One-dimensional moving three-dimensional rotating parallel machine tool

A three-dimensional rotation and parallel technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in ensuring high rigidity, complex NC programming, and unsuitable processing, and achieve good structural shock resistance and cutting stability , Good processing technology, convenient decoupling of position and posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

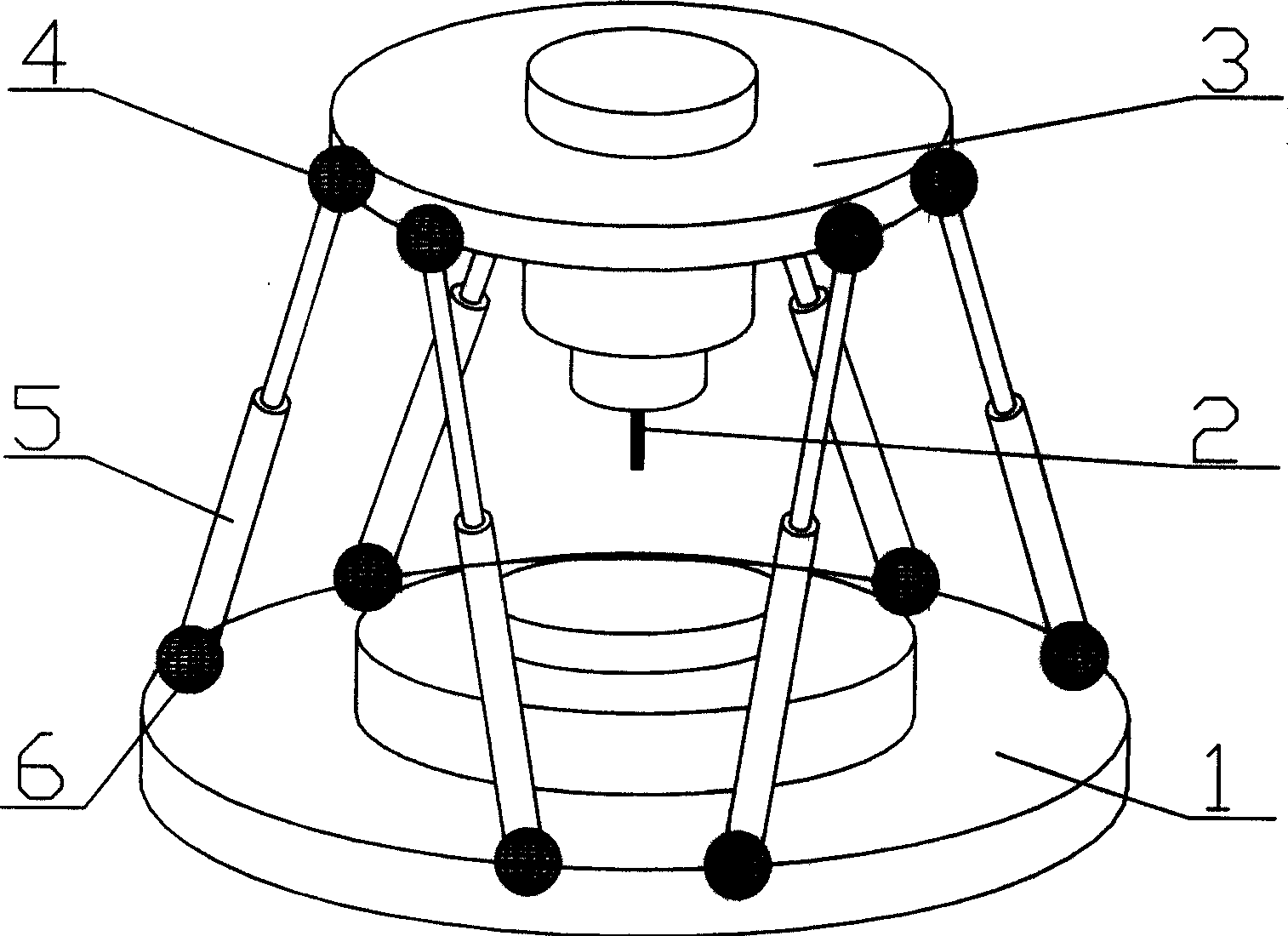

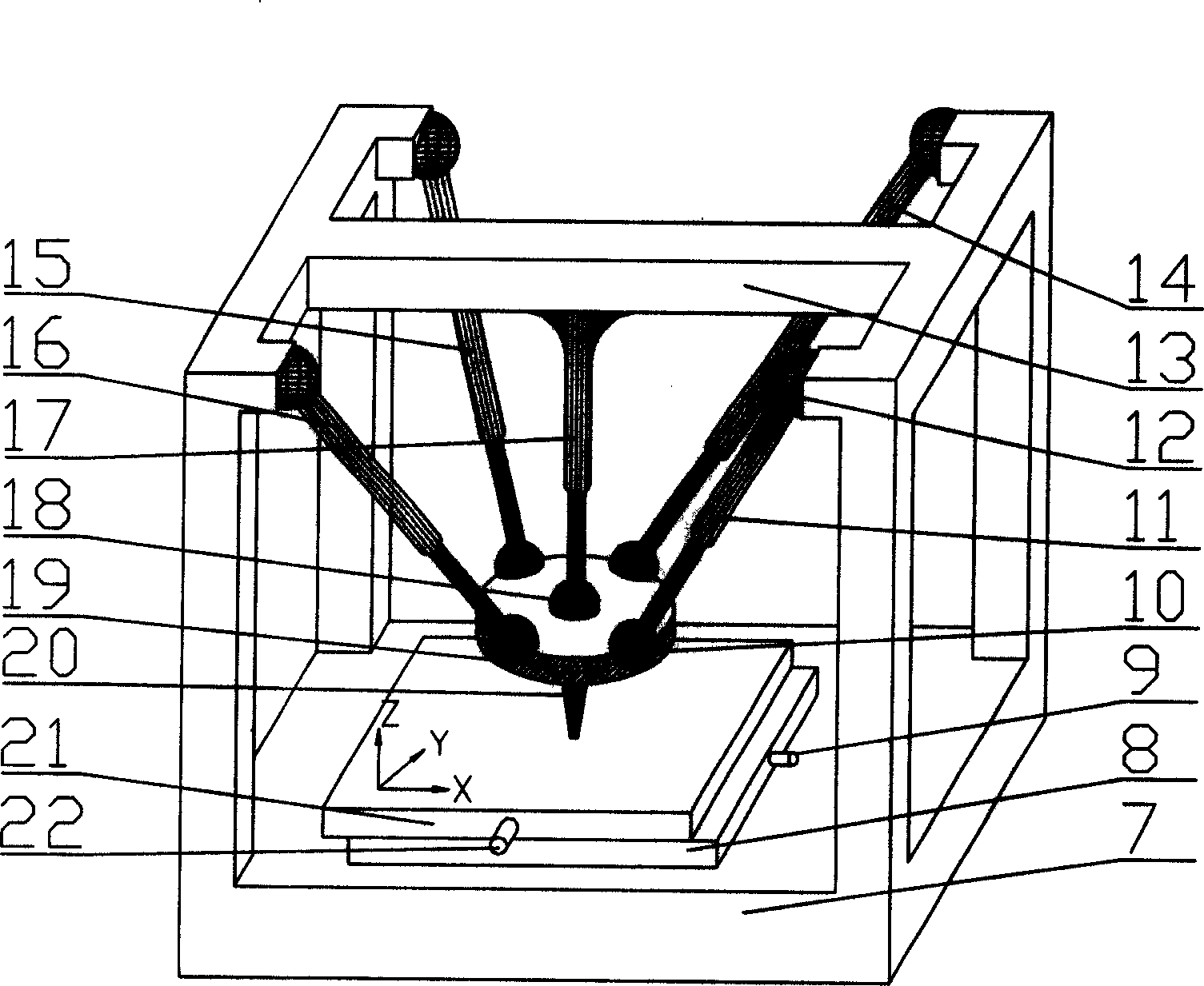

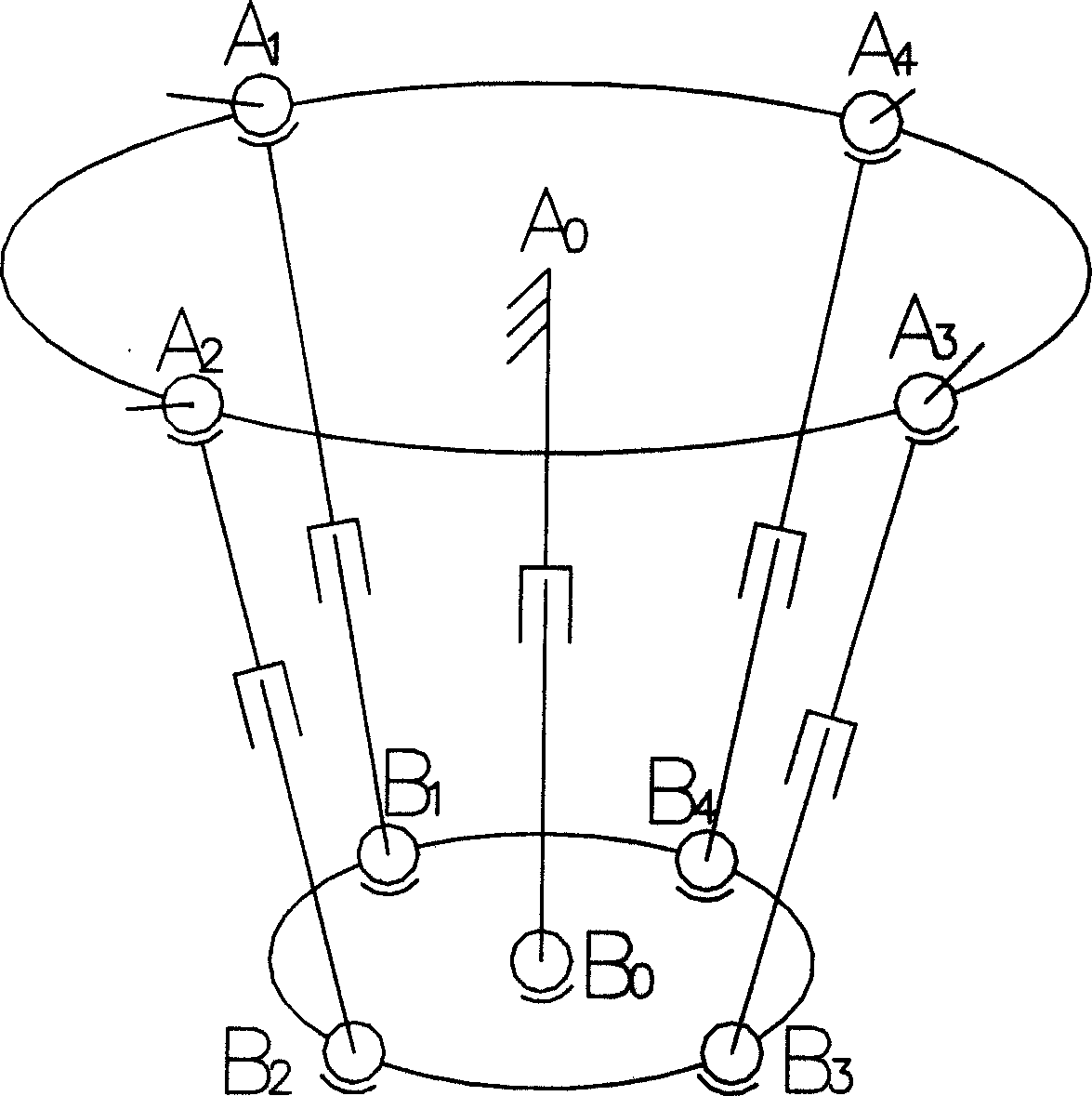

[0038] The general structure of embodiment one is as figure 2 As shown, in this embodiment, it includes a fixed table 13, a moving platform 19 for installing cutting tools, two-way mobile platforms 8 and 21 that can move along the X and Y directions, and a workbench for installing workpieces to be cut. It is characterized in that the fixed platform 13 is connected with the moving platform 19 by 5 legs, and the surrounding 4 telescopic legs (11, 14, 15, 16) are connected with the fixed platform 13 by a Hooke hinge or a spherical hinge (such as a spherical hinge 12) , the surrounding 4 telescopic legs (11, 14, 15, 16) are connected with the moving platform 19 by a ball joint (such as the ball joint 10). One end of the middle leg 17 is rigidly connected to the center of the fixed platform 13 , and the other end is connected to the moving platform 19 through a ball joint 18 . Thus a space parallel closed-chain structure is formed, and the two-way mobile platforms 8 and 21 that c...

Embodiment 2

[0042] The general structure of embodiment two is as Figure 4 As shown, in the present embodiment, the machine tool bed 23 and the frame 32 form a fixed platform, and the fixed platform and a moving platform 37 for installing cutting tools, fixed-length peripheral legs (27, 30, 33, 34), and an intermediate leg 35 form a space Parallel closed chain mechanism. One end of the legs (27, 30, 33, 34) around the fixed length is connected with a slide block (such as a slide block 29) by a Hooke hinge or a ball joint (such as a ball joint 28), and the slide block is driven by a servo motor (such as a servo motor 31). ) Driven by the lead screw nut drive. The moving platform 37 is connected with the fixed-length surrounding legs (27, 30, 33, 34) by a ball joint (such as the ball joint 26). The middle leg 35 is rigidly connected to the center of the frame 32 , and the other end of the middle leg 35 is connected to the moving platform 37 through a ball joint 36 . When the displacement...

Embodiment 3

[0043] The general structure of embodiment three is as Figure 5 As shown, in the present embodiment, the lower platform 51 in the two-way mobile platform, the moving platform 56 on which the cutting tool is installed, the surrounding telescopic legs (43, 45, 50, 53), and the middle leg 54 form a space parallel closed-chain mechanism. And the two-way mobile platform can translate along the X and Y axis directions under the drive of the lead screw nuts driven by the servo motors 47 and 52 . Wherein the lower platform 51 in the two-way mobile platform is connected with the surrounding telescopic legs (43, 45, 50, 53) by a Hooke hinge or a ball joint (as the ball joint 44), and the moving platform 56 is connected with the surrounding telescopic legs (43, 53). 45, 50, 53) are connected by a ball joint (such as the ball joint 42). The middle leg 54 is rigidly connected to the center of the lower platform 51 in the two-way moving platform, and the other end of the middle leg 54 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com