Handheld pipeline groove bionic polishing device

A pipeline groove and hand-held technology, which is applied in the field of hand-held pipe groove bionic grinding devices, can solve the problems of difficulty in ensuring the consistency of pipeline grinding interfaces, increasing difficulty in grinding pipe interfaces, and different groove sizes. Great practicability and versatility, increase the applicable range, and improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

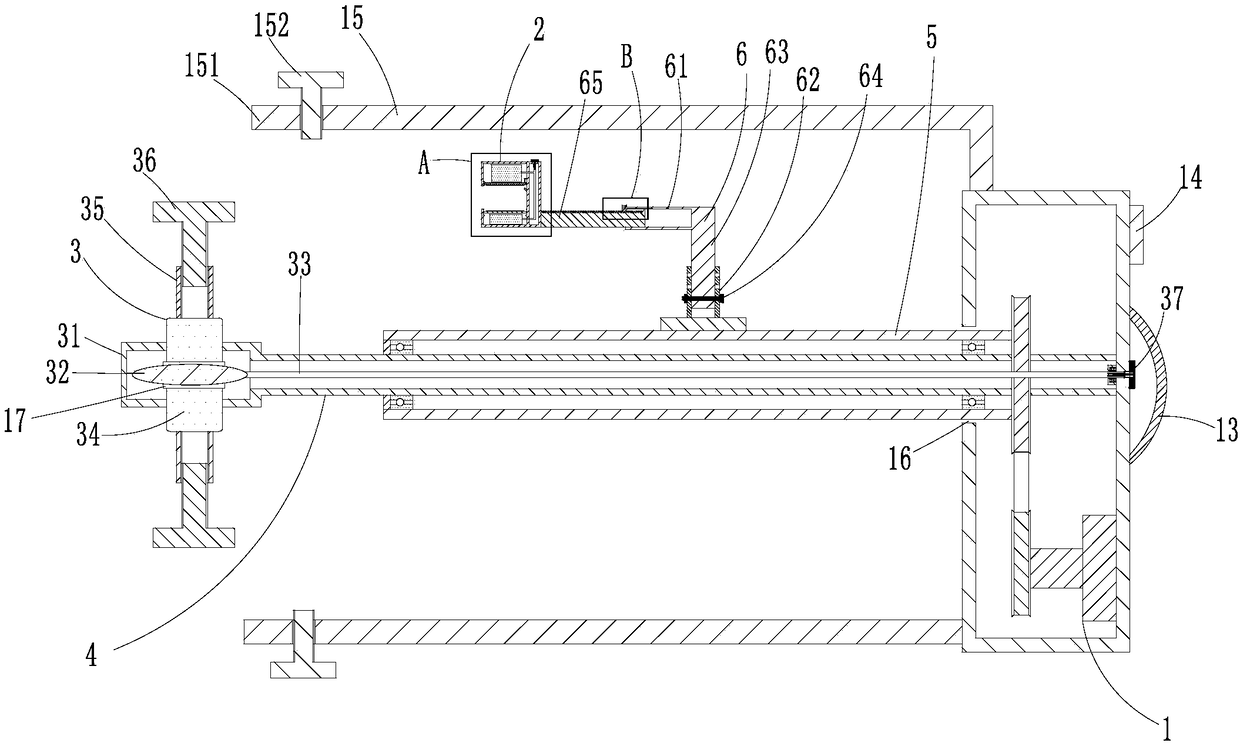

[0034] In order to understand the present invention better, below in conjunction with appendix Figure 1-7 Embodiments of the present invention will be explained in detail.

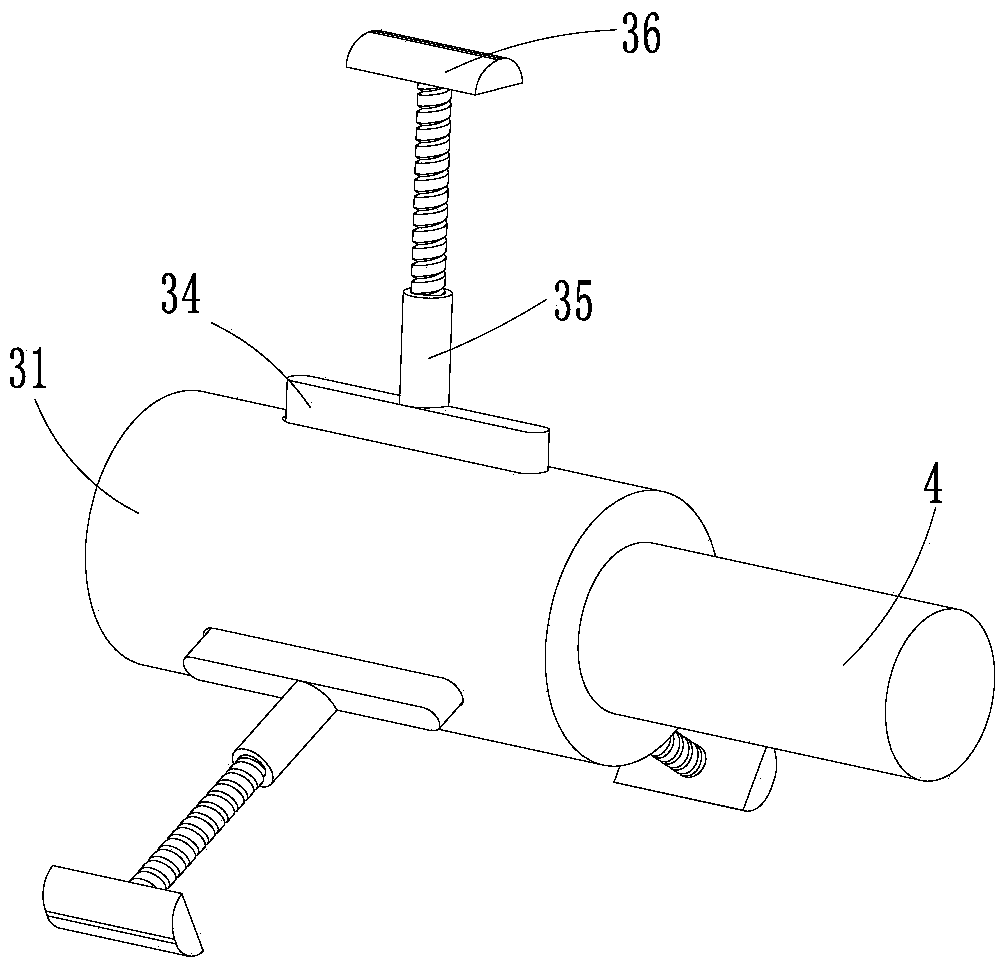

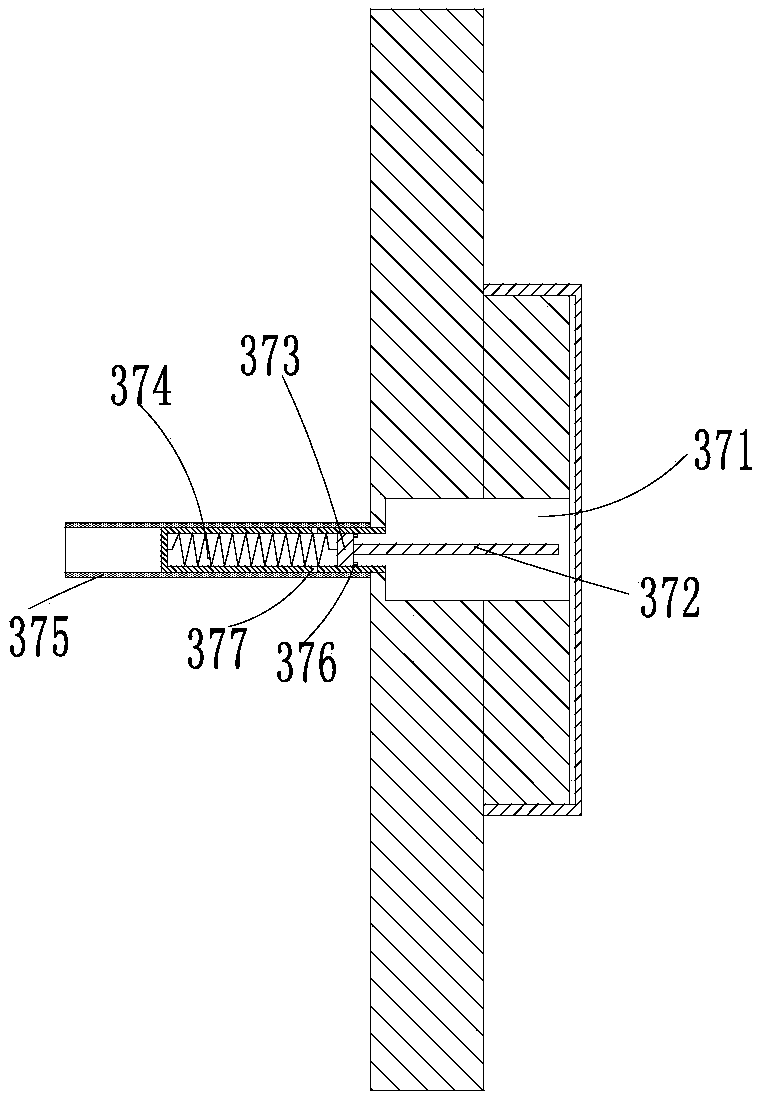

[0035]The present invention includes a power device 1, a grinding device 2 and a tensioning device 3, the housing of the power device 1 is fixedly connected with the tensioning device 3 through a fixed pipe 4, and the right end of the fixed pipe 4 is connected to the power The housing of the device 1 is fixedly connected, the fixed pipe 4 is sleeved with a rotating shaft 5, and the fixed pipe 4 and the rotating shaft 5 are connected by bearings, in order to ensure the smoothness of the fixed pipe 4 during grinding. Stability, a bearing can be provided in the gap 16 between the rotating shaft 5 and the housing of the power unit 1, so that the supporting effect of the bearing can increase the strength, and the rotating shaft 5 can be connected with the grinding device 2 through the bracket 6 Fixed connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com