Non-magnetic alloy and counterbalance produced thereby

A technology of balance weights and metal alloys, applied in the field of balance weights, can solve problems such as low production efficiency, affecting the performance of compressors, and easy to rust

Inactive Publication Date: 2008-02-06

NANCHANG ZHONGHAO MACHINERY

View PDF1 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the alloy material made with this formula is easy to rust due to the absence of corrosion-resistant elements such as chromium and nickel, resulting in quality problems in the compressor

In addition, the alloy material made of this formula has too ideal machinability, and the workpiece can only be manufactured by casting

The casting method needs to go through the steps of mold making, shell making, smelting, casting, finishing, solid solution heat treatment, surface sand blasting and mechanical processing. There are many production processes, long processing cycle, low production efficiency and high cost. The raw materials must be melted , poured into the mold, the pollution is large, and it is difficult to meet the needs of mass production with multiple specifications

In addition, the products processed by casting are prone to defects such as pores and slag inclusions, resulting in unbalanced balance weights and affecting the performance of the compressor, so the quality is difficult to improve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

[0022] According to the formula listed in Table 1, various metal elements were weighed, and samples 1 to 5 were prepared by conventional smelting methods.

[0023] Table 1, test sample formulation

[0024] Composition (wt%)

[0025] * Non-artificial addition. # non-measured value

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

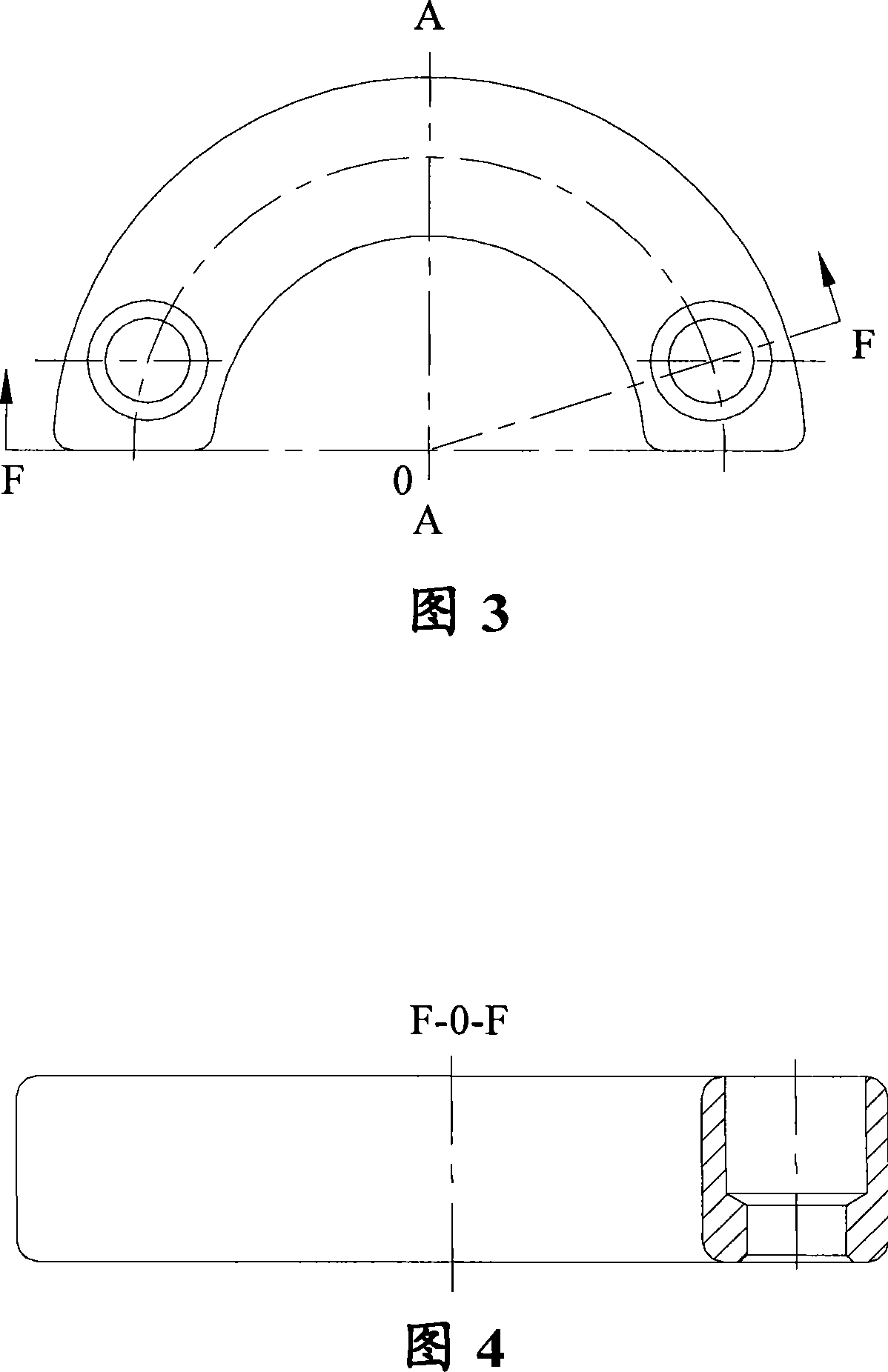

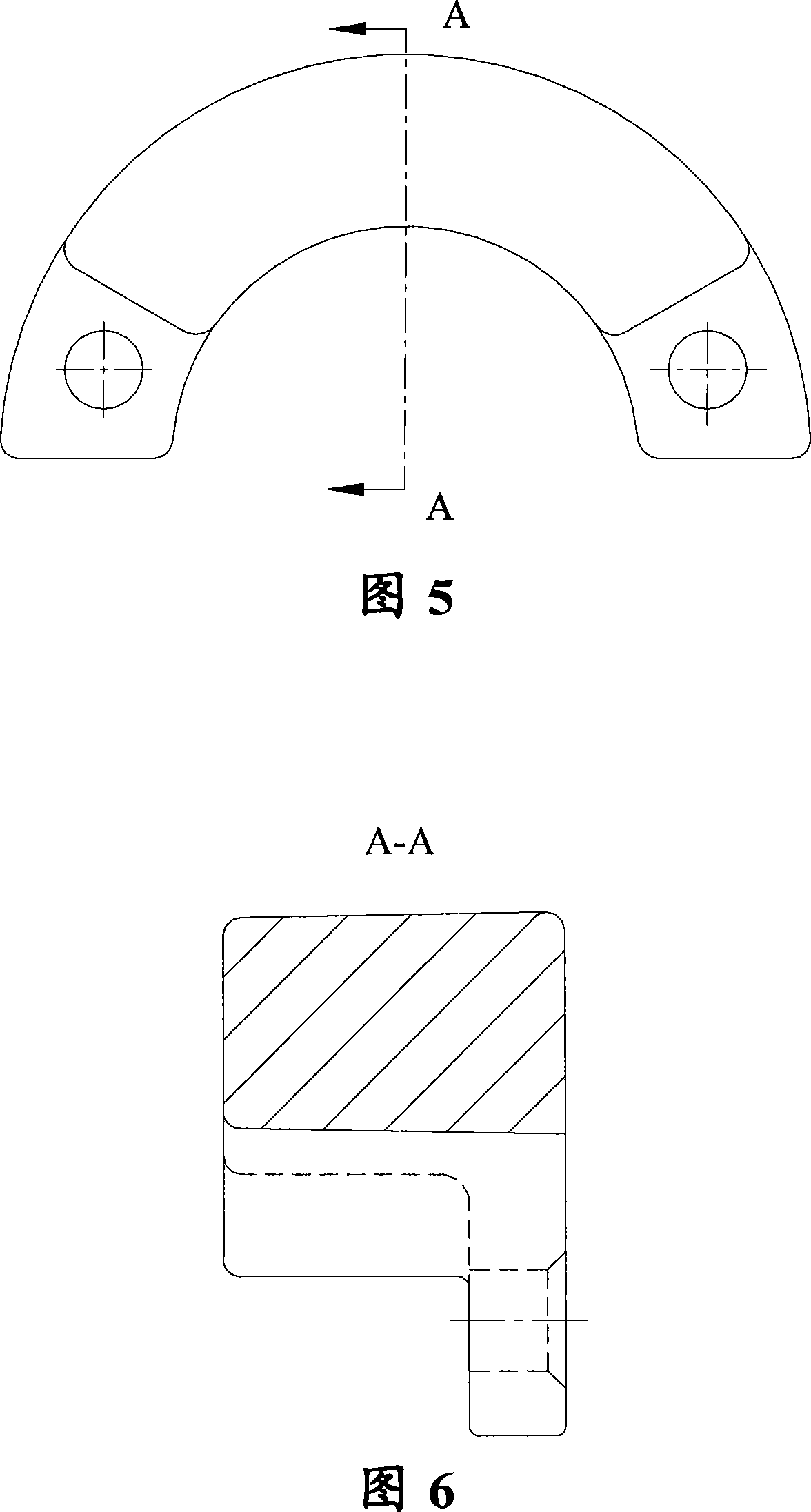

The present invention provides a non-magnetic metal alloy used for the balancing weight of a compressor, with a weight percentage of components as follows: Mn 5-20 percent, chromium 5-20 percent, sulfur 0.05-1.5 percent and the remainders are Fe and trace. The alloy can also contain Cu 0.4-3 percent and / or nickel less than or equal to 1.5 percent. The balancing weight used for a compressor can be made by adopting the materials with a method of forging and pressing. Advantages of the method are that the working procedure is simplified, the pollution is lowered and the processing is flexible. Simultaneously, the adoption of forging and pressing rids the product of pores and slag inclusions, and improves the balancing capacity of the balancing weight.

Description

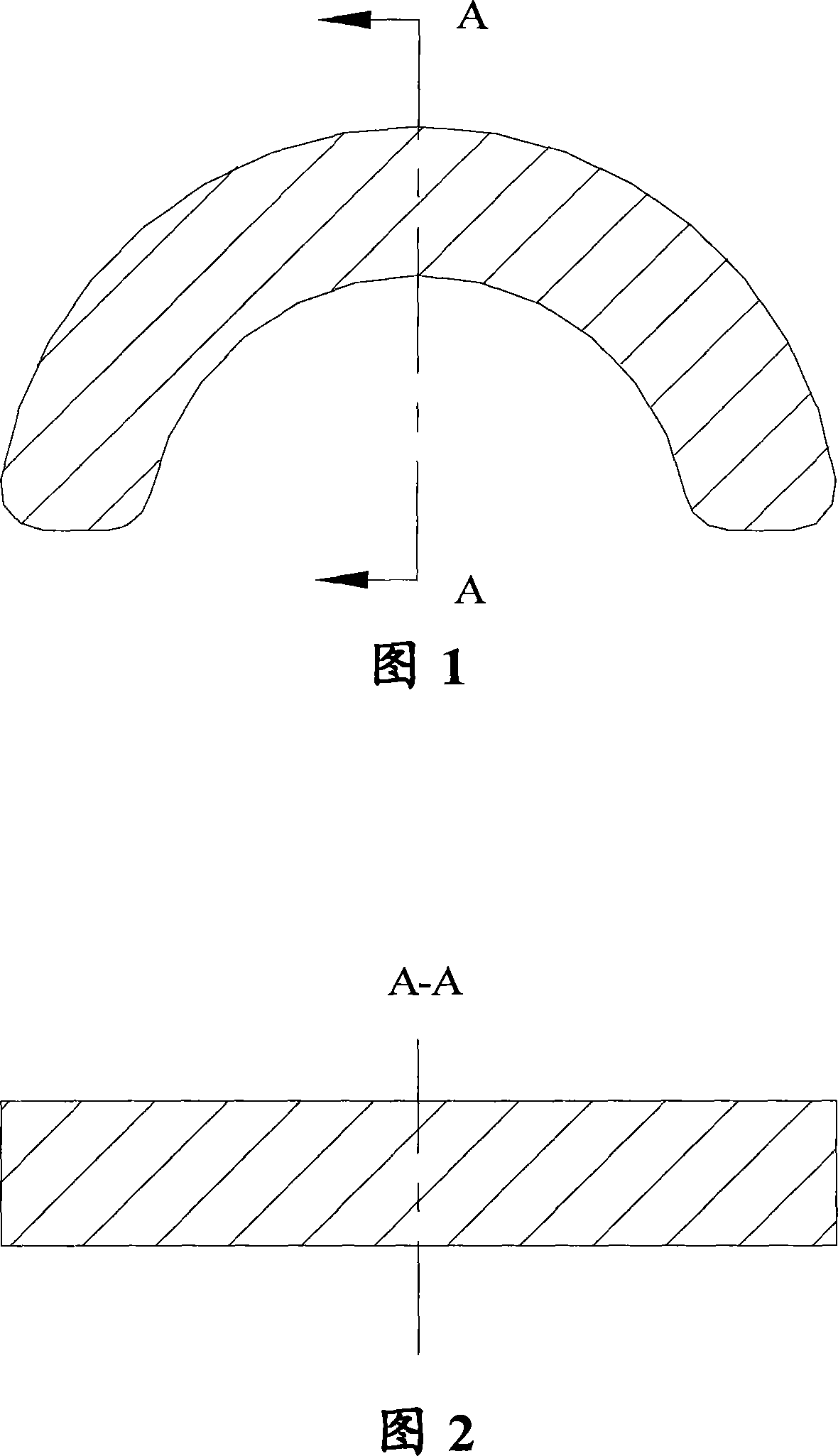

technical field [0001] The invention relates to a non-magnetic iron and steel alloy material, a method of using it to produce a balance weight for a compressor, and a balance weight produced by the method. Background technique [0002] The balance weight is an important part of the compressor rotor, which plays the role of balance, noise reduction and vibration reduction. At present, the balance weights for compressors are all made of copper alloy. Due to the high price of copper and the shortage of raw materials, the production cost is relatively high. Moreover, the lead element added to the copper alloy is more harmful to the human body and the environment, and has been listed as one of the six banned substances by the European Union. [0003] Application No. 200610116831 discloses a metal alloy for balance weight in Chinese patent application, which consists of 16.00-30.00% manganese, 0.50-2.50% aluminum, 0.04-0.10% vanadium, and 0.06-0.30% carbon, and the balance of ir...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/38C22C38/60F04C29/00C21D7/02

Inventor 杨建

Owner NANCHANG ZHONGHAO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com