Gantry type rough and finish composite five-axis precision machine tool and processing method thereof

A precision machine tool and gantry-type technology, applied in metal processing equipment, metal processing machinery parts, milling machines, etc., can solve the problems of inability to guarantee the processing accuracy of microscopic and complex surfaces, increase the processing time, and increase the processing error, etc., and achieve good application value and market prospects, the effect of low manufacturing cost and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

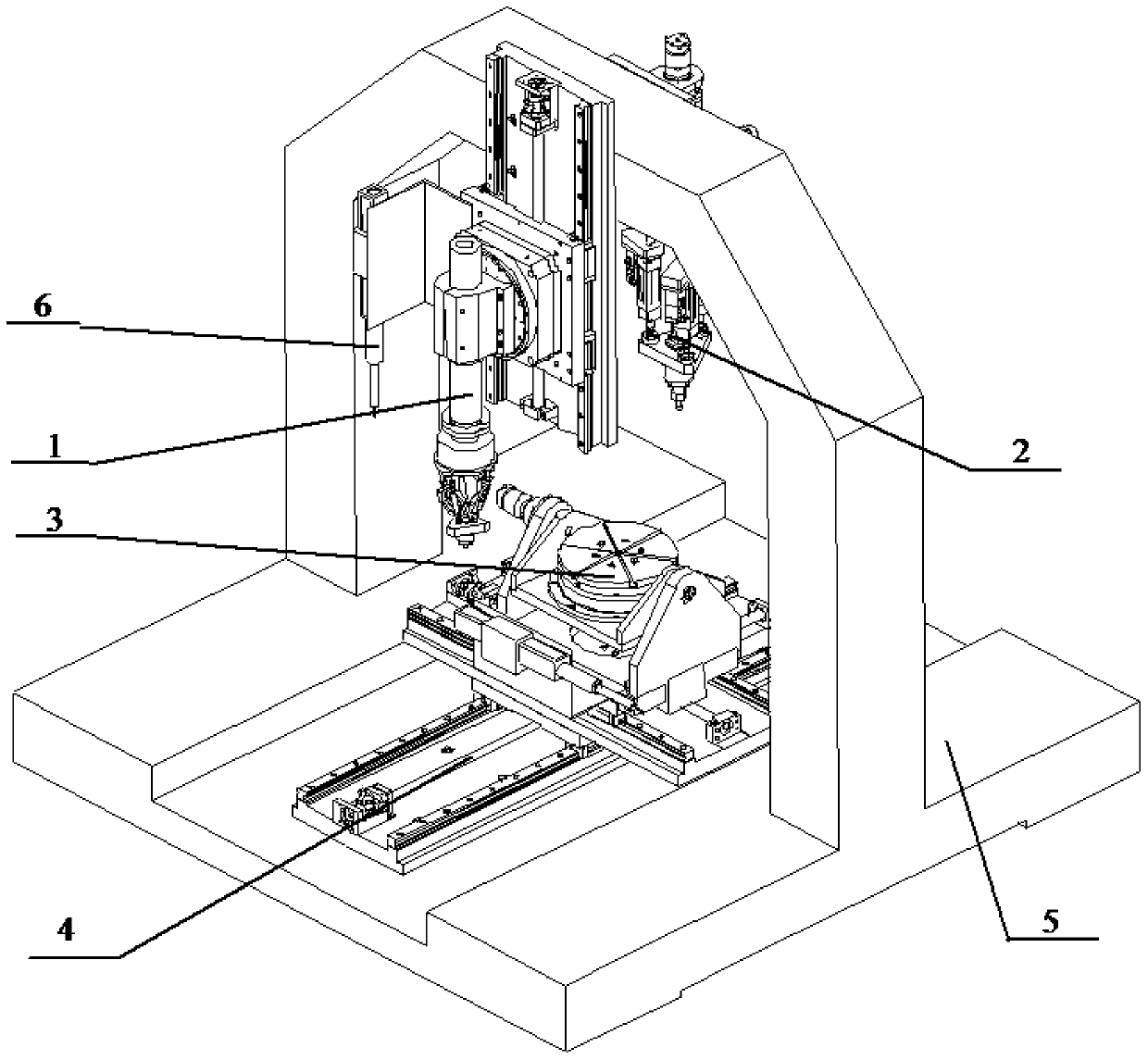

[0037] Such as figure 1 As shown, it includes a fast tool processing part 1, a quick removal part 2, a two-axis turntable part 3, an X-Y feed part 4, a frame 5 and a detector 6, wherein the frame 5 is arranged horizontally, and the X-Y feed part 4 is installed on the frame 5, the two-axis turntable part 3 is installed on the X-Y feed part 4 through the Y slide 404, and the fast tool processing part 1 and the quick removal part 2 are respectively installed on both sides of the gantry-shaped middle beam through the guide rail seat 106 and the vertical plate 204 , the detector 6 is installed on the slide 110 of the fast tool processing part 1 .

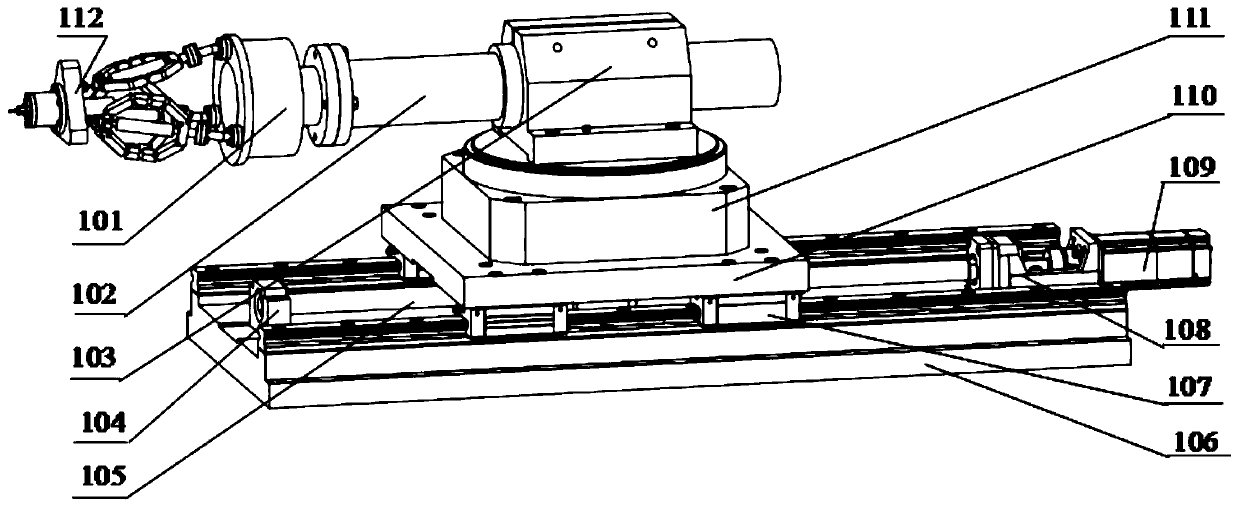

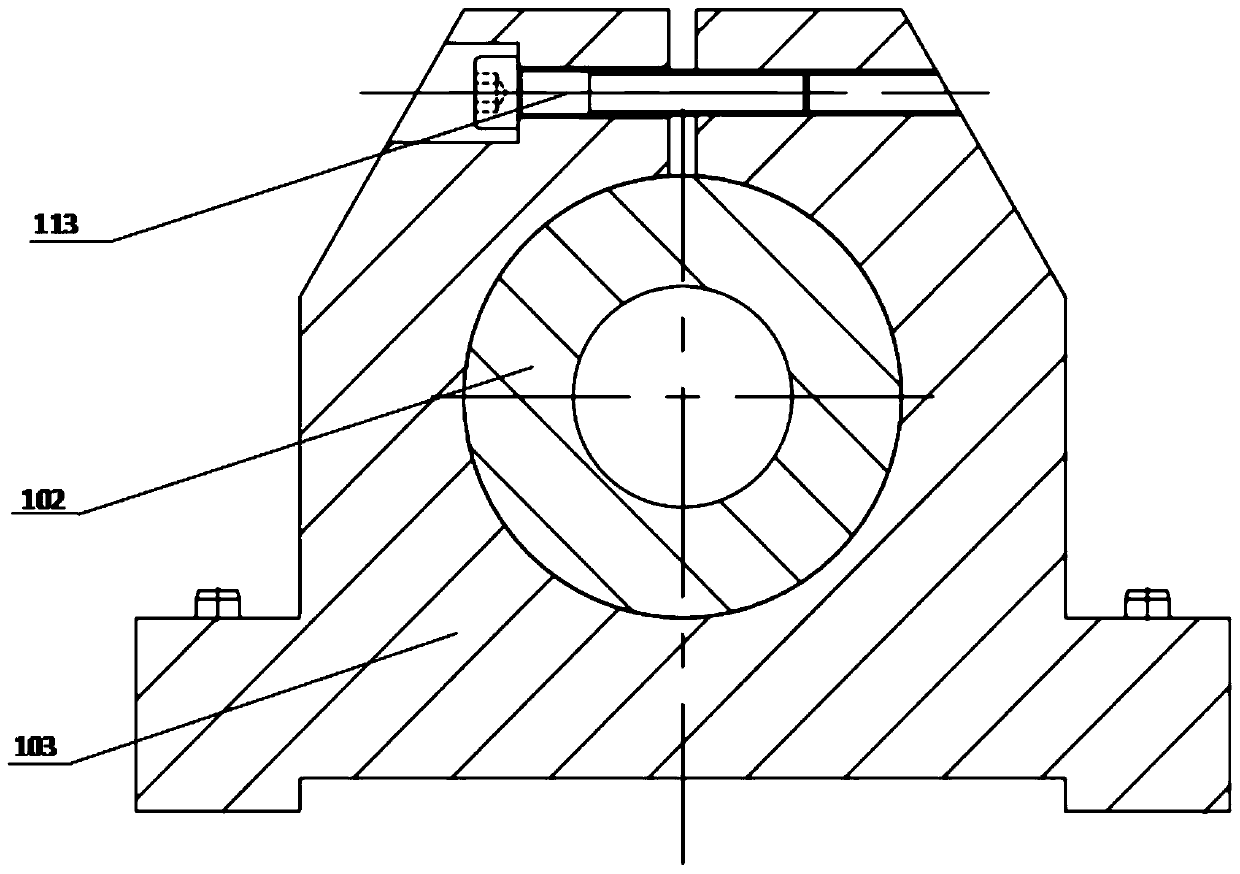

[0038] Such as figure 2 , image 3 , Figure 4 As shown, the fast tool processing part 1 of the present invention includes a connecting sleeve 101, an adapter shaft 102, a shaft seat 103, a left screw support seat 104, a ball screw 105, a guide rail seat 106, a linear guide rail slider 107, a right side Lead screw support seat 108, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com