Special wire suitable for electric reactor of single-sealing structure under high-current

A reactor, high-current technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor components, circuits, etc., can solve the problems of complex inductance adjustment, complex coil structure, and many packages, Achieve the effect of saving electric energy, improving dynamic stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

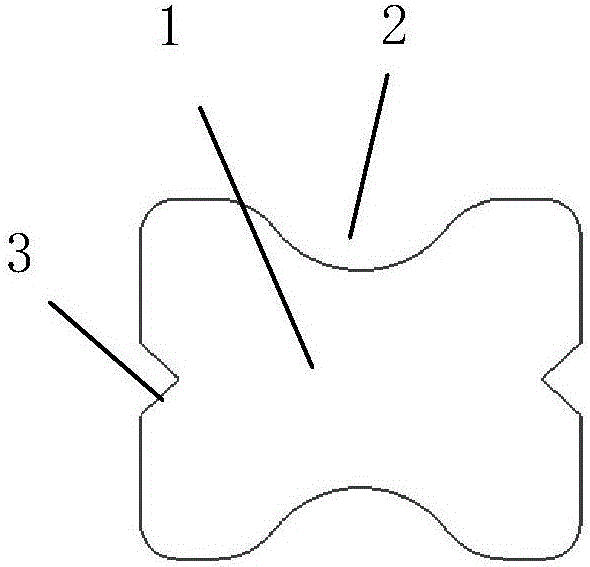

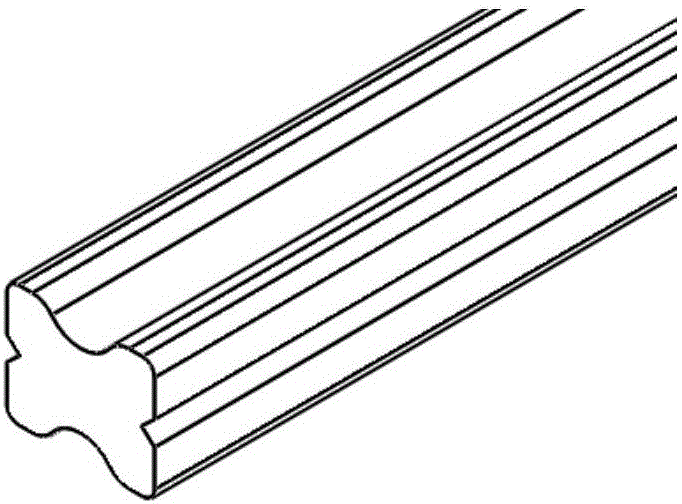

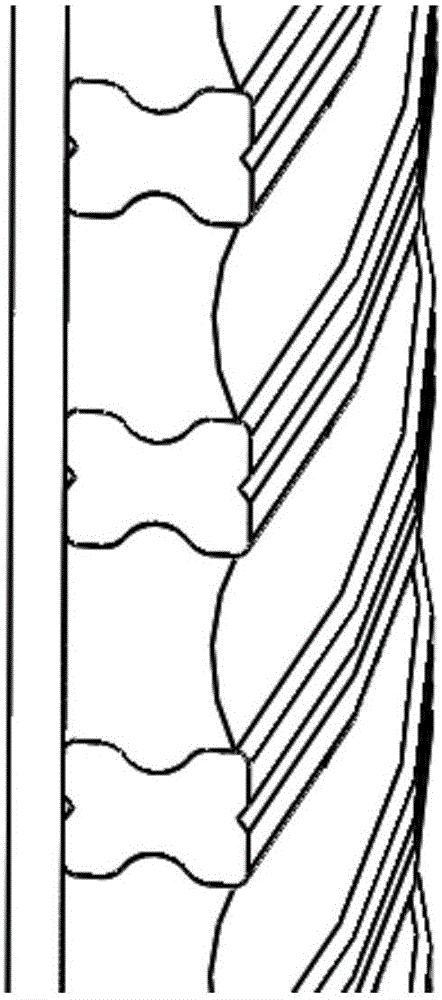

[0012] The specific implementation of the present invention will be described in detail below in conjunction with the drawings and preferred embodiments. Such as figure 1 with figure 2 As shown, a special wire suitable for a single-encapsulated structure reactor under high current includes a wire 1 pultruded from an aluminum alloy material. The upper side and the lower side of the wire are respectively provided with arc-shaped grooves 2 , V-shaped grooves 3 are respectively provided on the left and right sides of the wire. The V-shaped grooves on the left and right of the wire are used to locate the center of the tap, and the upper and lower arc grooves are used to fix the shape of the wire with epoxy-impregnated glass fiber. The four corners of the wire are chamfered structures. The special conductor designed for the reactor under high current with this structure is pultruded with aluminum alloy material, and no insulating material is required.

[0013] For example, if an adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com