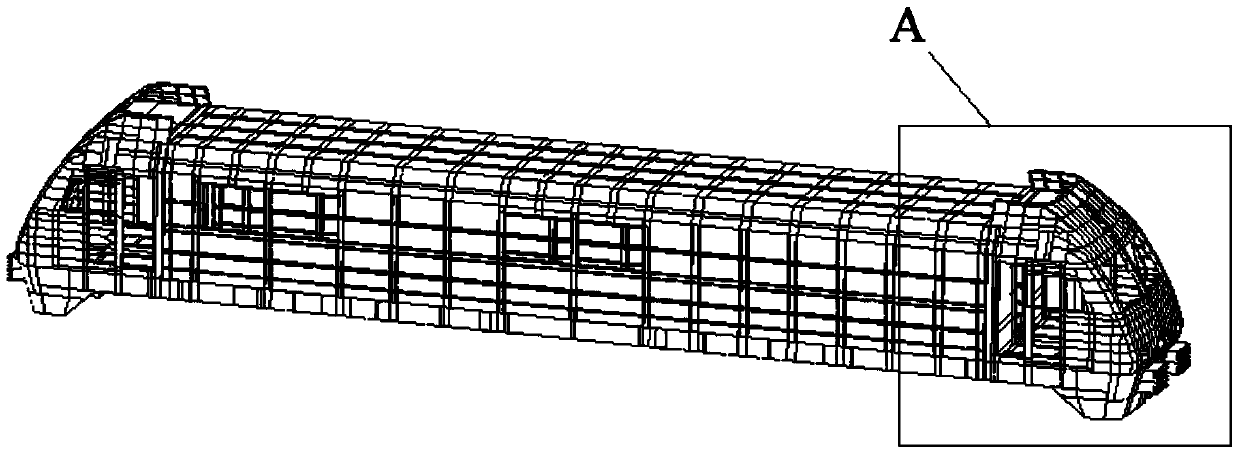

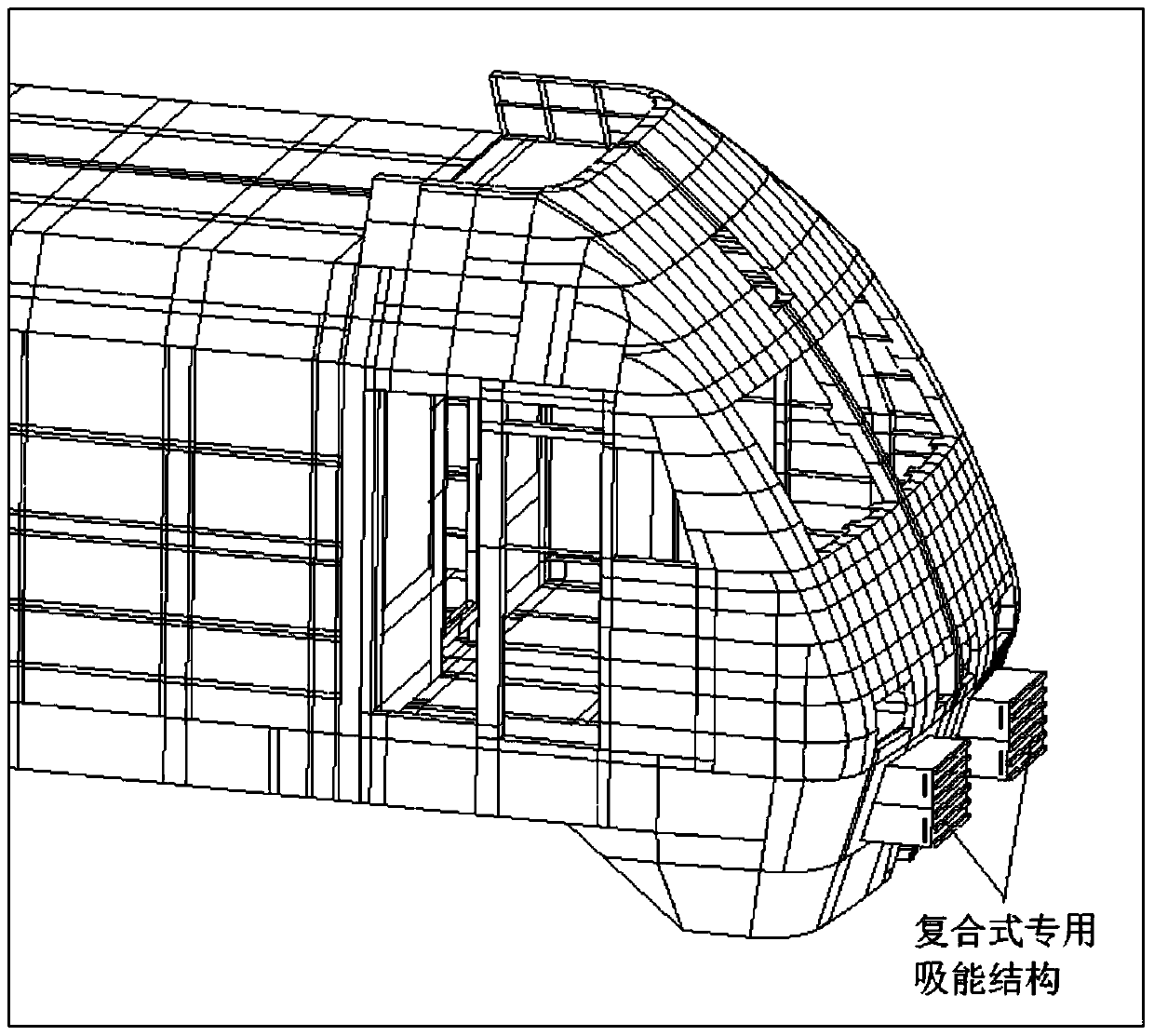

Guidance composite special energy-absorbing structure and its application on trains

An energy-absorbing structure and composite technology, applied in railway car body parts, railway vehicle wheel guards/buffers, transportation and packaging, etc., can solve the problems of difficult installation, cumbersome production, complex structure, etc. The process is simple, the deformation is stable and controllable, and the effect is larger than the energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

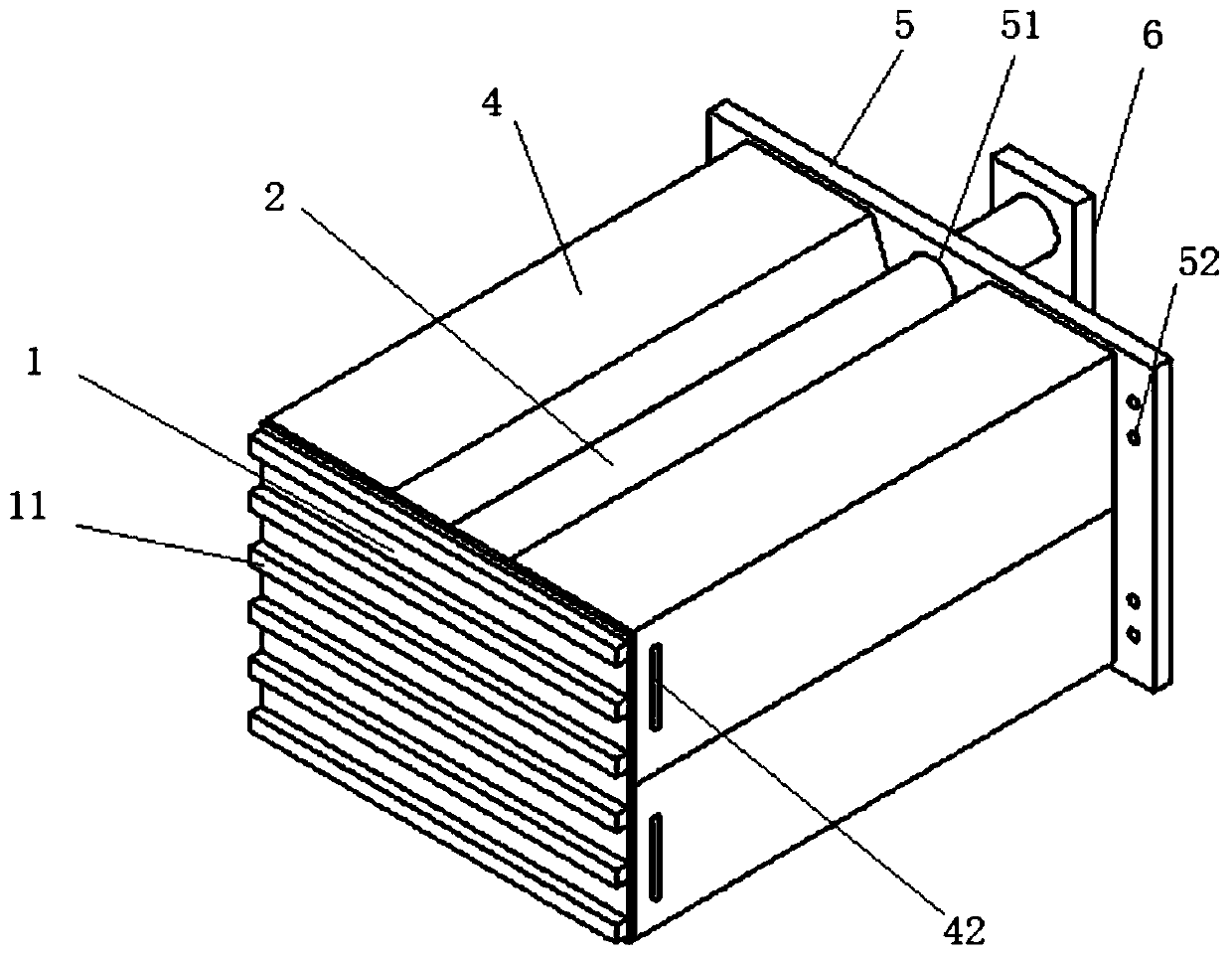

[0038] a kind of like Figure 3-Figure 6 The guide compound special energy-absorbing structure of the present invention is shown, and the special energy-absorbing structure includes a front baffle 1, a guide rod 2, a thin-walled metal energy-absorbing structure 4 and a rear baffle 5, and the front baffle 1 absorbs energy through the thin-walled metal. The energy structure 4 is fixedly connected with the tailgate 5 as a whole. One end of the guide rod 2 is affixed to the back of the front baffle 1, and the other end of the guide rod 2 passes through the thin-walled metal energy-absorbing structure 4 and is inserted into the through hole 51 provided on the rear baffle 5, and the thin-walled metal absorbs energy. The outer surface of the structure 4 is provided with a groove 41 through which the guide rod 2 passes.

[0039] Such as image 3 , Figure 4 As shown, in the guide composite special energy-absorbing structure of this embodiment, the thin-walled metal energy-absorbing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com