Four-unit-cell metal tube for absorbing energy during automobile collisions

A technology of metal tubes and unit cells, applied in vehicle parts, vehicle safety arrangements, bumpers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

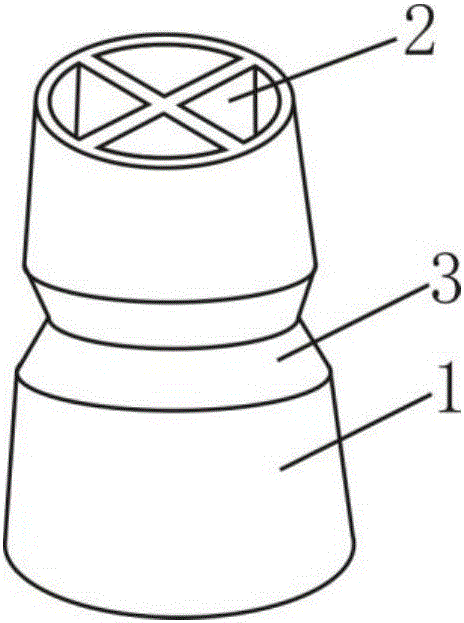

[0012] Such as figure 1 As shown, the four-cell metal tube used for energy absorption when the car is collided, the main body 1 is a tapered thin-walled tube, and a "ten"-shaped tube wall 2 is arranged inside the main body 1, and the tube wall 2 extends from the top of the main body 1 to the bottom. ; The middle part of the main body 1 is provided with a concave prefabricated deformation groove 3 . Body 1 has a taper of 0.3. The ratio of the wall thickness to the height of the main body 1 is 1:15-1:30, and the optimal ratio is 1:25. The prefabricated deformation groove 3 is a continuous annular groove or a discontinuous annular groove. The cross section of the prefabricated deformation groove 3 is triangular.

[0013] The finite element model of the four-cell conical tube is established, and the collision simulation analysis is carried out on the finite element model, and the deformation mode after the collision simulation is obtained. The deformation of the four-cell con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com