Part grinding device for production of planar transformer

A technology for plane transformers and parts, applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., can solve the problems of inconvenient speed regulation of grinding machines, low processing efficiency, and inability to achieve double-station grinding, etc. Achieve the effect of increasing efficiency, ensuring transmission, and enriching functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

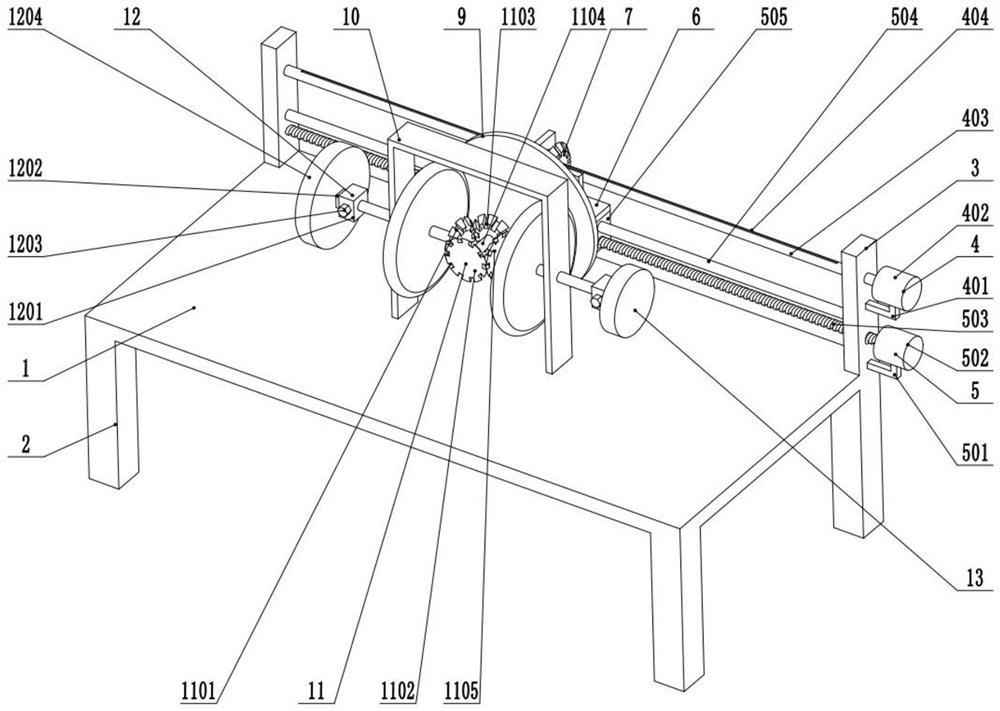

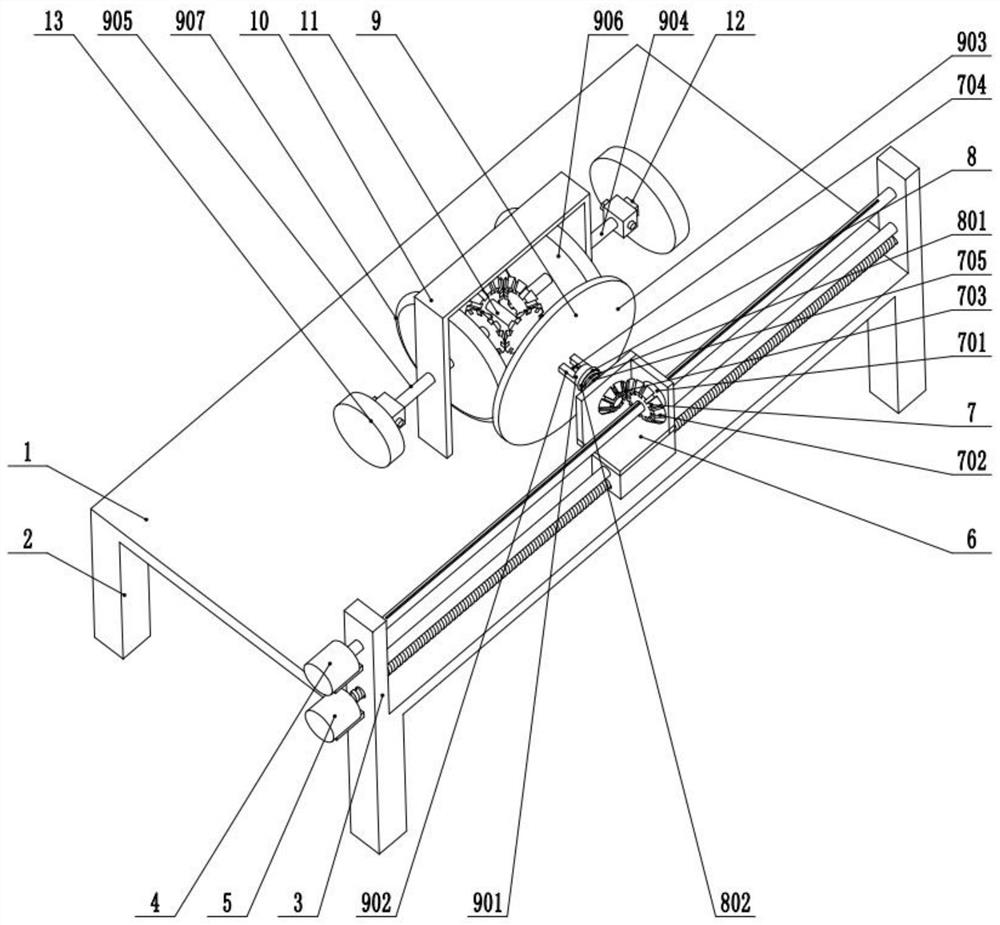

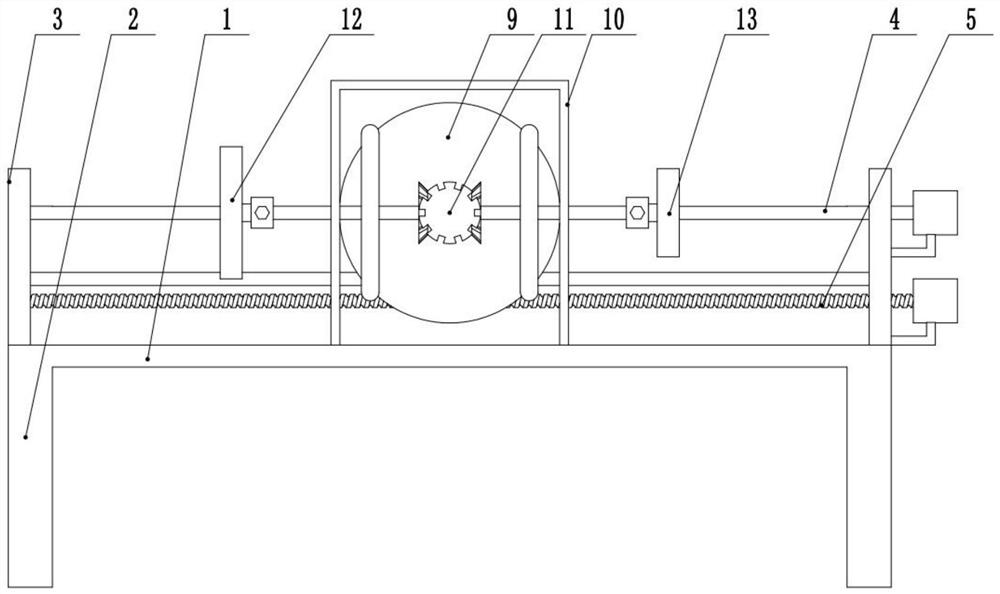

[0023] see Figure 1-3 , a component grinding device for plane transformer production, comprising a mounting seat 1, the lower surface of the mounting seat 1 is fixedly connected to the supporting legs 2, the upper surface of the mounting seat 1 is fixedly connected to a vertical plate 3, and the vertical plate 3 is provided with two pieces. The plate 3 is fixedly connected to the drive mechanism 4 and the position adjustment mechanism 5, the position adjustment mechanism 5 is fixedly connected to the moving frame 6, the moving frame 6 is rotatably connected to the first transmission mechanism 7, the moving frame 6 is fixedly connected to the pressing mechanism 8, and the first transmission mechanism 7 is connected. A variable speed transmission mechanism 9 is provided, the upper surface of the mounting base 1 is fixedly connected to the fixing frame 10 , the variable speed transmission mechanism 9 is fixedly connected to the second transmission mechanism 11 , and the variable ...

Embodiment 2

[0031] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the first grinding mechanism 12 includes an installation sleeve 1201, the installation sleeve 1201 is provided with an installation rod 1202, the installation sleeve 1201 is threadedly connected to the installation bolts 1203, and the installation The bolt 1203 passes through the mounting rod 1202 , and the mounting rod 1202 is fixedly connected to the grinding wheel 1204 .

[0032] The structures of the second grinding mechanism 13 and the first grinding mechanism 12 are the same.

[0033]During the implementation of the present invention, if the rotational speed of the first grinding mechanism 12 and the second grinding mechanism 13 needs to be adjusted, the second motor 502 can be turned on, and the rotation of the output shaft of the second motor 502 will drive the threaded rod 503 to rotate. The position adjusting block 505 is driven to move along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com