Carrier rocket guide pipe inner wall scratch detecting and polishing device and method

A carrier rocket and catheter technology, applied in the field of sheet metal forming, can solve the problems of catheter lumen bruising, limited grinding stroke, limited grinding area, etc., to achieve the effects of saving processing costs, effective grinding, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

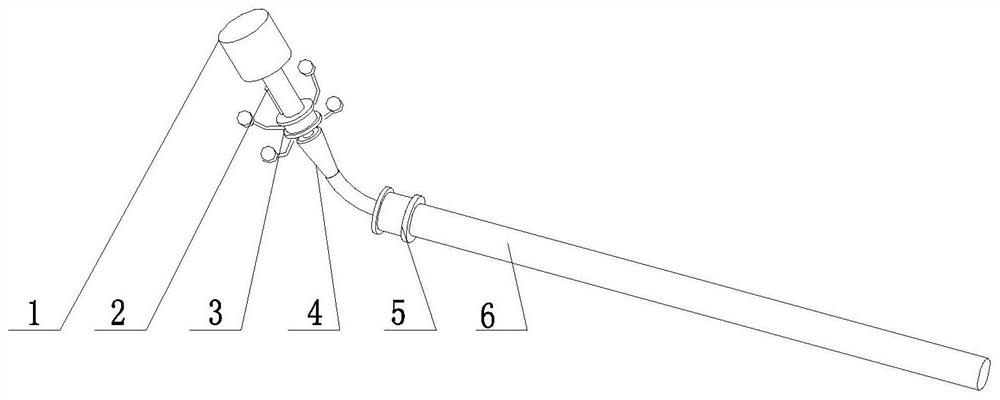

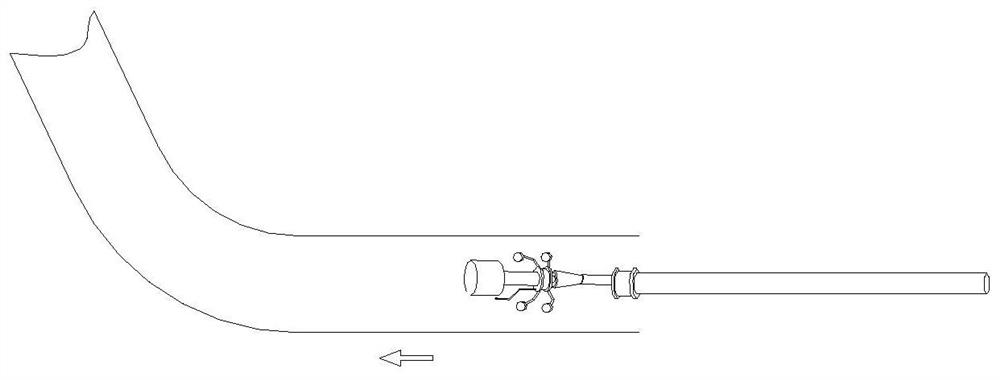

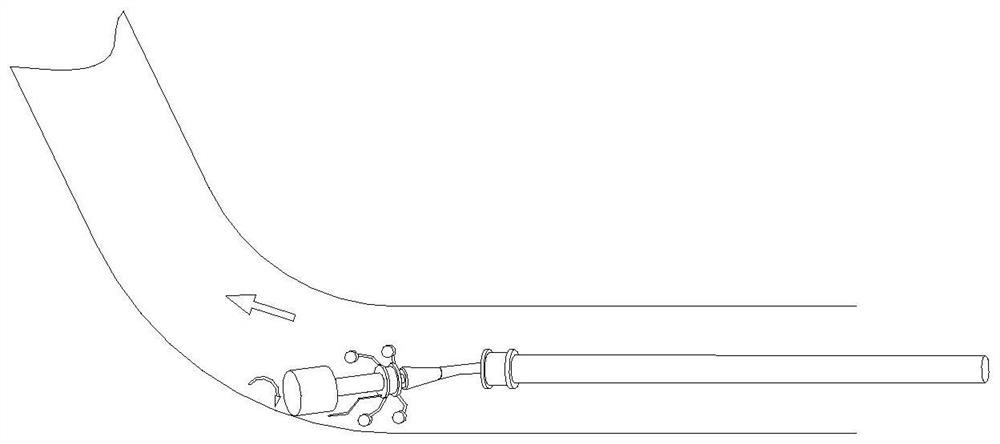

[0034] According to the present invention provides a scratch detection and grinding device for the inner wall of the launch vehicle tube, such as Figure 1-4 As shown, it includes: grinding wheel 1, endoscope probe 2, planetary wheel 3, driving motor 4, universal joint 5 and main pipe 6;

[0035] The grinding wheel 1 is connected with the planetary wheel 3 through a connecting column; the endoscopic probe 2 is arranged on the wall of the connecting column; the planetary wheel 3 is connected with the driving motor 4; the driving motor 4 is connected with the The universal joint 5 is connected; the universal joint 5 is connected with the main pipe 6 to realize the movement turning at the elbow of the conduit.

[0036] Specifically, the drive motor 4 is connected to the universal joint 5 through a connecting column.

[0037] Specifically, grinding heads are installed on the grinding wheel 1, and grinding heads with different roughness are selected according to different scratch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com