Gear grinding device

A technology of gears and driving gears, applied in gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve problems such as missing grinding and inability to guarantee the quality of grinding, and achieve the effect of avoiding omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

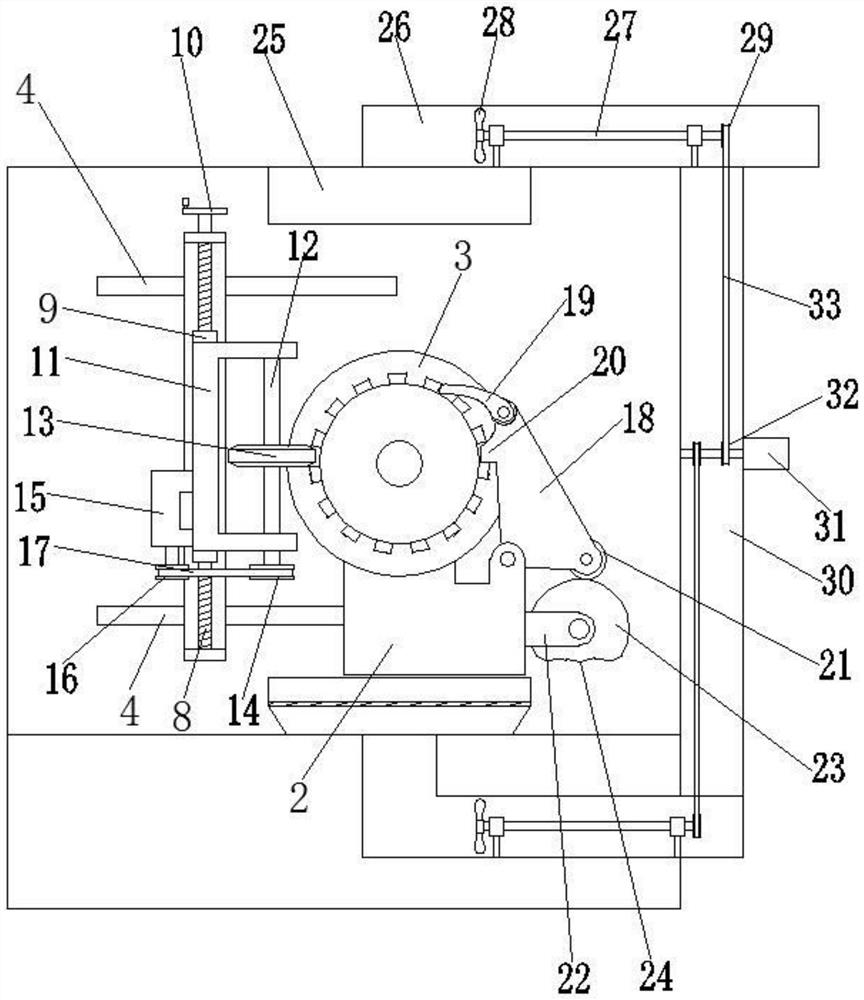

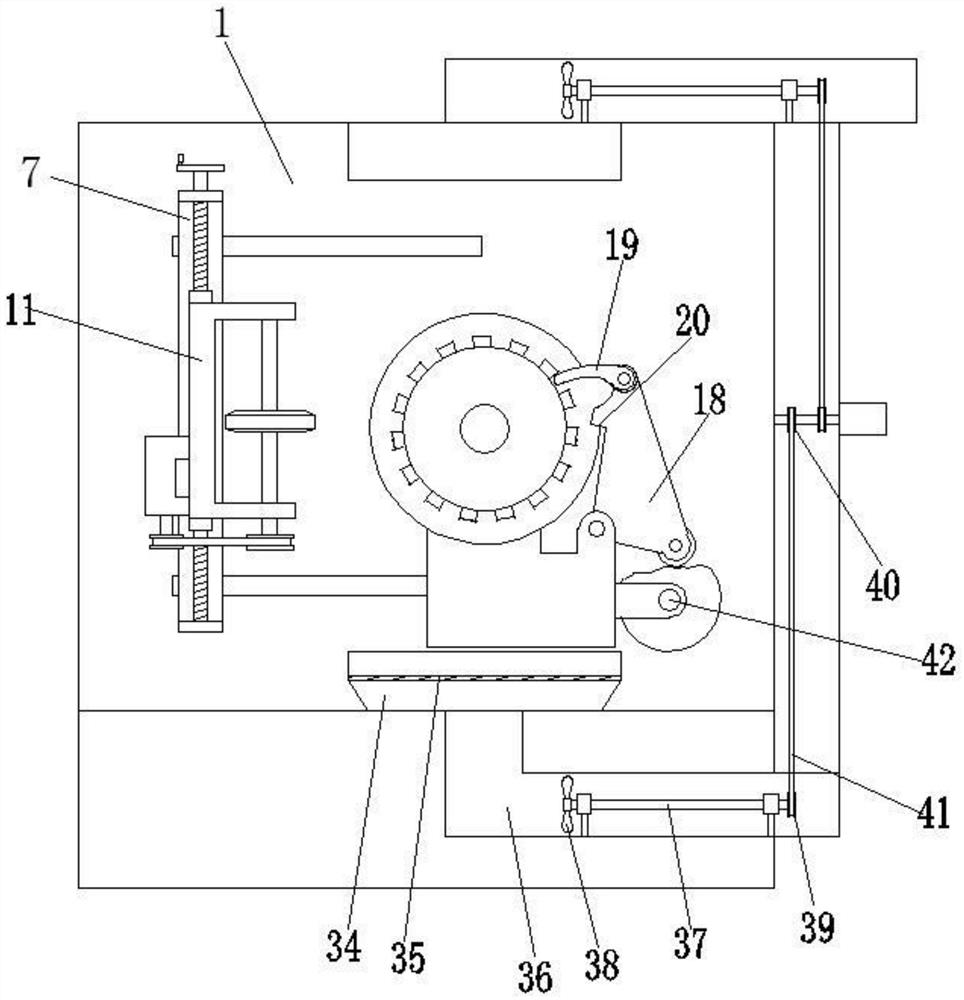

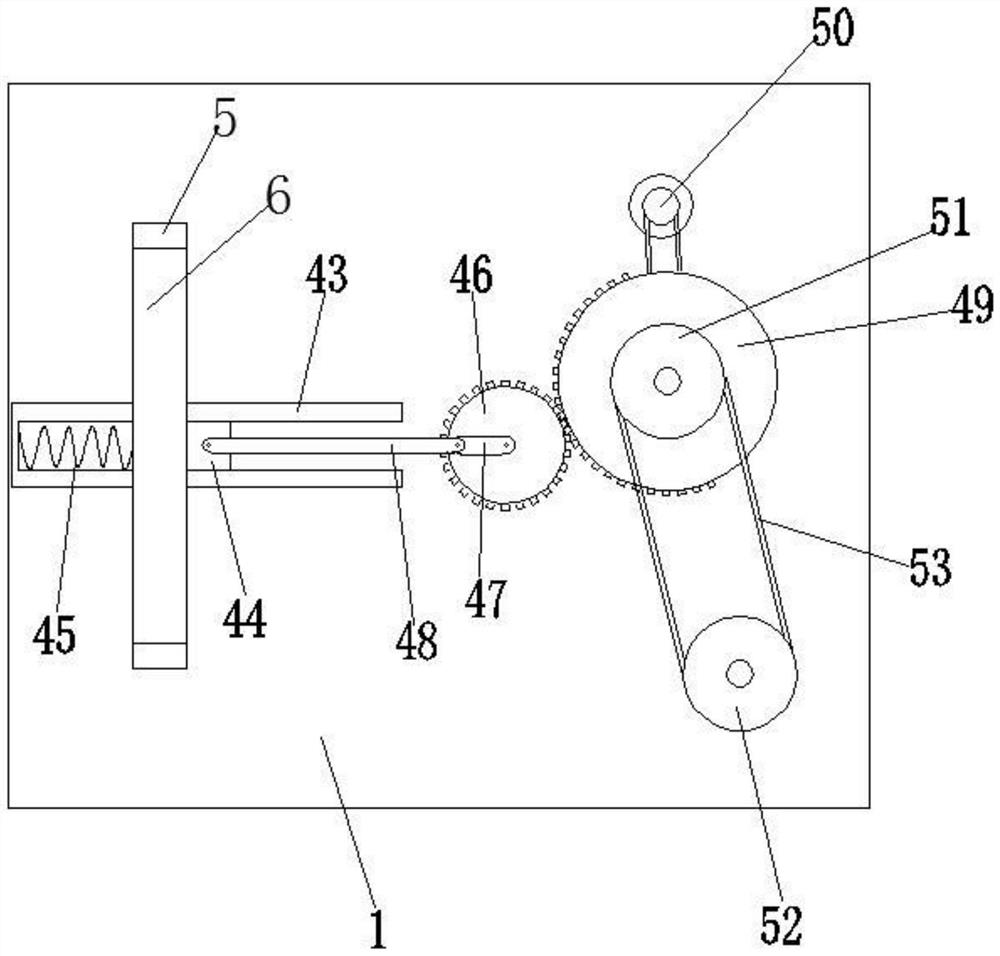

[0023] Attached below Figure 1-8 The embodiments of the present invention are described in detail.

[0024]A gear grinding device comprises a frame 1, an installation table 2 is arranged on the front side of the frame 1, a turntable 3 is rotated on the front side of the installation table 2, a gear fixing assembly is arranged on the turntable 3, and a rotating block is hinged on the installation table 2 18. The upper part of the rotating block 18 is hinged with a claw 19; the left side of the rotating block 18 is provided with a clamping block 20; There is a second rotating shaft 42, and a diameter reducing wheel is arranged on the second rotating shaft 42. The diameter reducing wheel includes a large diameter part 23 and a small diameter part 24, the arc between the large diameter part 23 and the small diameter part 24 is excessive, and the outer circumference of the roller 21 and the small diameter part 24 are excessive. The outer peripheries of the reducing wheels are in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com