Automatic grinding machine for metal plate

A kind of grinding machine, automatic technology, applied in the direction of grinding frame, grinding machine parts, machine tools suitable for grinding the edge of workpiece, etc. Low efficiency and other problems, to achieve the effect of simple structure, large contact area, and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

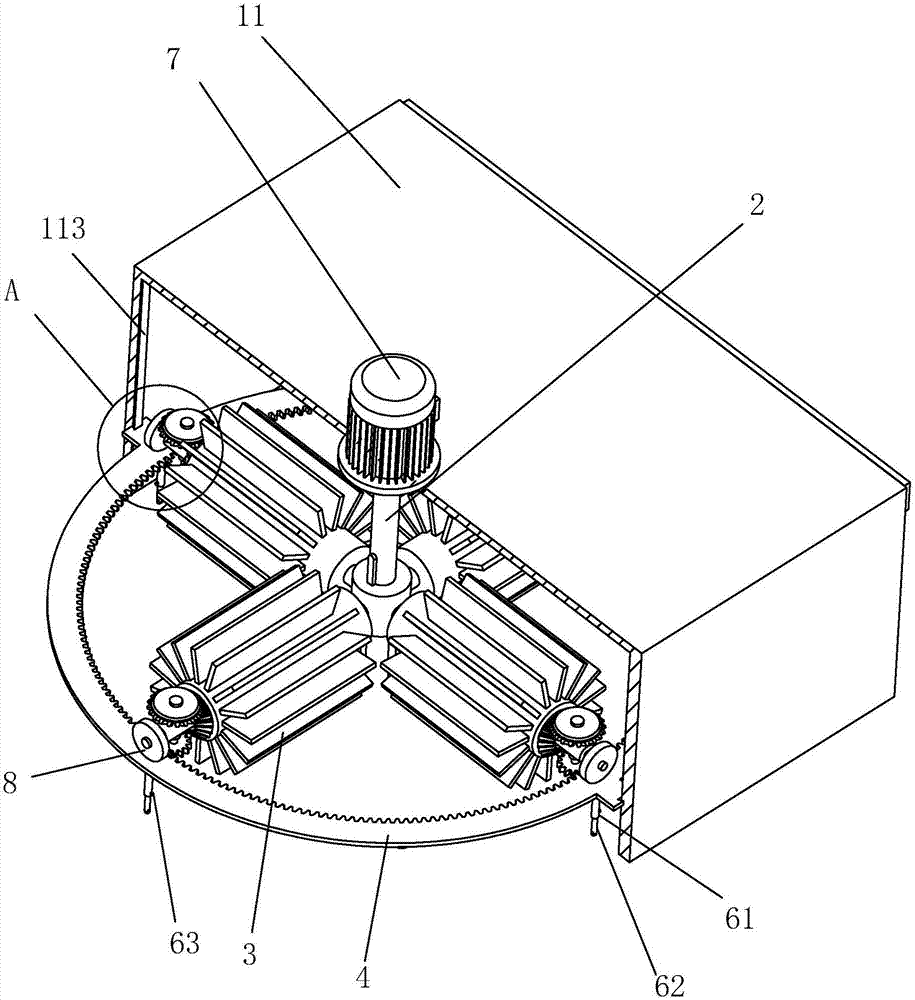

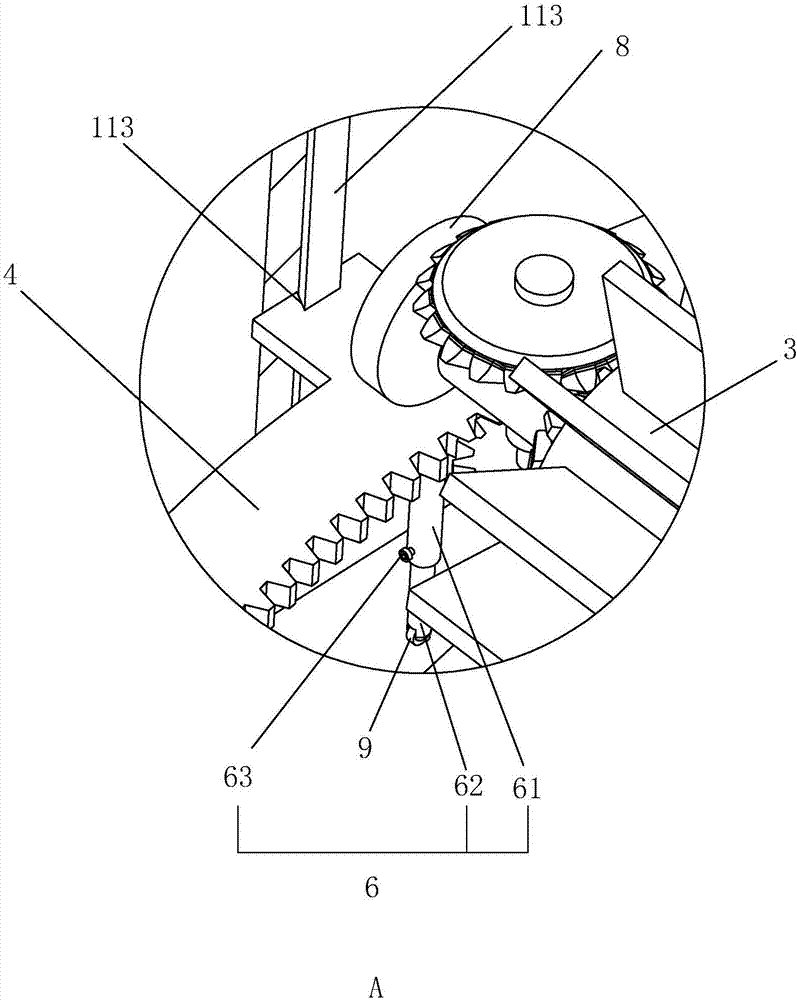

[0033] The following is attached Figure 1-5 The present invention is described in further detail.

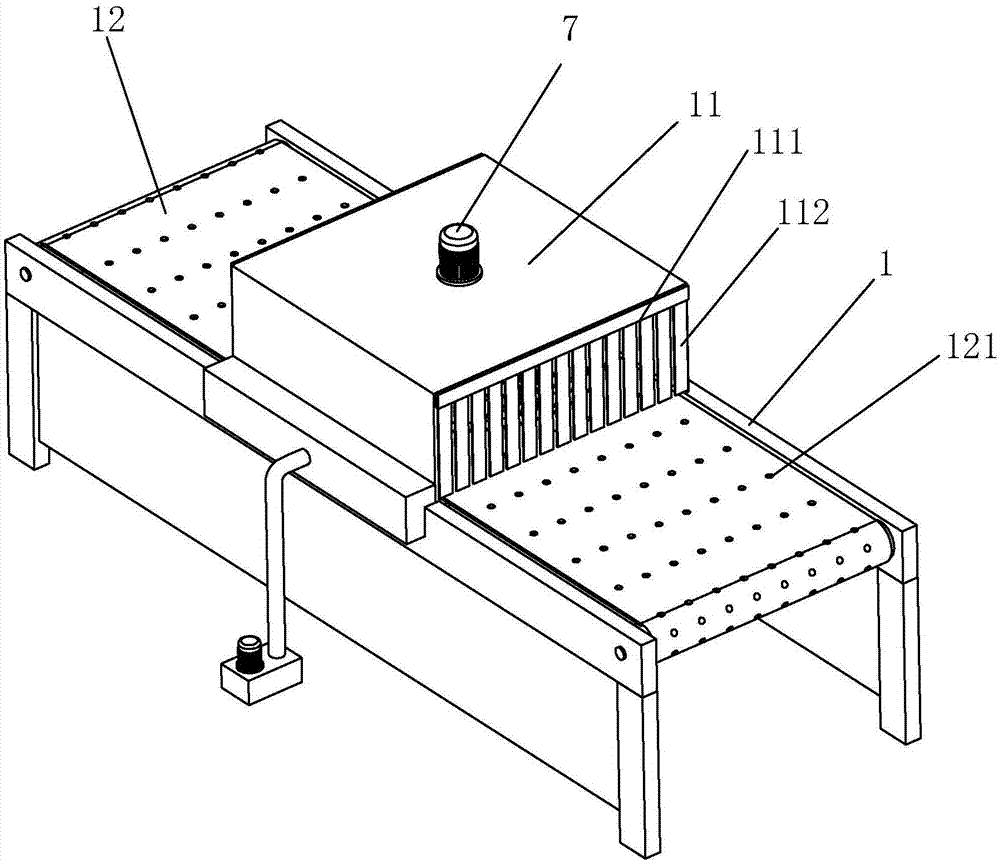

[0034] A kind of sheet metal automatic grinding machine, with reference to figure 1 as well as Figure 4 , including a frame 1, which is provided with a conveyor belt 12 for placing sheet metal parts, a protective cover 11 is arranged above the conveyor belt 12 on the frame 1, openings 111 are provided at both ends of the protective cover 11, and the conveyor belt 12 passes through The opening 111 enters and exits the protective cover 11 , and the protective cover 11 is provided with a dustproof curtain 112 at the opening 111 for covering the opening 111 . Be positioned at the both sides of conveyor belt 12 in protective cover 11 and be provided with suction port 14, and suction port 14 links to each other with blower fan, because when grinding, can produce a certain amount of dust, during work, suction port 14 can play the effect of dust removal, guarantees the working envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com