Automatic grinding and cleaning platform for inner hole of connecting rod piece and grinding and cleaning method of automatic grinding and cleaning platform

A connecting rod and inner hole technology, which is applied in the field of automatic grinding and cleaning platform for inner holes of connecting rods, can solve the problems of poor grinding quality, low grinding and cleaning efficiency, achieve good sealing effect, ensure grinding and cleaning effect, and prevent shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

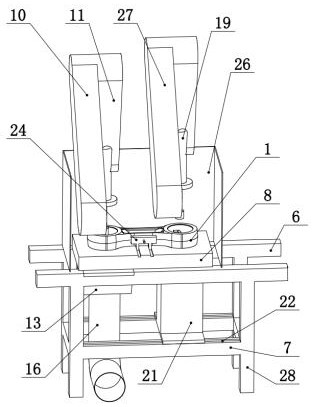

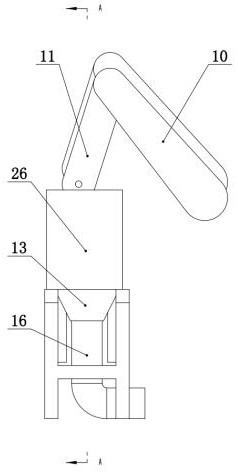

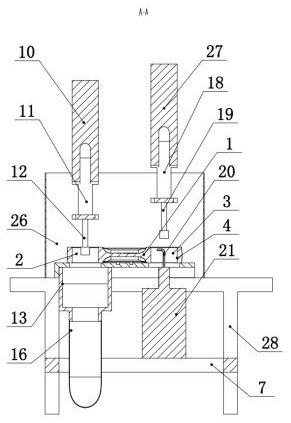

[0043] The following is attached Figure 1-8 The present invention is further described in detail.

[0044] The inner hole of the connecting rod is automatically polished and cleaned, including a support frame and a workbench 8 located at the upper end of the support frame, such as figure 1As shown, the support frame includes a stand 28 and an upper side frame 6 positioned at the upper end of the stand 28, and a workbench 8 is positioned at the upper end of the upper side frame 6; the workbench 8 is provided with a processing through hole that matches the inner hole of the connecting rod ; A grinding assembly and a cleaning assembly are arranged above the processing through hole, the grinding assembly is used for grinding the inner hole of the connecting rod 1, and the cleaning assembly is used for cleaning the inner hole of the connecting rod 1 after grinding; corresponding to the grinding assembly The bottom of the processing through hole is provided with a dust suction ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com