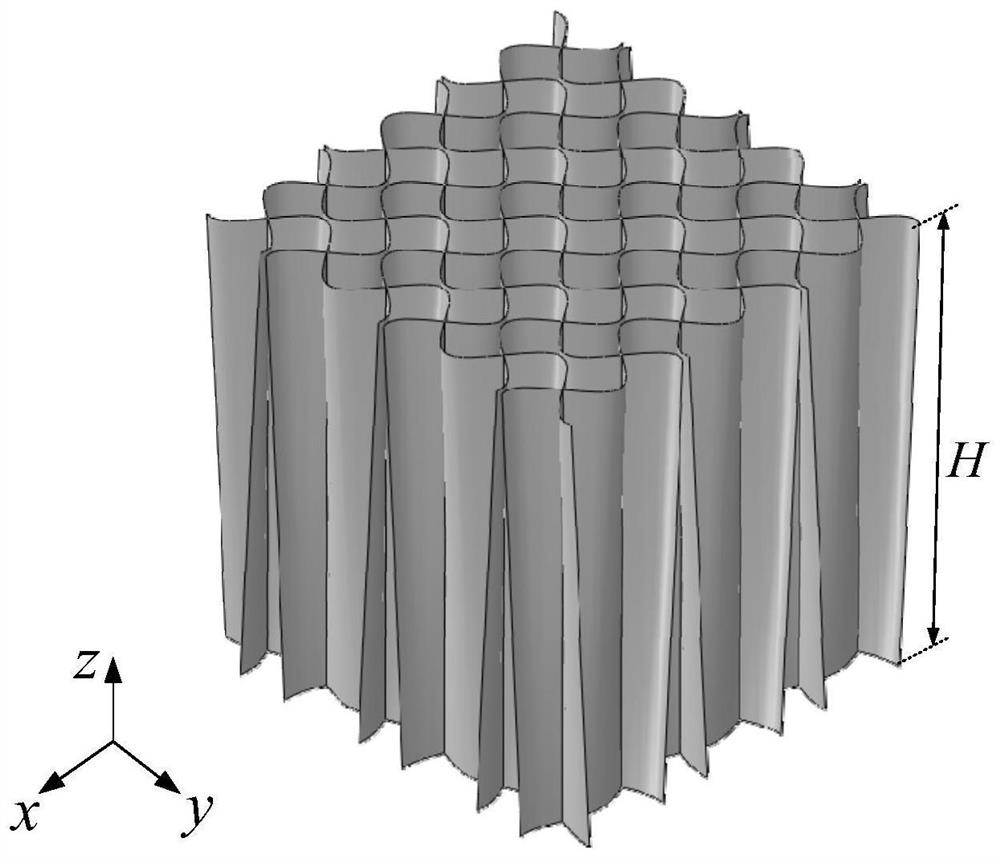

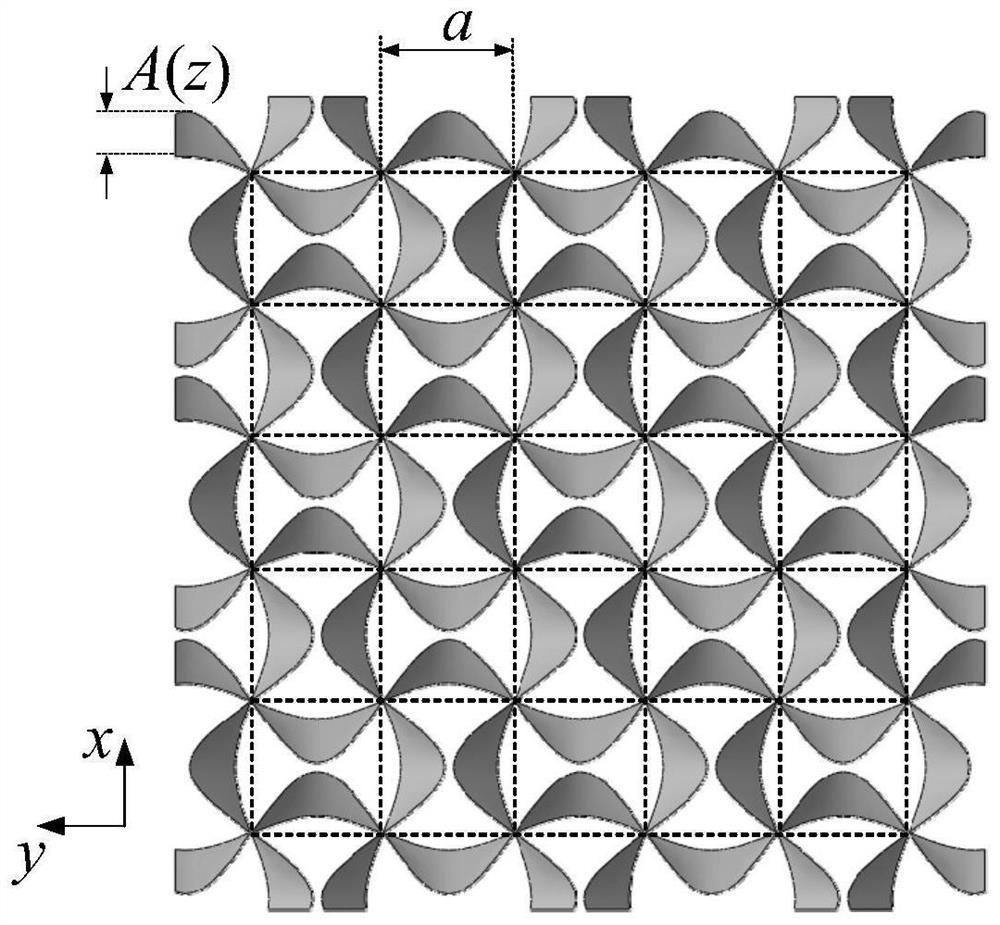

[0037] A three-dimensional curved wall mixed with regular tetragon chiral cell, which is a thin-walled structure, consistent thickness at each position. like Figure 1-5 As shown in the chirality of straight-wall honeycomb cellular skeleton (e.g. Figure 1-5The black dashed line is shown) and the surface of the straight wall honeycomb skeleton configurations by several honeycomb metades; the surface is spliced to the honeycomb cell forming a three-dimensional curved wall mixed phase honeycomb. More specifically, the straight wall honeycomb skeleton and the curved surface are processed using a conventional method or 3D printing. Among them, the traditional method is to process a separate curved wall through the mold, then cut the appropriate length, the number of straight mouth, and the number of doubts of energy is spliced together, and then bonded, welding, etc. Reinforcement in the manner. Each surface is connected to each other by the form of a stable structure of the positiv...

Embodiment 2

[0044] The present embodiment is based on the three-dimensional curved wall mixing of the three-dimensional curved wall of Example 1. Comparison with the analysis of the conventional straight wall honeycomb impact load.

[0045] This embodiment is an adhesive protection effect when the assembled suction protection device is subjected to a hunch impact load through a finite element numerical simulation. Dynamic simulation by Abaqus / ExPlicit.

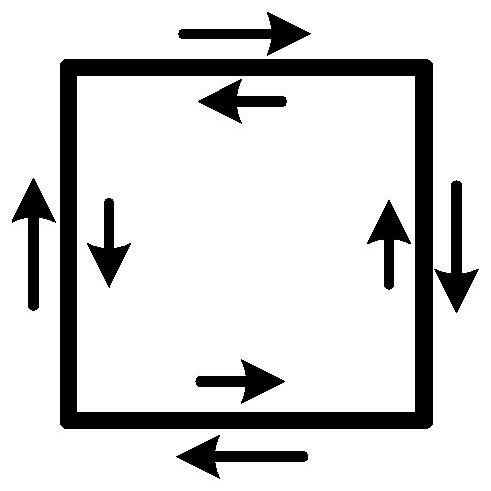

[0046] The three-dimensional curved wall mixed phase positive quadrilateral honeycomb and conventional straight wall thickness is 1 mm, the height is 95mm, and the material is all the stainless steel, the three-dimensional curved wall mixed phase of the four-sided gear cellular honeycomb. The straight wall honeycomb silicon is 15mm long, and the side length of the conventional straight wall honeycomb is also 15mm. Three-dimensional curved wall mixed phase positive quadrangular honeycombs set two sets of models, top and underlying horizontal...

Embodiment 3

[0049] The difference in this embodiment is that the number of the honeycomb cell is disposed in accordance with the destructive force of the actual safety accident, and the number of curved surfaces is adapted to the number of honeycomb metals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com