Hydraulic telescopic protective cover for cutting head of roadheader and implementation method thereof

A hydraulic telescopic and fully mechanized excavator technology, which is applied to earth-moving drilling, cutting machinery and other directions, can solve the problems of occupying regular cycle time, increasing labor intensity of employees, and large weight and volume, so as to improve tunneling efficiency and reduce labor intensity of employees. , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0021] See Figure 1-6 An embodiment of the present invention is provided.

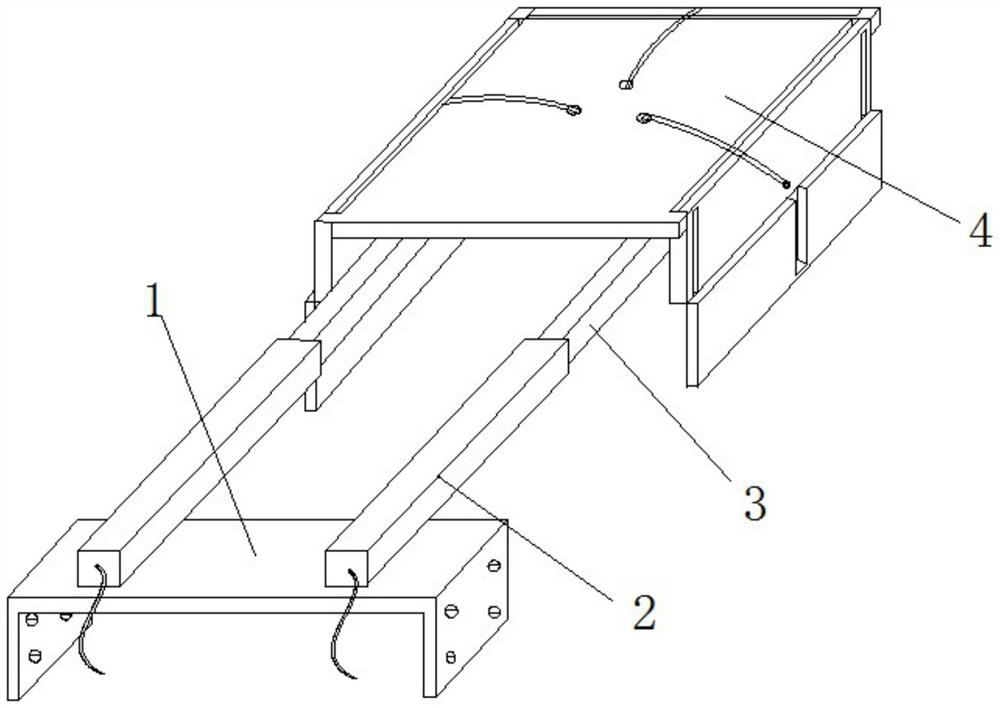

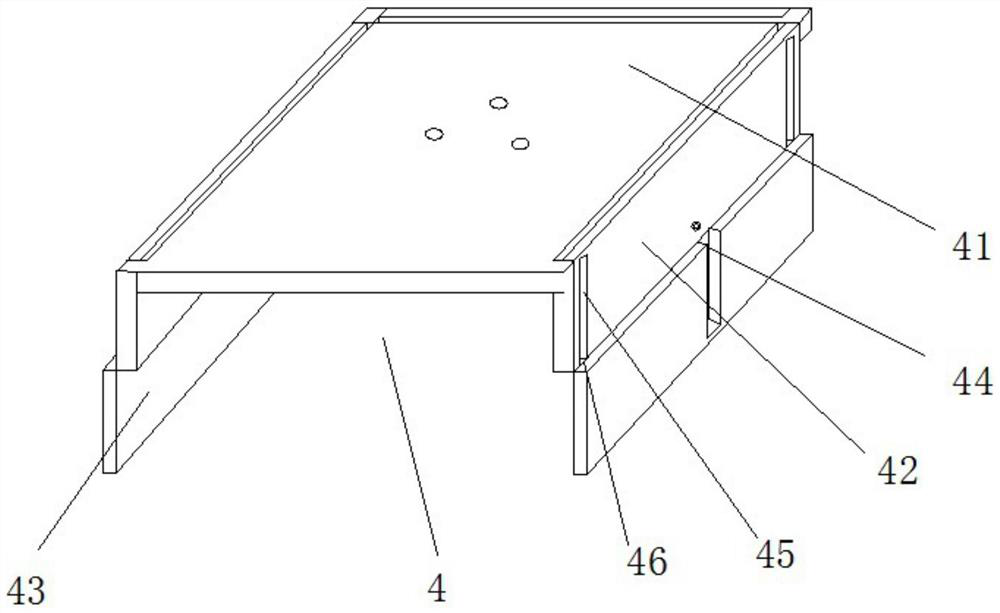

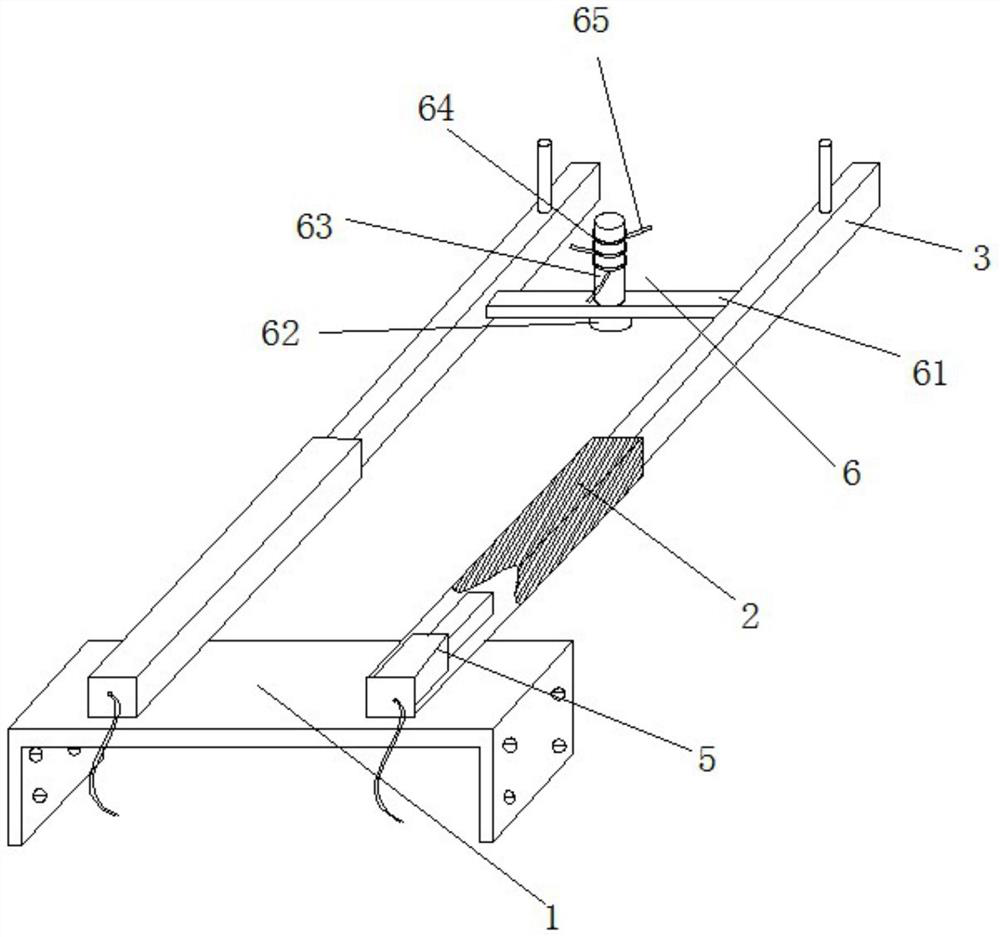

[0022] like figure 1 As shown, a liquid retracting head hydraulic retractable shield includes a fixing frame 1, an outer casing 2 on the top of the fixed frame 1, sliding connected to the outer casing 2 inner casing 3 And the protective cover 4 is fixed to the top of the inner sleeve 3 by the support rod, the fixing frame 1 is fixed to the cover 7 by a fixed bolt, and the outer sleeve 2 and the inner sleeve 3 constitute a double arm two-stage square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com