Polishing device for caddy

A technology of tea pots and rotating rods, which is applied in the direction of grinding drive devices, grinding machines, grinding workpiece supports, etc., which can solve the problems of complex operation, low efficiency of grinding devices, and increased processing time of a single tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

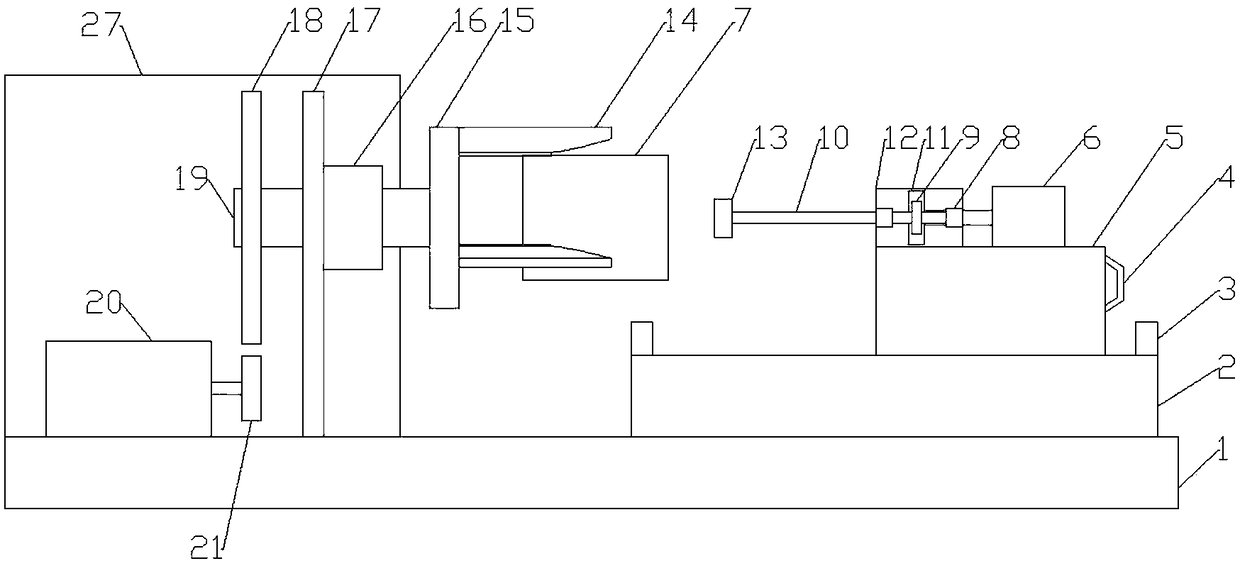

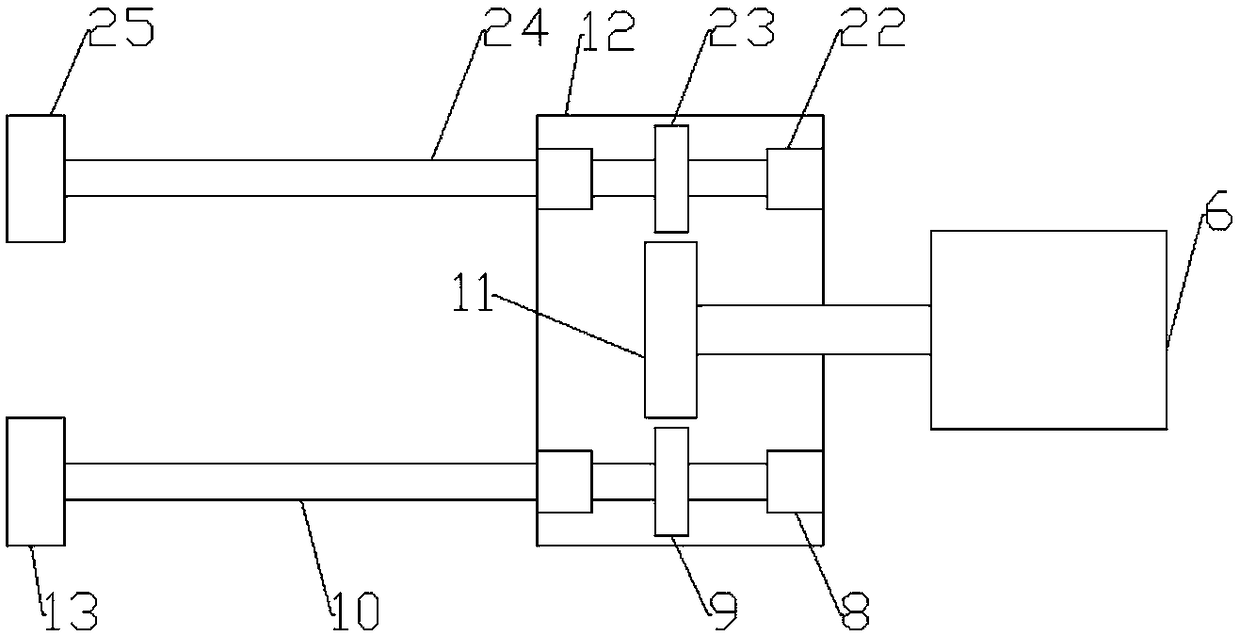

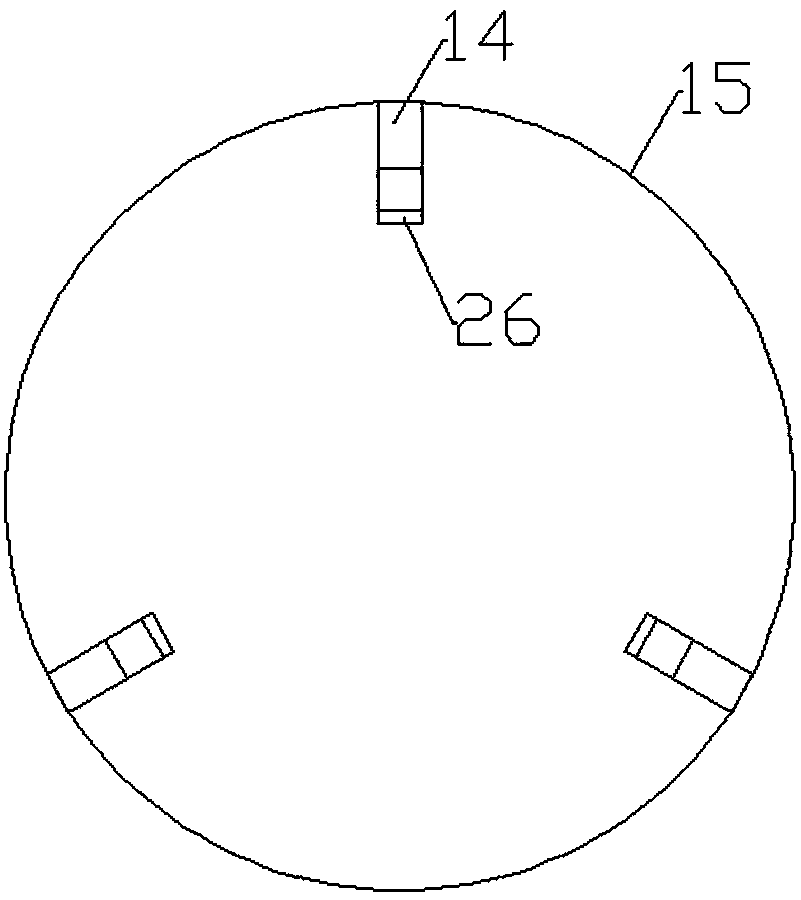

[0015] Figure 1-4 Show the specific embodiment of the present invention: a kind of polishing device of tea canister, comprise base plate 1, described base plate 1 two ends are respectively provided with outer casing 2 27 and slide rail 2, described outer casing 2 27 internal bottoms are provided with There are motor two 20 and fixed plate 17, described motor main shaft is provided with pinion 21, and described fixed plate 17 is fixed with rotating rod seat three 16, and described rotating rod seat three 16 is provided with rotating rod three 19, and described One end of the rotating rod three 19 is connected with a large gear 18 meshing with the pinion 21, and the other end is provided with a rotating disk 15. The rotating disk 15 is provided with three clamping blocks 14 evenly distributed along the center of the circle. The slide block 5 that slides in the longitudinal direction of the slide rail 2, the upper end of the slide block 5 is provided with an outer casing 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com