Cutting mill for two-position porcelain shell

A technology of a grinding machine and a cutting mechanism, which is applied to machine tools, grinding machines, grinding/polishing equipment suitable for grinding workpiece planes, etc. Processing efficiency and quality of finished products, reducing processing costs, and ensuring the effect of parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

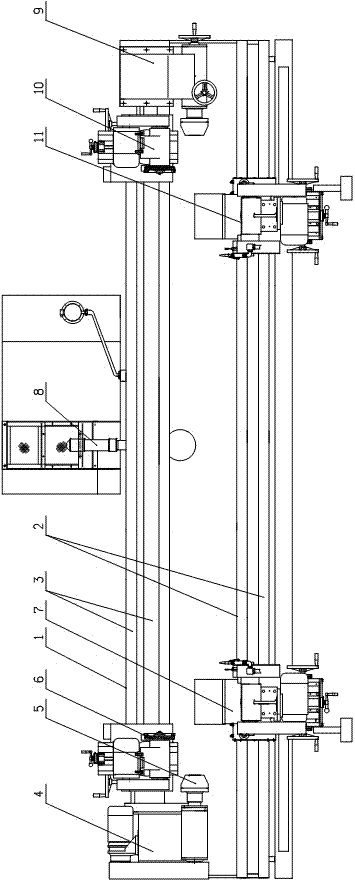

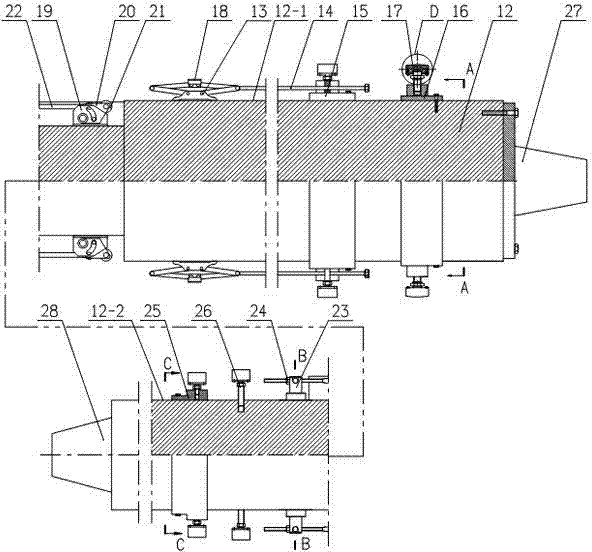

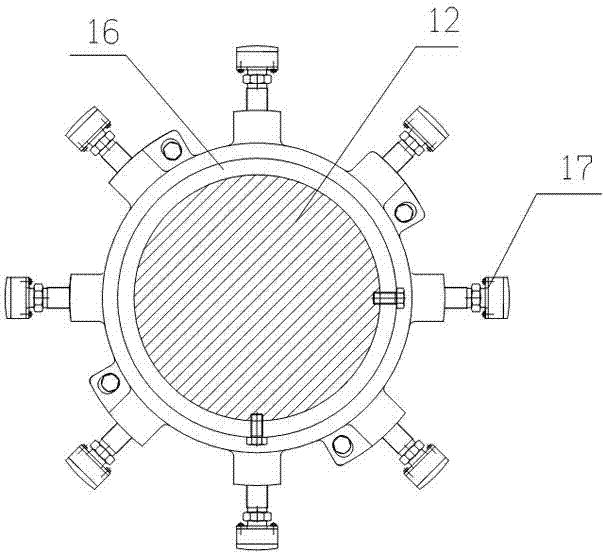

[0021] The specific embodiment of the equipment body in the double-position porcelain sleeve cutting and grinding machine of the present invention is as follows: figure 1 As shown, it includes a machine base 1, and the two ends of the machine base 1 are respectively equipped with a main shaft drive box 4 and an auxiliary tail box 9. The main shaft in the main shaft drive box 4 is driven by a cycloidal pin gear reducer driven by a motor. The belt drive spindle rotates. The first rail group 2 and the second rail group 3 arranged in parallel are respectively installed on both sides of the machine base 1. The two rail groups 2 and 3 are respectively composed of two parallel plane rails. To cutting mechanism 7,11, the cutting saw blades on the two cutting mechanisms 7,11 are arranged in parallel, and the saw blades on the two cutting mechanisms 7,11 rotate in the same direction as the main shaft in the main shaft drive box 4; A pair of grinding mechanisms 6,12 are installed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com