Clamping mechanism for seal surface grinding unit of valve

A technology of grinding device and clamping mechanism, which is applied in the direction of grinding device, grinding machine tool, grinding workpiece support, etc., and can solve the problems of valve leakage, flatness damage and loss of valve sealing surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

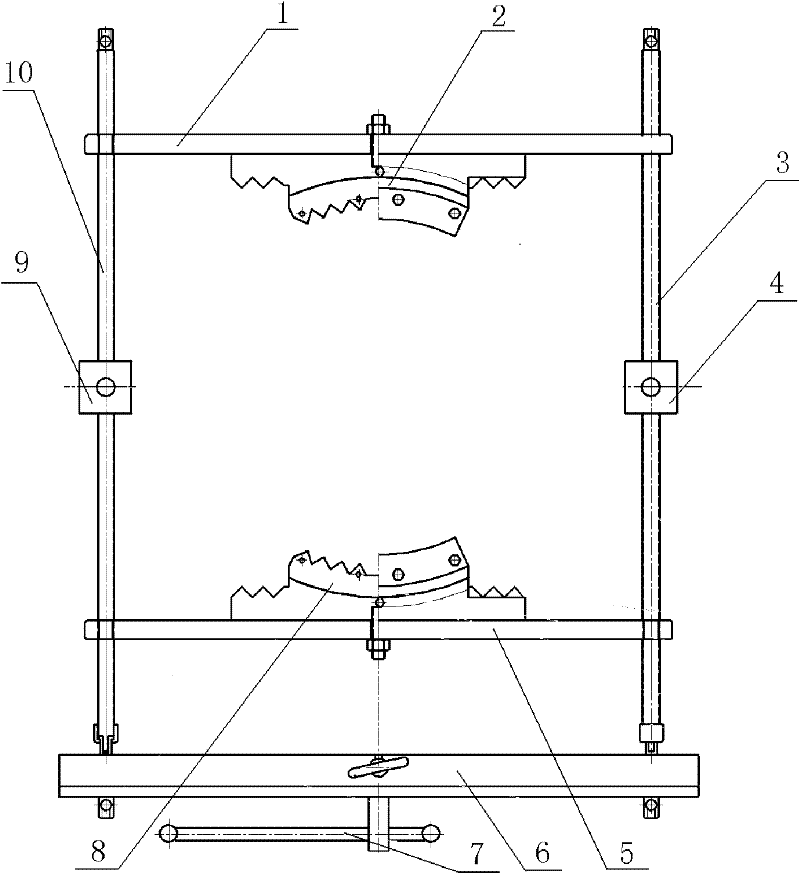

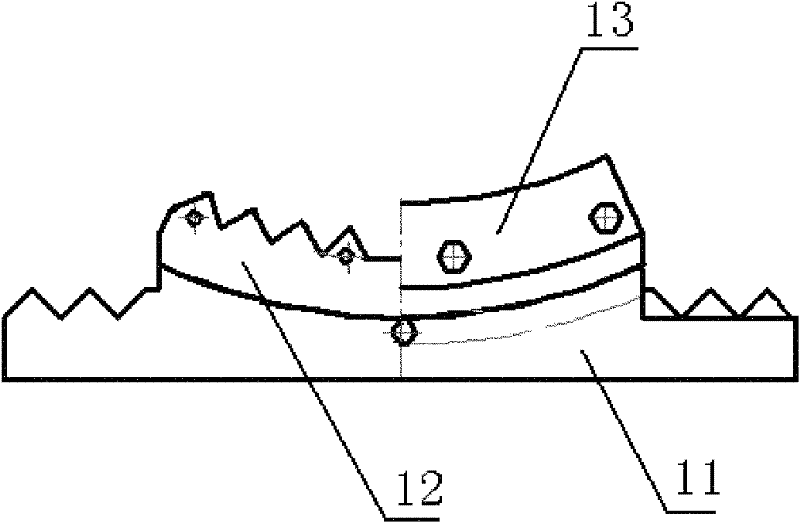

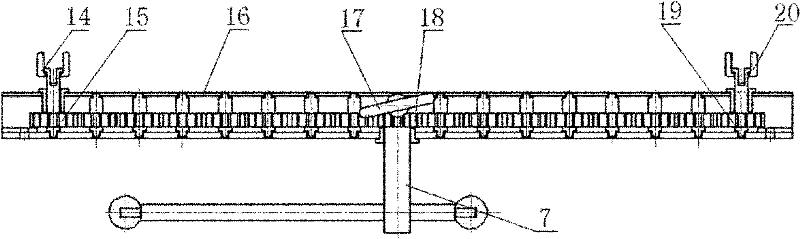

[0016] Such as figure 1 , figure 2 , image 3 As shown, the clamping mechanism of the valve sealing surface grinding device includes a synchronous linkage 6, an operating handle 7, a first screw 3, a second screw 10, a first clamping piece and a second clamping piece, and the synchronous linkage 6 can drive The first screw rod 3 and the second screw rod 10 rotate simultaneously with the operating handle 7, and the synchronous linkage 6 includes a driving gear 18 arranged in the center of the gear box 16, and eight driven gears arranged symmetrically on both sides of the driving gear 18. , the first screw connecting seat 20 affixed to the first screw 3, the second screw connecting seat 14 affixed to the second screw 10, the first end of the first screw connecting seat 20 and the outer side of the gearbox 16 are driven Gear 19 is affixed, and the second screw connection seat 14 is affixed with the second end driven gear 15 of the other end outside of gear box 16, and driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com