Optical Glass Recycling Process

A technology of optical glass and craftsmanship, which is applied in the field of optical glass recycling technology, can solve problems such as troublesome, easy to scratch fingers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

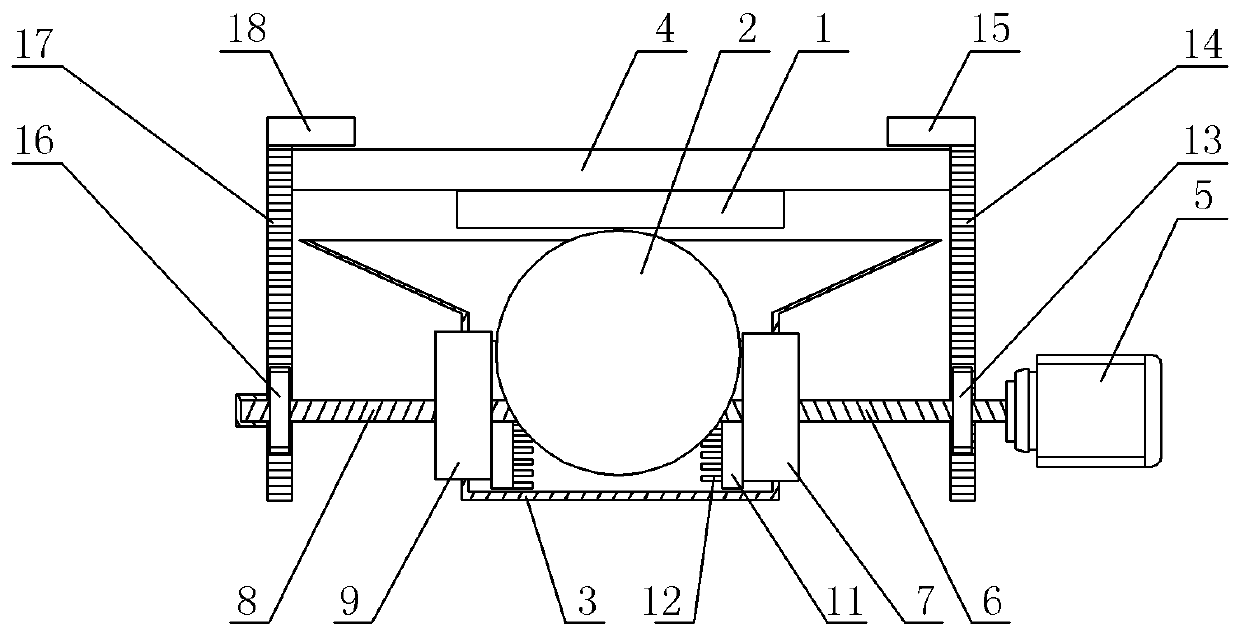

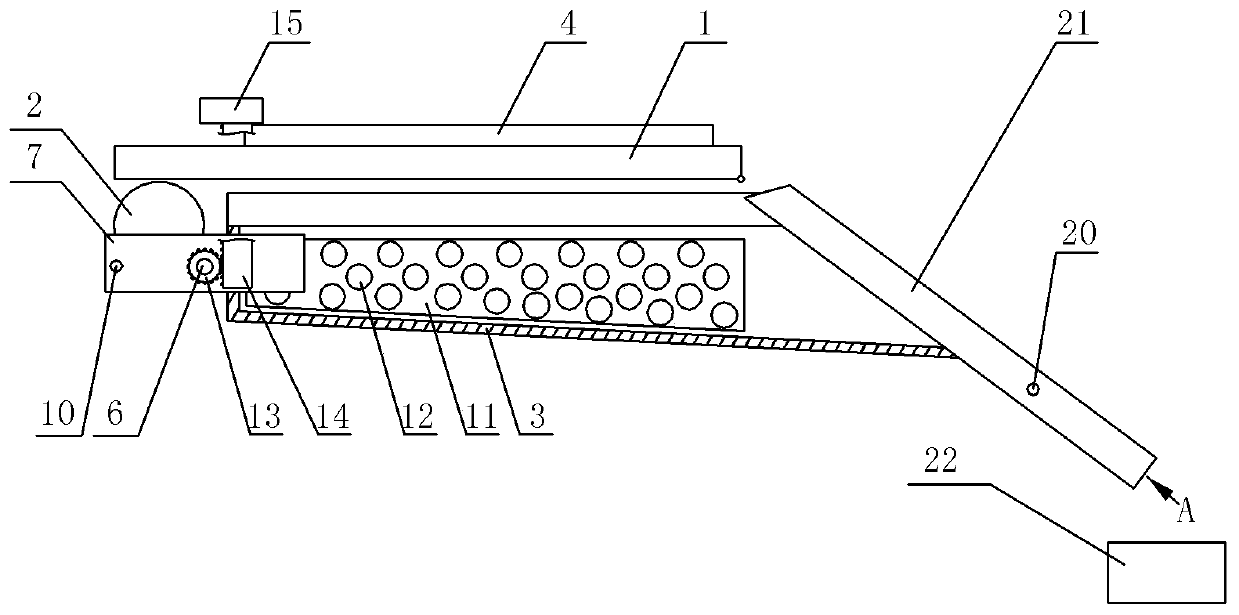

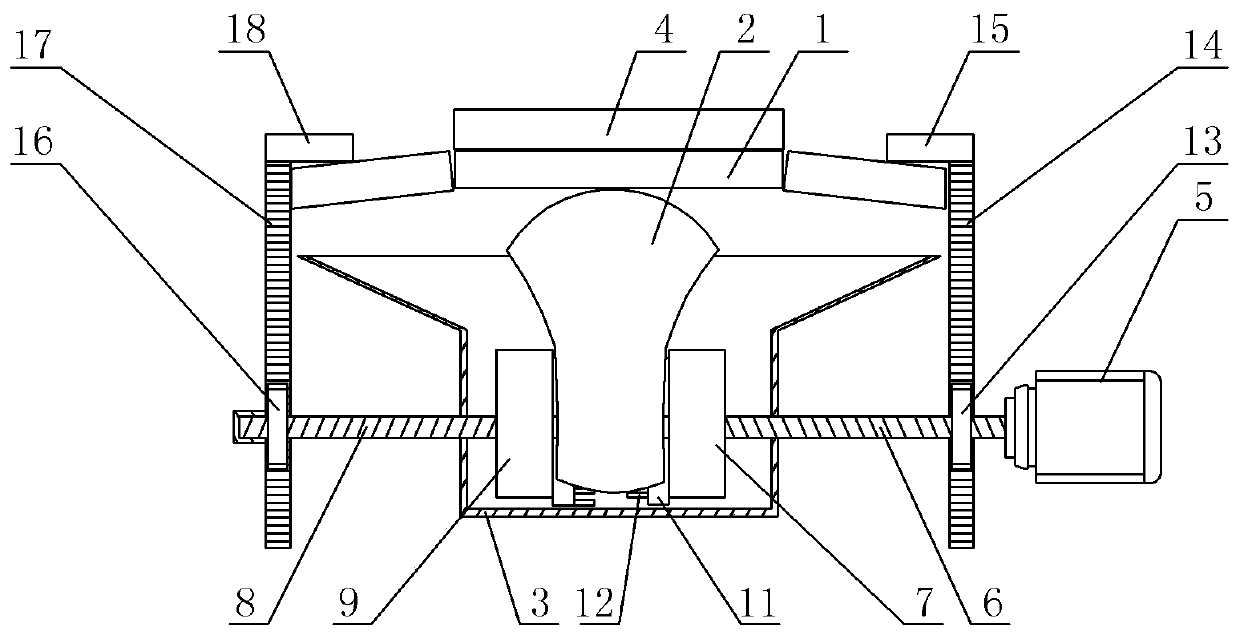

[0022] The reference signs in the drawings of the description include: support plate 1, air bag 2, box body 3, optical glass 4, servo motor 5, first screw rod 6, first nut seat 7, second screw rod 8, second nut seat 9 , limit rod 10, crushing plate 11, crushing nail 12, first gear 13, first rack 14, first separation block 15, second gear 16, second rack 17, second separation block 18, material receiving Cloth 19, spring 20, material receiving chute 21, collection box 22.

[0023] The optical glass recycling process specifically includes the following steps:

[0024] Step 1: Prepare a figure 1 , 2 The shown optical glass crushing device includes a support plate 1, an air bag 2, a box body 3, a crushing mechanism, a separation mechanism and a material receiving mechanism. Such as figure 2 As shown, the box body 3 is located below the support plate 1, and the bottom of the box body 3 is inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com