Dust-free wall surface grinding machine for decoration engineering

A grinding machine and engineering technology, applied in machine tools suitable for grinding workpiece planes, grinding frames, grinding machine parts, etc., can solve the problem of reducing the quality of wall grinding, unable to cope with different wall grinding requirements, reducing Problems such as wall fitting and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

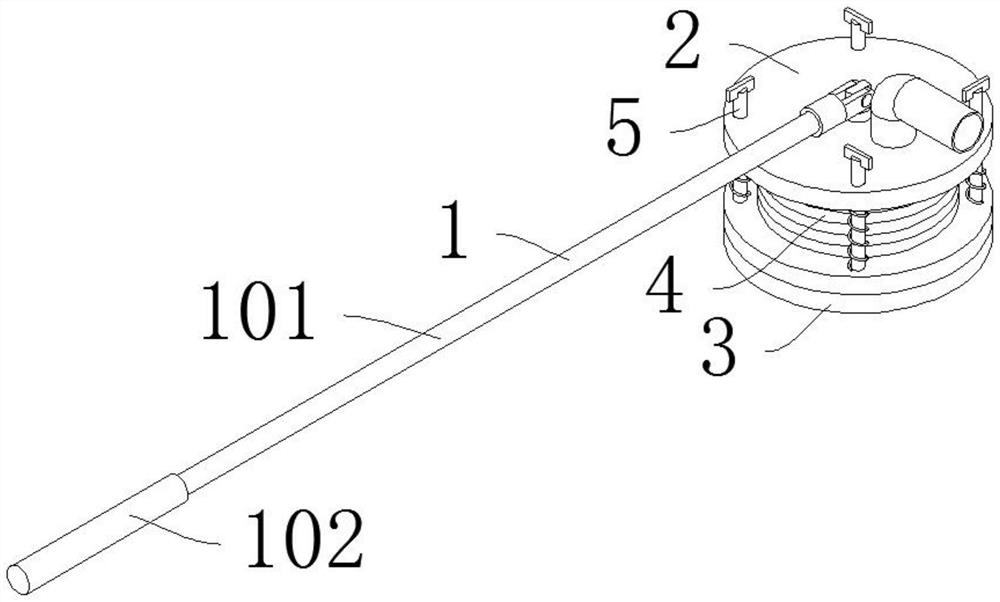

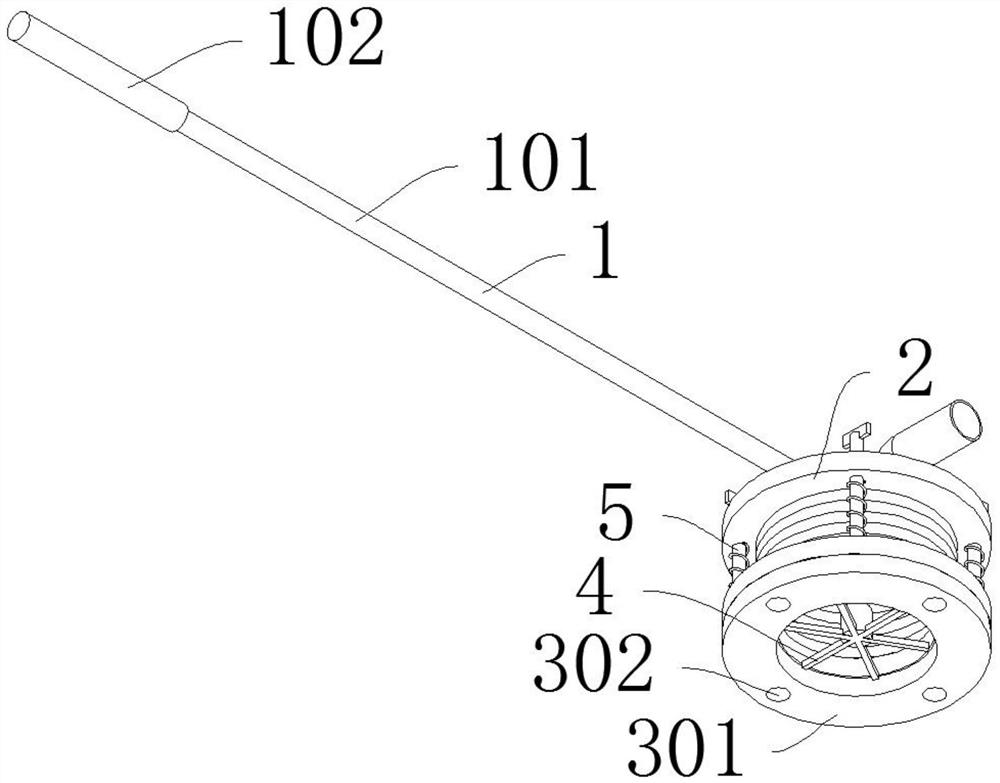

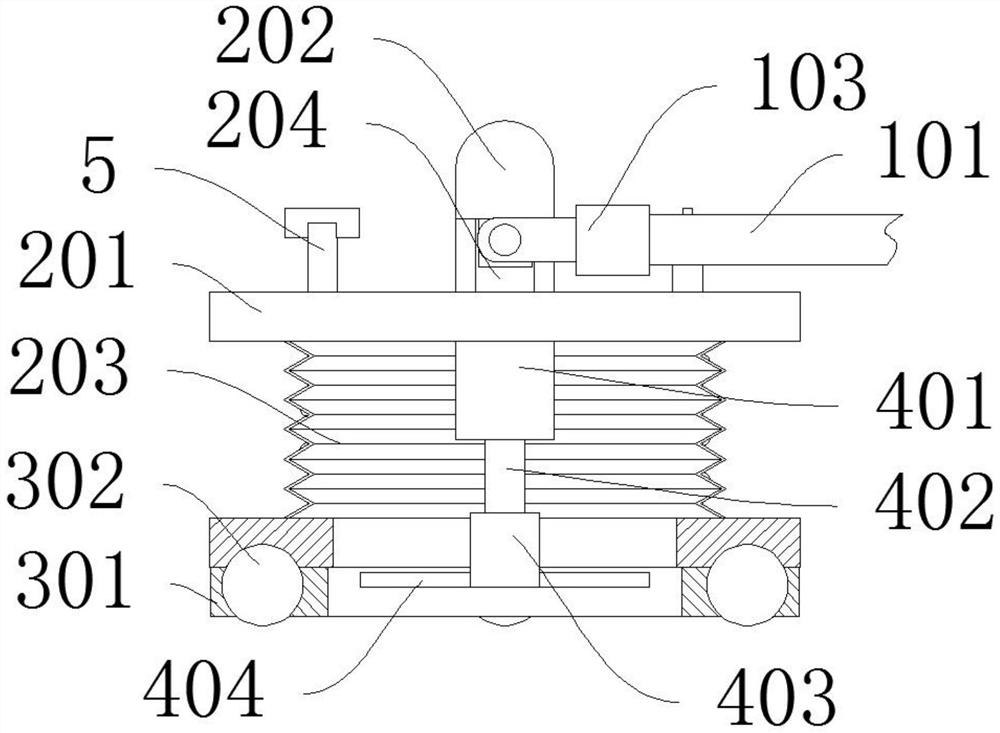

[0035] Such as Figure 1-Figure 4 As shown, a dust-free wall grinder for decoration engineering includes a control device 1 for moving, and a racking device 2 for supporting. A grinding device 4 is installed in the racking device 2, and a Adjustment device 5, below the adjustment device 5, the lower frame device 3 is installed.

[0036] Further: the adjustment device 5 includes a connecting plate 501, four screw rods 502 are evenly distributed on the connecting plate 501, a spring 503 is arranged on the screw rod 502, a screw handle 504 is arranged on the top of the screw rod 502, and the screw rod 502 and the connecting plate 501 are rotationally connected, and the screw rod 502 is connected in rotation. 504 and the screw rod 502 are bolted, and the screw rod 502 is threadedly connected with the racking device 2; the control device 1 includes a handle 102, an extension rod 101 is installed on the handle 102, and a connection fork 103 is installed on the extension rod 101, and...

Embodiment 2

[0038] Such as figure 1 and Figure 5 As shown, a dust-free wall grinder for decoration engineering includes a control device 1 for moving, and a racking device 2 for supporting. A grinding device 4 is installed in the racking device 2, and a Adjustment device 5, below the adjustment device 5, the lower frame device 3 is installed.

[0039]Further: the adjustment device 5 includes a connecting plate 501, four screw rods 502 are evenly distributed on the connecting plate 501, a spring 503 is arranged on the screw rod 502, a screw sleeve 505 is arranged on the spring 503, the screw rod 502 and the connecting plate 501 are riveted together, and the screw rod 502 502 is threadedly connected with the screw sleeve 505, and the screw sleeve 505 is rotationally connected with the racking device 2; the control device 1 includes a handle 102, an extension rod 101 is installed on the handle 102, and a connection fork 103 is installed on the extension rod 101, and the handle 102 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com