Patents

Literature

49results about How to "Guaranteed sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

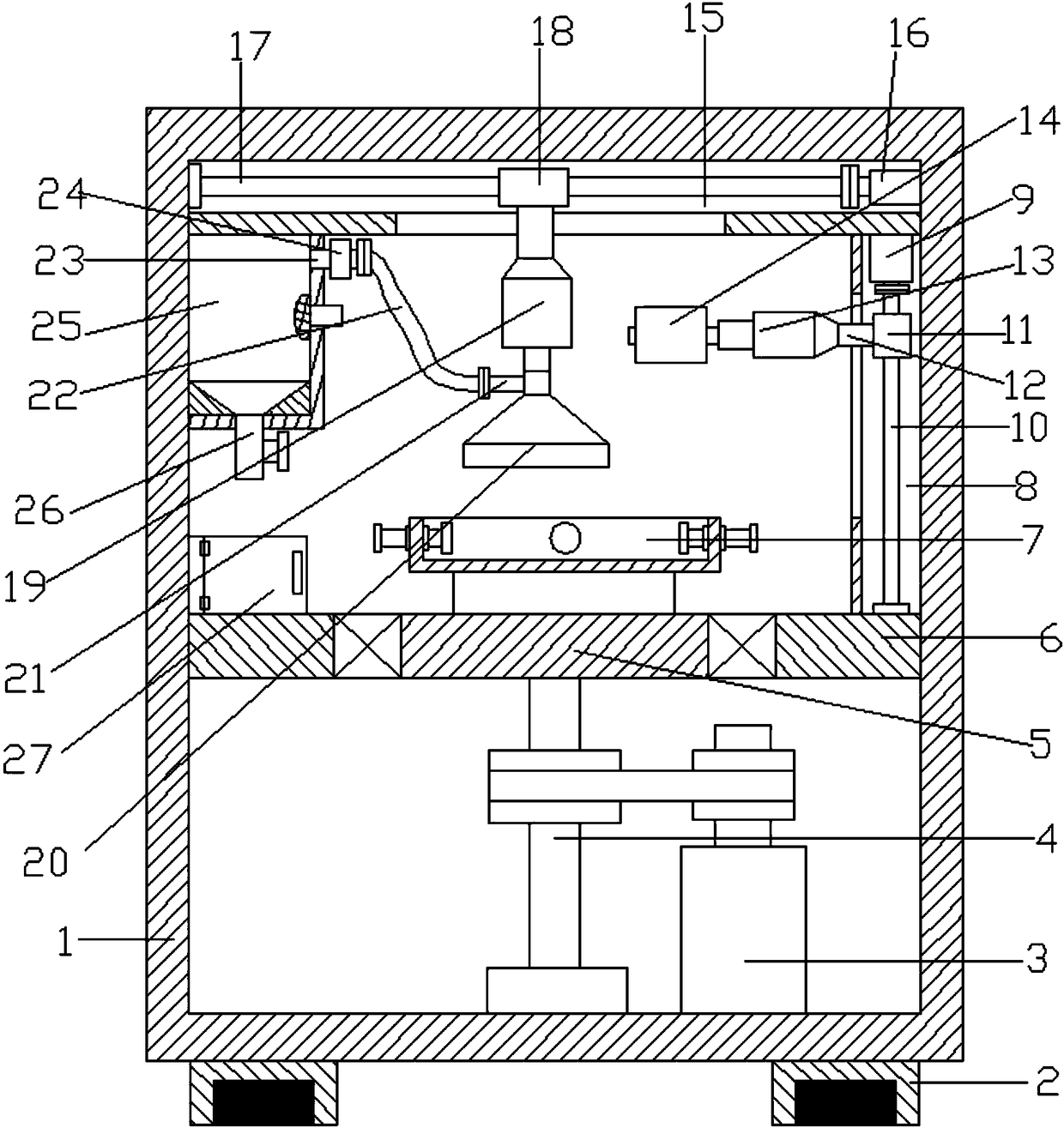

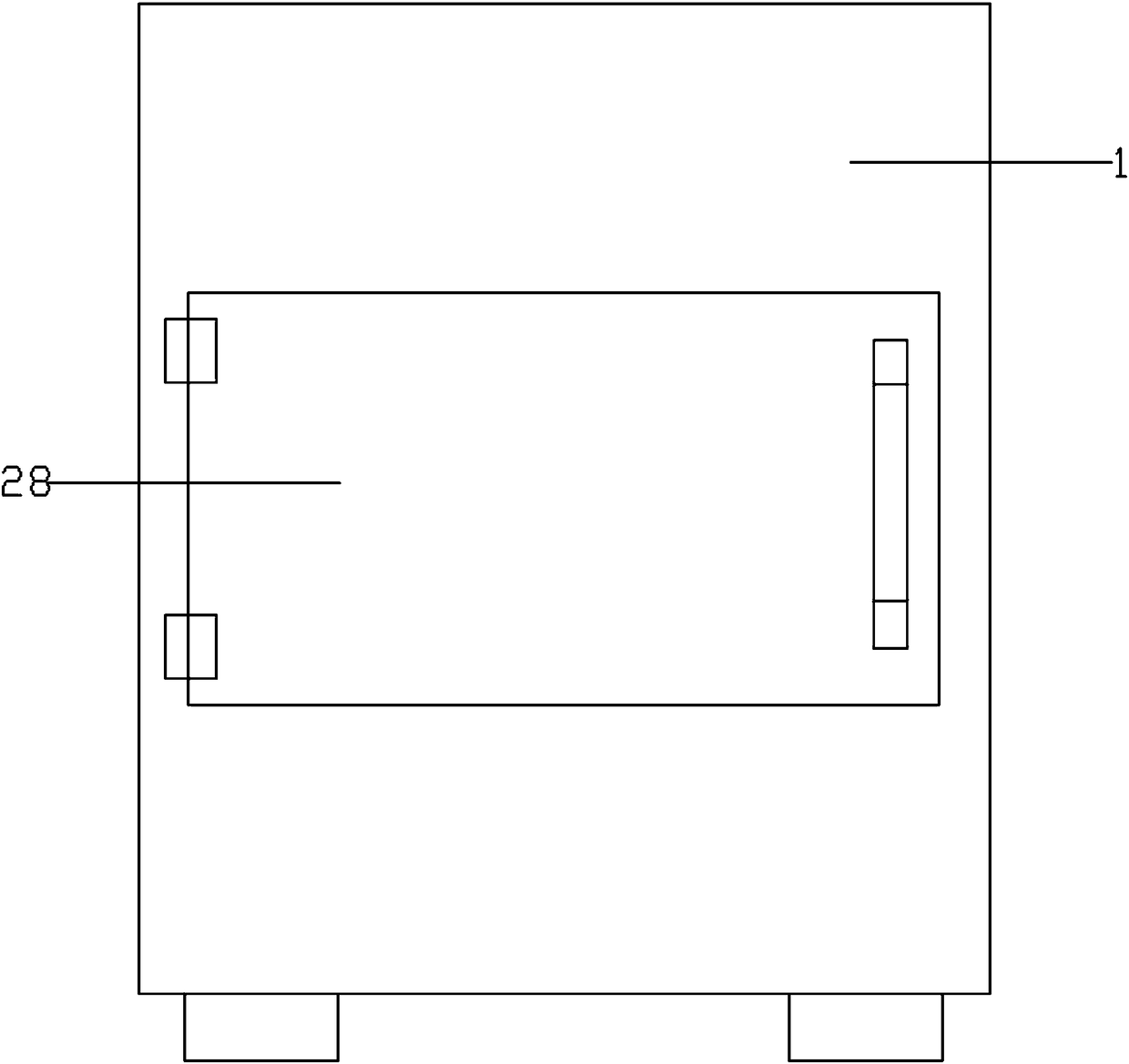

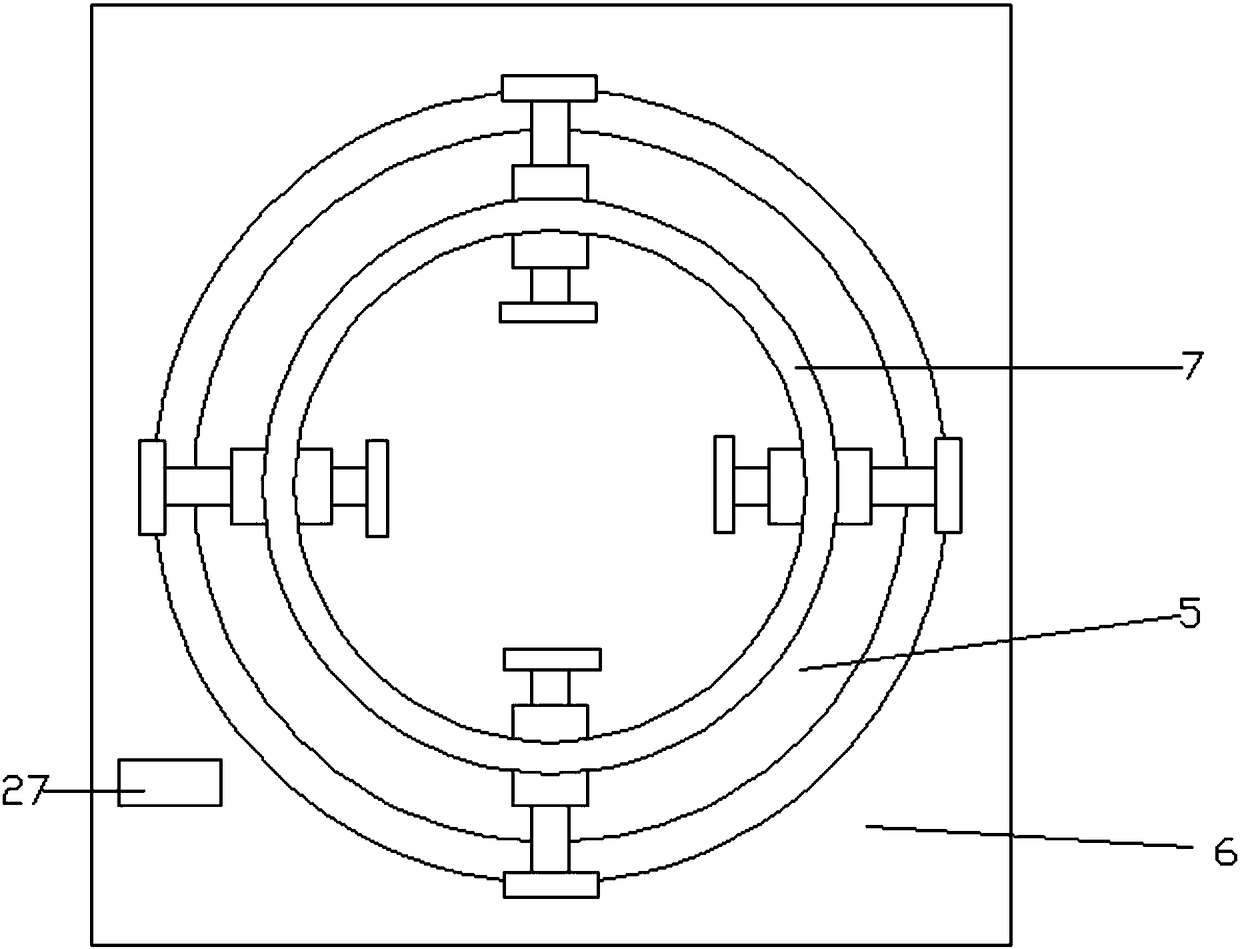

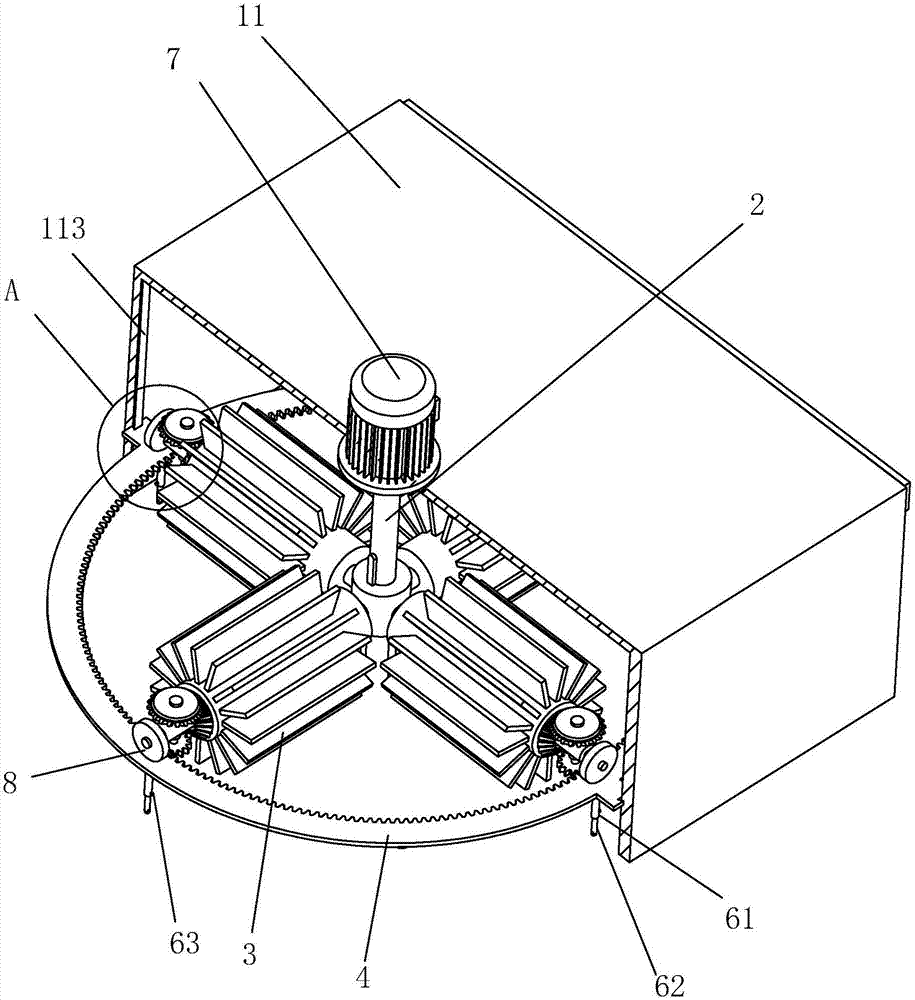

Efficient rotary grinding device

InactiveCN108067990ASmooth rotationGuaranteed sandingGrinding machinesGrinding work supportsAerospace engineering

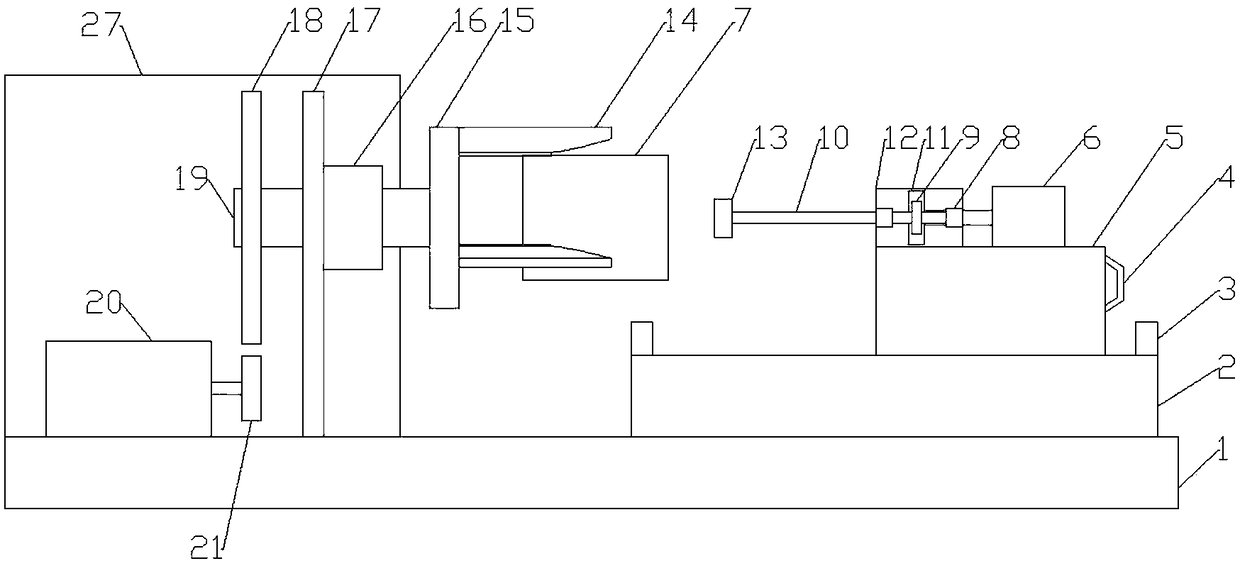

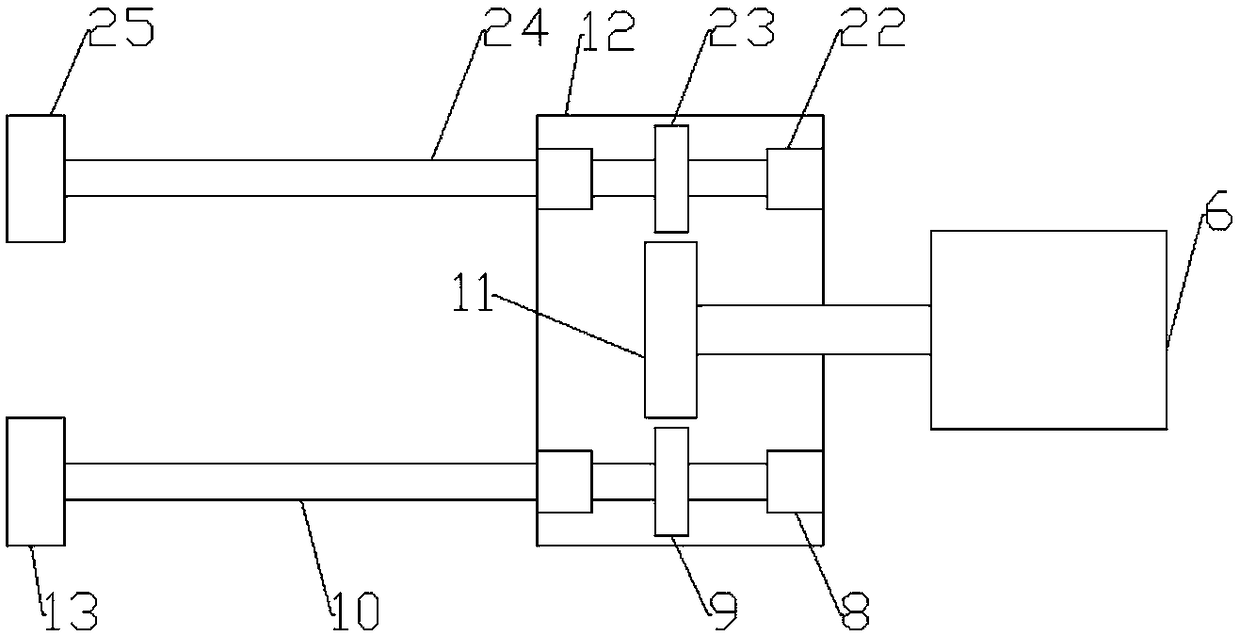

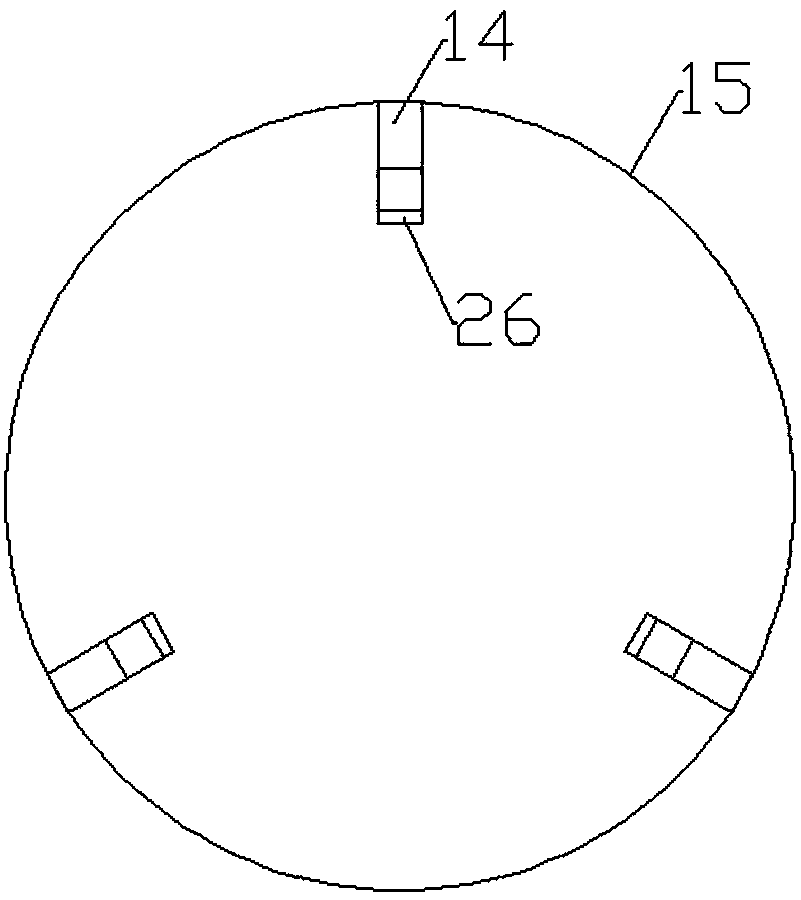

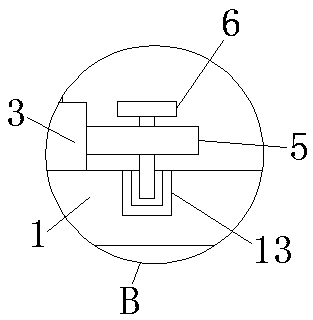

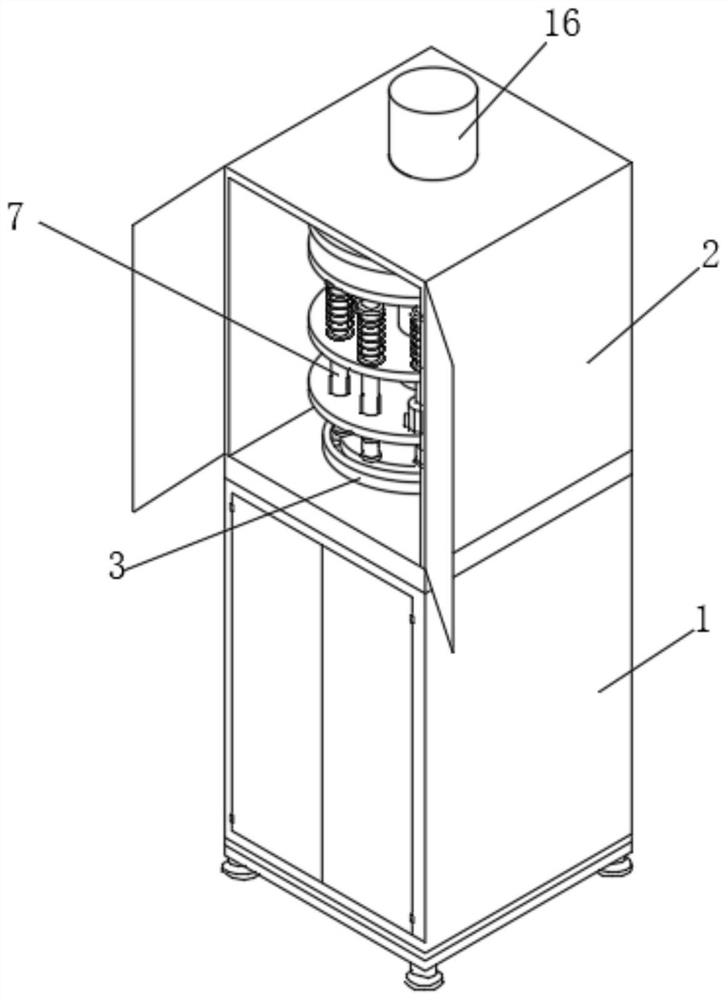

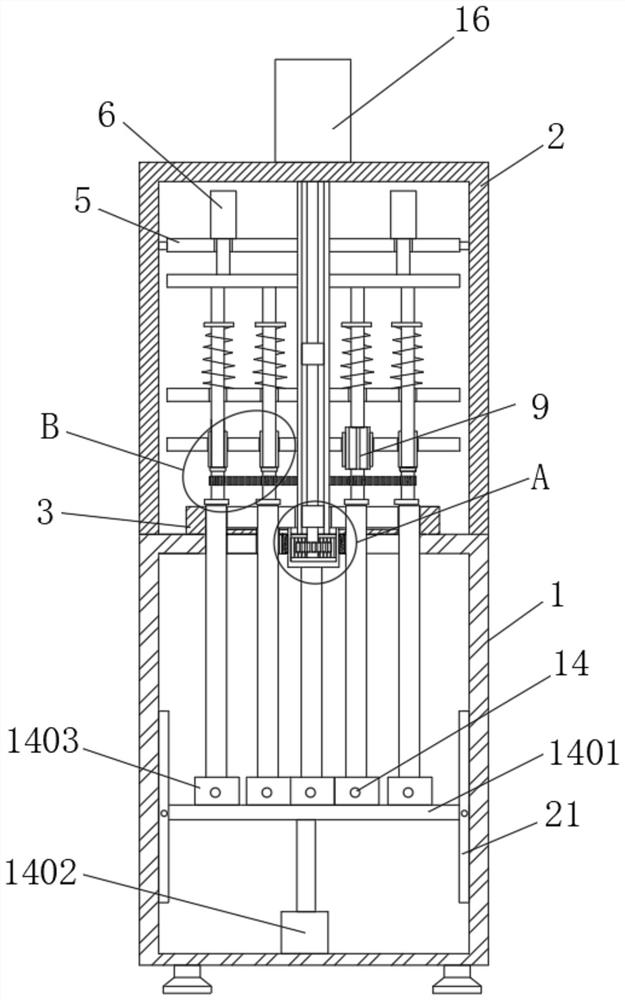

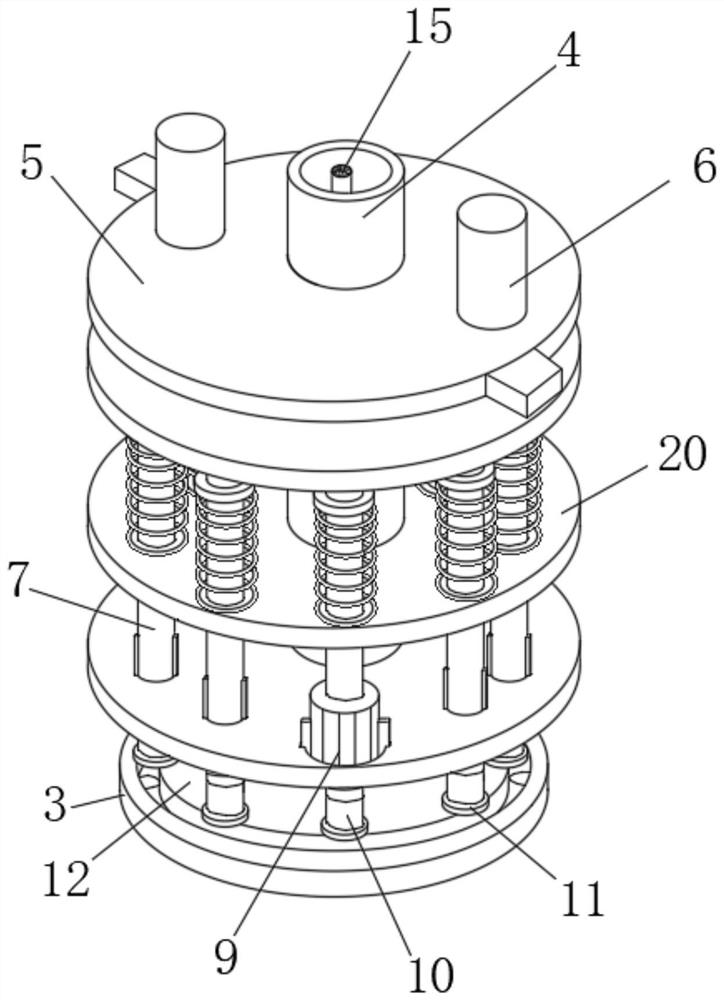

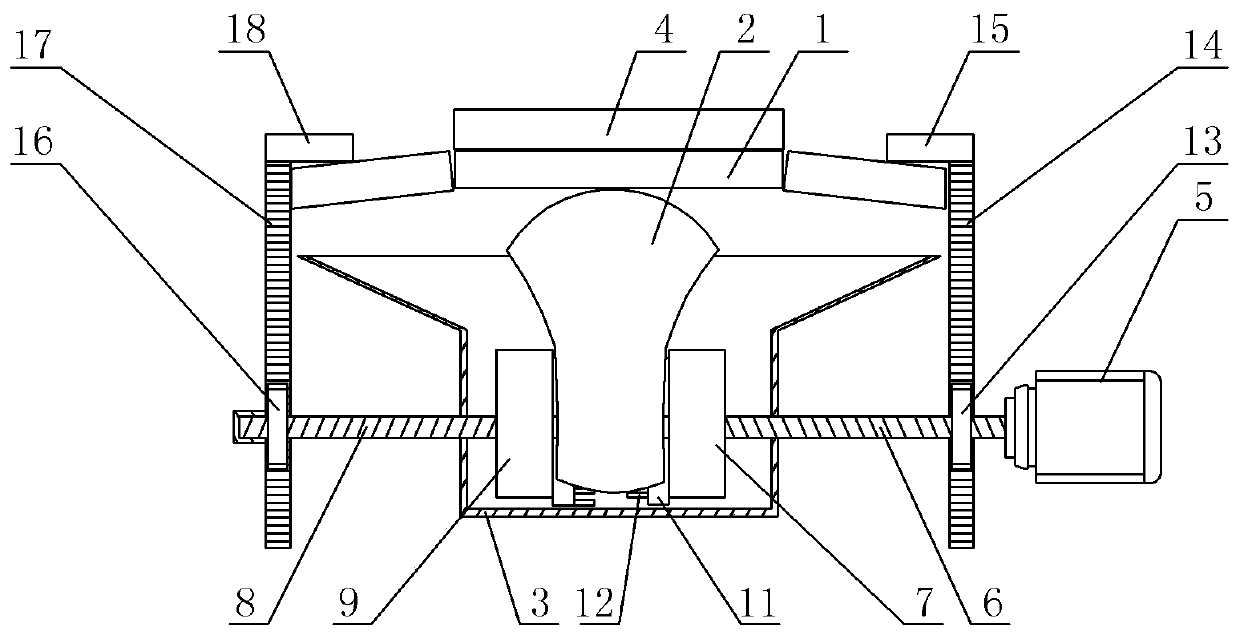

The invention discloses an efficient rotary grinding device. The efficient rotary grinding device comprises a box; a first motor is disposed at the lower end of the interior of the box; a rotary shaftis disposed on the left side of the first motor; a rotary plate is disposed on the upper side of the rotary shaft; a supporting plate is disposed on the outer side of the rotary plate; a first sliding groove is formed in the right end of the upper side of the supporting plate; a first sliding block is disposed in the first sliding groove; a first connecting rod is disposed on the left side of thefirst sliding block; a first telescopic rod is disposed on the left side of the first connecting rod; a grinding roller is disposed on the left side of the first telescopic rod; a second sliding groove is formed in the upper end of the interior of the box; a second sliding block is disposed in the second sliding groove; a second telescopic rod is disposed on the lower side of the second sliding block; a powerful dust suction hood is disposed on the lower side of the second telescopic rod; a first connecting pipe, a connecting hose and a second connecting pipe are disposed on the upper side ofthe powerful dust suction hood; and a dust suction box is disposed on the left side of the second connecting pipe. By means of the efficient rotary grinding device, rotary grinding of equipment can be performed effectively and conveniently, therefore the grinding quality of the equipment can be effectively guaranteed, the working efficiency of the equipment is improved, and the cleanliness of theequipment is guaranteed.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

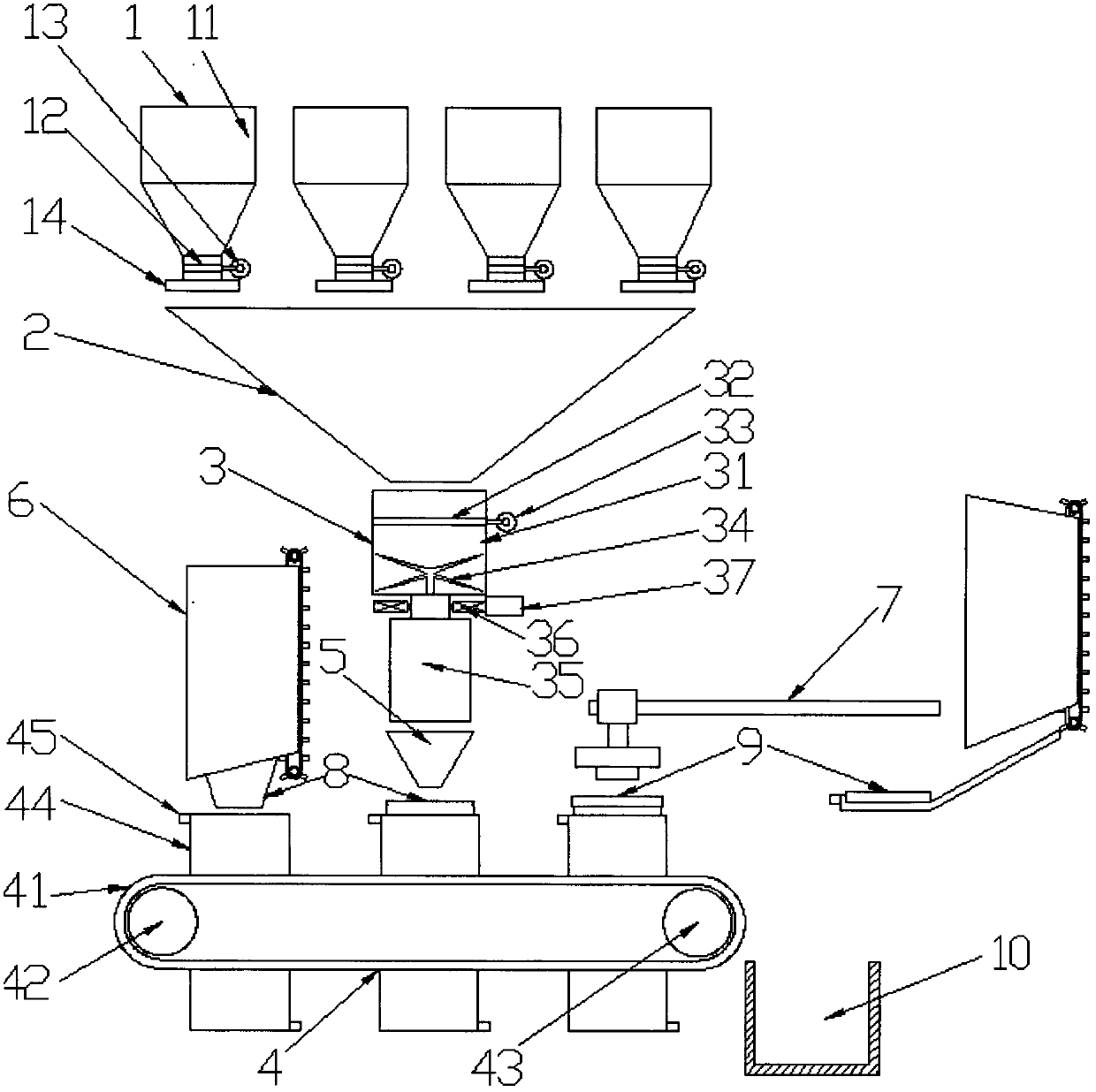

Intelligent powdering and selling robot and method

The invention discloses an intelligent powdering and selling robot and method. The intelligent powdering and selling robot mainly comprises a material bin device, a collecting hopper, a powdering device, a feeding device, a feeding hopper, a storing tank device, a sealing device, a packaging tank, a tank cover, a discharging box, a noiseless air pump, an air pressure sensor, a vacuum pump and a vacuum sensor. The intelligent powdering and selling method of the intelligent powdering and selling robot comprise the steps that the intelligent powdering and selling robot completes online charging according to materials and weight needed by users, and the intelligent powdering and selling robot processes the materials automatically. With requirements of current human cost and food processing safety and health degrees increasing, the intelligent powdering and selling robot can automatically complete selecting, weighing, powdering and packaging of grains without person, remote management and control such as online statistics, online charging, online maintenance and online early warning is achieved through the network, and remote management and control can also be achieved through mobile phone APPs.

Owner:JIAXING UNIV

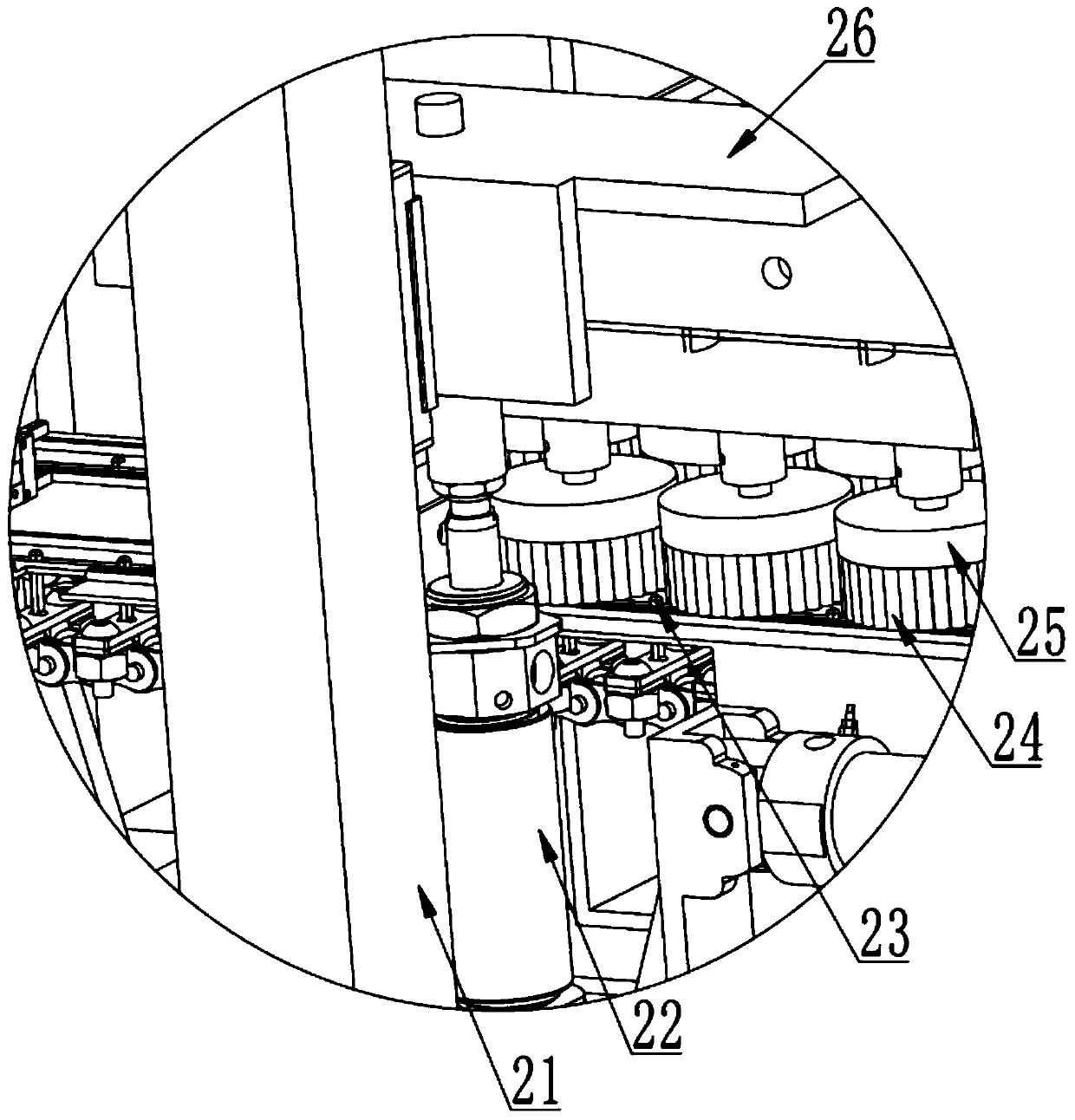

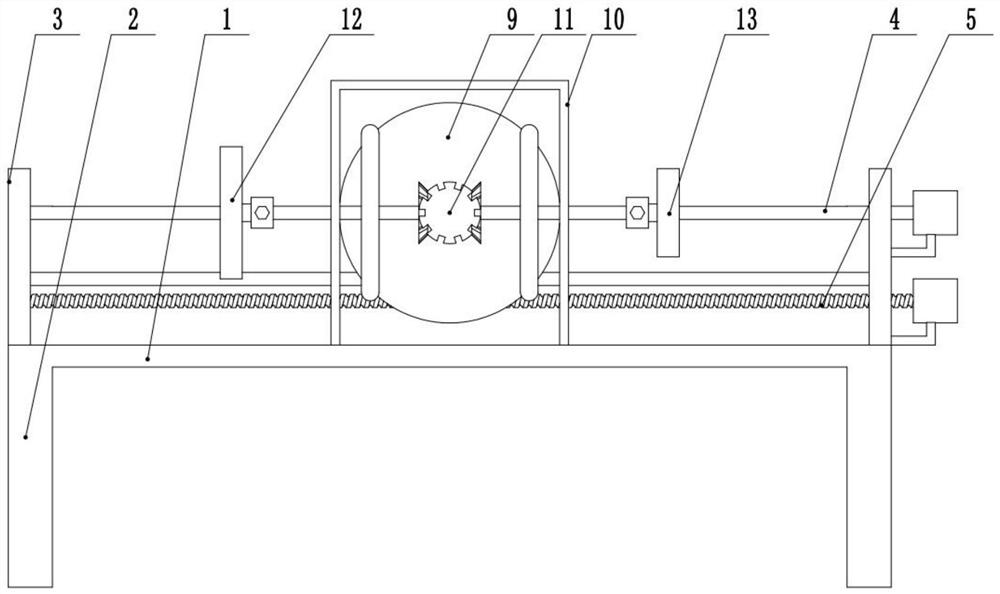

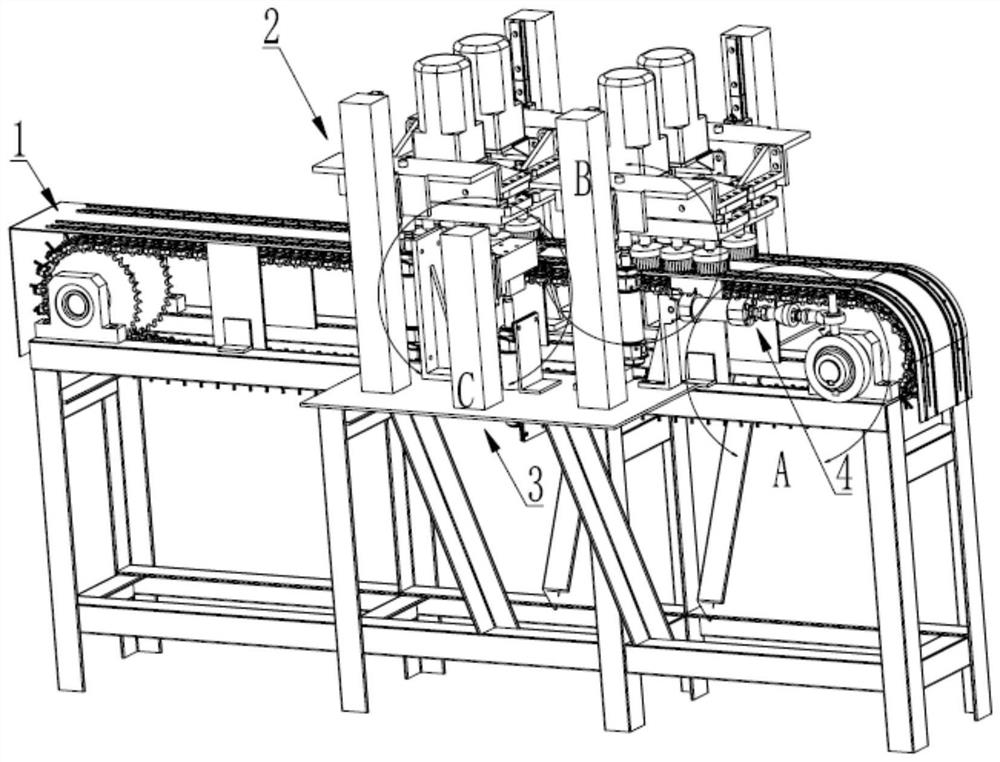

Automatic grinding machine for metal plate

ActiveCN106956179AIncrease contact areaImprove grinding efficiencyEdge grinding machinesGrinding carriagesEngineering

The invention discloses an automatic grinding machine for a metal plate. The essentials of the technical scheme are that the automatic grinding machine comprises a rack, wherein a conveyor belt for placing a metal plate piece is arranged on the rack; on the rack, a grinding device for grinding the upper surface of the metal plate piece is arranged on the upper part of the metal plate piece; the grinding device comprises a grinding shaft perpendicular to the conveyor belt; a plurality of grinding brushes which can contact the metal plate piece are arranged on the peripheral surface of the grinding shaft in a manner of surrounding the circumference array of the grinding shaft; and a first driving piece for driving the grinding shaft to rotate is arranged on the rack. After the mounting is completed, the grinding shaft is driven by the first driving piece to rotate; because the grinding brushes are arranged in a manner of surrounding the circumference array of the grinding shaft, the grinding brushes rotate in a horizontal direction, so that the grinding brushes can contact the metal plate piece when burrs are removed; due to large contact area of the grinding brushes and the metal plate piece, the grinding efficiency also can be improved; meanwhile, the grinding brushes can be directly driven by a separate grinding shaft to rotate; and therefore, the structure is simple, and the production is very convenient.

Owner:苏州宝罗机械工程有限公司

Double-side deburring device

ActiveCN111300199AExtend sanding timeImprove stabilityEdge grinding machinesGrinding drivesStructural engineeringGrinding process

The invention discloses a double-side deburring device. The double-side deburring device comprises a controller, a conveying mechanism, at least four deburring mechanisms and two turnover mechanisms.The controller is connected with the conveying mechanism, the deburring mechanisms and the turnover mechanisms. The conveying mechanism comprises a one-way intermittent driving mechanism and a plurality of fixing pins arranged linearly and driven through the one-way intermittent driving mechanism. The four deburring mechanisms are divided into two sets and are oppositely arranged on the left and right sides above the fixing pins arranged linearly. The two turnover mechanisms are arranged between the deburring mechanisms located on the same sides of the fixing pins arranged linearly. The double-side deburring device can drive workpieces intermittently through the intermittent driving mechanism so as to prolong the grinding time of the workpieces in one working position. Moreover, in the grinding process, the driving mechanism can also improve the stability of the workpieces to prevent the workpieces from deviating from the grinding position, and accordingly the grinding and deburring effects are ensured.

Owner:LISHUI UNIV

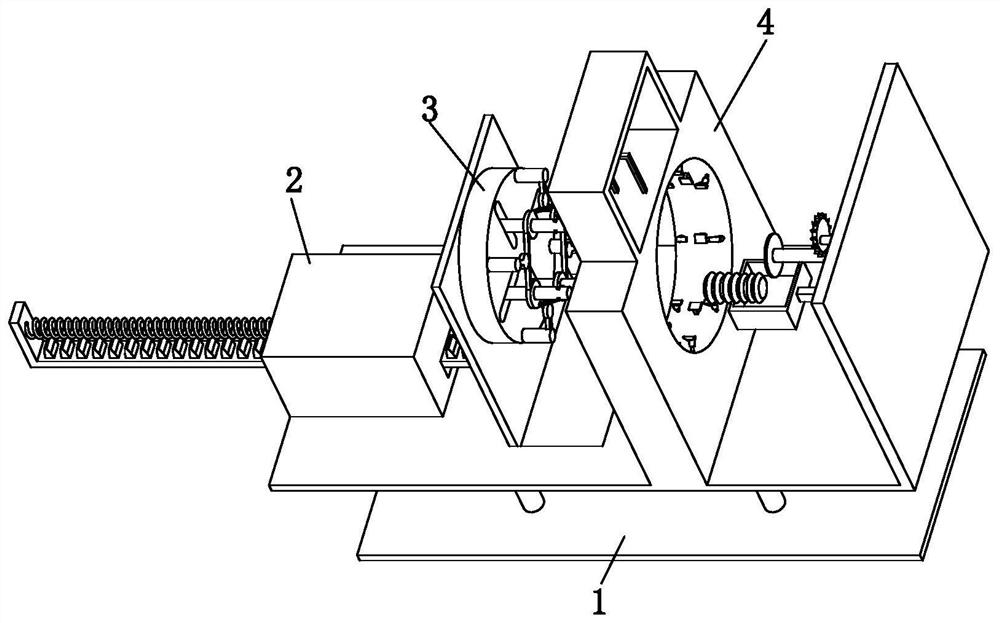

Polishing device for caddy

InactiveCN108481116AEasy accessSo as not to damageEdge grinding machinesGrinding drivesEngineeringPinion

The invention discloses a polishing device for a caddy. The polishing device comprises a bottom plate. The two ends of the bottom plate are provided with a second outer motor shell and a sliding rail.A second motor and a fixed plate are arranged at the bottom end in the second outer motor shell. A motor spindle is provided with a pinion. A third rotary rod seat is fixed to the fixed plate and isinternally provided with a third rotary rod. One end of the third rotary rod is connected with a large gear. The other end of the third rotary rod is provided with a rotary disc. The rotary disc is provided with a clamping block. The sliding rail is provided with a sliding block. A first outer motor shell and a first motor are arranged at the upper end of the sliding block. A spindle of the firstmotor is provided with a third gear. A first rotary rod seat and a second rotary rod seat and are arranged on the side face of the first outer motor shell. A first rotary rod is arranged in the firstrotary rod seat. A second rotary rod is arranged in the second rotary rod seat. A first gear is arranged on the first rotary rod. A polishing wheel is arranged at the front end of the first rotary rod. A second gear is arranged on the second rotary rod. A brush wheel is arranged at the front end of the second rotary rod. According to the polishing device, an operation method is simple, burrs attaching to the surface are brushed off immediately through the brush wheel after polishing, polishing work and deburring work are conducted simultaneously, cleanliness in the caddy is ensured, and machining efficiency is improved.

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

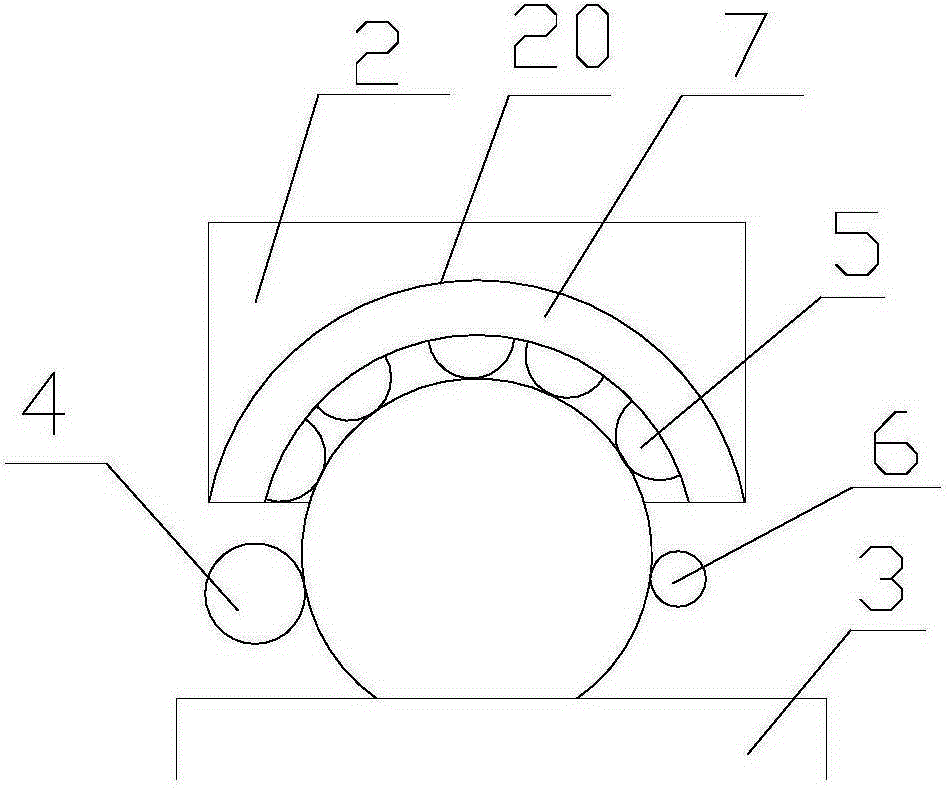

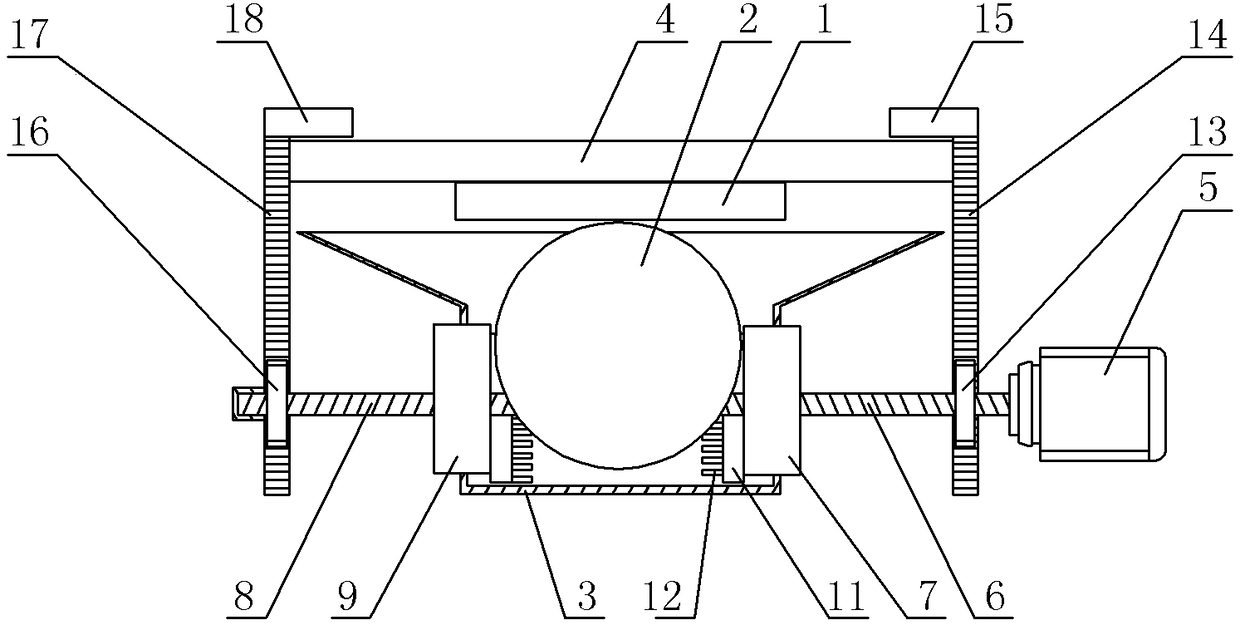

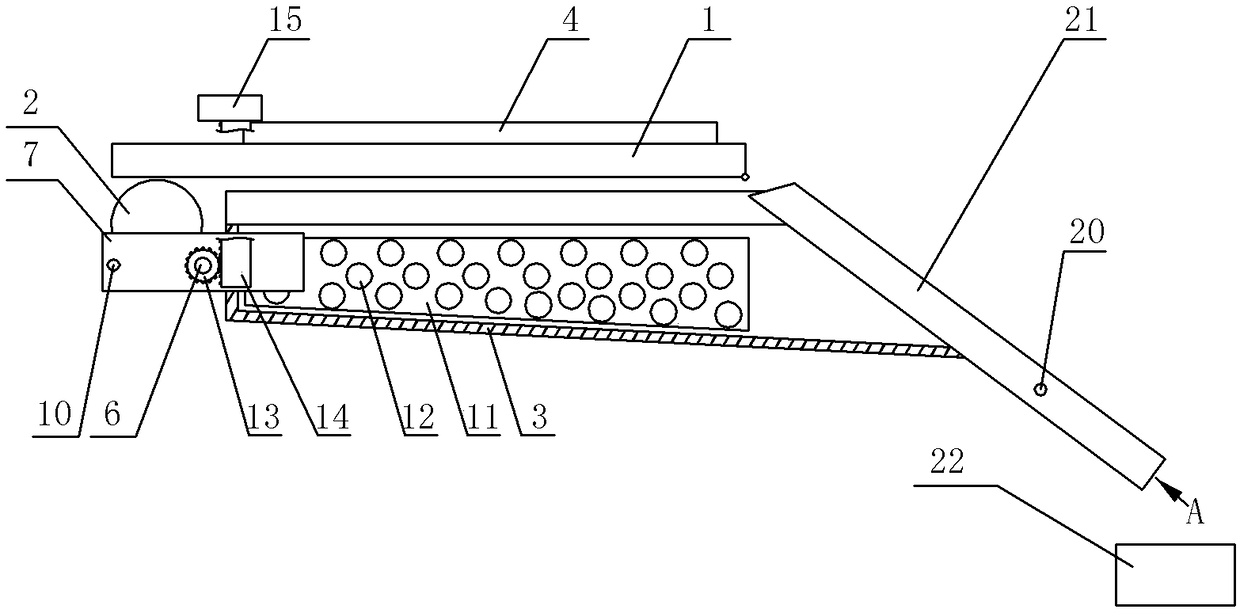

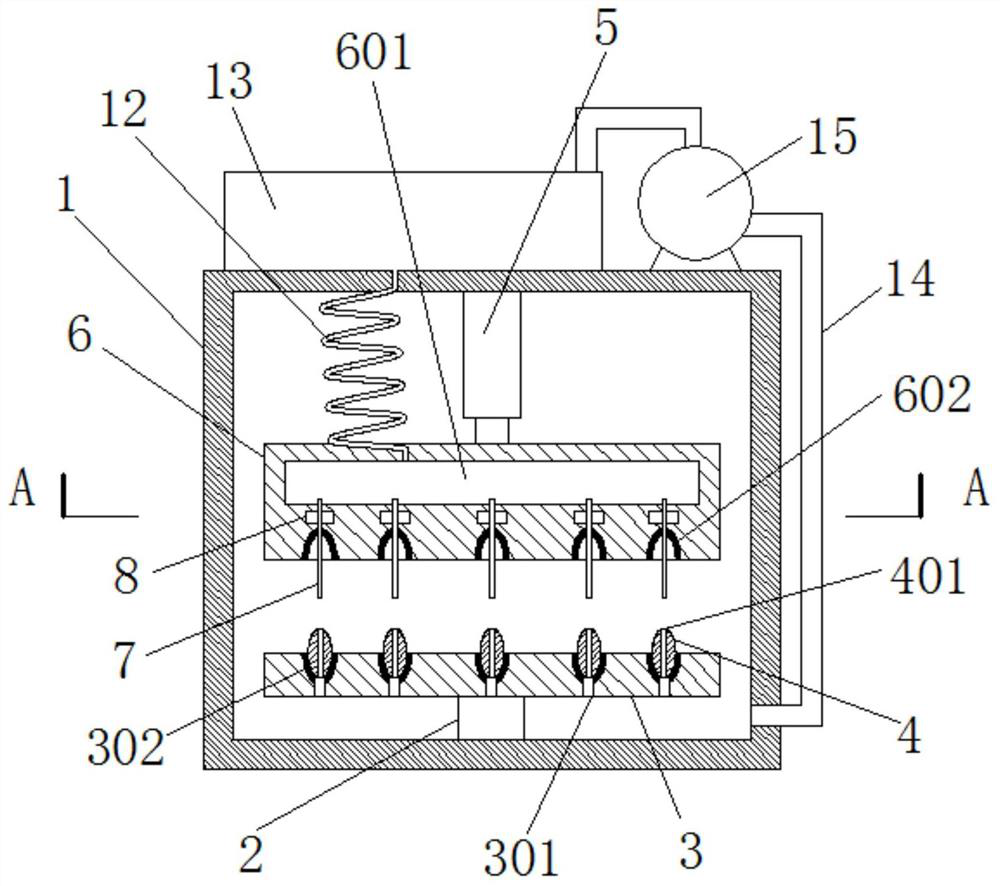

Wear-resisting ball surface treating device

InactiveCN105215824AReasonable structureEnergy savingSpherical surface grinding machinesSurface finishingEngineering

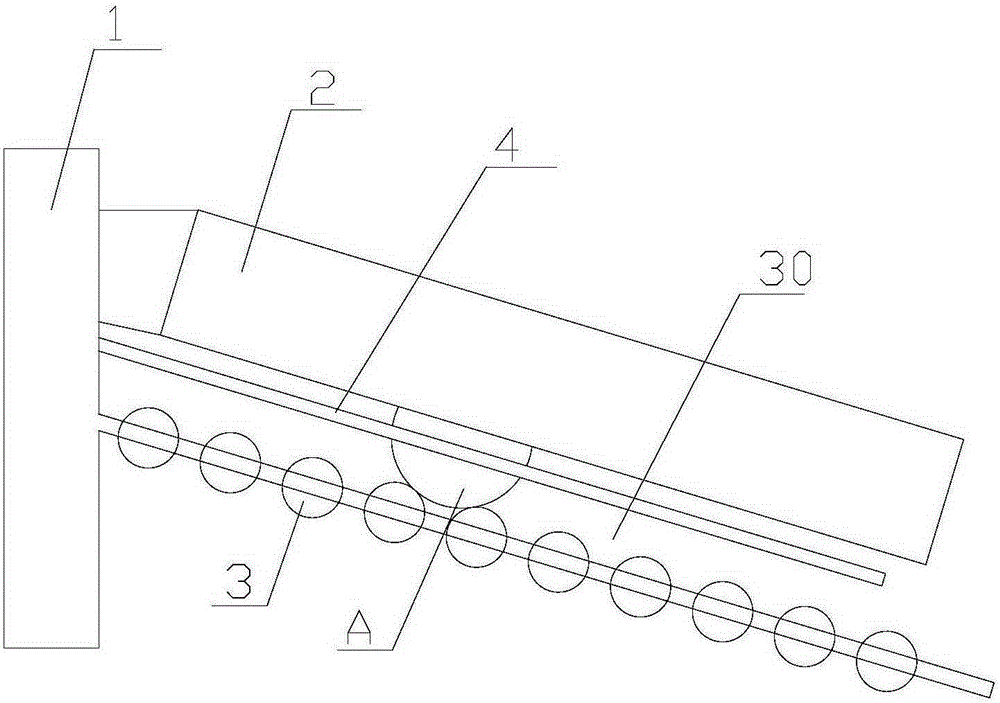

The invention discloses a wear-resisting ball surface treating device. The wear-resisting ball surface treating device comprises a support, a rust removing structure, a plurality of first rollers, a second roller, a first driving mechanism and a second driving mechanism. The multiple first rollers are installed on the support and arranged on an inclined plane in parallel to form a conveying rail. The first driving mechanism is connected with the first rollers and drives the first rollers to rotate around a central shaft. A wear-resisting ball on the conveying rail rolls from the higher end to the lower end. The rotation direction of the first rollers is opposite to the movement direction of the wear-resisting ball. According to the wear-resisting ball surface treating device, all-dimensional rotation of the wear-resisting ball can be achieved under the action of self-weight and the friction force by means of the conveying rail and the second roller which are arranged obliquely, so that during rolling, relative friction is achieved between the whole ball surface and the grinding structure, and the grinding effect is achieved. The wear-resisting ball surface treating device is reasonable in structure, the gravity action is utilized sufficiently, energy sources are saved easily, and the working efficiency is improved.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

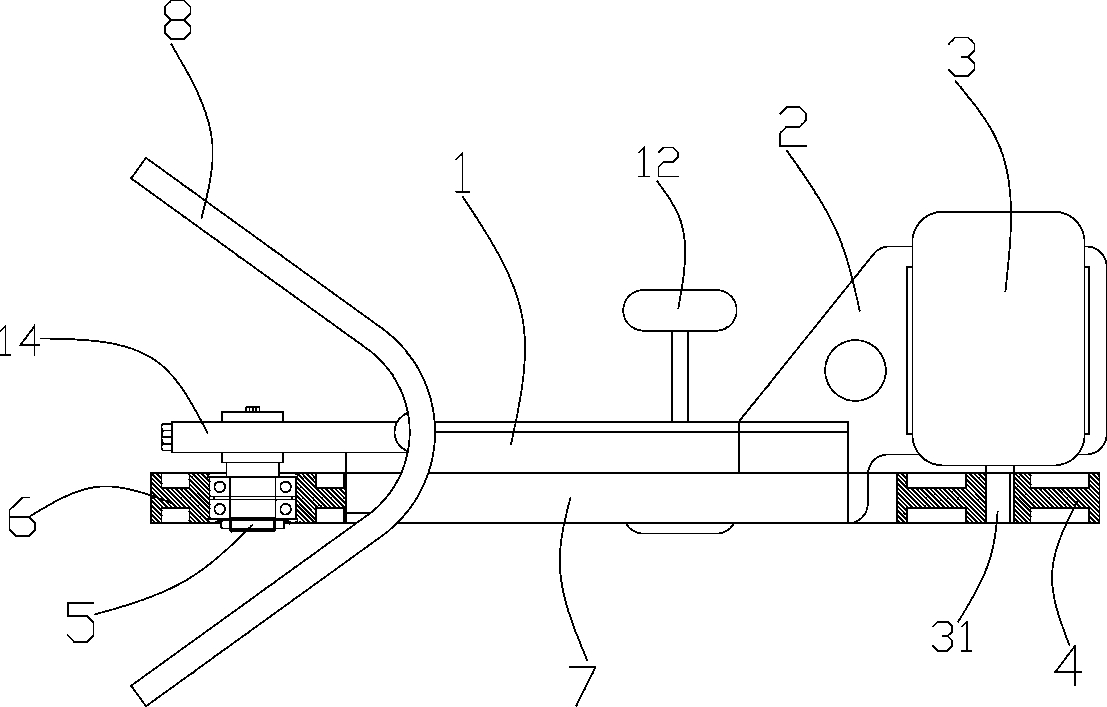

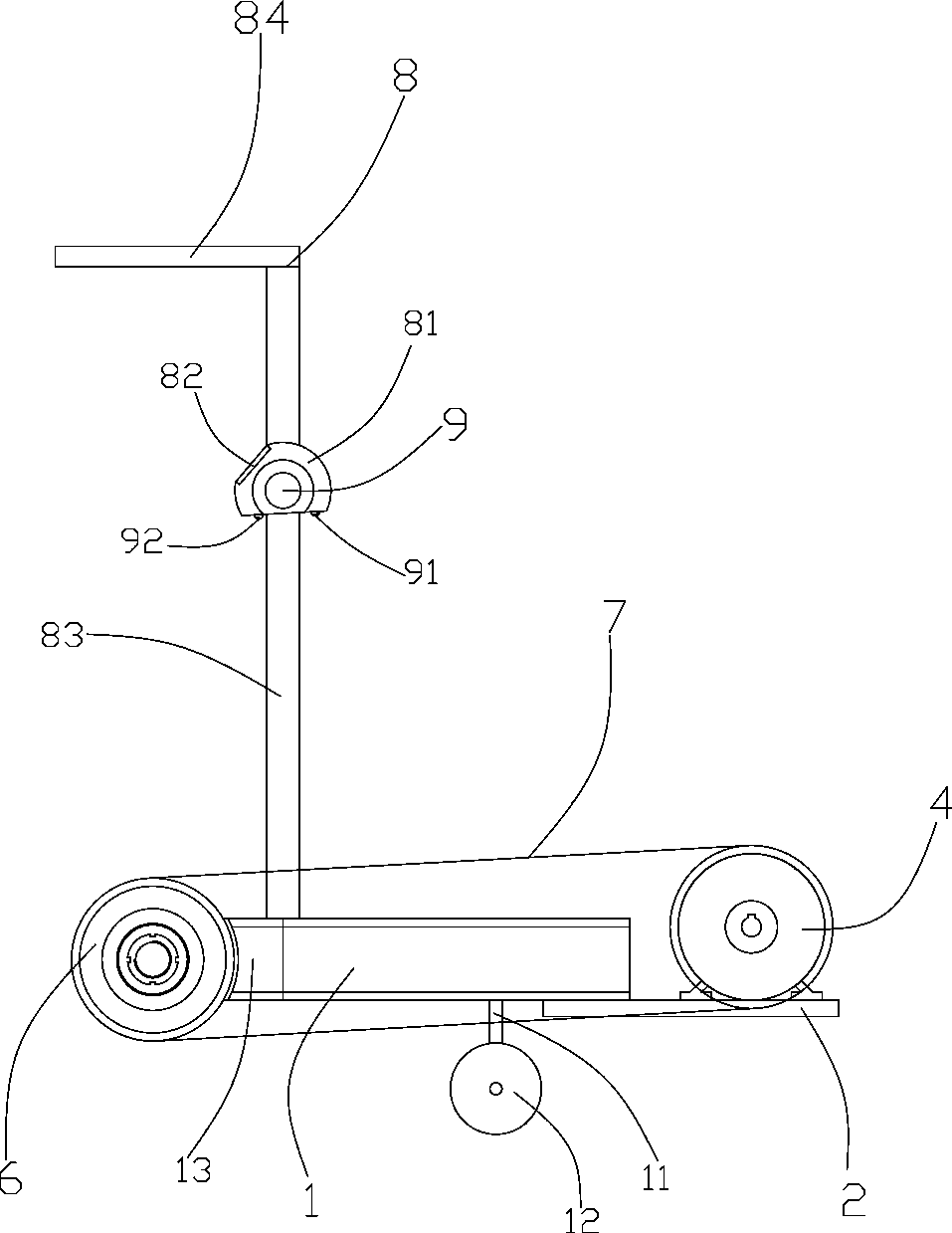

Steel grinding device

InactiveCN104290010AEasy to produce and processImprove production and processing efficiencyBelt grinding machinesGrinding feed controlSteel platesEngineering

The invention discloses a steel grinding device and relates to grinding cleaning equipment of sheet metal. The steel grinding device comprises a supporting base, a driving wheel and a driven wheel; an abrasive belt is connected onto the driving wheel and the driven wheel in a sleeving mode; the supporting base is provided with a hand-held frame which is provided with a cross rod; the cross rod is provided with an infrared distance measurement device which comprises a first probe and a second probe; the first probe and the second probe are arranged on the lower end surface of the cross rod; the first probe is towards the direction of the driving wheel; the second probe is towards the direction of the driven wheel. Compared with the prior art, the distance measurement is performed on the first probe and the second probe through the infrared distance measurement device which is arranged on the cross rod so as to determine whether a symmetric line of steel plates is consistent with a center line of the abrasive belt or not, a motor is started after the symmetric line and the center line are overlapped, the grinding is performed on the steel plates through a grinding wheel, and accordingly the middle position of the steel plates can be ground, the subsequent production and machining is facilitated, the convenient and practical effect is achieved, and the production efficiency is improved.

Owner:NINGBO HUAYE STEEL STRUCTURE

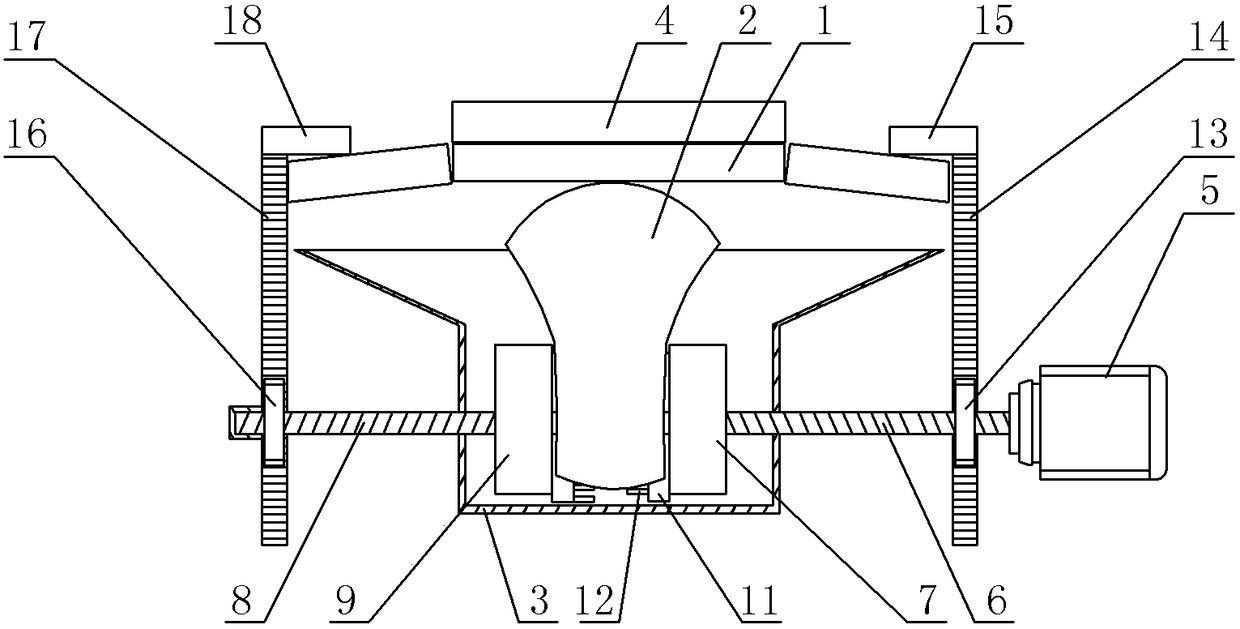

De-burring device for steel pipe orifice

ActiveCN110883629AWon't hurtIncrease sanding speedEdge grinding machinesGrinding drivesElectric machineryEngineering

The invention discloses a de-burring device for a steel pipe orifice. The de-burring device for the steel pipe orifice comprises a base; a fixed table is fixedly mounted on the base; a limiting hole is formed in the fixed table; a plurality of electromagnetic compacting mechanisms are embedded into the upper hole wall of the limiting hole; two supporting mechanisms are symmetrically embedded intothe lower hole wall of the limiting hole; an adjusting groove is formed in the base; an adjusting mechanism is mounted in the adjusting groove; and a grinding motor is fixedly mounted on the adjustingmechanism. According to the de-burring device for the steel pipe orifice, a steel pipe cannot shake greatly when being ground through the electromagnetic compacting mechanisms and the supporting mechanism; the situations of pipe orifice deformation and excessive grinding are reduced; through a rubber pressing wheel and a supporting wheel, the steel pipe is fixed non-destructively and certain rotating resistance is provided for the steel pipe, so that the steel pipe rotates relative to a grinding cone and a grinding post; the grinding speed is increased; and the device can be matched with thesteel pipes with different pipe diameters for grinding by adjusting the height of the grinding motor through the adjusting mechanism and changing the installation depth of the grinding cone.

Owner:TAIZHOU ANN WELDING EQUIP CO LTD

Part grinding device for production of planar transformer

ActiveCN112936042AAchieve grindingChange speedGrinding drivesGrinding machinesEngineeringPlanar transformers

The invention discloses a part grinding device for the production of a planar transformer, and relates to the technical field of planar transformers. The part grinding device comprises a mounting base, the lower surface of the mounting base is fixedly connected with supporting legs, the upper surface of the mounting base is fixedly connected with two vertical plates, the vertical plates are fixedly connected with a driving mechanism and a position adjusting mechanism, the position adjusting mechanism is fixedly connected with a moving frame, the moving frame is rotatably connected with a first transmission mechanism, the moving frame is fixedly connected with a pressing mechanism, a variable-speed transmission mechanism is arranged on the first transmission mechanism, the upper surface of the mounting base is fixedly connected with a fixing frame, the variable-speed transmission mechanism is fixedly connected with a second transmission mechanism, and the variable-speed transmission mechanism is fixedly connected with a first grinding mechanism and a second grinding mechanism. According to the device, the driving force can be provided by arranging a driving mechanism to drive the first grinding mechanism and the second grinding mechanism to rotate so that grinding of workpieces is achieved, the grinding efficiency of planar transformer parts is improved, and the functions of the whole device are enriched.

Owner:GUANGDONG LIWANG HI TECH

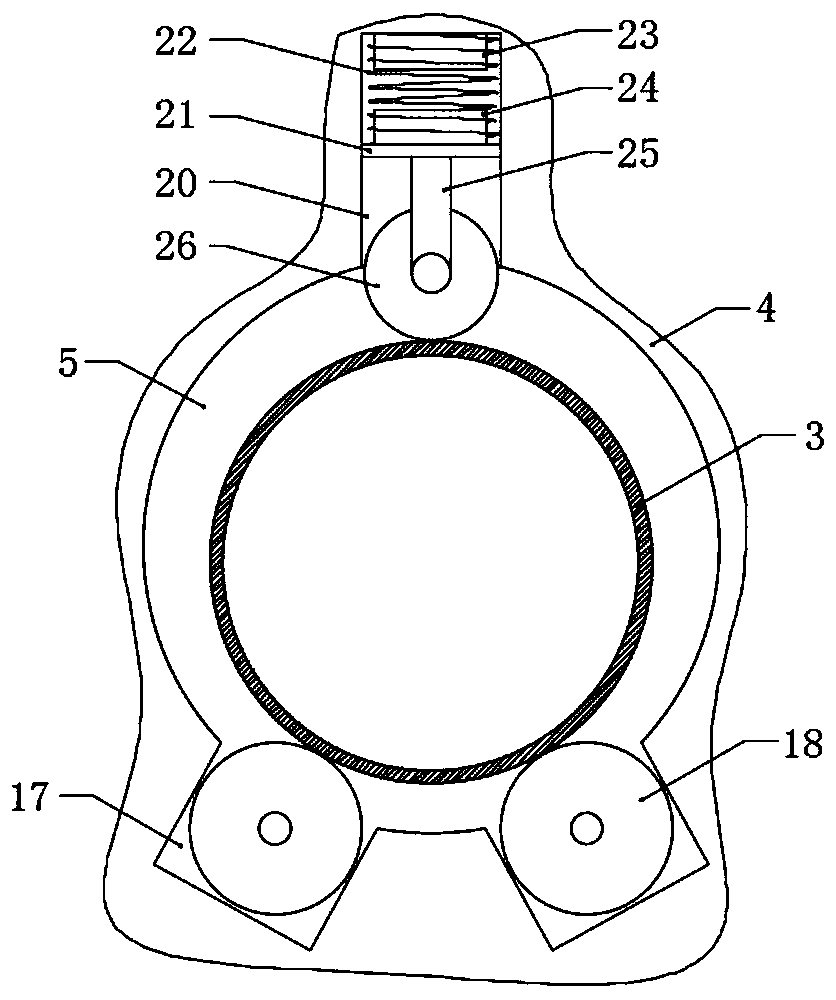

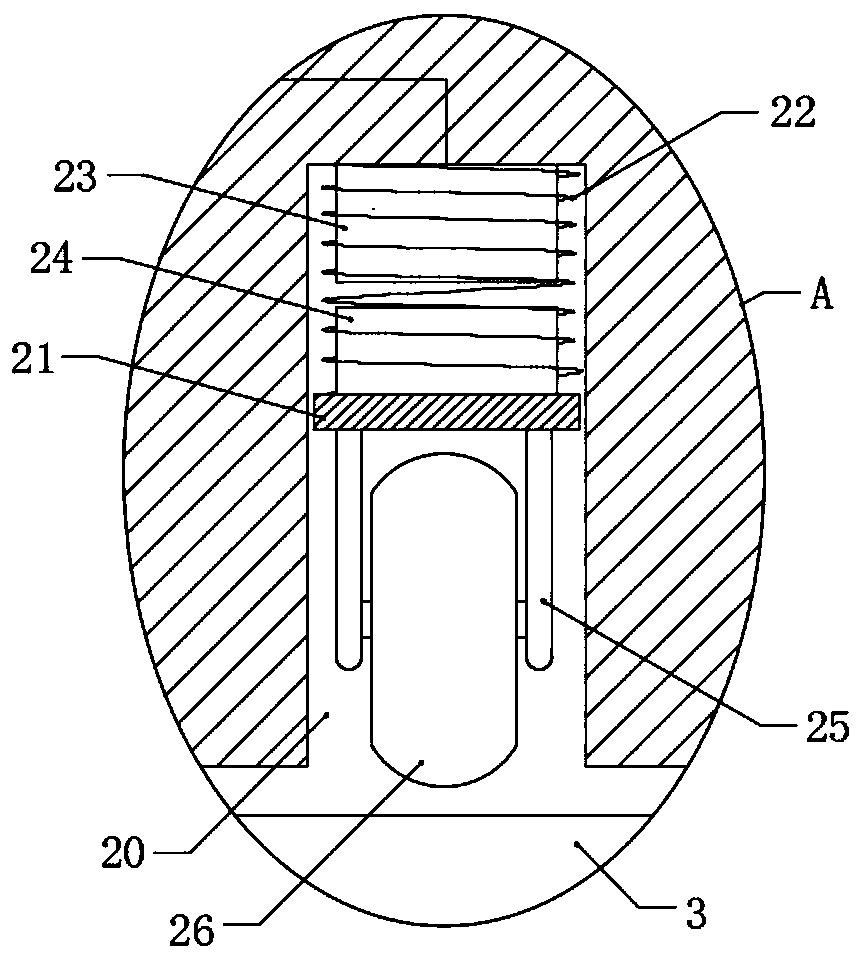

Magnetic isolation ring grinding device with roughness detection function

InactiveCN112123149AWith roughness detection functionGuaranteed sandingGrinding carriagesGrinding drivesEngineeringMagnetic isolation

The invention discloses a magnetic isolation ring grinding device with a roughness detection function. The magnetic isolation ring grinding device specifically comprises a bottom plate, a movable rail, a rotary disc and a magnetic isolation ring, wherein a mechanical table is installed on one side of the top of the bottom plate, a fixing seat is embedded in the top end of the interior of the mechanical table, a control panel is fixed to the middle position of one end of the mechanical table, and a waste chip collecting box is installed at the bottom end of the interior of the mechanical table.According to the magnetic isolation ring grinding device with the roughness detection function, a rotating seat, the movable rail and two telescopic seats are arranged, the tail ends of the two telescopic seats are correspondingly and fixedly provided with a group of grinding mechanisms, grinding heads of one group of grinding mechanisms are suitable for grinding the upper end surface and the side edge of an annular platform, the grinding heads of the other group of grinding mechanisms are suitable for grinding semicircular grooves and through holes of the annular platform, so that the grinding of the end surface, the side edge semicircular grooves and the through holes of the annular platform can be guaranteed through one-time clamping, and the machining efficiency is higher.

Owner:深圳市顺尔通工业设计有限公司

Grinding device for curved iron plate

InactiveCN108032192APolished full and fullPrevent iron filings from splashingGrinding drivesGrinding machinesScrapPulp and paper industry

The invention relates to a grinding device for a curved iron plate. The grinding device comprises a grinding head, a base and a rotating shell, wherein a supporting column is connected to the base, the rotating shell is rotationally connected to the supporting column, and a worm is arranged in the rotating shell in a rotating mode; the two ends of the worm extend to the outer side of the rotatingshell; the grinding head is connected to one end of the worm, and the other end of the worm is meshed with a worm gear; a first connecting rod is connected between the worm gear and the rotating shell, a motor and a fixed plate are arranged at the bottom of the rotary shell, and a second connecting rod is connected between the bottom surface of the worm gear and the fixed plate; the bottom of theworm gear is connected with a rotating shaft, a belt is connected between an output shaft of the motor and the rotating shaft, and a scrap iron hole is formed in the base; a collecting box is arrangedbelow the base, and the collecting box communicates with the scrap iron hole; and the end, far away from the grinding head, of the worm is fixedly connected with blades, and the end, far away from the grinding head, of the worm is covered with a sealing cover communicating with the collecting box; and the grinding head comprises a baffle and a plurality of grinding blocks, and a spring is connected between the grinding blocks and the baffle. According to the grinding device for a curved iron plate, grinding of the curved iron plate is realized.

Owner:重庆市合川区云天机械制造有限公司

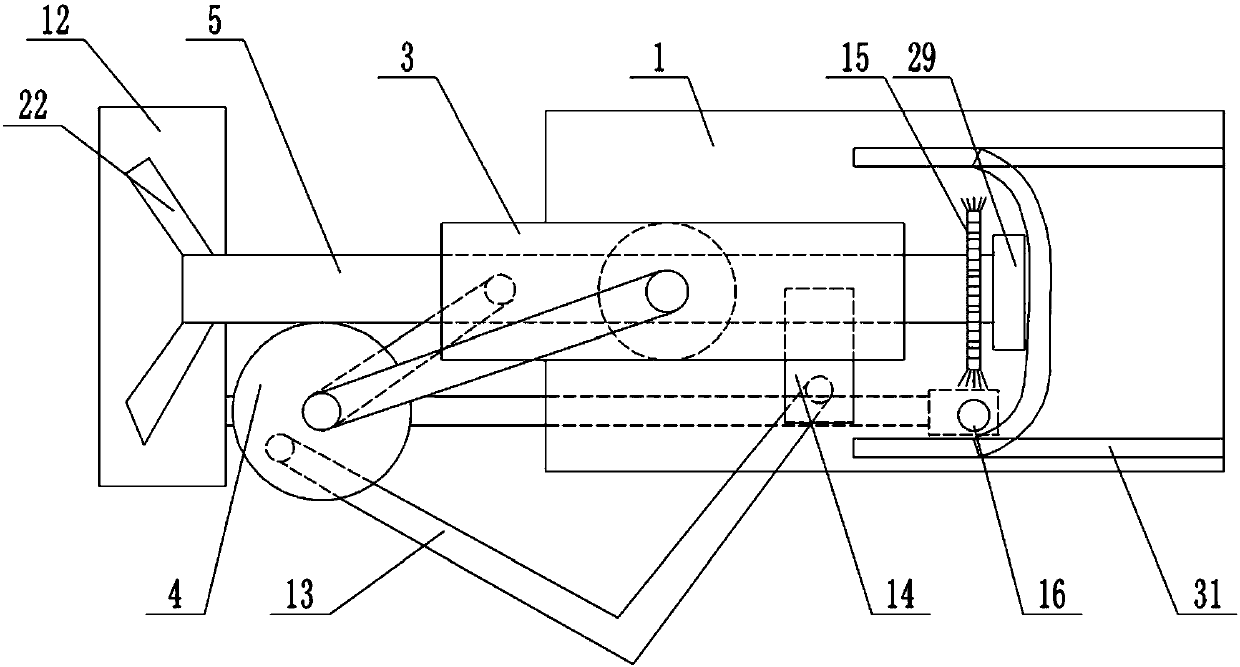

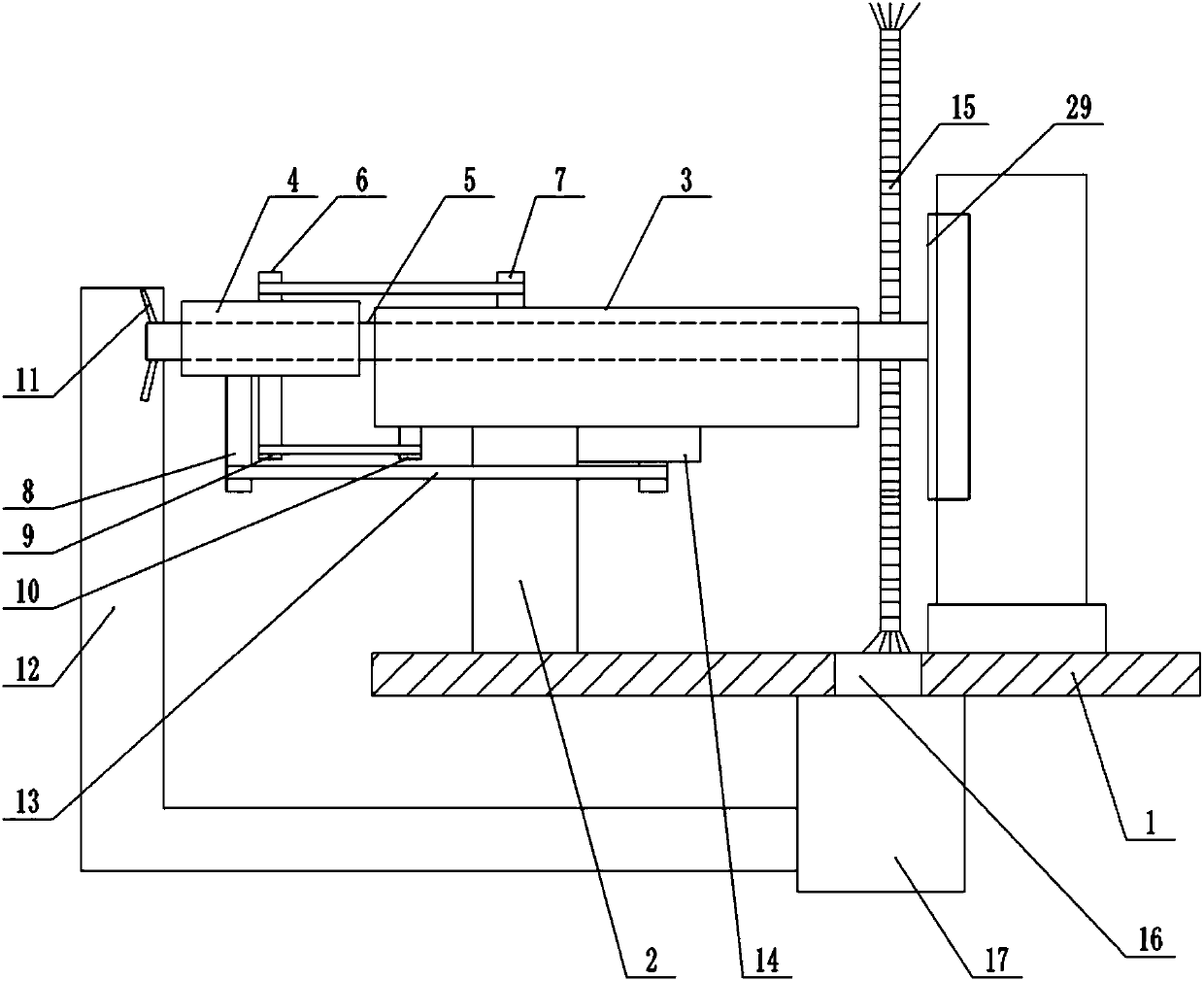

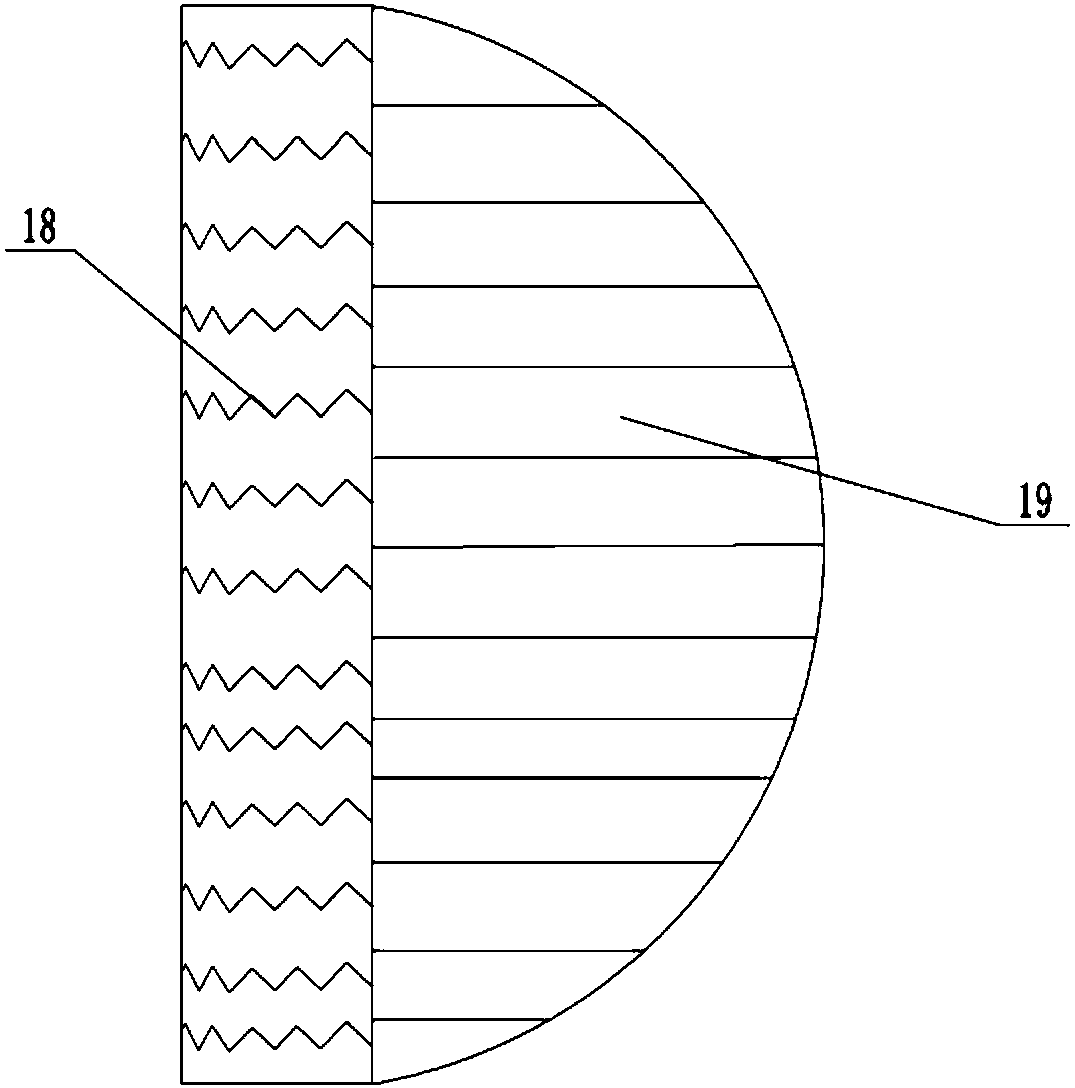

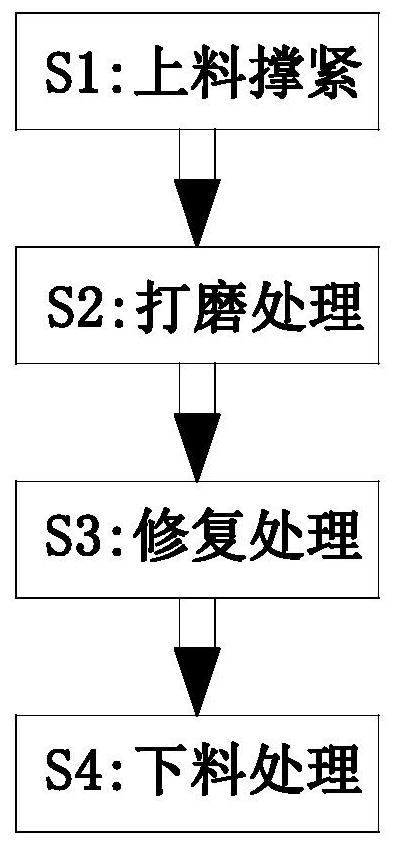

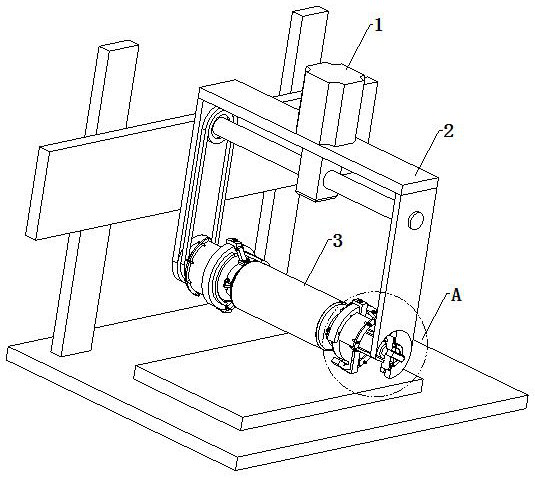

Dry-type transformer post insulator manufacturing and processing method

ActiveCN113053600AReduce investmentImprove grinding efficiencyGrinding machinesSupporting insulatorsTransformerPolishing

The invention relates to a dry-type transformer post insulator manufacturing and processing method, which comprises a supporting device, a driving device, a fixing device and a polishing and repairing device, the driving device is fixedly mounted at the left end of the upper end face of the supporting device, the right end of the driving device is fixedly connected with the fixing device, and the polishing and repairing device is arranged on the right side of the fixing device. According to the dry-type transformer post insulator manufacturing and processing method, the following problems possibly encountered in the manufacturing process of an existing dry-type transformer post insulator can be solved: a, as the side wall of a blank is uneven, the surface of the blank is usually manually polished, the mode is large in input labor force and extremely low in polishing efficiency, and the polishing effect cannot be guaranteed; and b, after polishing is completed, the polishing surface is manually coated with the repairing liquid, the situation of incomplete or non-uniform coating is likely to occur, therefore, the repairing cost is increased, and the production quality of the post insulator is reduced.

Owner:西安立达合成材料开发有限公司

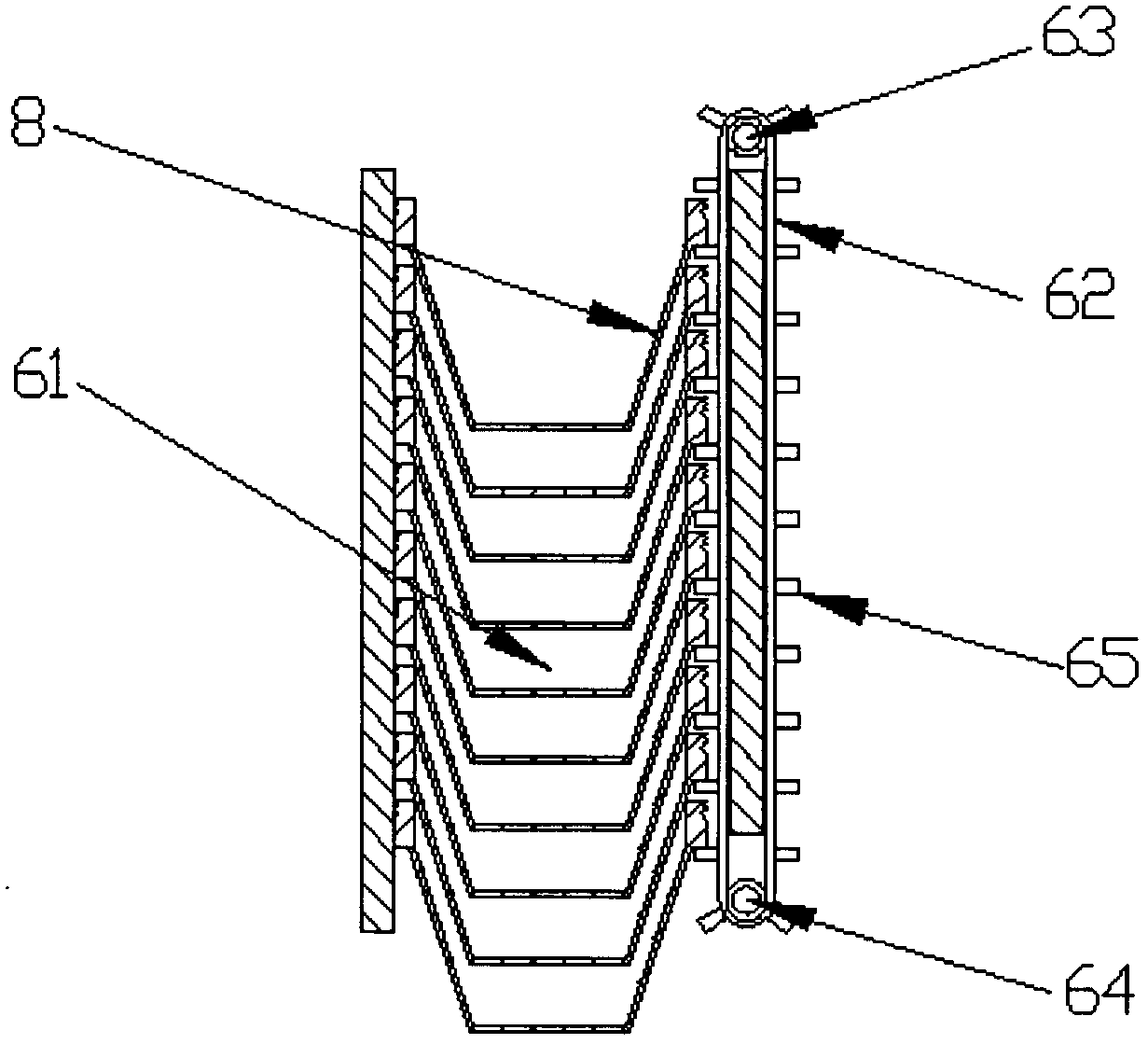

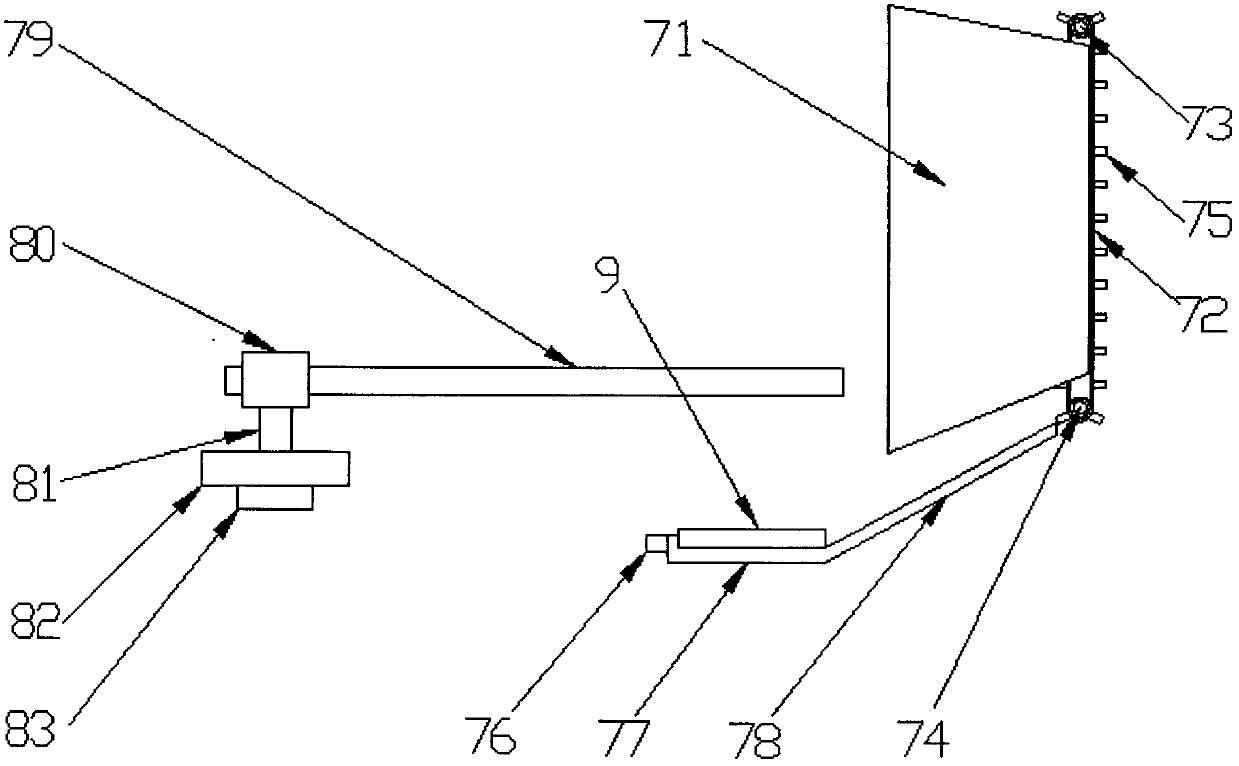

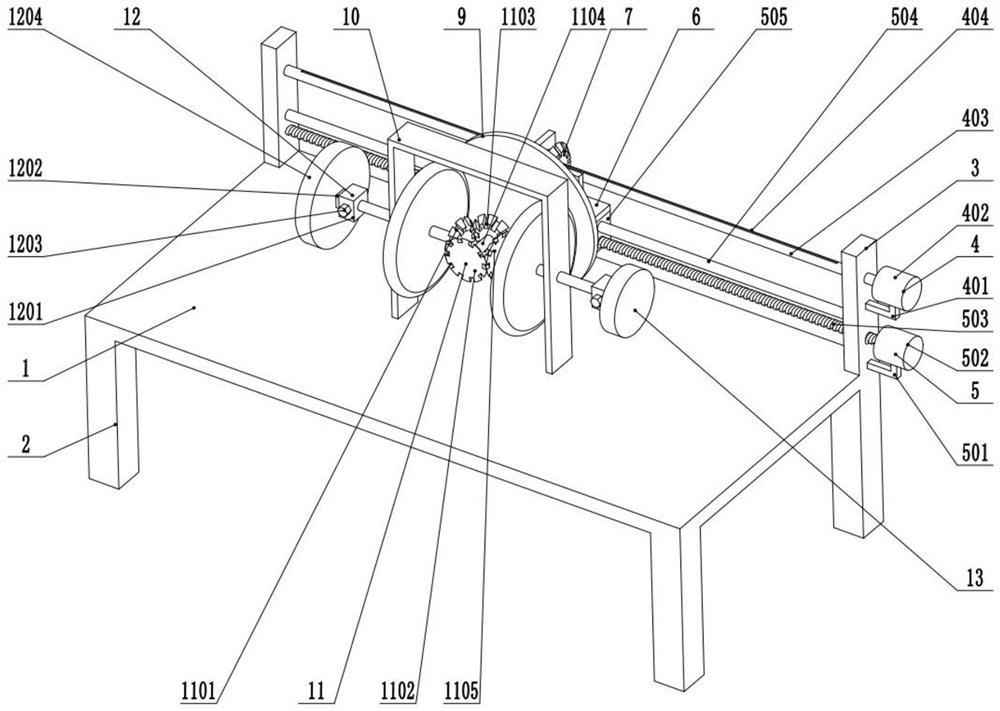

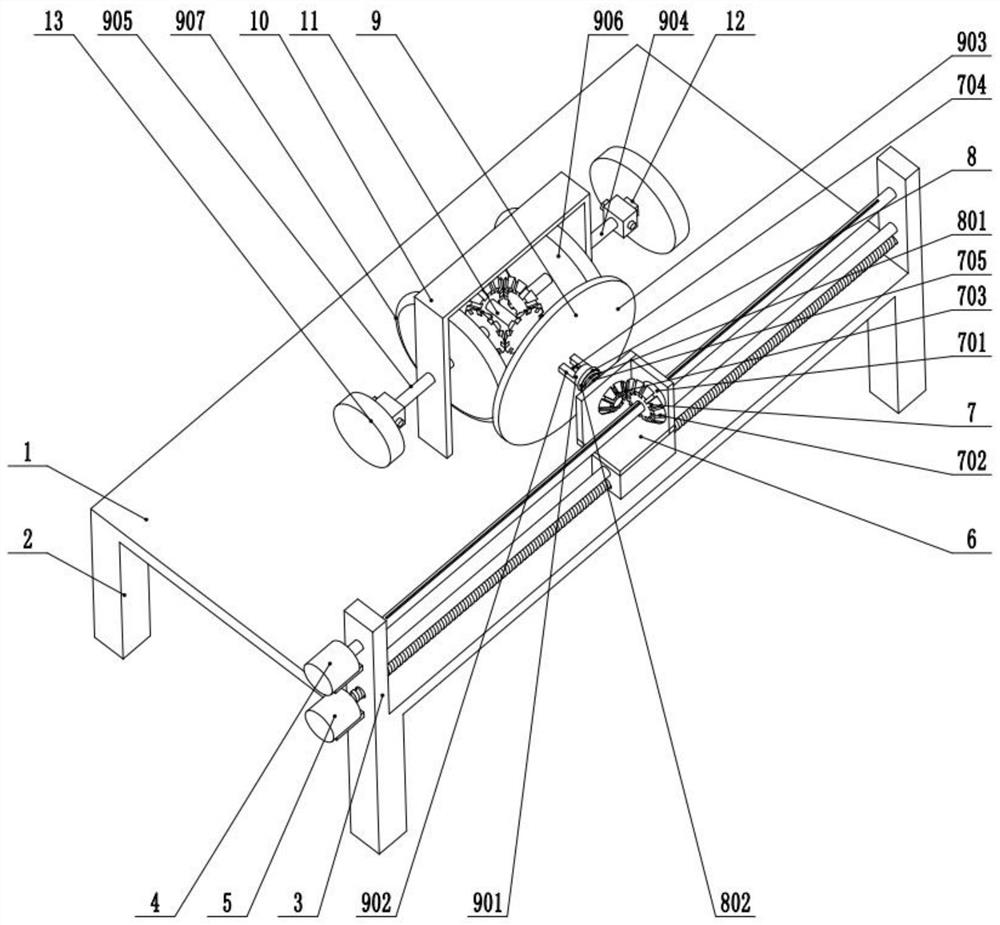

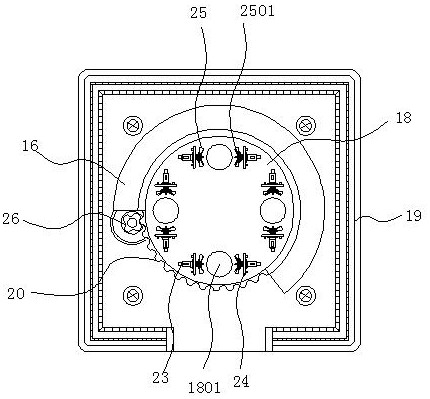

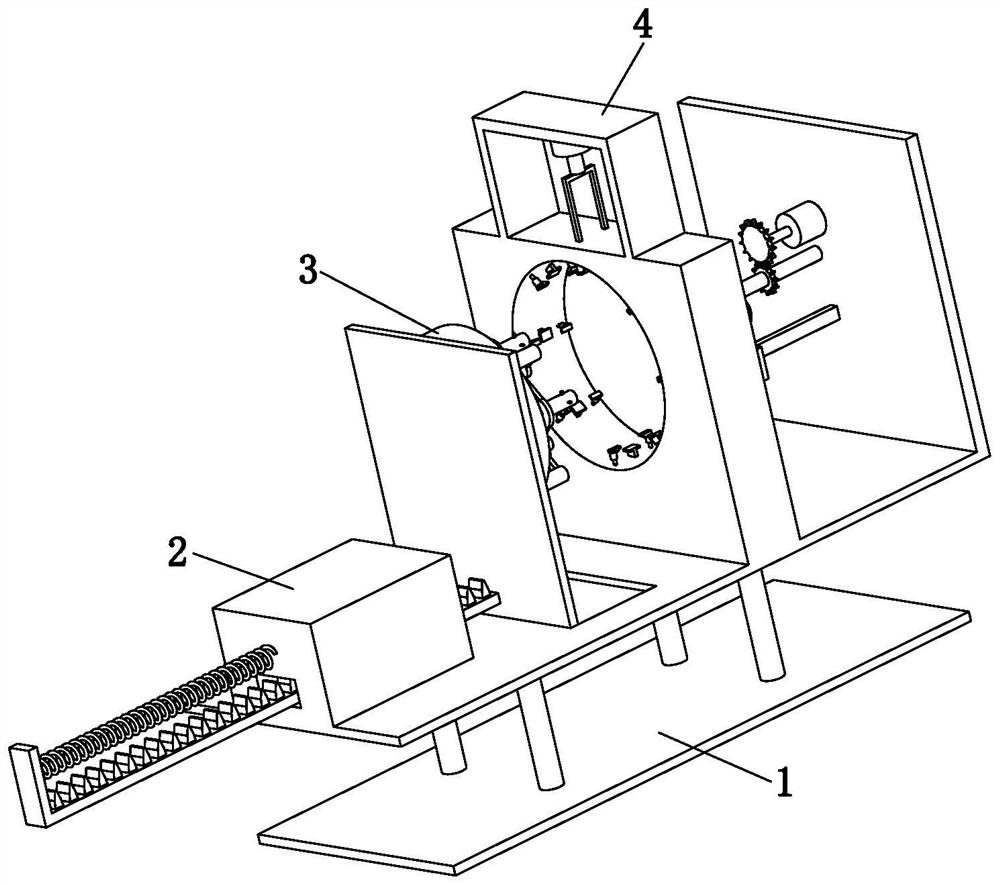

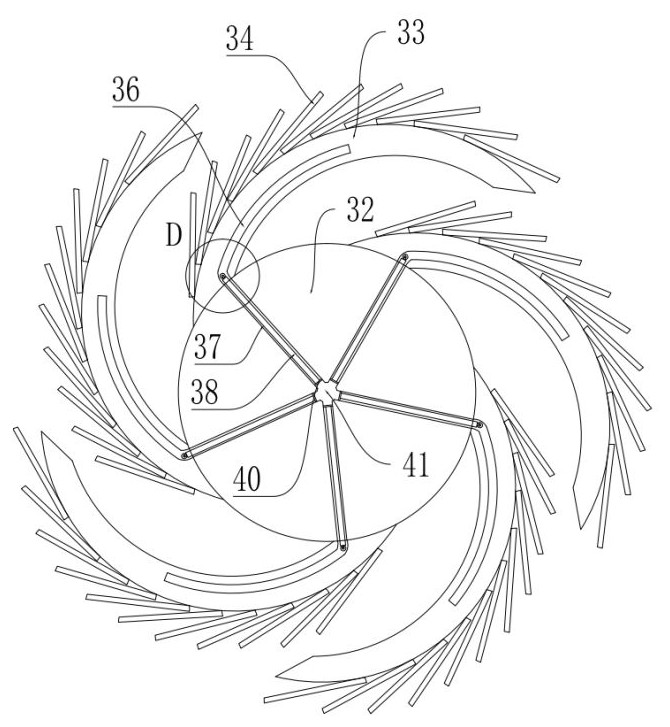

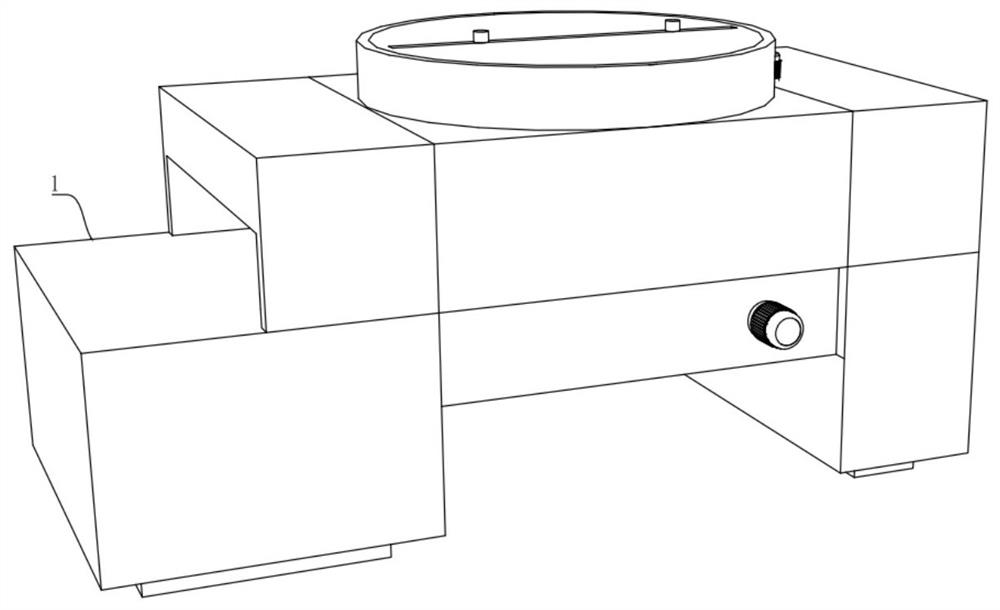

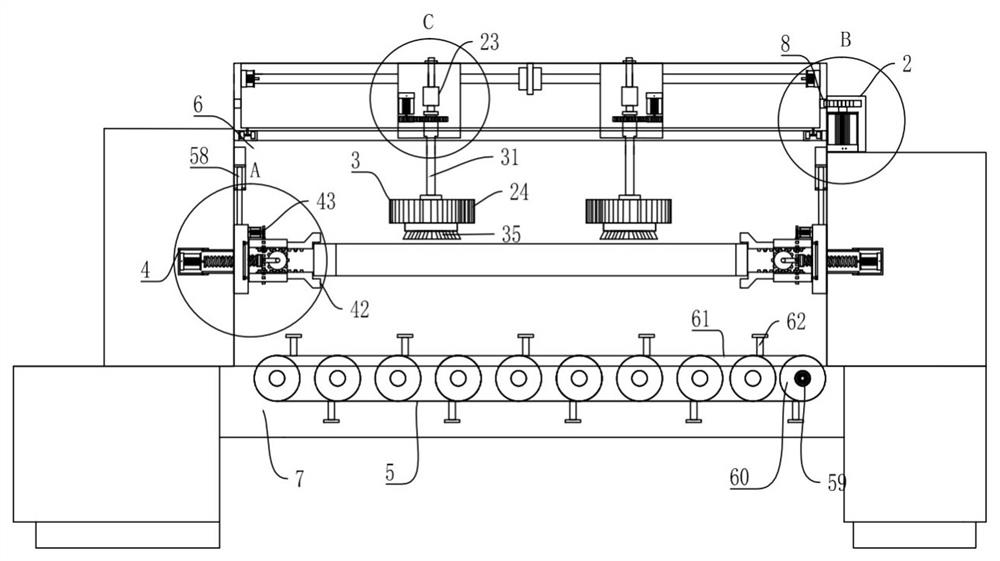

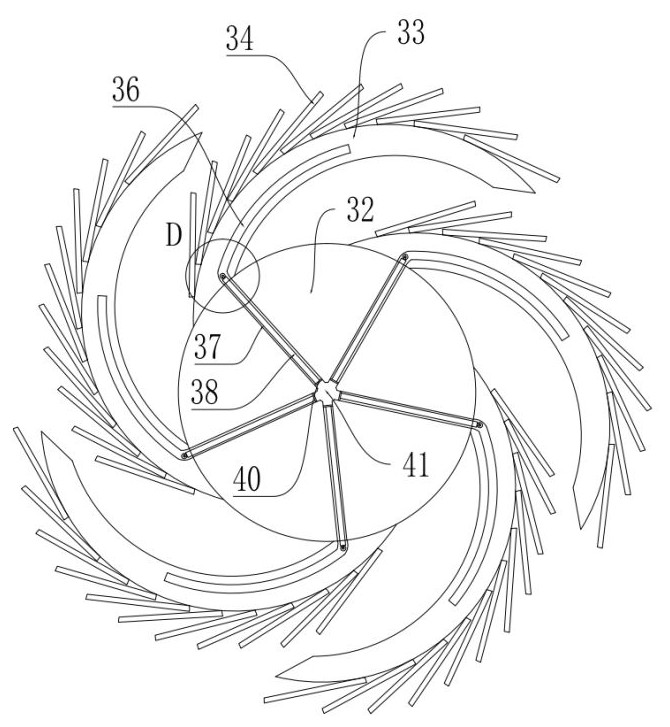

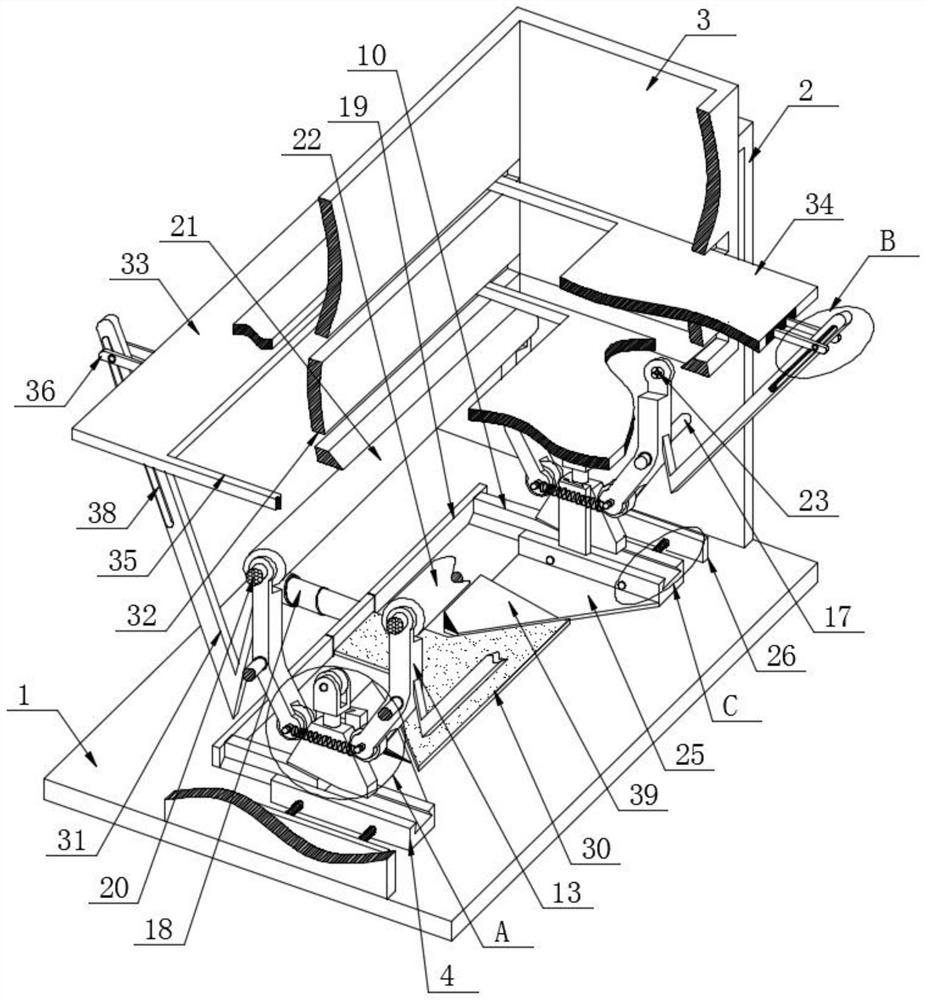

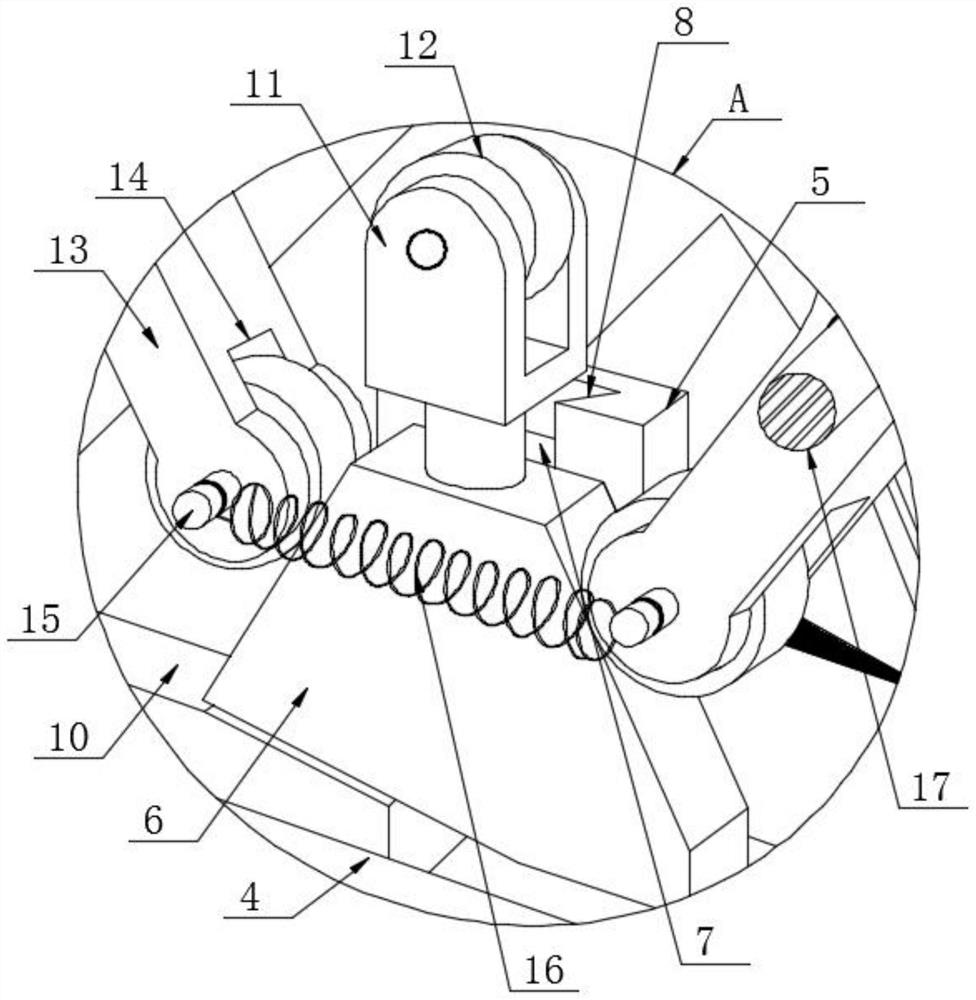

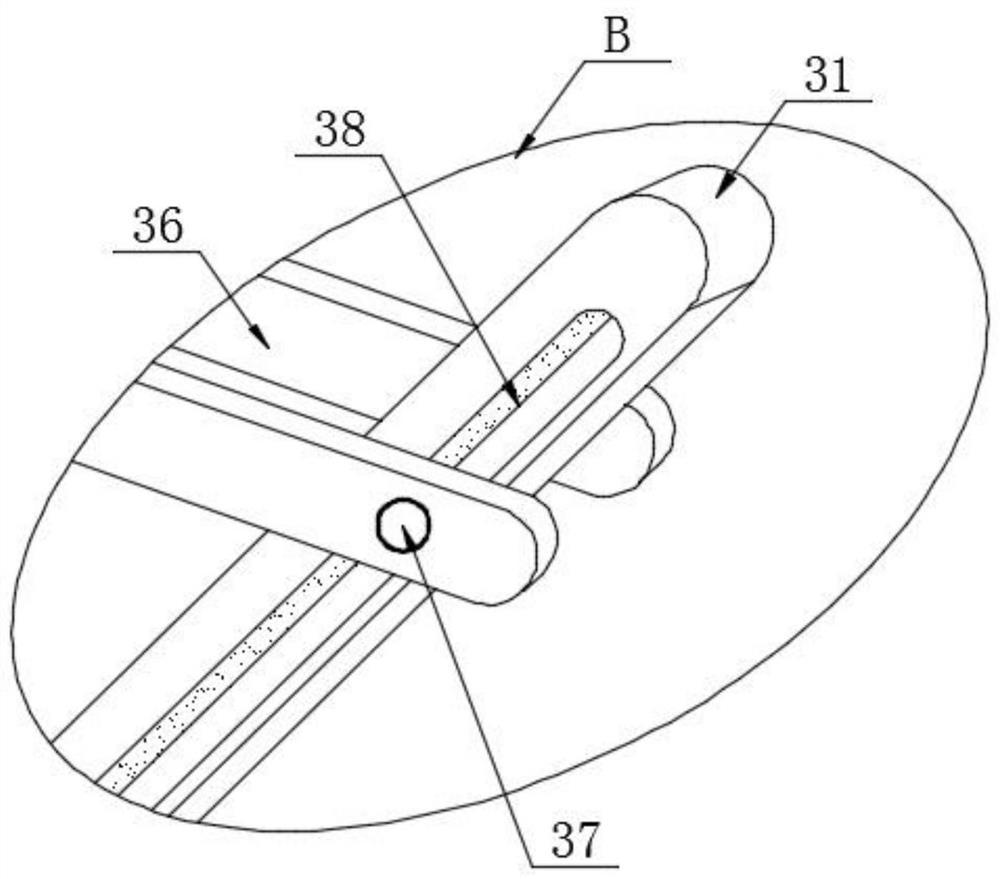

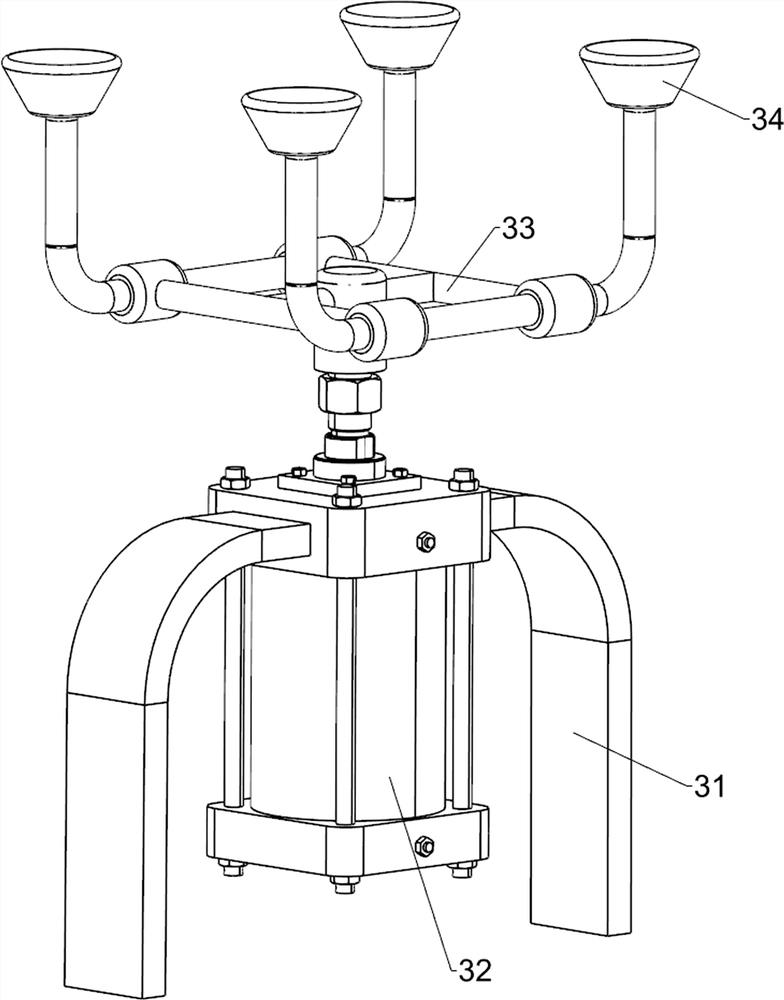

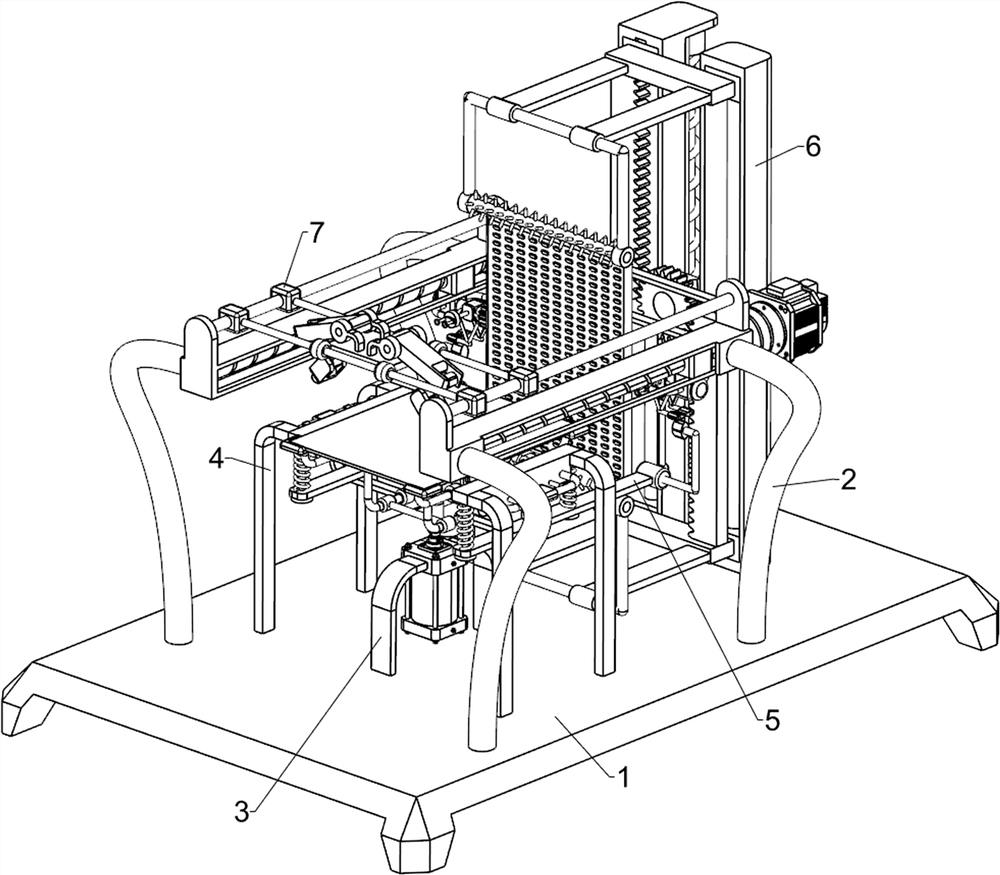

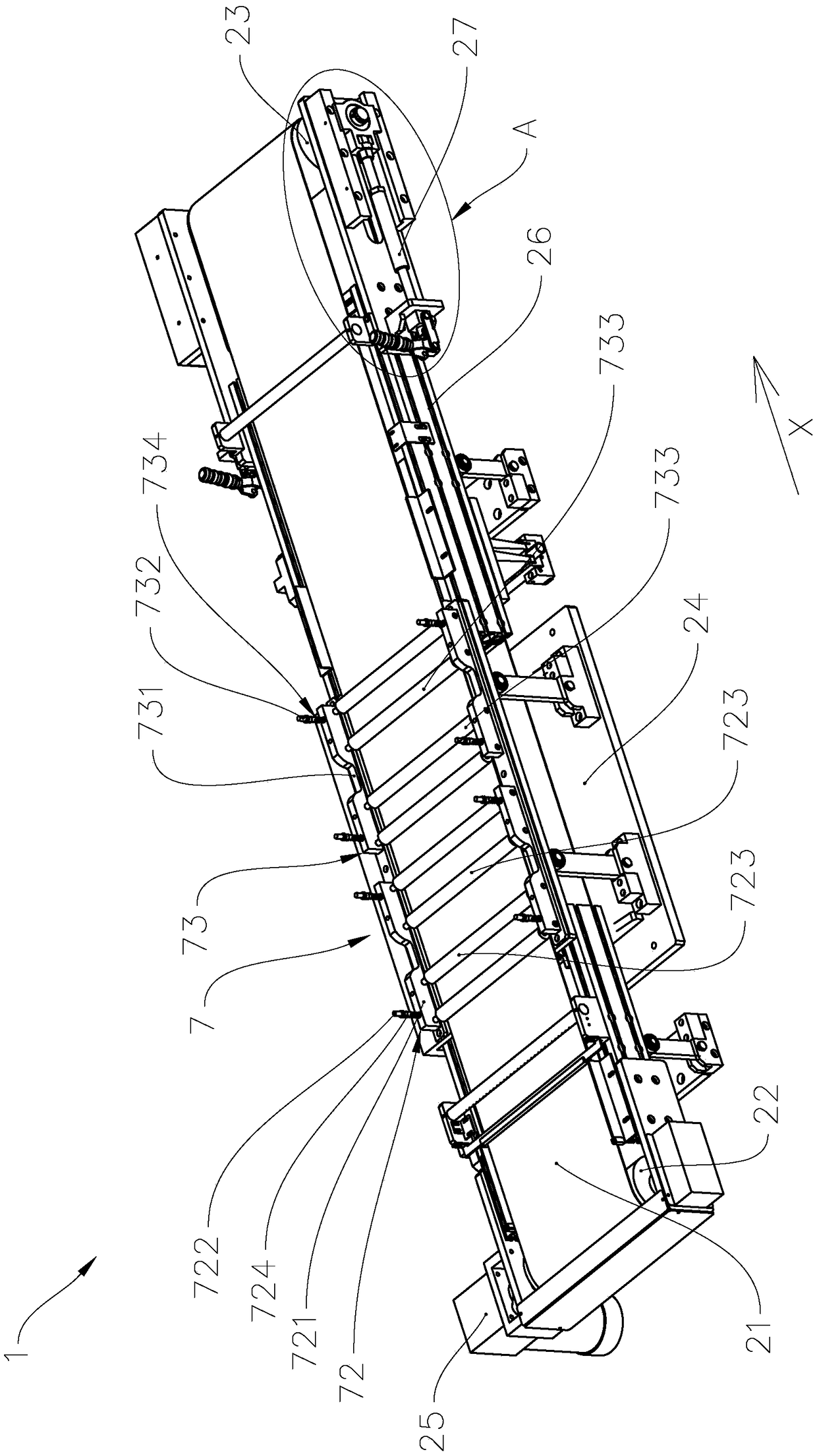

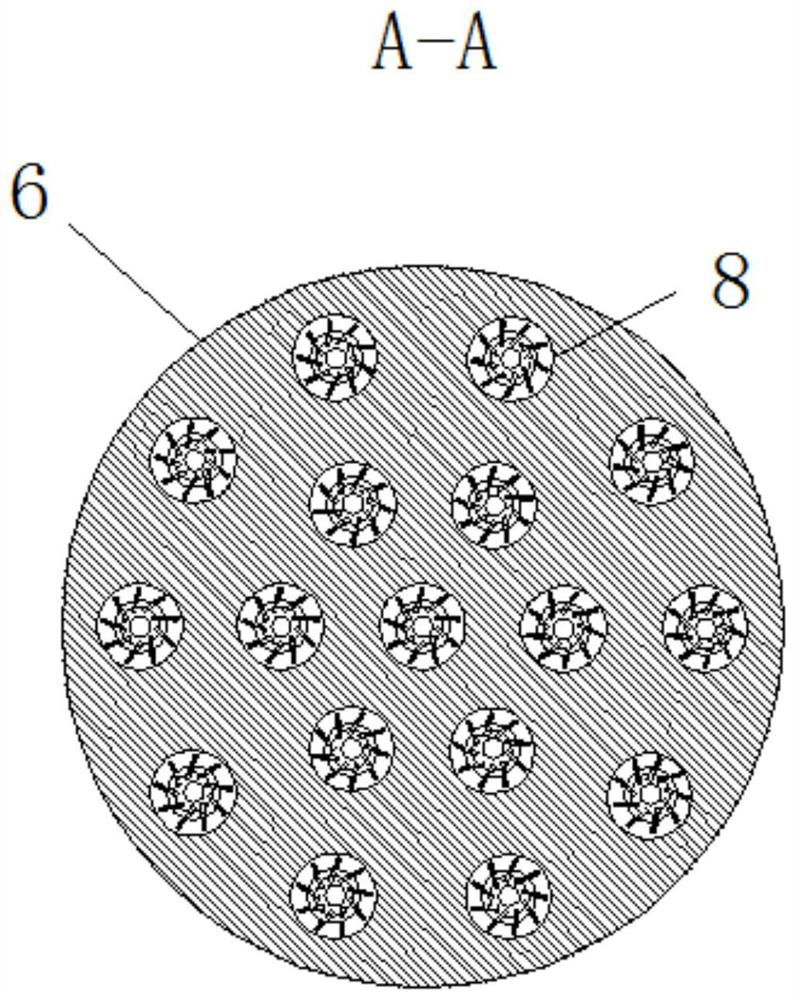

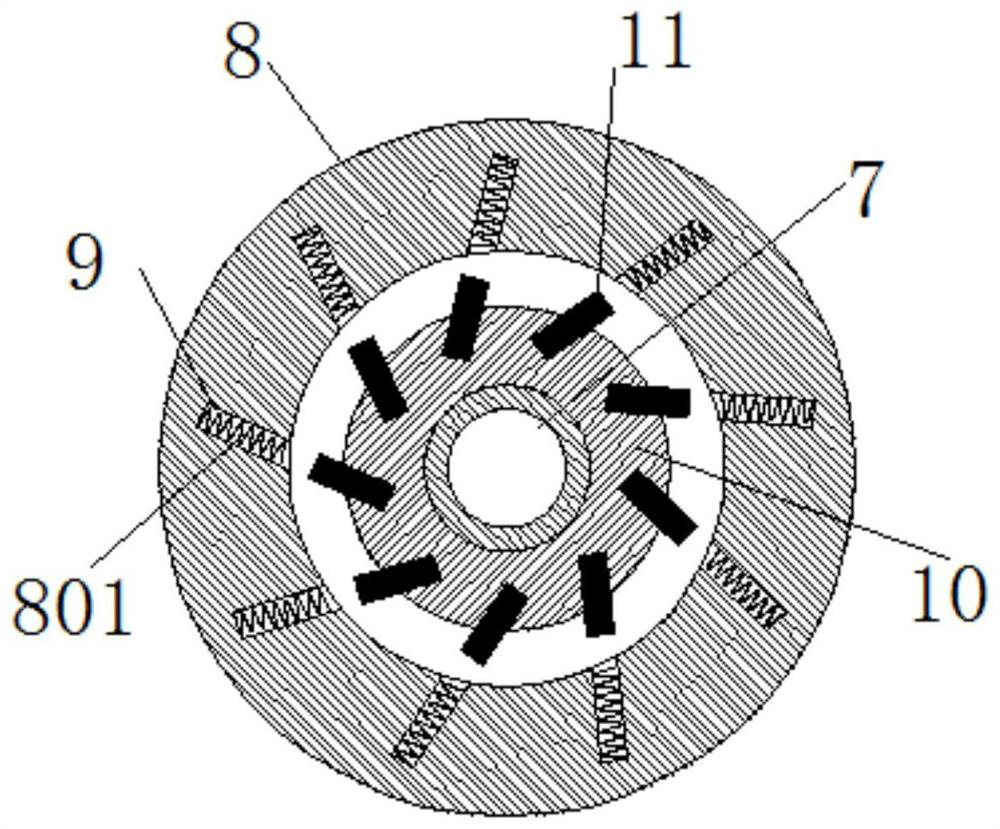

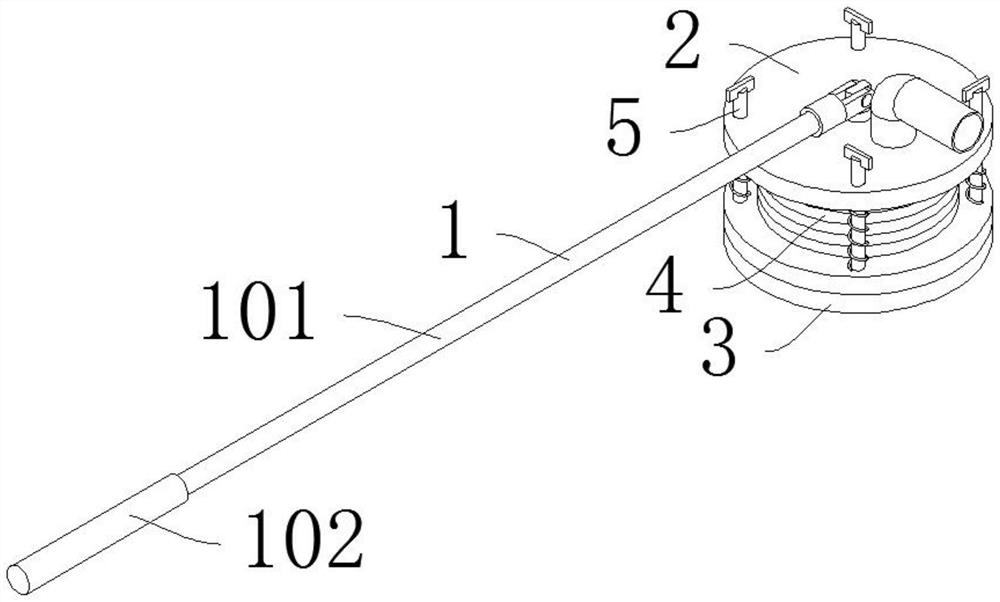

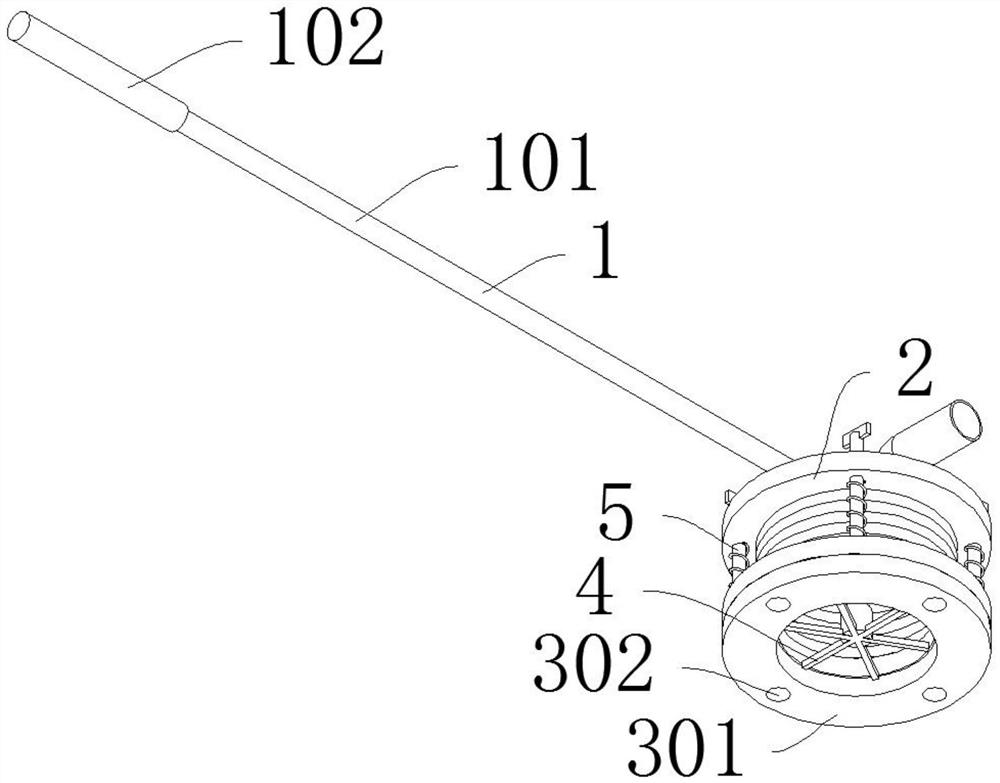

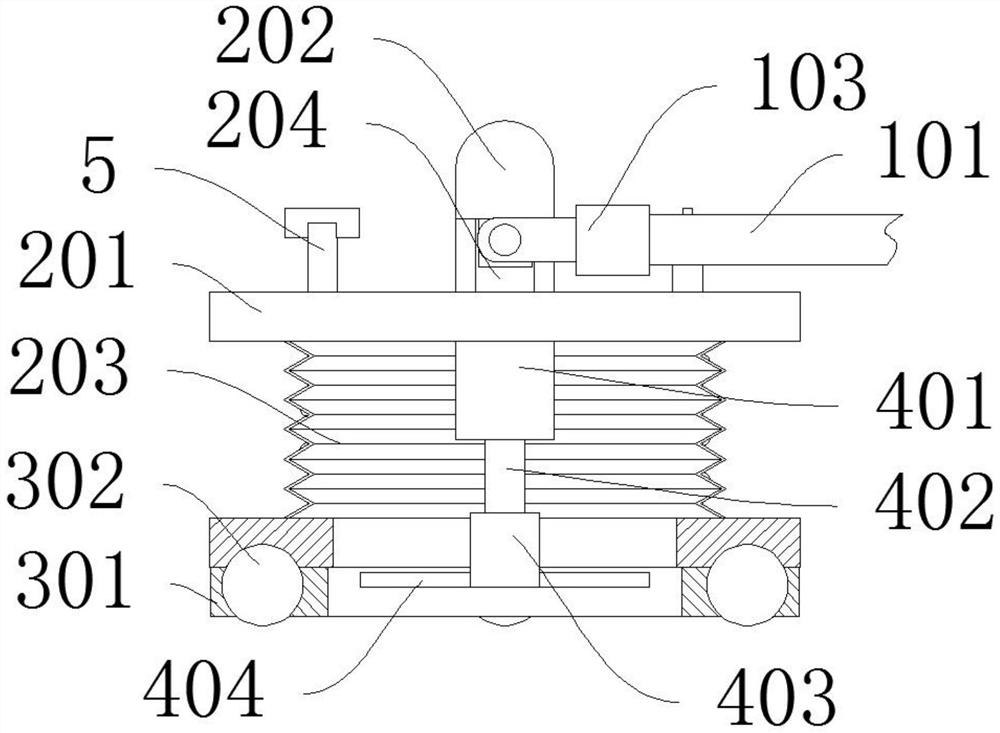

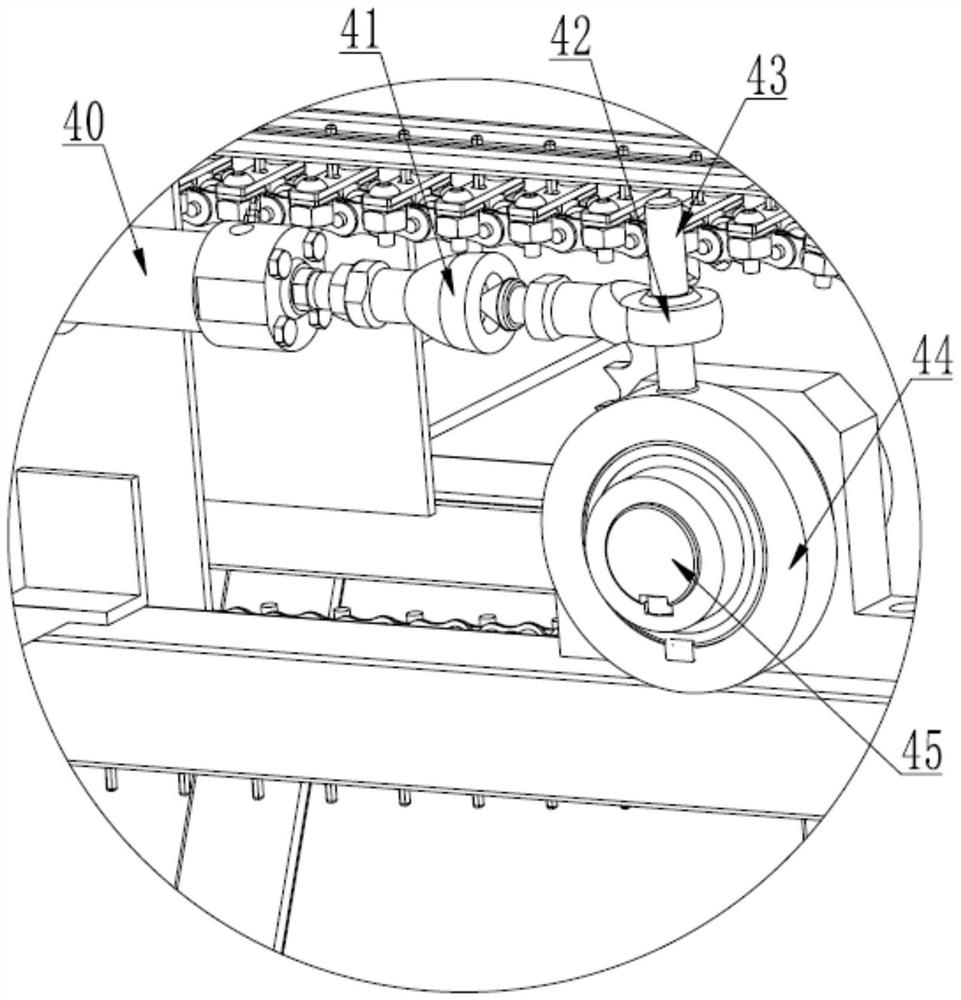

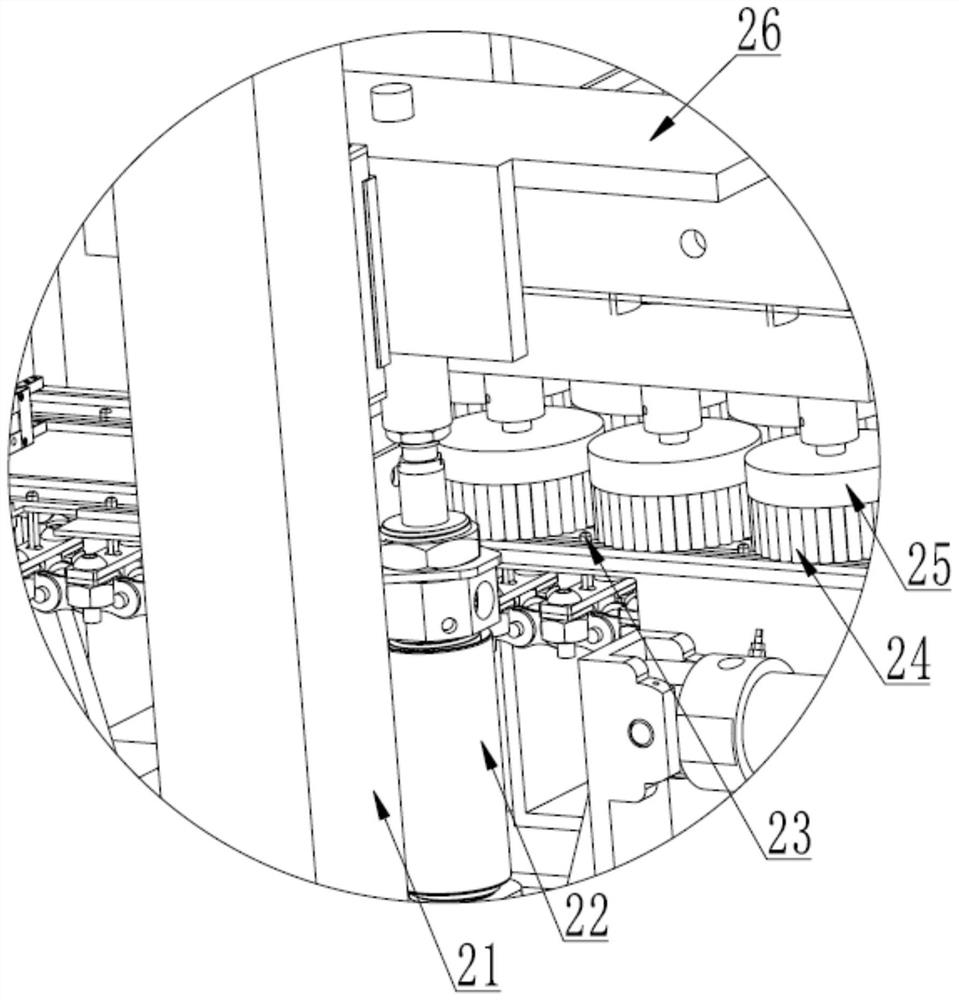

Reel type spray irrigation accessory polishing machine tool

ActiveCN113601378APolishing GuaranteeGuaranteed sandingGrinding carriagesPolishing machinesAgricultural sciencePolishing

The invention discloses a reel type spray irrigation accessory polishing machine tool. The reel type spray irrigation accessory polishing machine tool comprises an all-dimensional inflation type self-adjusting polishing body, a nested combined positioning device, a self-adaptive flexible composite material polishing device, a multi-dimensional dynamic and static interchange type positioning clamp and a supporting type circulating feeding device. The invention belongs to the technical field of reel type spray irrigation accessory polishing machine tools, and particularly relates to the reel type spray irrigation accessory polishing machine tool. A dynamic characteristic principle (an object is automatically adjusted to enable the performance of the object to be optimal in each action and stage or the structure of the object is divided into multiple components which can be changed and cooperate with one another) is creatively applied to the technical field of the reel type spray irrigation accessory polishing machine tool, the self-adaptive flexible composite material polishing device is used for polishing a bottom disc, it can be guaranteed that a gap in the bottom disc can be polished while the polishing surface is guaranteed, and the technical problem that the polishing device needs to be large and small in the polishing process is solved.

Owner:徐州沣收喷灌设备有限公司

A reel-type sprinkling irrigation accessories polishing machine

ActiveCN113601378BPolishing GuaranteeGuaranteed sandingGrinding carriagesPolishing machinesAgricultural scienceAgricultural engineering

The invention discloses a reel-type sprinkling irrigation accessory polishing machine tool, which includes an omnidirectional inflatable self-adjusting polishing main body, a nested combined positioning device, an adaptive flexible composite material polishing device, a multi-dimensional dynamic and static interchangeable positioning fixture and a support Type circulation feeding device. The invention belongs to the technical field of polishing machine tools for reel-type sprinkler irrigation accessories, and specifically refers to a polishing machine tool for reel-type sprinkler irrigation accessories. The structure is divided into several components that can be changed and cooperate with each other) applied to the technical field of polishing machine tools for reel sprinkler irrigation accessories, and the chassis is polished by using an adaptive flexible composite material polishing device. While ensuring the polished surface, it can also To ensure that the gap in the chassis can be polished, according to the technical problem that the polishing device must be both large and small during the polishing process.

Owner:徐州沣收喷灌设备有限公司

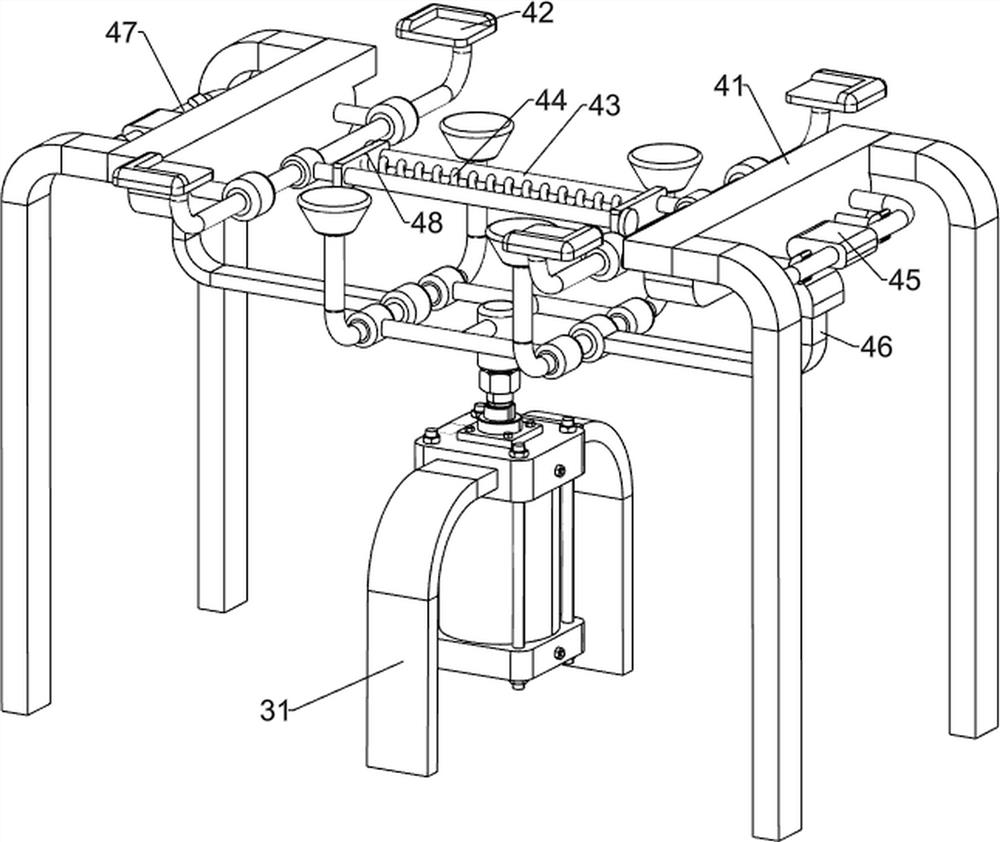

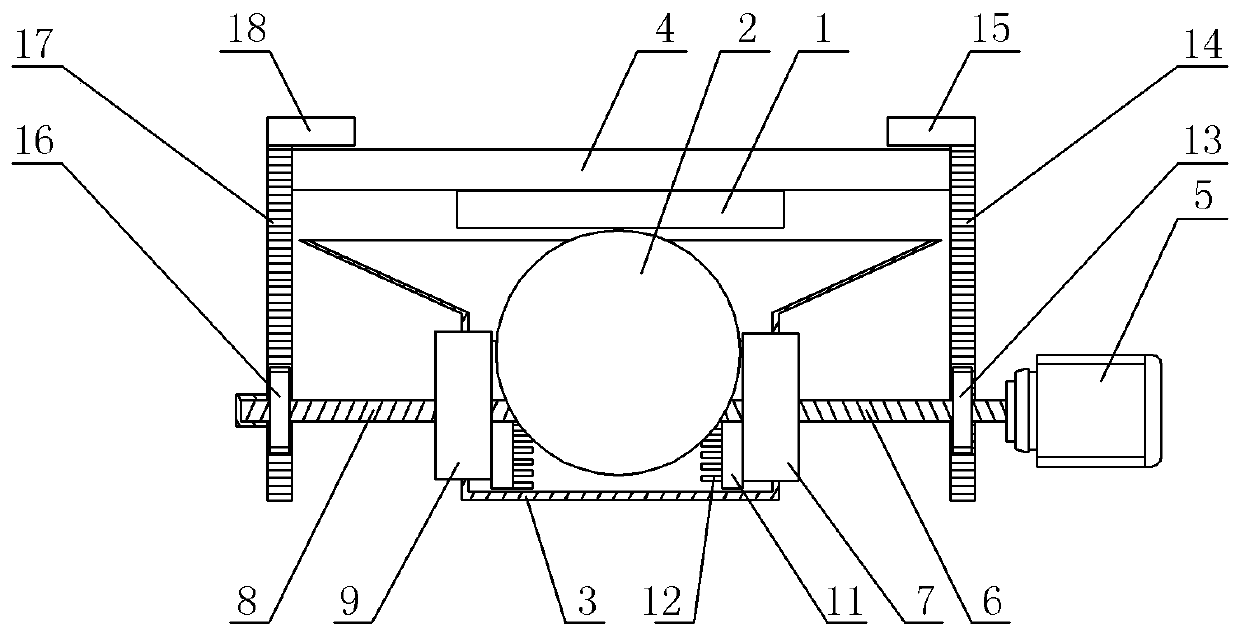

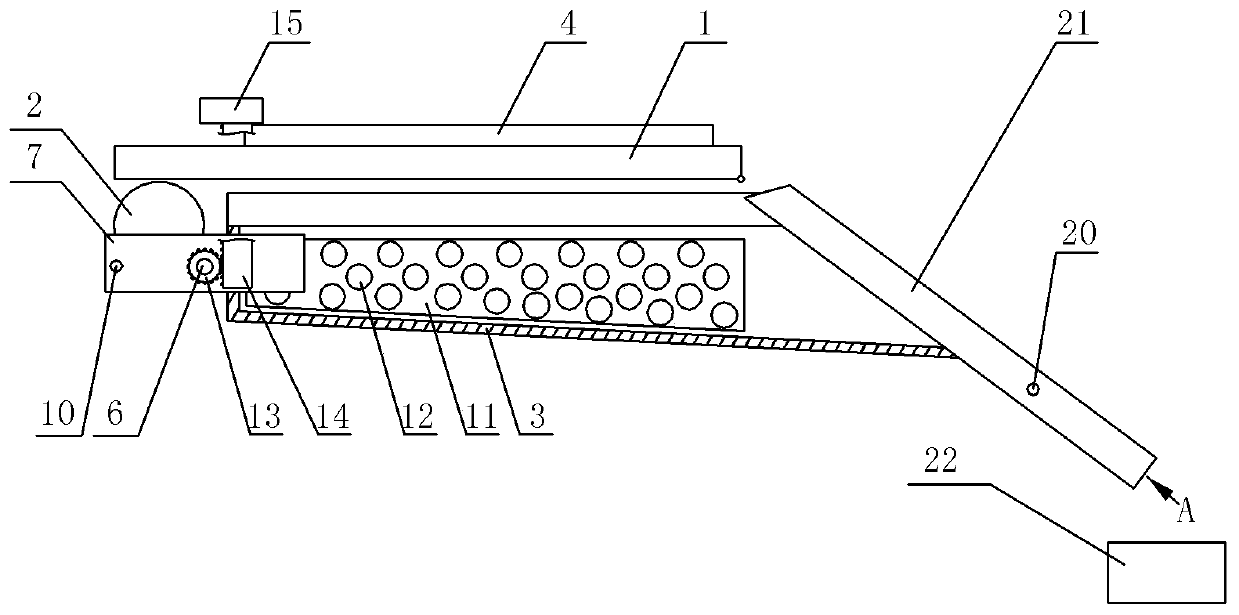

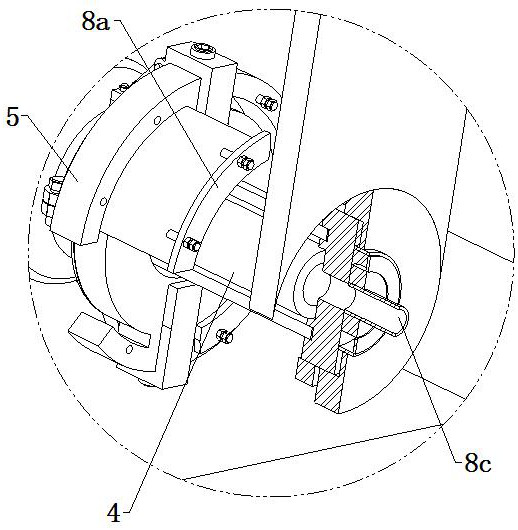

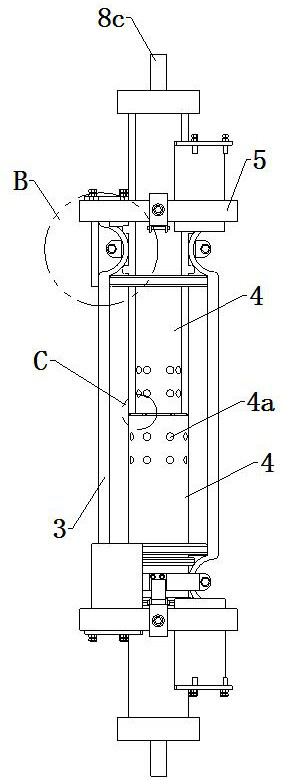

Grinding device for metal pipe fitting machining

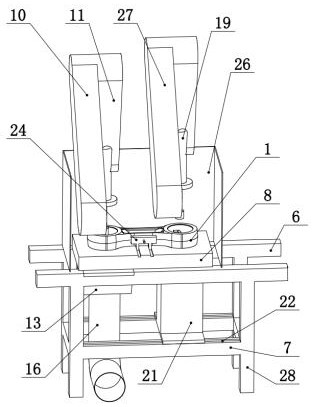

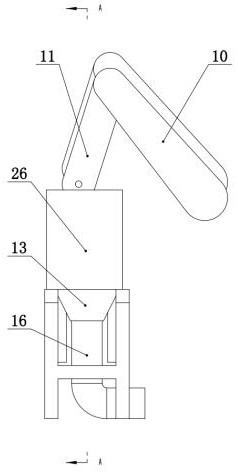

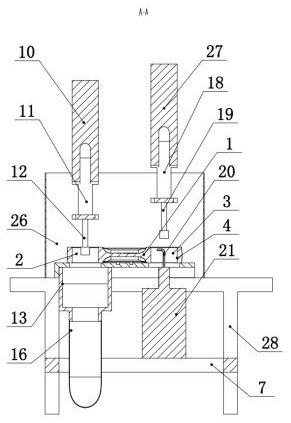

InactiveCN113199311AGuaranteed sandingThe grinding roller clamps the pipe to be ground to ensureRevolution surface grinding machinesGrinding drivesPipe fittingPipe

The invention discloses a grinding device for metal pipe fitting machining, and particularly relates to the technical field of metal pipe fitting machining. The grinding device comprises a base plate, inverted L-shaped stand columns are fixedly arranged at the two ends of the middle of the top of the base plate, a material box is arranged between the ends, away from the base plate, of the two L-shaped stand columns, the two L-shaped stand columns are fixedly connected with the outer wall of the material box at the corresponding positions, a clamping and grinding mechanism is arranged at the bottom of the material box between the two L-shaped stand columns, and a pipe fitting loading and unloading mechanism is arranged between the base plate and the material box; and the clamping and grinding mechanism comprises two transverse blocks which are arranged in an axial symmetry mode relative to the vertical central axis of the material box, and the two transverse blocks are arranged on the inner sides of the L-shaped stand columns at the corresponding positions of the two ends of the top of the base plate. The grinding device can push a push block to move rightwards through a push plate assembly to achieve continuous clamping of pipe fittings in the grinding process, automatic loading and unloading can be achieved through left-right movement of the push plate assembly, the machining effect is good, and efficiency is high.

Owner:邓超

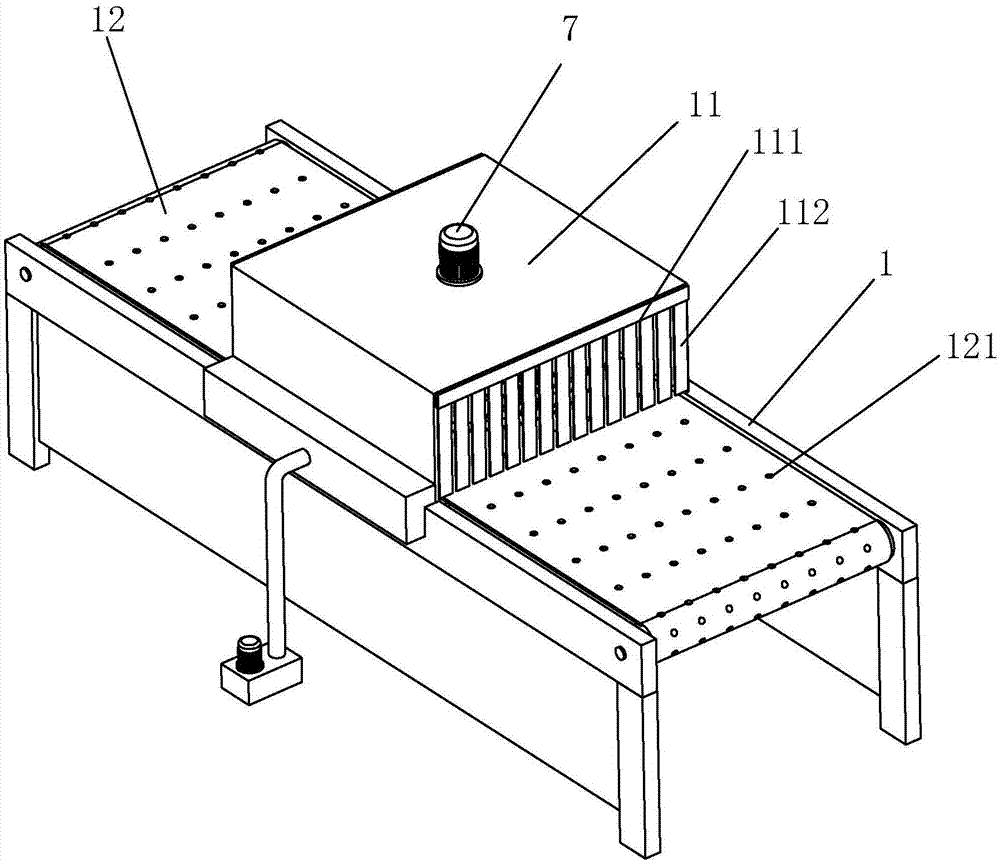

Board grinding device for PCB machining

InactiveCN112454082AImprove sanding qualityEasy loadingGrinding drivesGrinding machinesGrindingBackplane

The invention relates to a grinding device, in particular to a board grinding device for PCB machining. According to the board grinding device for PCB machining, automatic grinding is achieved, the position of a circuit board is limited, feeding is convenient, chippings on a grinding plate are easily removed, and the ground chippings are easily adsorbed. According to the technical implementation scheme, the board grinding device for PCB processing comprises a bottom plate and an adsorption mechanism, wherein a grinding mechanism is arranged at the upper part of the bottom plate; and the adsorption mechanism is arranged in the middle of one side of the upper part of the bottom plate. According to the board grinding device, a special-shaped frame at the upper side is pushed to move downwardsto drive a second rack at the upper side and a brush to move downwards; a second gear drives the second rack at the lower side to move upwards, so that the brush at the lower side is driven to move upwards, the brush sweeps away chippings on the grinding plate, the residual chippings on the grinding plate are easily removed, and the cleanness, tidiness and normal operation of the grinding plate are ensured.

Owner:深圳市骏欣铝基板有限公司

Cold-rolled tube polishing device

PendingCN110576352APolished evenlyGuaranteed sandingRevolution surface grinding machinesGrinding drivesArchitectural engineeringSteel tube

The invention relates to the technical field of cold-rolled tube processing equipment, and discloses a cold-rolled tube polishing device. The cold-rolled tube polishing device comprises a console, a moving groove is formed in the front surface of the console, a moving plate is movably connected into the moving groove in a sleeved mode, rollers are fixedly mounted at the bottom of the moving plate,fixing blocks are fixedly connected to the side surface of the moving plate, the tops of the fixing blocks are in threaded connection with the top of the console through dead bolts, a supporting plate is fixedly connected with the top of the moving plate, and a jacket is movably connected to the top of the side surface of the supporting plate. According to the cold-rolled tube polishing device, through the combination of the rollers, the fixing blocks, the dead bolts and fixed grooves, in the polishing process, a steel tube can be moved, so that the surface of the steel tube is comprehensively polished; and through the combination of the jacket and a motor, rotating polishing can be conducted on the steel tube, the fact that the surface of the steel tube cannot be thoroughly polished dueto the unevenness is avoided, thus the steel tube can be uniformly polished, and the polishing effect is improved.

Owner:江苏君睿智能制造有限公司

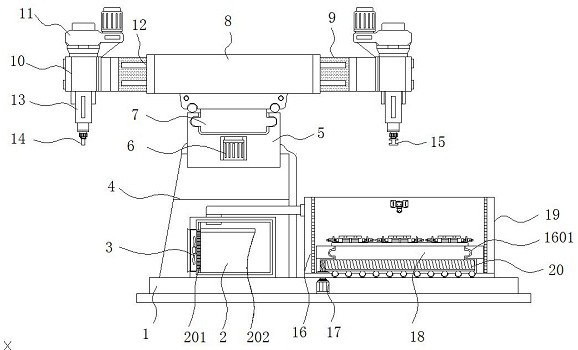

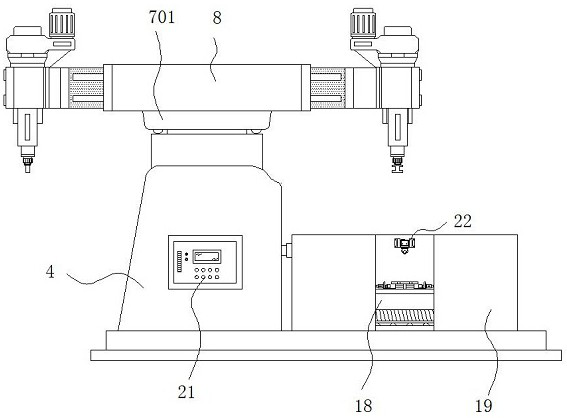

Intelligent machining equipment for ends of silicon carbide ceramic roller bars and roller bar machining process

PendingCN113199337AAchieve the effect of side grindingNot easy to damageEdge grinding machinesGrinding carriagesCarbide siliconEngineering

The invention discloses intelligent machining equipment for the ends of silicon carbide ceramic roller bars and a roller bar machining process, and belongs to the technical field of new material machining equipment. According to the technical scheme, the intelligent machining equipment is characterized by comprising a rack, wherein a shell is integrally formed at the top of the rack; a placement disc is arranged at the center of the top of the rack, and annularly-distributed through holes are formed in the bottom of the placement disc; a hollow pipe is fixedly connected to the top of the inner wall of the shell, a positioning disc fixed to the inner wall of the shell is arranged at the upper end of the surface of the hollow pipe, first air cylinders are arranged at the top of the positioning disc, annularly-distributed pressing rods are arranged at the bottoms of the first air cylinders through a pressing plate, and the bottom ends of the pressing rods right face the circle centers of the through holes; and a liftable material placement device is arranged on the inner wall of the rack and used for placing the roller bars, and the roller bars can penetrate through the through holes and extend into a grinding groove through lifting of the material placement device. The intelligent machining equipment reduces the damage of clamping to the ends of the silicon carbide ceramic roller bars, and is higher in grinding efficiency and better in grinding effect.

Owner:贾雪燕

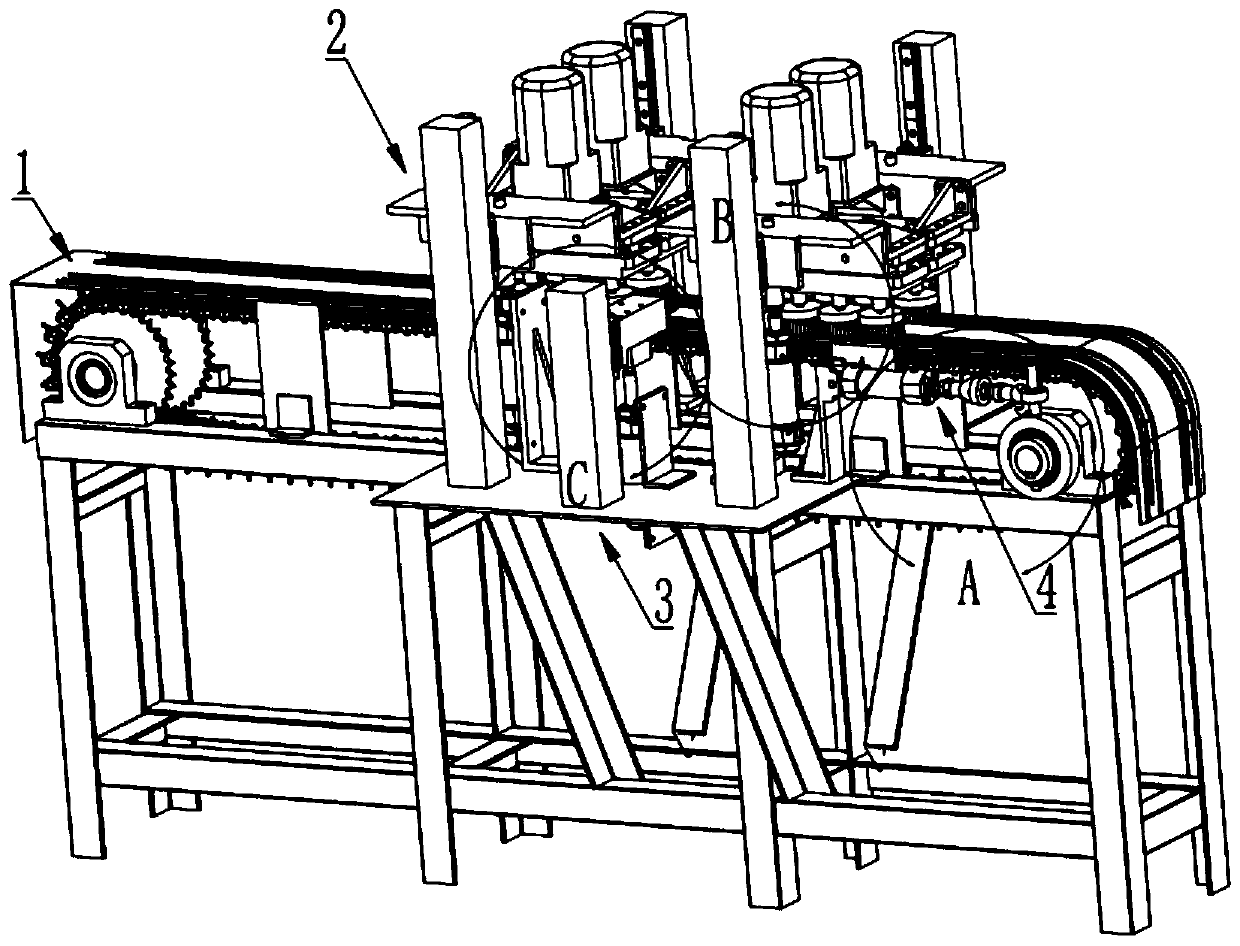

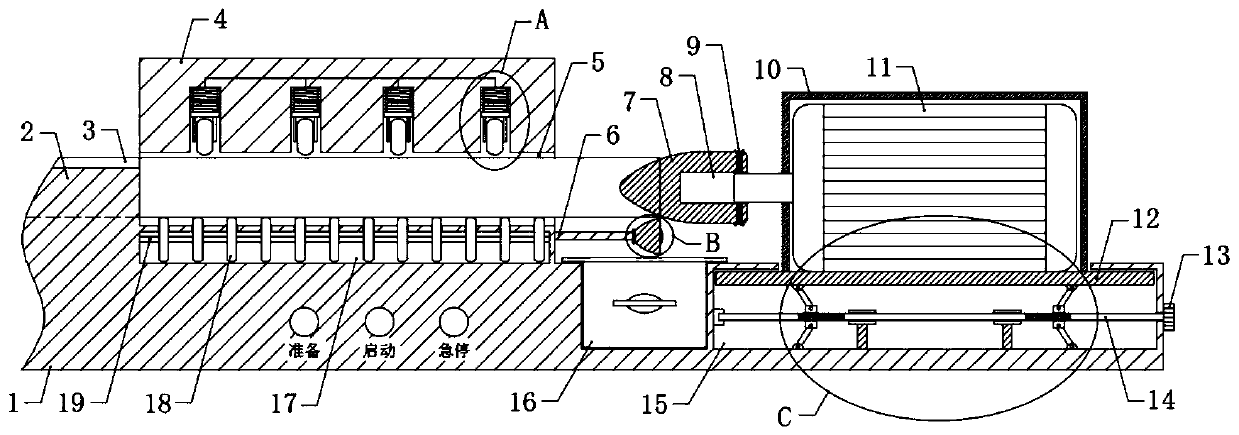

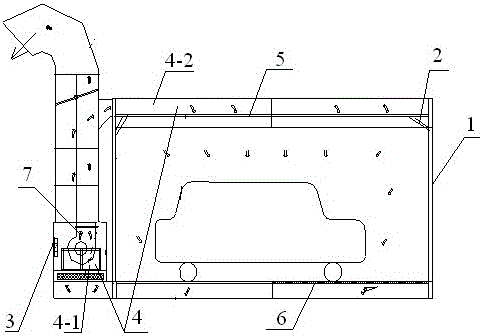

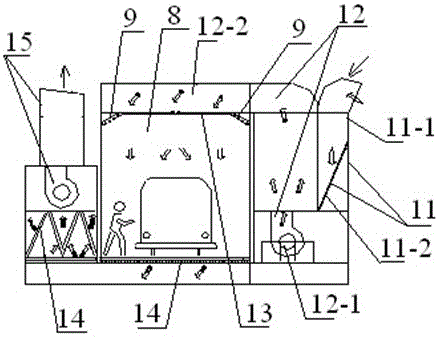

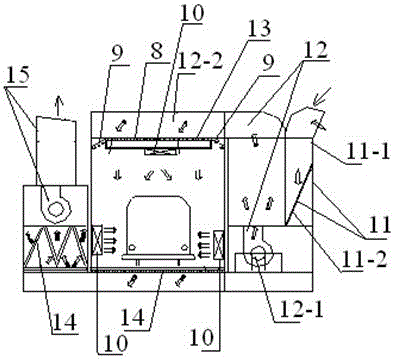

Parallel grinding, painting, drying sheet spraying system

InactiveCN104028408BStrong compactnessImprove corrosion resistancePretreated surfacesAbrasive machine appurtenancesEngineeringMirror effect

Owner:JIANGSU ZHONGYI AUTOMOBILE MACHINERY EQUIP MFG

Blue glass crushing device

ActiveCN108435289AEasy to cutRealize automatic unloadingEdge grinding machinesGrinding feedersEngineeringAirbag

The invention relates to the field of blue glass production, in particular to a blue glass crushing device. The blue glass crushing device comprises a support plate, an airbag, a box, a crushing mechanism, a separation mechanism and a receiving mechanism; the support plate is hinged with a frame; the airbag is positioned below the support plate; the crushing mechanism comprises a first screw rod,a first nut base, a second screw rod and a second nut base; the first screw rod and the second screw rod are opposite in thread rotating direction; the first nut base and the second nut base both canextrude the airbag, and are fixedly connected with crushing plates; the separation mechanism comprises two separation units; each separation unit comprises a gear, a rack and a separation block; the receiving mechanism comprises receiving cloth, and two receiving units; each receiving unit comprises a spring and a receiving chute; an opening is formed in the bottom of a box; and the opening is positioned at the upper end of the receiving cloth. The blue glass crushing device can automatically crush and collect leftovers, and meanwhile, polishes blue glass.

Owner:重庆晶宇光电科技有限公司

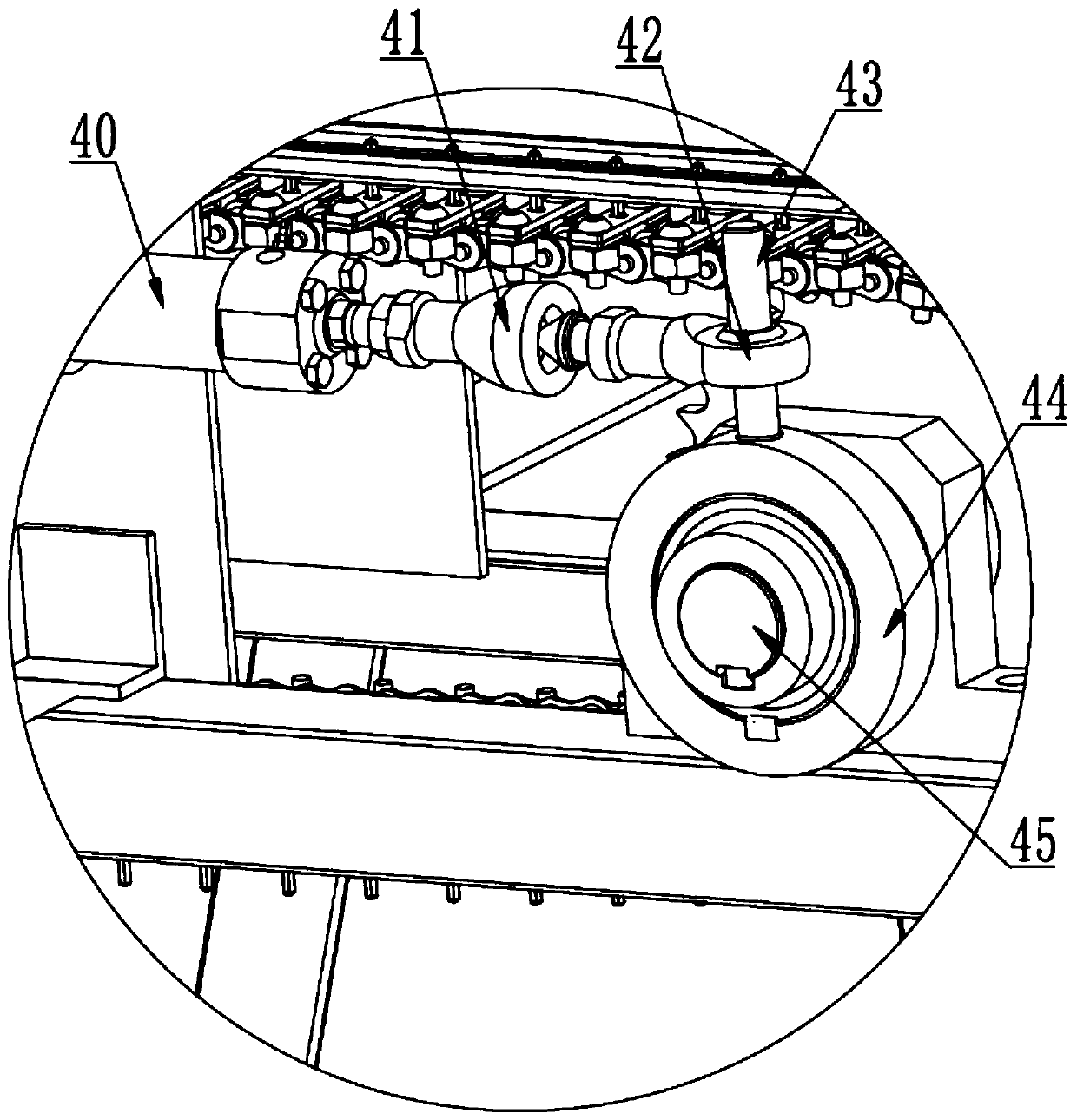

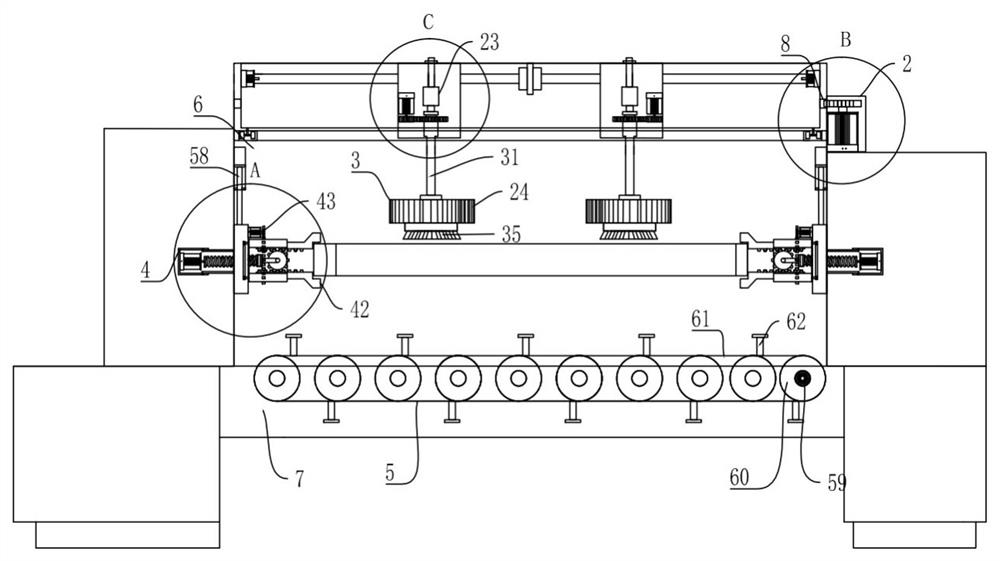

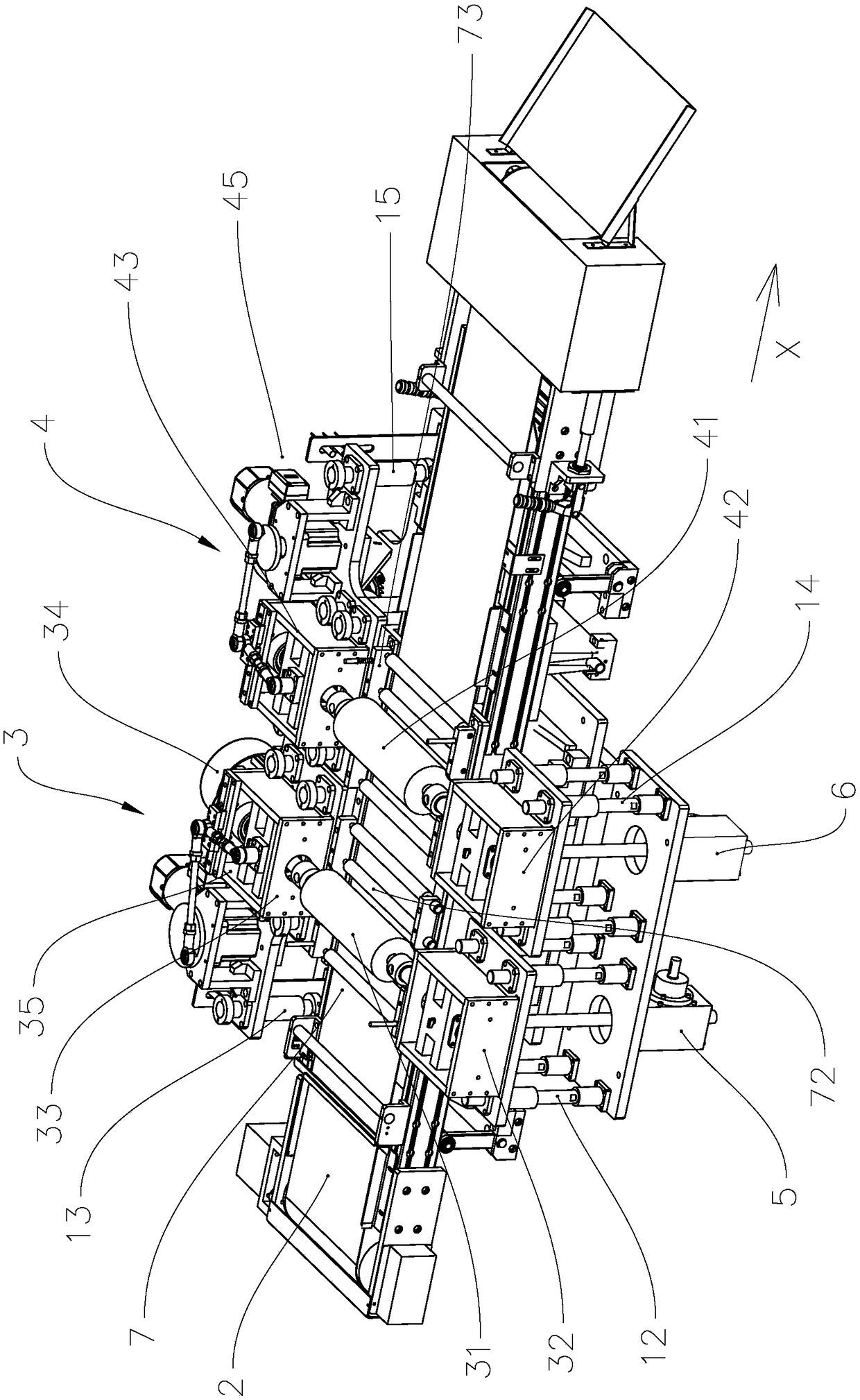

Precise polishing equipment for increasing friction force

PendingCN109227294AGuaranteed sandingGuaranteed polishing accuracyGrinding carriagesGrinding drivesEngineeringFriction force

The invention provides precise polishing equipment for increasing friction force. The precise polishing equipment comprises a workbench, a conveying line and a first sand roller device; the conveyingline is installed on the workbench, the first sand roller device comprises a first sand roller, a first connecting base, a second connecting base, a first driving unit and a second driving unit, the two ends of the first sand roller are connected with the first connecting base and the second connecting base respectively, and the first connecting base and the second connecting base are located at the two opposite sides of the conveying line respectively in the conveying direction of the conveying line; the conveying line is located between the first sand roller and a mounting face of the workbench, the first driving unit drives the first sand roller to rotate relative to the first connecting base and the second connecting base around the axis of the first sand roller, and the second drivingunit drives the first sand roller to slide relative to the first connecting base and the second connecting base in the axial direction of the first sand roller. The precise polishing equipment for increasing the friction force has the advantages that the machining precision is high, the production efficiency is high, and friction sheets can be automatically ground and polished.

Owner:GUANGDONG HESHI AUTOMATION TECH CO LTD

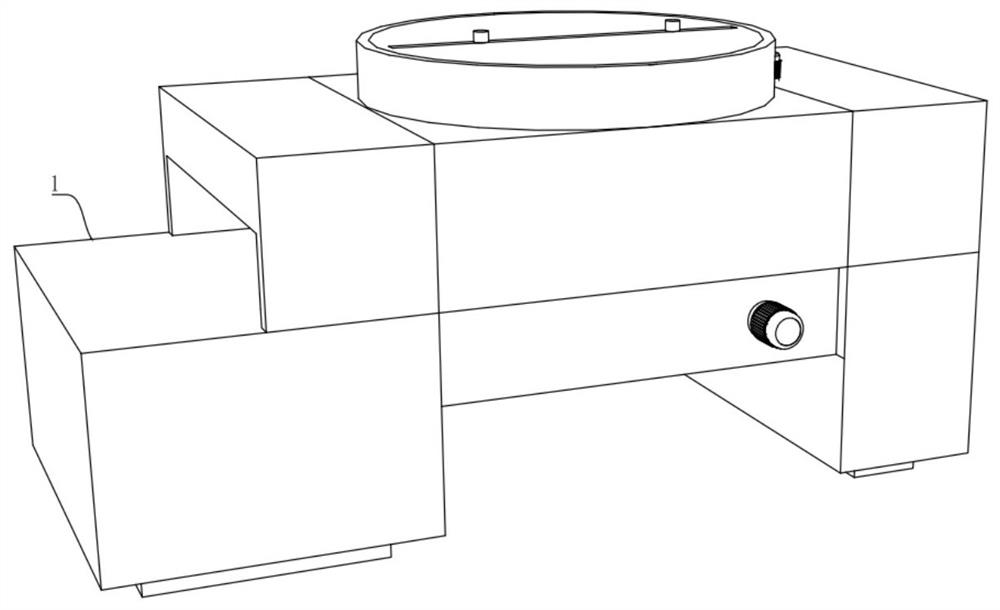

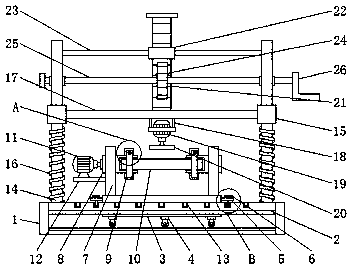

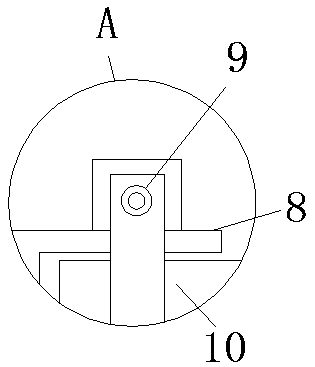

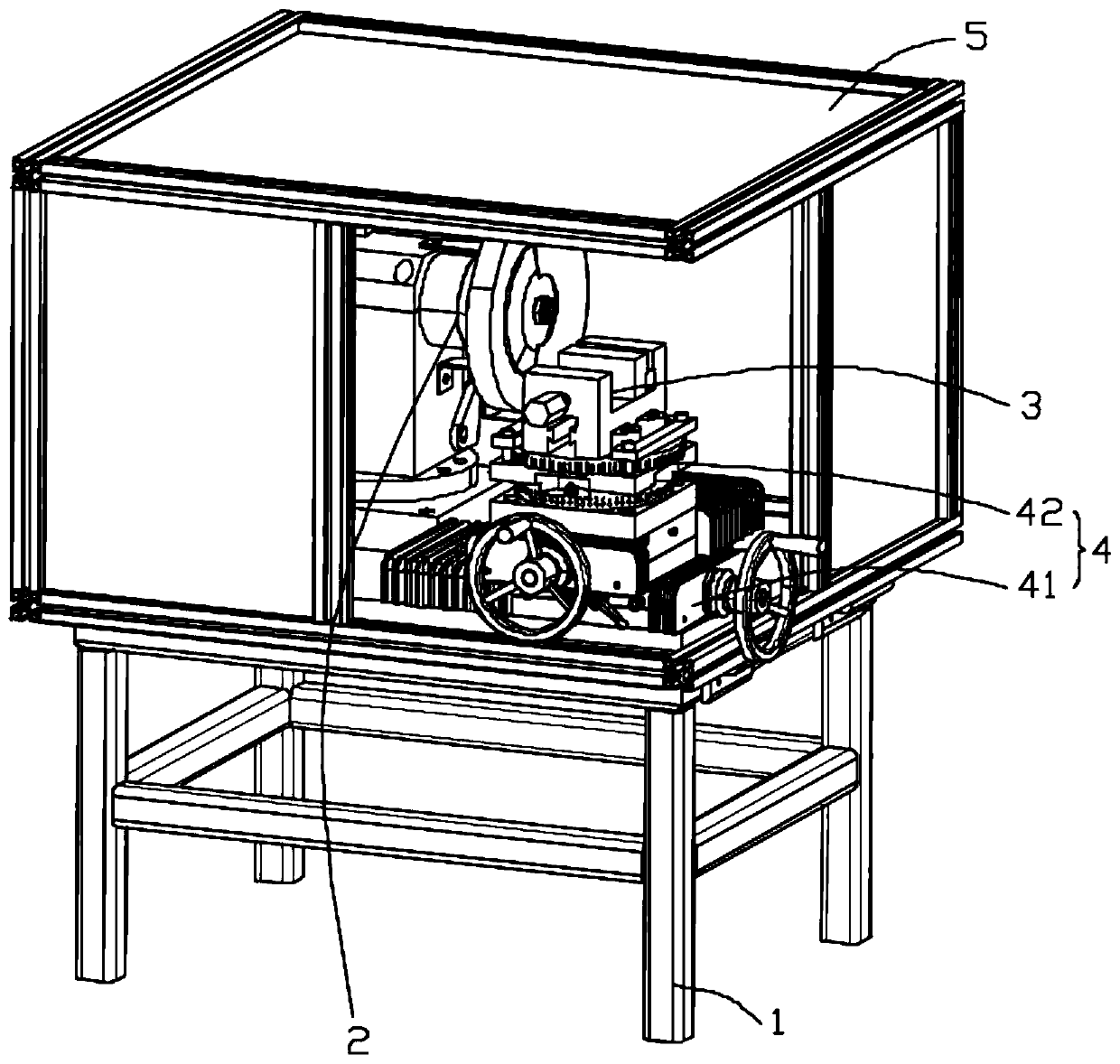

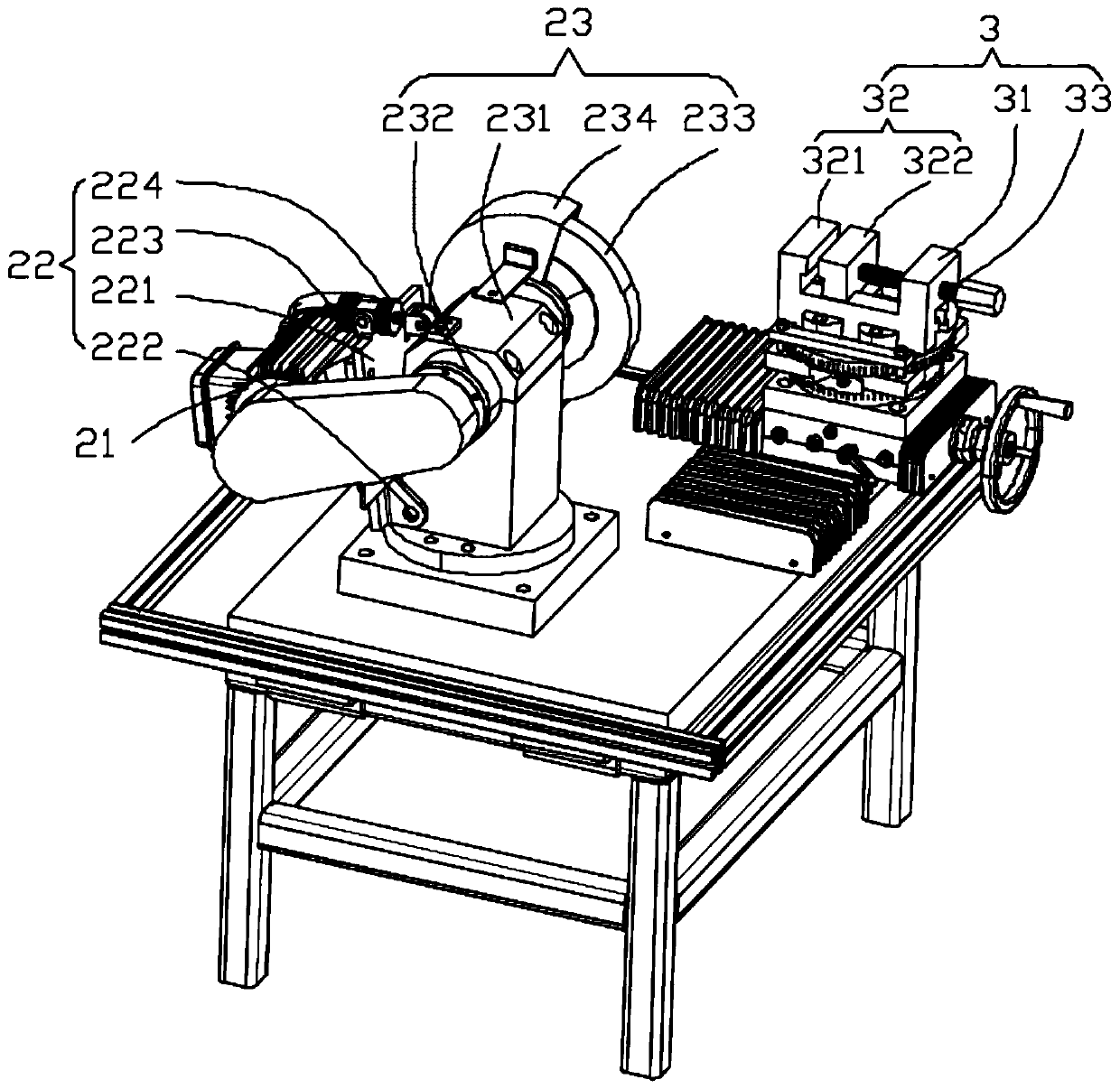

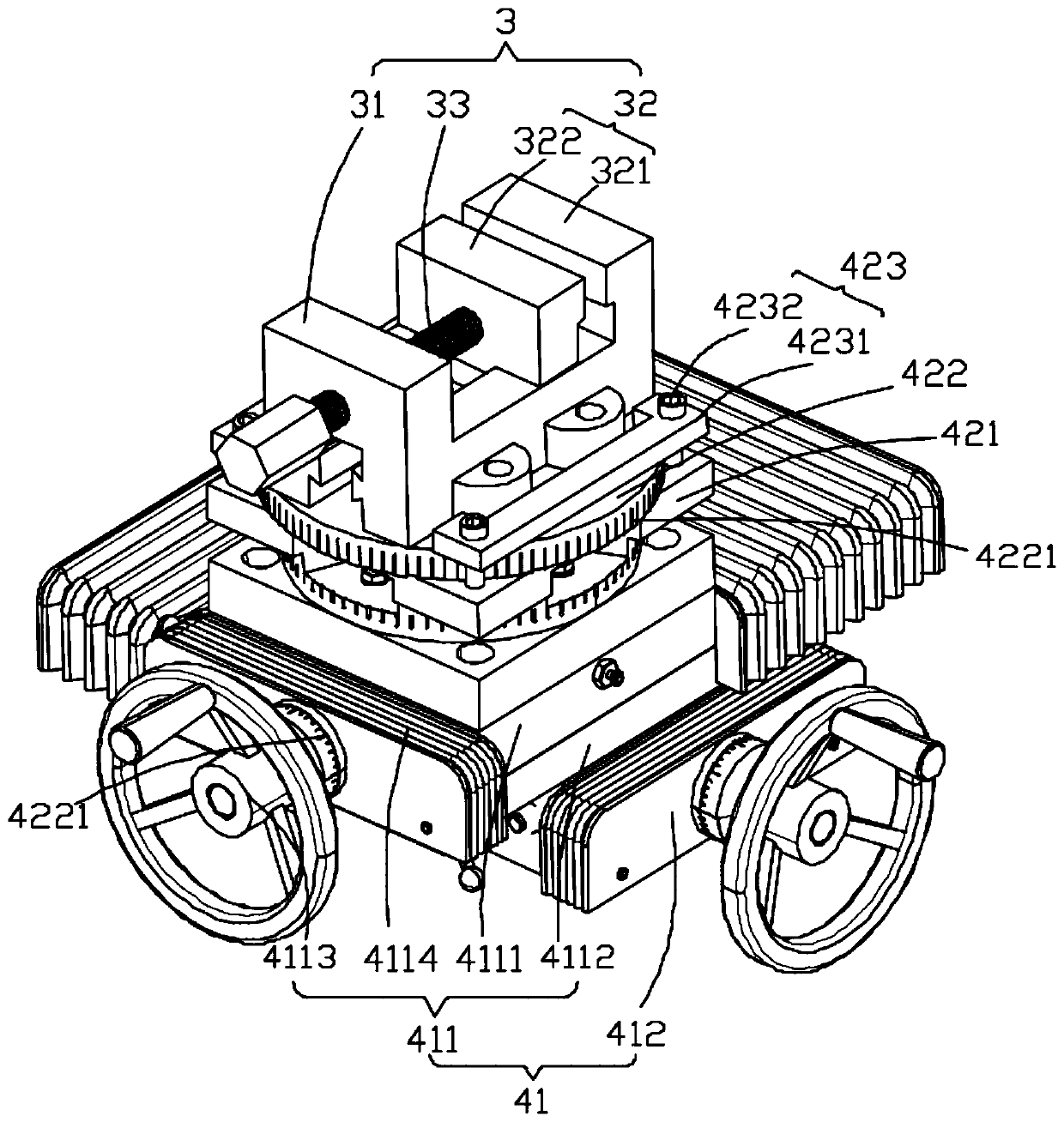

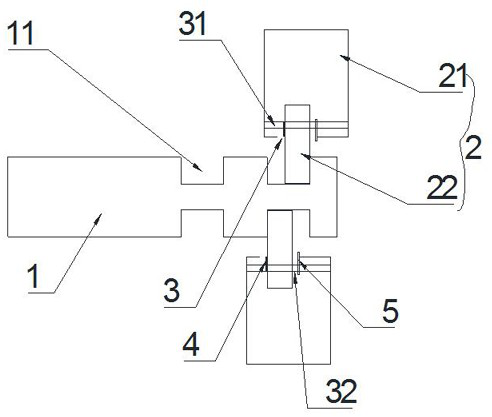

Polishing machine

ActiveCN110340782AEnsure safetyGuaranteed sandingGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention provides a polishing machine. The polishing machine comprises a base device, a polishing device, a clamp device and an adjusting device, wherein the polishing device is fixed at the upper end of the base device, the adjusting device is fixed at the upper end of the base device, and the clamp device is fixed at the upper end of the adjusting device. The adjusting device comprises a direction adjusting structure and an angle adjusting structure, wherein the angle adjusting structure is fixed at the upper end of the direction adjusting structure, and the direction adjusting structure is fixed at the upper end of the base device. The angle adjusting structure comprises a main body part and a dial, wherein the main body part is fixed at the upper end of the direction adjusting structure, the dial is arranged at the upper end of the main body part, and the dial is rotationally connected with the main body part. According to the polishing machine, workpieces can be precisely polished and accurately cut through the direction adjusting structure and the angle adjusting structure, iron scraps are prevented from splashing by means of a protection hood, the grinding safety of workers is improved, the tightness of a belt is conveniently adjusted, and normal polishing of a polishing wheel is guaranteed.

Owner:SHAOYANG UNIV

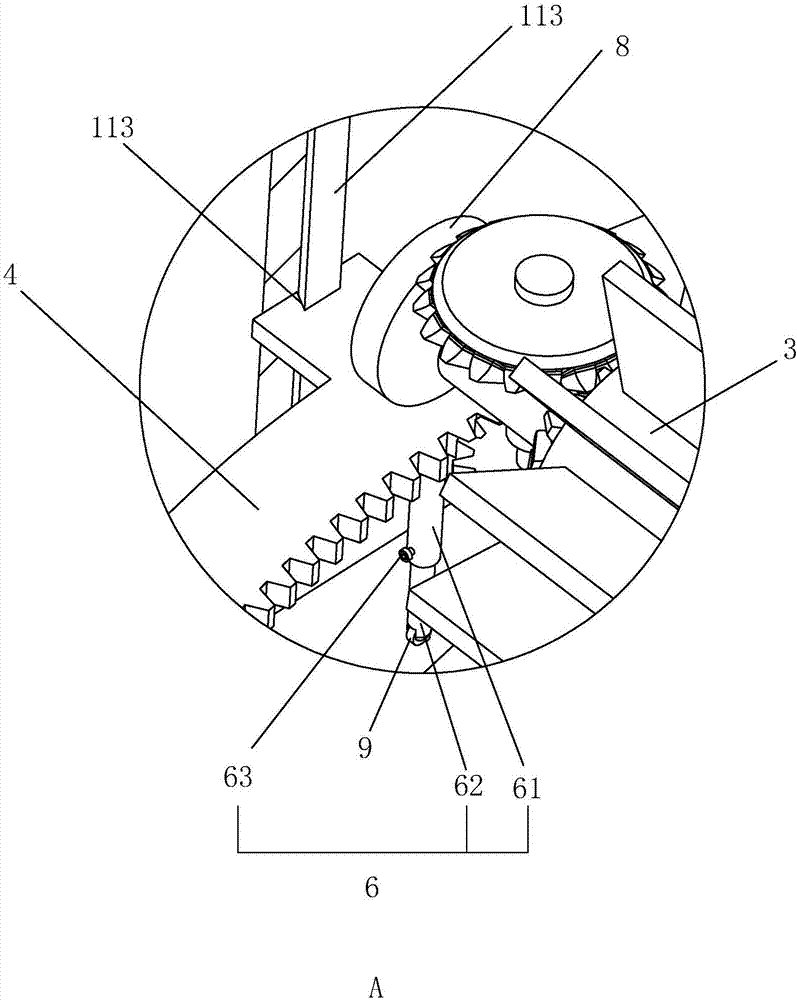

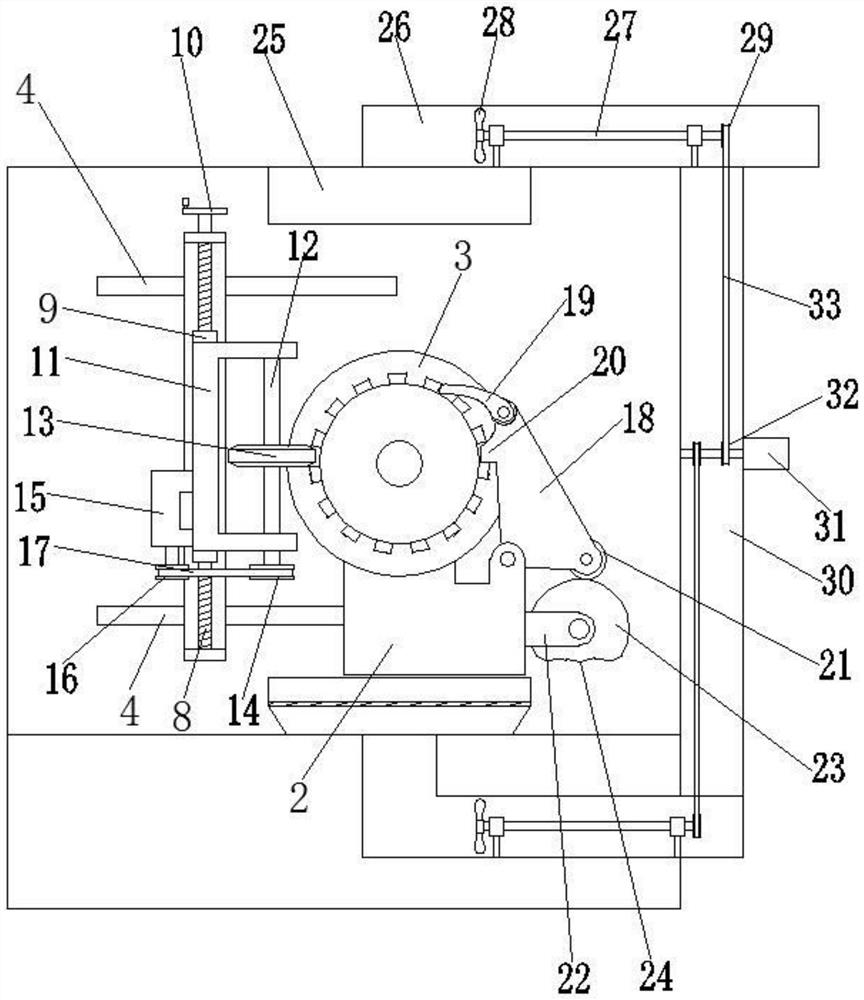

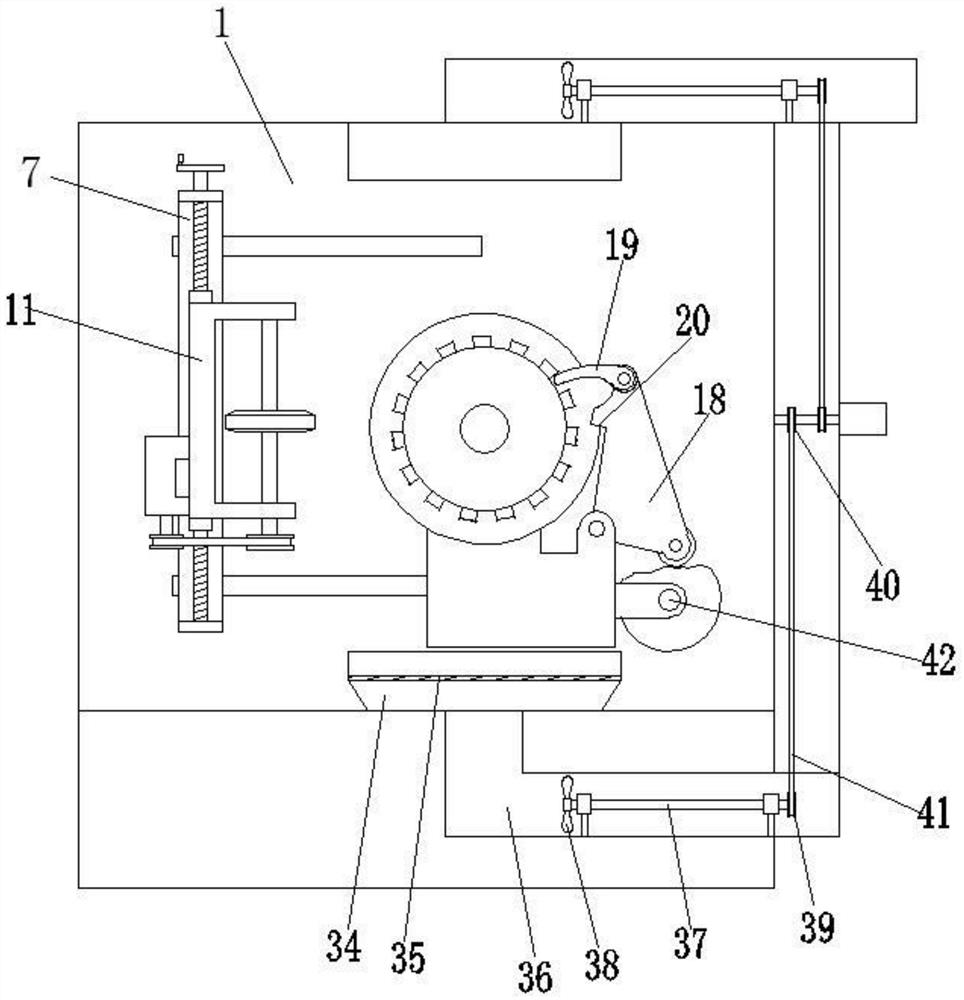

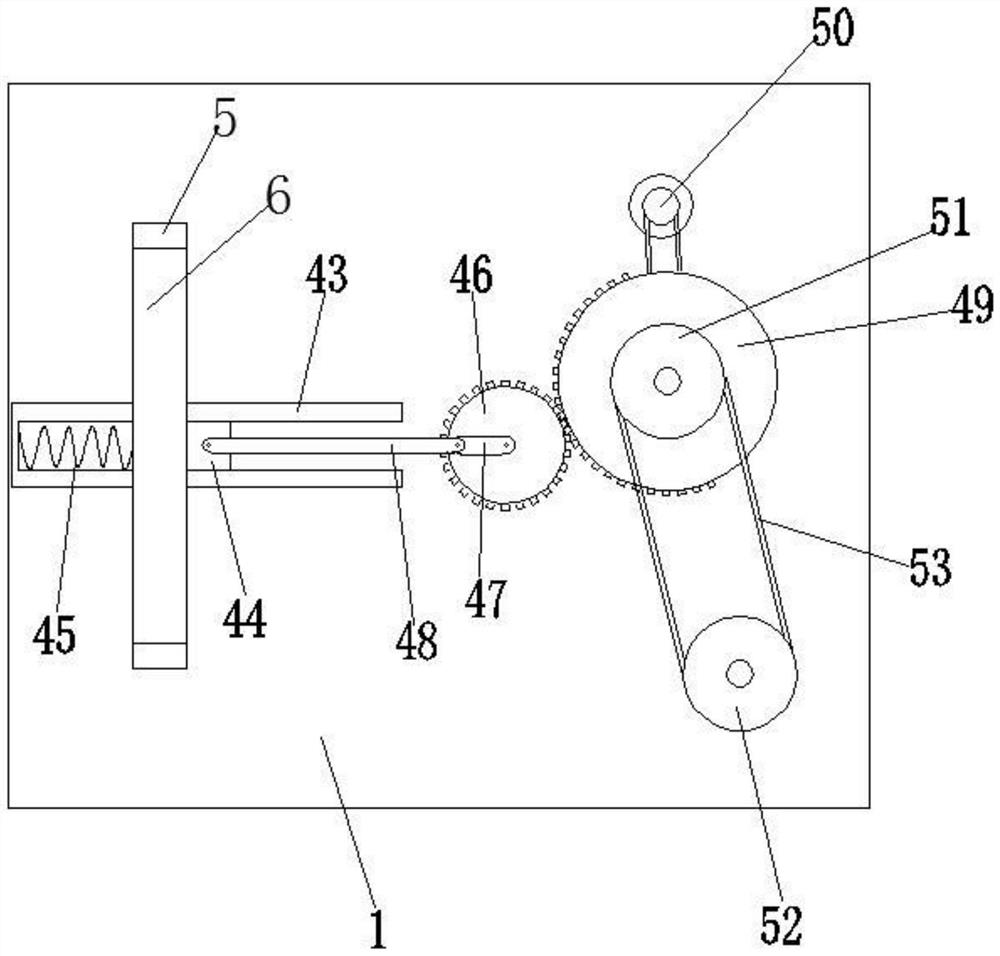

Gear grinding device

ActiveCN114632976AGuaranteed sandingAvoid missingGear-cutting machinesMaintainance and safety accessoriesGear grindingGear wheel

The invention discloses a gear grinding device which is characterized by comprising a rack, a mounting table is arranged on the front side of the rack, a rotating disc is rotationally arranged on the front side of the mounting table, a gear fixing assembly is arranged on the rotating disc, a rotating block is hinged to the mounting table, a pusher dog is hinged to the upper portion of the rotating block, a clamping block is arranged on the left side of the rotating block, and a roller is rotationally arranged on the lower portion of the rotating block; a rotating shaft frame is arranged on the right side of the mounting table, a second rotating shaft is rotationally arranged on the rotating shaft frame, a variable-diameter wheel is arranged on the second rotating shaft, the variable-diameter wheel comprises a large-diameter part and a small-diameter part, the large-diameter part and the small-diameter part are in arc transition, the periphery of the rolling wheel makes contact with the periphery of the variable-diameter wheel, and two guide notches are formed in the front side of the rack; and a connecting block is arranged in the guide notch. According to the gear grinding device, the gear can be rotated quantitatively, so that each tooth space of the gear is ground.

Owner:SHAOXING UNIV YUANPEI COLLEGE

A jewelry inner hole grinding device using centrifugal principle

InactiveCN110666704BSolve wear and tearNot to be wornBlast gunsAbrasive machine appurtenancesEngineeringField coil

The invention relates to the technical field of jewelry processing equipment, and discloses a device for polishing inner holes of jewelry by utilizing a centrifugation principle. The device for polishing the inner holes of the jewelry by utilizing the centrifugation principle comprises a box body, wherein rotary pipes are connected in a polishing device, an inclined hole is formed in the outer side of the lower end of each rotary pipe in a surrounding mode, a drive device is connected with the outer side of each rotary pipe, a coil is arranged in each drive device, a fixing disk is connected with the outer side of the upper end of each rotary pipe, and a permanent magnet is connected with the outer side of each fixing disk in a surrounding mode. According to the device for polishing the inner holes of the jewelry by utilizing the centrifugation principle, a magnetic field opposite to the permanent magnet is generated by the coil, the magnetic field generated by the coil pushes the permanent magnet to rotate, the permanent magnet drives the rotary pipes to rotate through the fixing disk, the inclined holes in the lower ends of the rotary pipes spray water or water-sand mixed liquidfor polishing the inner holes of the jewelry, and the structure achieves the effect of evenly polishing the inner holes of the jewelry, and avoids the problems that due to vibration of a motor and a polishing rod of an existing polishing device, the diameter of the inner holes of the jewelry is different from the top down, and abrasion is easily caused to the jewelry.

Owner:浦江狸步机电科技有限公司

Optical Glass Recycling Process

ActiveCN108673758BImprove crushing effectGuaranteed sandingWorking accessoriesGrain treatmentsPhysical chemistryOptical glass

The invention relates to the field of production of optical glass, in particular to an optical glass recycling process. The optical glass recycling process comprises the following steps that 1, an optical glass smashing device is prepared; 2, optical glass is cut; 3, the optical glass is unloaded into receiving sliding grooves; 4, a separation unit separates waste optical glass from optical glasson a supporting board; 5, the waste optical glass is crushed into optical glass particles through a crushing nail; and 6, the optical glass particles slide to receiving cloth, the two receiving sliding grooves are driven to get close to each other, and the optical glass inside the receiving sliding grooves is polished. By the adoption of the technical scheme, leftover materials can be automatically smashed and collected, and the optical glass is polished at the same time.

Owner:重庆晶宇光电科技有限公司

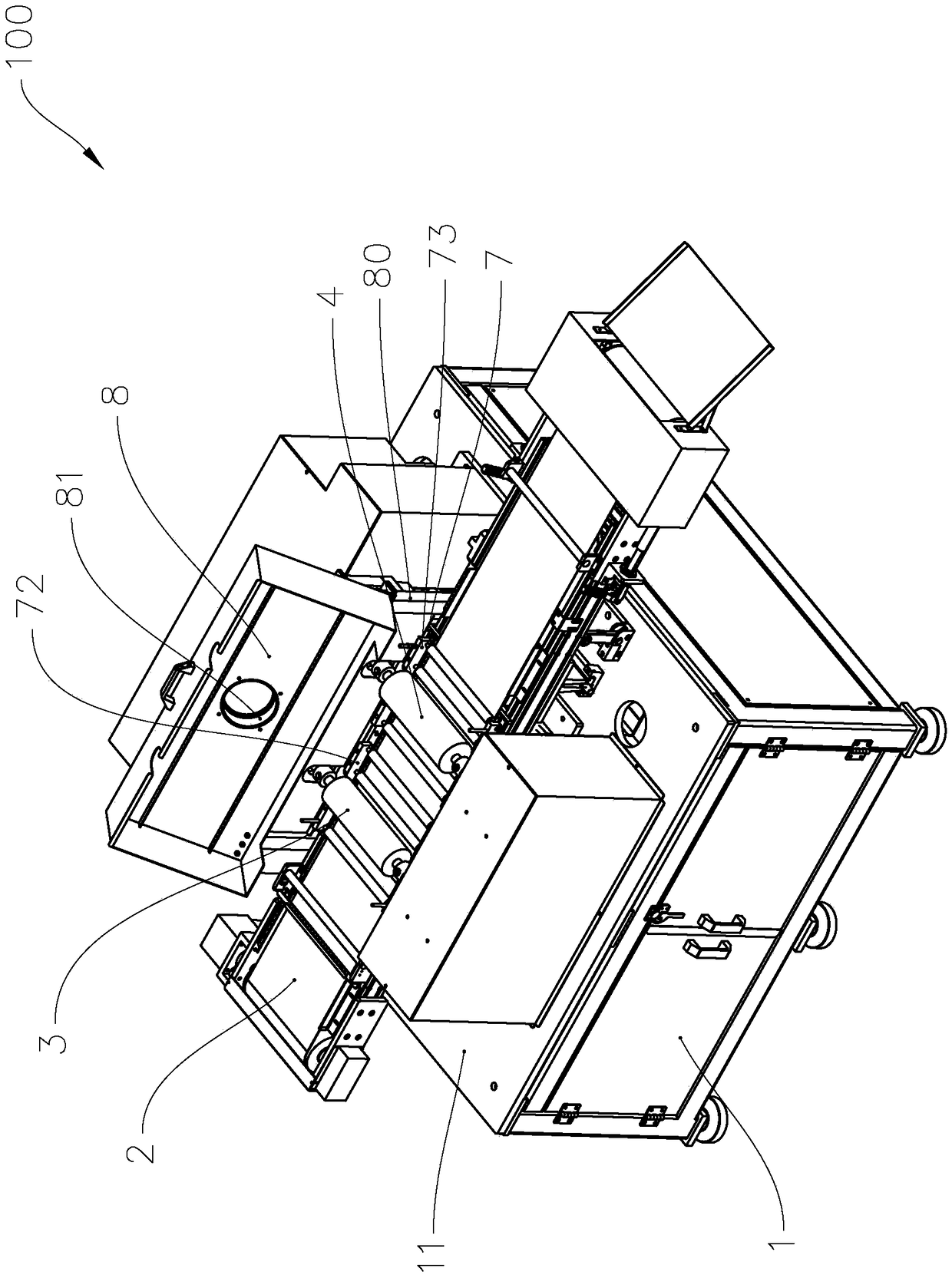

Automatic grinding and cleaning platform for inner hole of connecting rod piece and grinding and cleaning method of automatic grinding and cleaning platform

ActiveCN113953931AEasy to fixAvoid shakingEdge grinding machinesGrinding feedersEngineeringMachining

The invention belongs to the technical field of machining equipment of railway vehicle connecting rod pieces and rubber nodes, and discloses an automatic grinding and cleaning platform for an inner hole of a connecting rod piece. The automatic grinding and cleaning platform comprises a supporting frame and a workbench positioned at the upper end of the supporting frame, and a machining through hole matched with inner holes of connecting rod pieces is formed in the workbench; a grinding assembly and a cleaning assembly are arranged above the machining through hole, the grinding assembly is used for grinding the inner hole of the connecting rod piece, and the cleaning assembly is used for cleaning the ground inner hole of the connecting rod piece; a dust collection assembly is arranged below the machining through hole corresponding to the grinding assembly and used for cleaning scrap iron or dust generated after the inner hole is ground by the grinding assembly; and a clamping part used for clamping a connecting rod piece to be machined is further arranged on the workbench. According to the automatic grinding and cleaning platform for the inner hole of the connecting rod piece and a grinding and cleaning method of the automatic grinding and cleaning platform, the inner hole of the connecting rod piece can be ground, subjected to dust collection and cleaned, the grinding and cleaning efficiency is high, and the grinding quality is good. The invention further provides the method for grinding and cleaning the inner hole of the connecting rod piece.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Dust-free wall surface grinding machine for decoration engineering

InactiveCN113070756AEasy to adjustGuaranteed grinding qualityGrinding carriagesGrinding drivesEngineeringSurface grinding

The invention discloses a dust-free wall surface grinding machine for decoration engineering. The dust-free wall surface grinding machine comprises a control device used for movement, and further comprises an upper frame device used for achieving supporting operation, wherein a grinding device is installed in the upper frame device, an adjusting device is installed at the bottom of the upper frame device, and a lower frame device is installed at the bottom of the adjusting device. According to the dust-free wall surface grinding machine for the decoration engineering, due to the arrangement of the adjusting device, the grinding depth can be conveniently adjusted, and the grinding quality is guaranteed; due to the arrangement of supporting balls of the lower frame device, the attached supporting operation of a wall surface is guaranteed; and due to the arrangement of a dust suction pipe and a corrugated pipe of the upper frame device, dust gathering and collecting are guaranteed, and dust-free grinding is guaranteed.

Owner:长兴科澳厨卫洁具有限公司

A double-sided deburring device

ActiveCN111300199BExtend sanding timeImprove stabilityEdge grinding machinesGrinding drivesControl engineeringControl theory

Owner:LISHUI UNIV

A Processing Technology of Oil Hydraulic Jack Rolling to Remove the Fast Port of Pump Core

ActiveCN113579932BImprove integrityReduce frictionGrinding wheel securing apparatusGrinding machinesMachining processMachine tool

Owner:江苏海力达机电制造有限公司

Multi-angle grinding device for metal keyboard shell of computer keyboard

ActiveCN113084654AImprove connection stabilityQuick disassemblyGrinding wheel securing apparatusGrinding carriagesCircular discElectric machinery

The invention relates to the field of keyboard shell processing, in particular to a multi-angle grinding device for a metal keyboard shell of a computer keyboard. The multi-angle grinding device comprises a grinding motor, a rack, an expansion airbag, polishing abrasive cloth, an air pump and a positioning pipe, wherein the positioning pipe is positioned on the inner wall of the expansion airbag; air holes are formed in the middle section of the positioning pipe, and discs are separately arranged at two ends of the positioning pipe; two arc-shaped plates are arranged at one sides of the two discs separately, two ends of the two arc-shaped plates are detachably connected through bolts, each arc-shaped plate is connected with the disc at the corresponding position through a guide part, and the arc-shaped plates can be spliced into a ring body; two lantern rings are arranged on the outer surface of the positioning pipe, and two ends of the positioning pipe are in coupling fit with the rack separately; a main shaft of the grinding motor is in transmission connection with the positioning pipe; and the positioning pipe communicates with the air pump. According to the multi-angle grinding device, the polishing abrasive cloth is convenient to remove and replace, the whole machine is convenient to maintain, and meanwhile, the characteristic that the keyboard shell can be ground at multiple angles is kept.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com